Top 6 Overhead Crane Manufacturers,Overhead Crane List and Guide: …

Introduction: Navigating the Global Market for overhead crane manufacturers,overhead crane

In today’s dynamic global market, sourcing overhead cranes can pose significant challenges for businesses across various industries. Whether you’re a manufacturer in Germany or a logistics provider in Nigeria, selecting the right overhead crane manufacturer is crucial for enhancing operational efficiency and ensuring safety in material handling. This guide is designed to navigate the complexities of the overhead crane market, offering insights into the diverse types of cranes available, their applications, and the critical factors to consider when vetting suppliers.

Our comprehensive resource will delve into the various types of overhead cranes—including bridge, gantry, and workstation cranes—while outlining their specific applications across industries such as automotive, construction, and manufacturing. Additionally, we will explore essential considerations for evaluating potential suppliers, including quality certifications, customer service, and maintenance support.

With a focus on international B2B buyers from Africa, South America, the Middle East, and Europe, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs and budget constraints. By equipping you with the knowledge to assess costs and benefits effectively, we aim to facilitate a seamless procurement process, ensuring your investment in overhead crane technology yields maximum returns.

Top 10 Overhead Crane Manufacturers,Overhead Crane Manufacturers & Suppliers List

1. American Equipment – Overhead Bridge Cranes

Domain: amquipinc.com

Registered: 2002 (23 years)

Introduction: American Equipment offers a range of overhead bridge cranes designed for moving extremely heavy or bulky loads. Key features include:

– Types of Cranes: Patented Track Cranes, Top-Running Double Girder, Top-Running Trolley, Top-Running Single Girder, Under-Running Single Girder, and Under-Running Trolley.

– Specifications:

– Patented Track Cranes: 3 to 15-ton capacities, rated loads span up t…

2. Demag Cranes – Overhead Cranes and Components

Domain: mazzellacompanies.com

Registered: 1998 (27 years)

Introduction: Top Overhead Bridge Crane and Gantry Crane Manufacturers: 1. Demag Cranes & Components Corp. – Founded: 1965, U.S. Headquarters: Solon, Ohio. Specializes in overhead cranes and components, manufacturing in 16 countries. Industries Served: Aircraft, Automotive, Chemical, Coal Mining, Cement, Glass, Bricks, Concrete, Metal Processing, Mining, Power/Energy, Pulp and Paper, Ships and Boats. 2. DeShazo…

3. Wazee Crane – Overhead Bridge Cranes

Domain: wazeecrane.com

Registered: 1996 (29 years)

Introduction: Wazee Crane specializes in the manufacture and supply of overhead bridge cranes and hoists. They have a complete manufacturing facility in Broomfield, Colorado, capable of fabricating cranes of various complexities, including welded plate box girders with spans exceeding 100 feet. Wazee Crane designs and builds cranes in compliance with CMAA, NEC, OSHA, MSHA, and ASME standards. Their services inc…

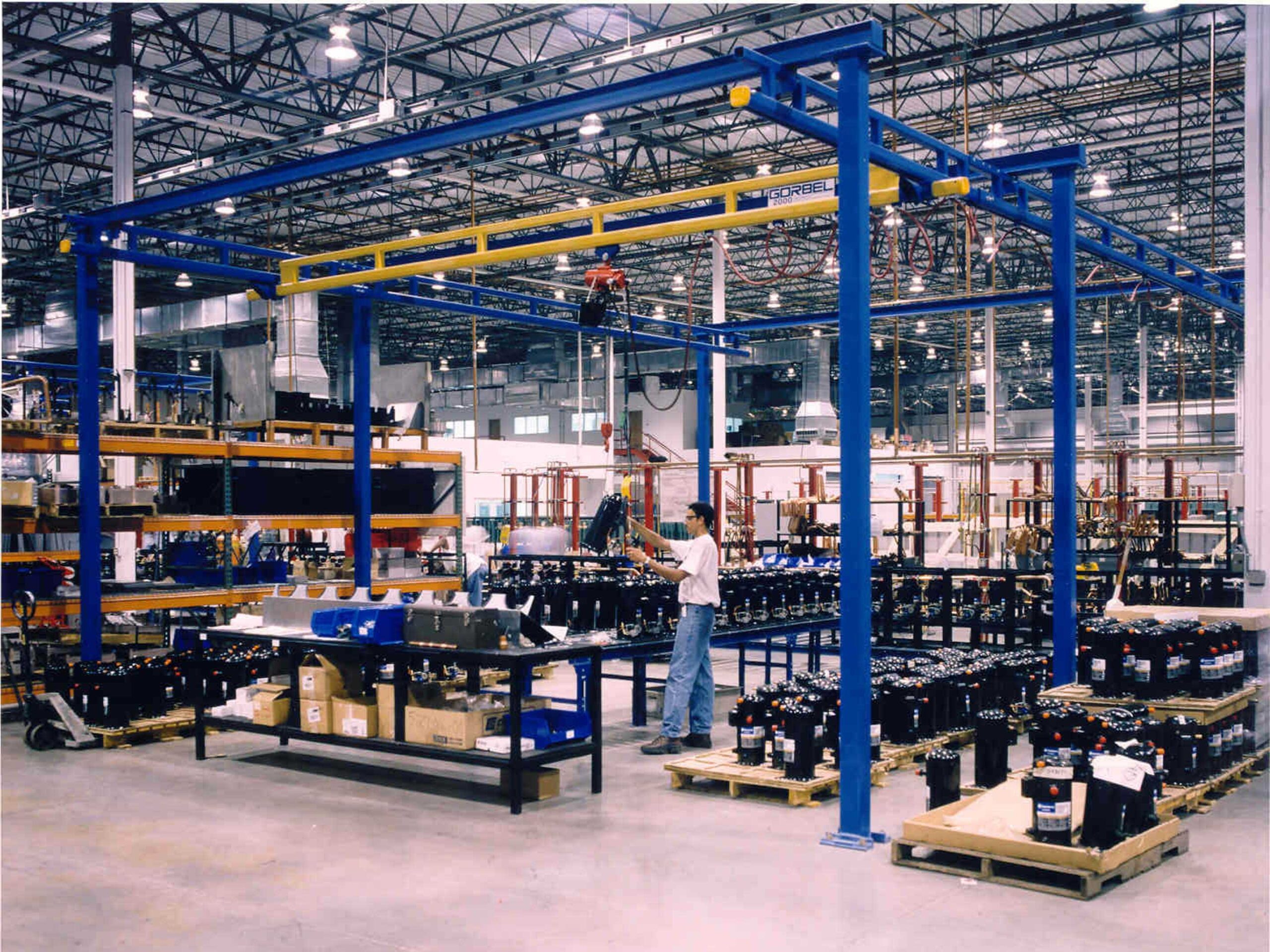

4. TS Overhead Crane – Overhead Cranes & Hoists

Domain: tsoverheadcrane.com

Registered: 2013 (12 years)

Introduction: Overhead Cranes: Overhead Bridge Cranes, Gorbel Bridge Cranes, Overhead Crane Kits, Patented Track Cranes; Hoists: Electric Chain Hoists, Wire Rope Hoists, Manual Chain Hoists, Air Chain Hoists; Jib Cranes: Foundationless Jib Cranes, Light Duty Jib Cranes, I-Beam Jib Cranes, Wall or Column Mounted Jib Cranes, Work Station Jib Cranes, Articulating Jib Cranes, Portable Jib Cranes; Gantry Cranes: Por…

5. GH Crane & Components – Overhead Cranes

Domain: ghcranes.com

Registered: 2005 (20 years)

Introduction: Overhead Crane USA – GH Crane & Components offers a range of overhead cranes including single girder and double girder configurations. The cranes feature a robust construction with high standardization, making them modular and adaptable to various needs. They utilize optimized box girder or standard profile structures, designed through computer calculations for enhanced mechanical value and space …

6. EMH Inc. – Overhead Material Handling Equipment

Domain: emhcranes.com

Registered: 2004 (21 years)

Introduction: EMH Inc. manufactures a complete line of overhead material handling equipment including: Overhead Cranes, Bridge Cranes, Gantry Cranes, Free Standing Bridge Crane System (NOMAD®), Aluminum Rail Workstation Cranes (AL SYSTEMS™), Jib Cranes, Standard Packaged Wire Rope Hoists, Engineered Wire Rope Hoists, End Trucks (Top Running Single and Double Girder Model DLVM, Under Running Model EDL), and Over…

Understanding overhead crane manufacturers,overhead crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overhead Bridge Crane | Utilizes a bridge that spans the width of the work area; high lifting capacity | Manufacturing, Warehousing, Heavy Industry | Pros: High load capacity, efficient space utilization. Cons: Requires significant overhead space and installation effort. |

| Gantry Crane | Supported by freestanding legs; can be mobile or fixed | Construction, Shipyards, Outdoor Applications | Pros: Versatile and adaptable; can work in outdoor environments. Cons: Limited height compared to bridge cranes. |

| Jib Crane | Rotates around a pivot point; ideal for localized lifting tasks | Assembly Lines, Workshops, Maintenance Facilities | Pros: Space-efficient, easy to use for small loads. Cons: Limited lifting capacity and range. |

| Under-Running Crane | Supported by overhead structures; frees up floor space | Manufacturing, Assembly, Warehousing | Pros: Maximizes floor space; lightweight design. Cons: Limited to specific building structures. |

| Top-Running Crane | Mounted on top of the runway; allows for greater lifting height | Heavy Manufacturing, Steel Mills, Automotive | Pros: High load capacities and spans; efficient for heavy-duty tasks. Cons: Requires robust installation and structural support. |

What are the Characteristics and Suitability of Overhead Bridge Cranes?

Overhead bridge cranes are characterized by a horizontal bridge that moves along two parallel runways. They are ideal for heavy lifting and are commonly used in manufacturing, warehousing, and heavy industry. When considering a bridge crane, businesses should evaluate their operational space and load requirements, as these cranes require significant overhead clearance and structural support. Their high lifting capacity and efficiency in moving loads across large areas make them a preferred choice for facilities handling heavy materials.

How Do Gantry Cranes Differ in Application?

Gantry cranes, distinguished by their freestanding legs, can be either mobile or fixed, making them versatile for various applications, including construction and shipyards. They are particularly suited for outdoor tasks and can easily navigate uneven surfaces. Buyers should consider their specific lifting needs and environmental conditions when selecting a gantry crane, as its adaptability and mobility can be significant advantages in dynamic work sites.

What Makes Jib Cranes a Practical Choice for Businesses?

Jib cranes are designed to rotate around a fixed point, making them ideal for localized lifting tasks in assembly lines or workshops. Their compact design allows them to be installed in spaces with limited headroom, providing a space-efficient solution for handling lighter loads. Buyers should assess the weight and range of motion required for their operations, as jib cranes offer ease of use but have limitations in lifting capacity and operational range.

Why Choose Under-Running Cranes for Specific Facilities?

Under-running cranes are supported by existing overhead structures, which allows for maximum floor space utilization. They are particularly effective in manufacturing and assembly environments where floor space is at a premium. When purchasing an under-running crane, businesses need to ensure that their facility can accommodate the specific structural requirements, as these cranes depend on the building’s design for support.

What Advantages Do Top-Running Cranes Offer for Heavy-Duty Tasks?

Top-running cranes are mounted on top of the runway, providing greater lifting height and load capacity, making them suitable for heavy manufacturing and steel mills. Their ability to handle substantial weights and spans makes them ideal for operations requiring robust material handling solutions. However, potential buyers should consider the installation complexity and the need for strong structural support in their facilities, as these factors can influence overall costs and feasibility.

Key Industrial Applications of overhead crane manufacturers,overhead crane

| Industry/Sector | Specific Application of overhead crane manufacturers,overhead crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Lifting and transporting heavy materials on production lines | Increases efficiency and reduces labor costs | Evaluate load capacity, span length, and safety features |

| Construction | Hoisting structural components and equipment during building projects | Improves project timelines and ensures safety on-site | Consider crane mobility, power supply options, and terrain adaptability |

| Mining | Moving raw materials and equipment within mining sites | Enhances productivity and minimizes downtime | Assess environmental conditions and equipment durability |

| Shipbuilding | Handling large ship components and materials in dry docks | Streamlines operations and enhances safety during assembly | Look for specialized features like corrosion resistance |

| Energy Production | Transporting heavy machinery and components in power plants | Supports operational efficiency and safety in high-demand environments | Ensure compliance with industry regulations and safety standards |

How Are Overhead Cranes Used in Manufacturing?

In the manufacturing sector, overhead cranes are essential for lifting and transporting heavy materials along production lines. They enable the movement of bulky items such as metal sheets, automotive parts, and machinery components with precision and speed. This application solves challenges related to manual handling, which can lead to workplace injuries and inefficiencies. For international buyers, it is crucial to evaluate load capacity and span length to ensure the crane meets specific operational demands, as well as to consider safety features to comply with local regulations.

What Role Do Overhead Cranes Play in Construction?

In construction, overhead cranes are utilized to hoist structural components such as steel beams and precast concrete panels. They significantly enhance project timelines by allowing for quick and safe placement of materials at heights. This application addresses issues of manual material handling and improves safety on-site, reducing the risk of accidents. Buyers should consider crane mobility options and power supply requirements to match the site’s infrastructure, especially in regions with limited access to electricity.

How Are Overhead Cranes Applied in Mining?

Overhead cranes in the mining industry facilitate the movement of raw materials and heavy equipment throughout mining sites. Their use improves productivity by enabling quick transport of materials to processing areas while minimizing equipment downtime. Buyers must assess environmental conditions, such as dust and moisture, to select cranes with durable components that can withstand harsh conditions. Additionally, understanding the specific lifting requirements based on the materials being handled is crucial for optimal performance.

What Benefits Do Overhead Cranes Provide in Shipbuilding?

In shipbuilding, overhead cranes are vital for handling large ship components and materials within dry docks. They streamline operations by enabling the precise placement of heavy items, reducing the time required for assembly. This application enhances safety by minimizing the risk of accidents associated with manual handling of bulky materials. Buyers should look for cranes with specialized features, such as corrosion resistance, to ensure longevity in maritime environments, along with compliance with industry safety standards.

How Do Overhead Cranes Support Energy Production?

In energy production facilities, overhead cranes are used to transport heavy machinery and components, such as turbines and generators. This application is critical for maintaining operational efficiency in high-demand environments, where downtime can be costly. Buyers should ensure that the cranes comply with industry regulations and safety standards, particularly in environments where explosive materials may be present. Assessing the crane’s load capacity and operational speed is also essential to meet the specific demands of energy production.

3 Common User Pain Points for ‘overhead crane manufacturers,overhead crane’ & Their Solutions

Scenario 1: The Challenge of Ensuring Compliance with Safety Regulations

The Problem:

B2B buyers often face the daunting challenge of ensuring that their overhead crane systems comply with stringent safety regulations. With varying standards across different regions, including those set by organizations such as OSHA in the United States or local safety regulations in Africa and Europe, it can be overwhelming for companies to navigate compliance. A lack of understanding of these regulations can lead to costly fines, unsafe working conditions, and potential operational shutdowns, placing significant pressure on procurement teams to source compliant equipment.

The Solution:

To overcome compliance challenges, buyers should prioritize working with reputable overhead crane manufacturers who have a proven track record in safety standards. Begin by conducting thorough research on manufacturers’ certifications and compliance history. When engaging with potential suppliers, ask for documentation that demonstrates their adherence to local and international safety regulations. Additionally, consider manufacturers that offer training programs for crane operators, as these can help ensure that your team is well-versed in safe operating procedures. Regular safety audits and maintenance checks should also be incorporated into the operational protocol, ensuring that the cranes remain compliant throughout their lifecycle.

Scenario 2: Difficulties in Customization for Unique Operational Needs

The Problem:

Many businesses operate under unique conditions that require customized overhead crane solutions. Buyers often encounter challenges when standard crane models do not meet specific operational requirements, such as load capacities, dimensions, or environmental conditions (e.g., extreme temperatures or corrosive environments). This mismatch can lead to inefficiencies, increased operational costs, and delays in project timelines, causing frustration for procurement teams and operations managers alike.

The Solution:

To address customization issues, buyers should engage with manufacturers that specialize in bespoke crane solutions. Start by clearly outlining your operational needs and constraints in a detailed specification document. Schedule consultations with potential manufacturers to discuss your requirements and solicit their expert recommendations on feasible customizations. Look for manufacturers that utilize advanced design software and prototyping technologies, as these tools can help visualize the final product and ensure that it aligns with your expectations. Additionally, consider the manufacturer’s ability to support you post-installation with maintenance services tailored to your customized system, ensuring long-term operational success.

Scenario 3: Navigating the Complexity of Installation and Maintenance Services

The Problem:

The installation and ongoing maintenance of overhead cranes can be complex and resource-intensive, particularly for companies lacking in-house expertise. Buyers may struggle with coordinating installation schedules, ensuring that their facilities are ready for new equipment, and establishing a routine maintenance plan to prevent unexpected downtime. This complexity often leads to delays, increased costs, and interruptions in production, all of which can impact the bottom line.

The Solution:

To simplify the installation and maintenance process, buyers should select manufacturers that provide comprehensive installation services as part of their offering. Look for companies that not only supply the cranes but also handle the entire installation process, including site assessments, structural modifications, and safety checks. Establish a clear communication plan with the manufacturer regarding timelines and responsibilities. After installation, work with your manufacturer to develop a tailored maintenance schedule that suits your operational needs. Many manufacturers offer service contracts that include regular inspections, preventive maintenance, and 24/7 emergency support, which can significantly reduce the risk of unplanned downtime and extend the lifespan of your overhead crane system.

Strategic Material Selection Guide for overhead crane manufacturers,overhead crane

What Are the Key Materials Used in Overhead Crane Manufacturing?

The selection of materials for overhead cranes is critical, as it directly influences the crane’s performance, durability, and overall safety. Here, we analyze four common materials used in the manufacturing of overhead cranes, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel: The Backbone of Overhead Cranes

Key Properties: Steel is renowned for its high tensile strength and ability to withstand significant loads. It typically has a temperature rating of up to 400°F (204°C) and offers excellent fatigue resistance, making it suitable for heavy-duty applications.

Pros & Cons: Steel is durable and cost-effective, providing a long lifespan with minimal maintenance. However, it is susceptible to corrosion, necessitating protective coatings or treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel’s strength makes it ideal for supporting heavy loads in various environments, including factories and warehouses. However, its weight can impact the overall design and installation of the crane.

International Considerations: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM A36 or EN 10025. In Africa and South America, local sourcing may affect material availability and cost.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for environments where moisture is a concern. It can withstand temperatures up to 300°F (149°C) without losing its structural integrity.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier installation and reduces the load on supporting structures. However, it has lower tensile strength compared to steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum is ideal for lighter loads and environments where corrosion is a significant concern, such as chemical plants. However, its limited load capacity may not suit all applications.

International Considerations: When sourcing aluminum cranes, buyers should look for compliance with standards like ASTM B221. In regions like Germany, adherence to DIN standards is crucial for quality assurance.

Composite Materials: Innovative Solutions for Specialized Needs

Key Properties: Composites, often made from a combination of materials like fiberglass and resin, offer high strength-to-weight ratios and excellent corrosion resistance. They can operate effectively in temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros & Cons: Composites are lightweight and resistant to environmental factors, making them suitable for specialized applications. However, they can be more expensive to manufacture and may require specialized knowledge for repairs and maintenance.

Impact on Application: Composite materials are ideal for cranes used in corrosive environments, such as marine or chemical applications. Their unique properties can enhance performance but may limit widespread use due to cost.

International Considerations: Buyers should ensure that composite materials meet relevant standards, such as ASTM D638 for tensile properties. In regions with less stringent regulations, understanding local standards is essential for compliance.

High-Strength Alloys: Enhanced Performance Under Stress

Key Properties: High-strength alloys, such as those containing nickel or chromium, offer superior strength and resistance to wear and corrosion. They can perform in extreme temperatures, often exceeding 600°F (316°C).

Pros & Cons: These alloys provide exceptional durability and performance in demanding applications, making them suitable for heavy-duty cranes. However, they are often more expensive and may require specialized manufacturing processes.

Impact on Application: High-strength alloys are ideal for cranes operating in harsh environments, such as steel mills or mining operations. Their enhanced properties can significantly improve operational efficiency.

International Considerations: Buyers should consider compliance with international standards such as ASTM A572 or JIS G3106. Understanding regional material availability and standards is crucial for effective procurement.

Summary Table of Material Selection for Overhead Cranes

| Material | Typical Use Case for overhead crane manufacturers,overhead crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in factories and warehouses | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight cranes in corrosive environments | Excellent corrosion resistance | Lower load capacity | Medium |

| Composite Materials | Specialized applications in marine or chemical environments | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| High-Strength Alloys | Harsh environments like steel mills or mining operations | Exceptional durability and performance | Higher cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection considerations for overhead crane manufacturers, enabling international B2B buyers to make informed decisions tailored to their specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for overhead crane manufacturers,overhead crane

What Are the Main Stages in the Manufacturing Process of Overhead Cranes?

The manufacturing process for overhead cranes involves several critical stages, each designed to ensure that the final product meets the highest standards of quality and performance. Here’s a breakdown of the main stages:

Material Preparation

The first step in manufacturing overhead cranes is material preparation. This involves sourcing high-quality raw materials, typically steel, which is essential for the structural integrity of the crane. Manufacturers often utilize advanced material selection techniques, assessing tensile strength, ductility, and weldability to ensure the materials can withstand heavy loads and harsh operational environments.

Forming Techniques

Once materials are prepared, the forming stage begins. This includes processes such as cutting, bending, and welding. Modern manufacturers employ CNC (Computer Numerical Control) machinery for precision cutting and forming, which minimizes waste and maximizes accuracy. Techniques like laser cutting and plasma cutting are commonly used for their ability to produce clean edges and intricate designs.

Welding is another critical component of this stage, where different parts of the crane are joined together. Manufacturers may use MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding techniques, chosen based on the material thickness and type.

Assembly Process

Following the forming stage, assembly takes place. This is where all the components come together to create the crane. Skilled technicians perform the assembly, ensuring that all parts fit together correctly and that safety protocols are adhered to.

During this stage, manufacturers often implement modular designs, allowing for easier installation and maintenance. This is particularly beneficial for international buyers, as cranes can be shipped in sections and assembled on-site.

Finishing Touches

The final stage is finishing, which includes painting, coating, and applying protective treatments to the crane. This not only enhances aesthetic appeal but also protects against corrosion and wear, especially in challenging environments. Manufacturers may use powder coating or galvanization, depending on the operational requirements and environmental conditions where the crane will be used.

What Quality Assurance Practices Should B2B Buyers Expect from Overhead Crane Manufacturers?

Quality assurance (QA) is crucial in the manufacturing of overhead cranes, ensuring safety and reliability. Here are the core elements of QA that buyers should consider:

Which International Standards Should Overhead Crane Manufacturers Adhere To?

Overhead crane manufacturers typically comply with several international standards to assure quality and safety. The most recognized standard is ISO 9001, which outlines criteria for a quality management system. This certification indicates that a manufacturer has established processes for consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) standards are essential, particularly for cranes used in specialized industries like oil and gas.

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that any issues are identified and rectified early. These checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects during manufacturing, which is crucial for maintaining quality.

- Final Quality Control (FQC): Conducting thorough inspections and testing of the finished crane before it is shipped to the customer.

Which Testing Methods Are Commonly Used to Ensure Crane Quality?

Manufacturers employ various testing methods to verify the integrity and performance of overhead cranes. These methods include:

- Load Testing: Simulating the maximum load conditions to ensure the crane can handle specified weight limits.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and magnetic particle inspection to detect internal flaws without damaging the crane.

- Functional Testing: Verifying the operational capabilities, such as hoisting, traveling, and braking functions.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, especially those in diverse markets like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of a crane manufacturer is essential. Here are some actionable steps:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audits and quality assurance reports from potential suppliers. These documents should outline the manufacturer’s compliance with relevant standards and their internal QC processes.

It’s advisable to look for third-party audits conducted by recognized organizations, as these lend credibility to the manufacturer’s claims. An established manufacturer should be willing to share their certifications and audit results.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging a third-party inspection service can provide additional assurance regarding the quality of the crane. These services can conduct independent assessments at various stages of the manufacturing process, ensuring that the product meets all required specifications before delivery.

This is particularly important for international buyers who may not have the capacity to inspect the manufacturing process on-site.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must be aware of specific QC and certification nuances that may affect their purchasing decisions.

- Regulatory Compliance: Depending on the region, different compliance requirements may apply. For example, European buyers need to ensure CE marking, while buyers in the U.S. might focus on ANSI (American National Standards Institute) compliance.

- Cultural and Regional Considerations: Understanding the local manufacturing practices and standards in regions like Africa and South America can help buyers gauge the reliability of suppliers.

- Post-Purchase Support: Quality assurance doesn’t end with delivery. Buyers should consider manufacturers that offer robust after-sales support, including maintenance and training services, to ensure the longevity and reliability of their crane systems.

In conclusion, understanding the manufacturing processes and quality assurance practices of overhead crane manufacturers is vital for B2B buyers. By focusing on these key areas, buyers can make informed decisions that enhance operational efficiency and safety in their material handling operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘overhead crane manufacturers,overhead crane’

When considering the procurement of overhead cranes, it’s essential to approach the process with a structured strategy. This guide offers a practical checklist to help international B2B buyers make informed decisions when sourcing overhead crane manufacturers and equipment.

Step 1: Define Your Technical Specifications

Before reaching out to potential manufacturers, clarify your technical requirements. This includes load capacity, span, and the type of crane (e.g., top-running or under-running). Knowing these specifications ensures that suppliers can provide equipment that meets your operational needs.

Step 2: Research Potential Manufacturers

Identify a list of reputable overhead crane manufacturers. Look for companies with a strong track record in your industry and region, as this often indicates reliability. Utilize online resources, industry forums, and trade shows to gather information about various manufacturers.

- Consider Global Reach: Choose manufacturers with a presence in your target markets, such as Africa, South America, the Middle East, and Europe. This can simplify logistics and support.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that potential suppliers hold relevant industry certifications. Certifications such as ISO 9001 indicate a commitment to quality management, while compliance with safety standards ensures that the equipment meets operational safety requirements.

- Check for Local Standards: In regions like Germany or Nigeria, specific safety and operational standards may apply. Ensure your chosen manufacturer complies with these regulations.

Step 4: Request Detailed Proposals

After narrowing down your list, request detailed proposals from several manufacturers. These proposals should include pricing, lead times, and warranty information. A comprehensive proposal helps you compare the offerings effectively.

- Look for Customization Options: Depending on your needs, manufacturers may offer tailored solutions. Ensure you inquire about modifications that could enhance the crane’s functionality for your operations.

Step 5: Visit Manufacturing Facilities

If feasible, visit the manufacturing facilities of shortlisted suppliers. This firsthand experience allows you to evaluate the production process, quality control measures, and overall capabilities of the manufacturer.

- Assess Technical Expertise: Use this visit to gauge the manufacturer’s technical knowledge and ability to address specific concerns related to your operational environment.

Step 6: Check References and Reviews

Before finalizing your decision, ask for references from previous clients, especially those in similar industries or geographical areas. Contact these references to gain insights into their experiences with the manufacturer regarding product quality and after-sales support.

- Online Reviews Matter: In addition to direct references, consult online reviews and ratings. This can provide a broader perspective on the manufacturer’s reputation in the market.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a manufacturer, engage in negotiations to finalize terms. This includes delivery schedules, payment terms, and service agreements for maintenance and support. Clear terms help establish a strong working relationship and set expectations.

- Incorporate Performance Metrics: If possible, include performance metrics in your agreement to ensure that the manufacturer meets your operational requirements effectively.

By following this step-by-step checklist, B2B buyers can ensure a systematic approach to sourcing overhead cranes, ultimately leading to better procurement decisions and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for overhead crane manufacturers,overhead crane Sourcing

What Are the Key Cost Components for Overhead Crane Manufacturing?

When evaluating the costs associated with overhead crane manufacturing, several key components come into play. These include materials, which typically account for the largest share of production costs. High-strength steel, electrical components, and advanced control systems are crucial for ensuring reliability and safety. Labor costs also significantly impact overall pricing, especially in regions with varying wage standards.

Manufacturing overhead, which encompasses utilities, rent, and indirect labor, adds another layer of expense. Additionally, tooling costs for specialized equipment and molds can be substantial, especially for custom designs. Quality Control (QC) processes are essential for maintaining safety and compliance, particularly in industries with stringent regulations. Finally, logistics costs related to transportation and warehousing must be factored in, along with a reasonable margin for the manufacturer, which typically ranges from 10% to 30%.

How Do Price Influencers Affect Overhead Crane Costs?

Several factors influence the pricing of overhead cranes, making it essential for buyers to understand these dynamics. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often yield discounts due to economies of scale. The specifications and customization of cranes play a significant role in pricing, as bespoke designs require additional engineering and production time.

The choice of materials directly impacts cost; using premium materials for heavy-duty applications will increase the price but enhance durability and safety. Moreover, quality certifications such as ISO or CE can elevate costs but may be necessary for compliance with local regulations.

Supplier factors, including their reputation and experience, can also affect pricing. Finally, understanding Incoterms is crucial for international buyers, as they dictate the responsibilities of buyers and sellers regarding transportation and risk.

What Are the Best Negotiation Strategies for B2B Buyers?

Effective negotiation is vital for securing the best price and terms when purchasing overhead cranes. Begin by gathering multiple quotes from different manufacturers to create a competitive environment. Leverage your volume needs to negotiate better pricing or payment terms.

Understanding the Total Cost of Ownership (TCO) is also essential. This includes not only the purchase price but also installation, maintenance, and operational costs over the crane’s lifespan. Highlighting your commitment to a long-term partnership may encourage suppliers to offer better terms.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, it is essential to account for additional costs such as tariffs, import duties, and shipping fees, which can significantly affect the overall budget.

What Pricing Nuances Should International B2B Buyers Consider?

International buyers must navigate a complex landscape of pricing nuances that can vary by region. Currency fluctuations can impact costs, so consider locking in prices or negotiating in a stable currency. Additionally, be aware of local regulations and standards that may require specific certifications, potentially increasing costs.

It is advisable to evaluate suppliers not just on price but also on their ability to provide after-sales support and service, which can be critical for minimizing downtime and ensuring operational efficiency.

Conclusion: What to Keep in Mind When Sourcing Overhead Cranes

In summary, a comprehensive understanding of the cost structure and pricing influencers is critical for B2B buyers in the overhead crane market. By focusing on key cost components, leveraging negotiation strategies, and considering the unique pricing nuances of international procurement, buyers can make informed decisions that align with their operational needs and budget constraints. Always approach the procurement process with an awareness of the total costs involved and a strategy for maximizing value.

Alternatives Analysis: Comparing overhead crane manufacturers,overhead crane With Other Solutions

In the realm of material handling, selecting the right equipment is crucial for operational efficiency and safety. Overhead cranes are a popular choice among industries for their ability to lift and move heavy loads in confined spaces. However, there are alternative solutions that may also meet specific operational needs. This analysis compares overhead crane systems with two viable alternatives: automated guided vehicles (AGVs) and mobile cranes.

Comparison Table

| Comparison Aspect | Overhead Crane Manufacturers, Overhead Crane | Automated Guided Vehicles (AGVs) | Mobile Cranes |

|---|---|---|---|

| Performance | High load capacity, precise control | Moderate load capacity, flexible navigation | High load capacity, versatile applications |

| Cost | High initial investment, low long-term costs | Moderate initial investment, maintenance costs can be high | High initial cost, operational costs vary |

| Ease of Implementation | Requires significant installation time and expertise | Quick deployment, minimal infrastructure needed | Requires setup time and skilled operators |

| Maintenance | Regular inspections needed, but low costs | Moderate maintenance, potential software upgrades | High maintenance, skilled technicians required |

| Best Use Case | Heavy manufacturing, assembly lines | Warehousing, logistics, and distribution | Construction sites, outdoor applications |

What Are the Pros and Cons of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are increasingly popular in warehouses and distribution centers. They navigate autonomously using predefined paths, allowing for efficient material transport. The main advantage of AGVs lies in their flexibility; they can easily adapt to changing layouts and workflows without significant reconfiguration. However, their load capacities are generally lower than that of overhead cranes, making them unsuitable for extremely heavy items. Additionally, AGVs may incur higher maintenance costs due to the need for software updates and battery management.

How Do Mobile Cranes Compare?

Mobile cranes offer versatility in lifting and transporting heavy loads across different locations, making them ideal for construction sites. They can operate on uneven surfaces and are capable of reaching significant heights, which is advantageous in outdoor applications. However, the high operational costs associated with fuel, maintenance, and skilled operators can make mobile cranes less economically viable for long-term use in a stationary environment. Moreover, the setup time can be considerable, especially for larger models.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers evaluating material handling solutions, the choice between overhead cranes, AGVs, and mobile cranes should be driven by specific operational needs and constraints. Overhead cranes excel in high-capacity applications, particularly in manufacturing settings where space is limited. In contrast, AGVs may be more suitable for dynamic environments like warehouses, where flexibility is key. Mobile cranes are best for temporary outdoor projects but can be costly for prolonged use. By assessing factors such as load requirements, facility layout, and budget constraints, buyers can make informed decisions that optimize their operational efficiency and productivity.

Essential Technical Properties and Trade Terminology for overhead crane manufacturers,overhead crane

What Are the Key Technical Specifications for Overhead Cranes?

When evaluating overhead cranes for your business, understanding the technical specifications is crucial. Here are some essential properties to consider:

-

Load Capacity

The load capacity of an overhead crane indicates the maximum weight it can safely lift. It is typically measured in tons and can range from light-duty (1-10 tons) to heavy-duty (300 tons or more). This specification is vital for ensuring that the crane can handle your operational needs without risking safety or equipment failure. -

Span Length

Span length refers to the distance between the crane’s supporting structures (e.g., columns or walls) that the crane travels across. This measurement influences the crane’s coverage area in your facility and is crucial for maximizing material handling efficiency. A well-designed span length can help reduce the number of cranes needed for a given space. -

Travel Speed

Travel speed is the rate at which the crane moves along its runway, usually measured in feet per minute (FPM). Higher travel speeds can improve productivity but must be balanced with safety considerations. Understanding the required travel speed for your operations can help you select a crane that enhances workflow without compromising safety. -

Control System

The control system of an overhead crane can be either pendant-controlled or radio-controlled. Pendant controls involve a wired remote, while radio controls offer more flexibility and range. Choosing the right control system can significantly impact operator efficiency and safety, making it essential to consider the working environment and operator preferences. -

Material Grade

The material grade of the crane components (such as the steel used in the girders and hoists) is critical for durability and strength. Common grades include structural steel grades like ASTM A36 and A992. Selecting the appropriate material grade ensures the crane can withstand the operational stresses it will encounter, thus extending its lifespan. -

Safety Features

Safety features, such as anti-collision systems, overload sensors, and emergency stop functions, are critical for preventing accidents and ensuring safe operation. Understanding the safety features available can help you comply with industry regulations and protect your workforce.

What Are Common Trade Terms in the Overhead Crane Industry?

Navigating the overhead crane market requires familiarity with specific jargon and trade terms. Here are some key terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of overhead cranes, partnering with reputable OEMs ensures that you receive high-quality components and systems tailored to your operational needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is essential for B2B buyers as it can impact your purchasing strategy, especially when budgeting for large-scale projects or long-term contracts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. In the overhead crane industry, issuing an RFQ allows you to gather competitive pricing and terms, enabling informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and customs clearance. Understanding these terms helps you navigate logistics and manage risk in cross-border crane procurement. -

CMAA (Crane Manufacturers Association of America)

CMAA is an organization that sets standards for crane manufacturing and performance. Familiarity with CMAA classifications can guide you in choosing cranes that meet industry standards and ensure safety and reliability. -

HMI (Human-Machine Interface)

HMI refers to the interface through which operators interact with the crane control system. A user-friendly HMI can enhance operational efficiency and reduce training time for new operators.

By understanding these specifications and terms, B2B buyers can make informed decisions when selecting overhead cranes that align with their operational needs and safety standards.

Navigating Market Dynamics and Sourcing Trends in the overhead crane manufacturers,overhead crane Sector

What Are the Current Market Dynamics and Key Trends in the Overhead Crane Sector?

The overhead crane market is experiencing significant transformation, driven by advancements in technology, increased automation, and a growing emphasis on operational efficiency. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a shift towards smart crane systems integrated with IoT capabilities, allowing for real-time monitoring and predictive maintenance. These technologies not only enhance safety but also reduce downtime, providing a competitive edge.

Emerging trends include a rise in the customization of crane systems to meet specific industry requirements, ranging from heavy-duty applications in manufacturing to lighter solutions in logistics. Additionally, the demand for energy-efficient cranes is growing as companies seek to reduce operational costs and adhere to stricter environmental regulations. This has led manufacturers to innovate and offer cranes with lower energy consumption and enhanced performance metrics.

Furthermore, the global supply chain is becoming more interconnected, prompting buyers to evaluate suppliers based on their geographic location, lead times, and delivery capabilities. As companies expand their operations into new markets, understanding local regulations and standards becomes crucial. Buyers should prioritize partnerships with manufacturers that possess a global footprint and can provide localized support.

How Are Sustainability and Ethical Sourcing Influencing B2B Decisions in the Overhead Crane Industry?

Sustainability is becoming a focal point for B2B buyers in the overhead crane sector. The environmental impact of manufacturing processes and the materials used in crane production are under scrutiny. Companies are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste during production.

Ethical sourcing is equally important, as buyers are aware of the social implications of their supply chains. Manufacturers that can showcase certifications for responsible sourcing or demonstrate compliance with international labor standards are likely to gain favor among discerning buyers. This is particularly relevant in markets such as Europe, where regulatory frameworks around sustainability and ethical practices are more stringent.

Moreover, the adoption of “green” certifications, such as ISO 14001 for environmental management, is becoming a differentiator for manufacturers. Buyers should actively seek out suppliers who can provide transparent information regarding their sustainability initiatives and product life cycles, including the use of eco-friendly materials and energy-efficient designs.

What Is the Brief Evolution of the Overhead Crane Industry?

The overhead crane industry has evolved significantly since its inception in the early 20th century. Originally designed for basic material handling, cranes have seen technological advancements that have transformed their design, functionality, and safety features. The introduction of electric drives, remote control capabilities, and automated systems has allowed for increased precision and efficiency in operations.

In the late 20th century, the focus shifted towards enhancing safety protocols and compliance with rigorous industry standards. Manufacturers began to integrate more sophisticated safety features, such as anti-collision systems and load monitoring technologies, to mitigate risks associated with heavy lifting.

Today, the industry is on the brink of a new era characterized by digital transformation. The integration of IoT and AI technologies is paving the way for predictive maintenance and smart operations, enabling manufacturers to offer solutions that not only meet current market demands but also anticipate future needs. As the industry continues to evolve, international buyers must stay informed about technological advancements and market trends to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of overhead crane manufacturers,overhead crane

-

How do I choose the right overhead crane for my facility?

Choosing the right overhead crane involves assessing your specific material handling needs, including load capacity, span, and lifting height. Consider the type of materials you will be moving, as well as the frequency and speed of operations. It’s advisable to consult with multiple manufacturers to get insights on the best solutions tailored to your requirements. Additionally, evaluate the manufacturer’s experience in your industry and their ability to provide ongoing support, including maintenance and training. -

What are the key factors to consider when vetting overhead crane manufacturers?

When vetting overhead crane manufacturers, focus on their industry experience, reputation, and customer testimonials. Verify their compliance with international safety standards and certifications. Look for manufacturers that offer comprehensive services, including design, installation, and maintenance. It’s beneficial to inquire about their supply chain practices and the quality of materials used, as these factors significantly impact the durability and reliability of the cranes. -

What customization options are available for overhead cranes?

Customization options for overhead cranes can include various capacities, spans, and lifting heights tailored to specific operational needs. Manufacturers may offer features like specialized hoists, control systems, and safety devices to enhance functionality. It’s important to discuss your unique requirements with the manufacturer to explore available options. Be sure to inquire about the additional costs associated with customization and the expected lead times for production. -

What is the typical minimum order quantity (MOQ) for overhead cranes?

The minimum order quantity (MOQ) for overhead cranes can vary significantly among manufacturers and depends on factors like the type and complexity of the crane. Some manufacturers may accommodate single unit orders, especially for standard models, while others may have higher MOQs for custom solutions. It’s advisable to communicate your needs clearly and explore potential flexibility in MOQs, particularly if you are a first-time buyer or looking to establish a long-term partnership. -

What payment terms should I expect when purchasing an overhead crane?

Payment terms for overhead crane purchases typically include a deposit at the time of order, with the remaining balance due upon completion or delivery. Terms can vary widely, so it’s important to negotiate payment schedules that align with your cash flow needs. Some manufacturers may offer financing options or installment payments, especially for larger orders. Always ensure that the payment terms are clearly documented in the contract to avoid any misunderstandings. -

How do I ensure quality assurance during the overhead crane manufacturing process?

To ensure quality assurance during the manufacturing process, request information about the manufacturer’s quality control measures and certifications. Look for companies that adhere to international standards such as ISO 9001. Engage in regular communication with the manufacturer to monitor progress and request updates on testing and inspections. Some manufacturers may allow you to conduct site visits or audits during production to further ensure compliance with your quality expectations. -

What logistics considerations should I keep in mind for importing overhead cranes?

When importing overhead cranes, consider logistics factors such as shipping methods, customs clearance, and local regulations. Ensure that the manufacturer can provide necessary documentation for importation, including compliance certificates and safety standards. Additionally, plan for potential delays in shipping and customs processing. It may be beneficial to work with a logistics partner experienced in heavy equipment to navigate international shipping complexities and ensure timely delivery. -

What after-sales services should I expect from overhead crane manufacturers?

After-sales services can greatly influence the longevity and performance of your overhead crane. Look for manufacturers that provide comprehensive support, including installation, training, and maintenance services. Inquire about warranty terms and the availability of spare parts. A strong after-sales support system can help ensure that your crane operates efficiently and safely, minimizing downtime and extending the equipment’s lifespan.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for overhead crane manufacturers,overhead crane

As the demand for efficient material handling solutions continues to rise globally, strategic sourcing of overhead cranes becomes increasingly critical for businesses looking to enhance operational efficiency and productivity. By carefully evaluating manufacturers and their offerings, international buyers can ensure they select the right partner that aligns with their specific operational needs and budget constraints. Key considerations include the types of cranes available, technological advancements, and the manufacturer’s ability to provide comprehensive support services such as installation, maintenance, and training.

Investing in a high-quality overhead crane not only optimizes workflow but also contributes to workplace safety and compliance with industry regulations. As markets in Africa, South America, the Middle East, and Europe evolve, the importance of sourcing reliable crane solutions will only grow.

Looking ahead, businesses should actively seek out partnerships with reputable manufacturers who demonstrate a commitment to innovation and customer support. This proactive approach will not only secure competitive pricing but also position companies to thrive in an increasingly demanding marketplace. Engage with manufacturers today to explore customized solutions that will elevate your operational capabilities to new heights.