Top 7 Acp Panel Manufacturers List and Guide: How To Solve Scenar…

Introduction: Navigating the Global Market for ACP Panel Manufacturers

In today’s competitive landscape, sourcing high-quality Aluminium Composite Panels (ACP) presents a significant challenge for international B2B buyers. With a myriad of manufacturers and varying product standards, navigating the global market can be overwhelming, especially for companies in regions such as Africa, South America, the Middle East, and Europe. This guide is designed to demystify the procurement process by providing a thorough overview of ACP panel types, applications, and essential supplier vetting criteria, ensuring that buyers can make informed decisions tailored to their specific needs.

Throughout this guide, we will explore the diverse applications of ACP panels, from architectural innovations to signage solutions, underscoring their role in enhancing both functionality and aesthetic appeal. We will also discuss critical factors influencing cost, including manufacturing processes, material quality, and certification standards, which are essential for compliance in various markets.

By leveraging the insights shared here, B2B buyers can confidently engage with manufacturers, negotiate favorable terms, and select products that meet both their operational requirements and budget constraints. Whether you’re based in Nigeria or Germany, this comprehensive resource equips you with the knowledge needed to navigate the complexities of sourcing ACP panels effectively, ultimately streamlining your purchasing strategy and enhancing your project outcomes.

Top 10 Acp Panel Manufacturers Manufacturers & Suppliers List

1. Vanco – Aluminium Composite Panels

Domain: vancopanel.com

Registered: 2008 (17 years)

Introduction: Vanco offers a variety of Aluminium Composite Panels (ACP) including: 1. Fire-rated Aluminium Composite Panel 2. PVDF Aluminium Composite Panel 3. PE Aluminium Composite Panel 4. Brush Aluminium Composite Panel 5. Wooden Aluminium Composite Panel 6. Marble Aluminium Composite Panel 7. Metal Composite Panel 8. Billboard Aluminium Coil. The products have approvals from SGS, Cisro, Exova, and Interte…

2. ALUCOBOND – Aluminum Composite Panels

Domain: alucobondusa.com

Registered: 2004 (21 years)

Introduction: ALUCOBOND is a high-quality, lightweight aluminum composite panel known for its durability, design flexibility, and exceptional performance in exterior cladding applications. It is available in 91 colors and finishes. ALUCOBOND EasyFix is an innovative attachment system for both interior and exterior applications, offering easy fabrication and installation. ALUCOLUX is a flexible choice for trim o…

3. MakerStock – Aluminum Composite Panels (ACP)

Domain: makerstock.com

Registered: 2012 (13 years)

Introduction: Aluminum Composite Panels (ACP) – White

Price: $6.25 to $45.95 depending on size and thickness

Sizes Available:

– 1/8″ / 3mm:

– 12″ x 12″ – $6.25

– 12″ x 20″ – $9.45

– 12″ x 24″ – $10.45

– 18″ x 24″ – $15.75

– 24″ x 24″ – $20.25

– 24″ x 36″ – $29.75

– 1/4″ / 6mm:

– 12″ x 12″ – $8.45

– 12″ x 20″ – $13.95

– 12″ x 24″ – $15.95

– 18″ x 24″ – $23.45

– 24″ x 24″ – $30.95

– 24″…

4. Areca Alupanel – Aluminium Composite Panels

Domain: arecaacppanel.com

Registered: 2019 (6 years)

Introduction: Areca Alupanel Llp manufactures a variety of Aluminium Composite Panels (ACP) and ACP Sheets, including:

– ACP Sheet

– Aluminium Composite Panels

– Metallic Finish Aluminium Composite Panel

– Aluminium Panel Solid Color Aluminium Composite Panel

– Aluminum Composite Panel Marble Aluminium Composite Panel

– Wooden Aluminium Composite Panel

– Pvdf Aluminum Composite Panel

– Exterior Aluminiu…

5. Alutec – Aluminium Composite Panels

Domain: alutec.us

Registered: 2017 (8 years)

Introduction: Aluminium Composite Panels (ACP) ALUTEC® consists of two aluminum sheets attached to a low-density polyethylene core with fire-retardant material. It features PVDF paint for color longevity of up to 20 years against UV exposure. Alutec® offers over 40 colors for various construction projects, including 11 colors for facades (4 mm thickness) and 30 colors with textures like wood and marble for Aluc…

6. Fairfield Metal – ALUCOBOND

Domain: fairfieldmetal.com

Registered: 2010 (15 years)

Introduction: Fairfield Metal specializes in aluminum composite panel fabrication from top ACM manufacturers. Key products include:

1. **ALUCOBOND**: Original aluminum composite material with attributes like flatness, formability, durability, and ease of fabrication. Available as 4mm aluminum composite panels or .040” flat aluminum sheets in various sizes and finishes.

2. **Reynobond**: Composite panel with…

7. Wenzhou Jixiang – Aluminum Composite Panels

Domain: alusignpanel.com

Registered: 2013 (12 years)

Introduction: Aluminum Composite Panel (ACP) products offered by Wenzhou Jixiang include: PVDF Aluminum Composite Panel, PE (polyester) Aluminum Composite Panel, A2 FR Aluminum Composite Panel, FEVE Aluminum Composite Panel, PVDF Nano Aluminum Composite Panel, Fireproof (FR) Aluminum Composite Panel, Timber & Stone Aluminum Composite Panel, Brushed Aluminum Composite Panel, Mirror Aluminum Composite Panel, A2 F…

Understanding ACP Panel Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard ACP Panels | Lightweight, rigid, and available in various finishes | Architectural cladding, signage | Pros: Cost-effective, versatile; Cons: Limited customization options. |

| Fire-Rated ACP Panels | Compliant with fire safety standards, high durability | High-rise buildings, public facilities | Pros: Enhanced safety, regulatory compliance; Cons: Higher costs. |

| Customizable ACP Panels | Tailored sizes, colors, and finishes available | OEM applications, specialized architecture | Pros: Meets specific project needs; Cons: Longer lead times. |

| Eco-Friendly ACP Panels | Made from recycled materials, sustainable production | Green building projects, eco-conscious designs | Pros: Supports sustainability goals; Cons: May have higher initial costs. |

| Digital Print-Ready ACP Panels | Optimized for high-quality printing, smooth surface | Advertising, branding, and custom signage | Pros: Excellent visual impact; Cons: Requires careful handling to prevent damage. |

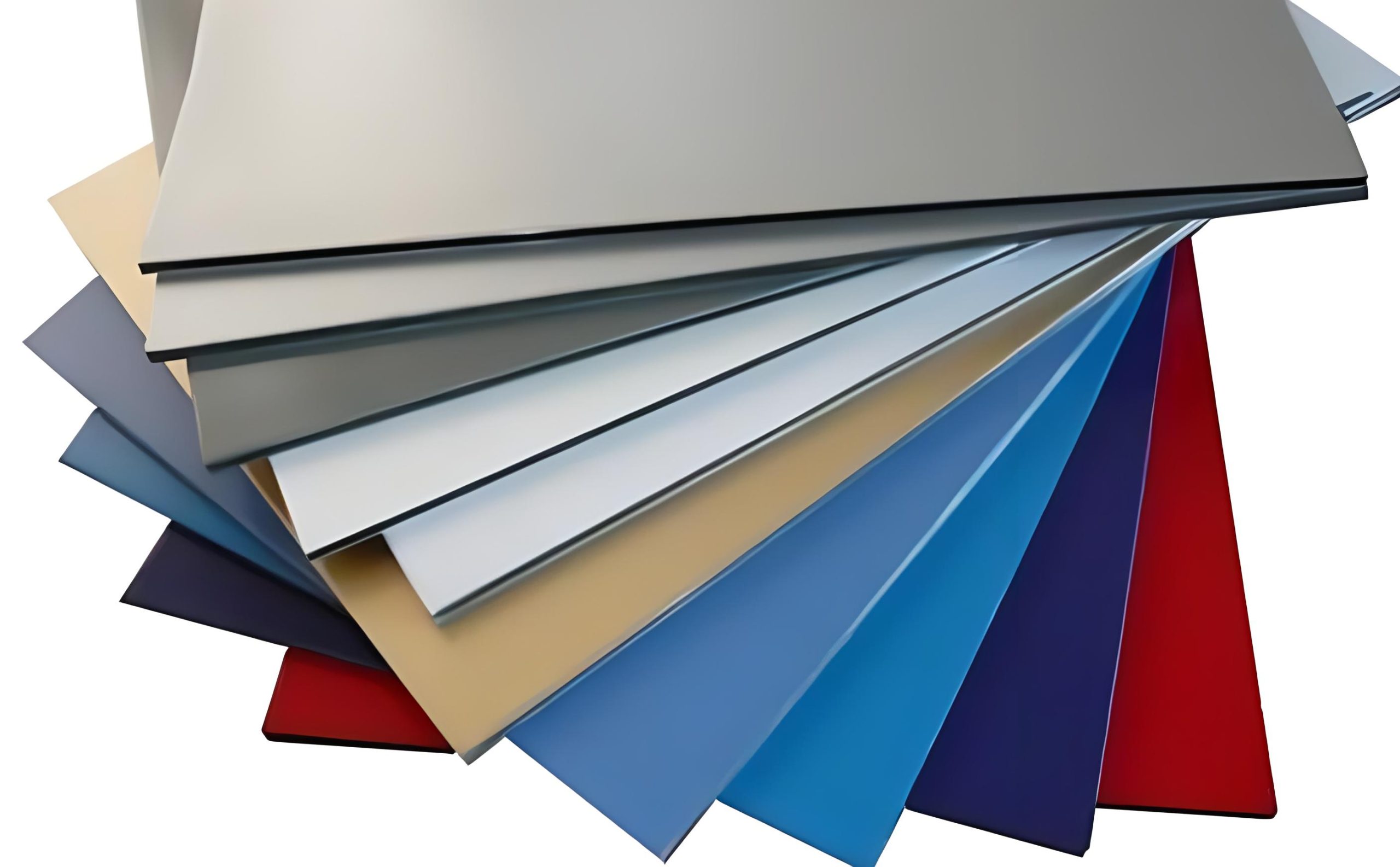

What Are the Characteristics of Standard ACP Panels?

Standard ACP panels are characterized by their lightweight and rigid structure, often available in a variety of finishes such as metallic, matte, or textured. These panels are primarily used in architectural cladding and signage due to their cost-effectiveness and versatility. B2B buyers should consider the panel’s thickness, surface finish, and warranty options, as these factors can influence the overall aesthetic and durability of the installation. However, while they are widely available, customization options may be limited compared to other types.

Why Choose Fire-Rated ACP Panels for Safety?

Fire-rated ACP panels are specifically designed to meet stringent fire safety regulations, making them ideal for high-rise buildings and public facilities. These panels are constructed with non-combustible materials that enhance safety and durability. When purchasing, B2B buyers should evaluate the fire rating certifications and compliance with local regulations. The initial investment may be higher, but the peace of mind and potential insurance benefits can justify the cost, particularly in safety-sensitive applications.

How Do Customizable ACP Panels Benefit Specialized Projects?

Customizable ACP panels allow B2B buyers to tailor dimensions, colors, and finishes to meet specific project requirements, making them suitable for OEM applications and specialized architectural designs. These panels are particularly beneficial for projects where unique aesthetics or functionality is essential. Buyers should be prepared for longer lead times due to the customization process and confirm that the manufacturer can meet their design specifications without compromising quality.

What Makes Eco-Friendly ACP Panels a Sustainable Choice?

Eco-friendly ACP panels are manufactured using recycled materials and sustainable production practices, catering to green building projects and eco-conscious designs. These panels help businesses meet sustainability goals while maintaining aesthetic appeal. B2B buyers should assess the environmental certifications of the panels and consider the potential for higher initial costs against long-term savings and benefits associated with sustainable building practices.

How Do Digital Print-Ready ACP Panels Enhance Branding Efforts?

Digital print-ready ACP panels are optimized for high-quality printing and feature a smooth surface that allows for vibrant graphics. These panels are commonly used in advertising, branding, and custom signage, providing a visually impactful solution for businesses. Buyers should ensure that the panels are compatible with their printing processes and consider handling requirements to maintain the integrity of the printed designs. While they offer exceptional visual appeal, careful management is necessary to avoid damage during installation and use.

Key Industrial Applications of ACP Panel Manufacturers

| Industry/Sector | Specific Application of ACP Panel Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architecture & Construction | Exterior cladding and facades | Enhances aesthetic appeal, durability, and insulation | Compliance with local building codes and regulations |

| Signage & Branding | Custom signage solutions | Provides high visibility and brand recognition | Availability of various colors and finishes |

| Transportation | Interior and exterior panels for vehicles | Lightweight, durable, and weather-resistant | Customization options for specific vehicle types |

| Retail & Commercial Spaces | Interior wall panels and displays | Creates engaging customer experiences | Quick turnaround for projects and diverse design options |

| Industrial Applications | Functional panels for machinery and equipment housing | Improves safety and operational efficiency | Fire ratings and material certifications |

How Are ACP Panels Used in Architecture & Construction?

In the architecture and construction sectors, ACP panels are extensively used for exterior cladding and facades. These panels not only enhance the aesthetic appeal of buildings but also provide excellent insulation, which is crucial in diverse climates, particularly in regions like Africa and the Middle East where temperatures can vary significantly. Buyers in this sector must ensure that the panels comply with local building codes and regulations, especially concerning fire safety and environmental sustainability.

What Role Do ACP Panels Play in Signage & Branding?

ACP panels serve as a versatile solution for custom signage applications, crucial for businesses aiming to enhance brand visibility. Their lightweight nature and the ability to print high-quality graphics make them ideal for both interior and exterior signs. For international buyers, particularly in Europe and South America, sourcing panels that offer a variety of colors and finishes can significantly impact the effectiveness of signage in attracting customers and conveying brand identity.

How Are ACP Panels Utilized in Transportation?

In the transportation industry, ACP panels are used for both interior and exterior applications in vehicles, including buses, trains, and trucks. Their lightweight yet durable composition allows for improved fuel efficiency and easier handling during manufacturing. Buyers should consider customization options to meet the specific requirements of different vehicle types, as well as ensure that the panels are weather-resistant and compliant with safety standards.

What Are the Benefits of ACP Panels in Retail & Commercial Spaces?

Retail and commercial spaces utilize ACP panels for interior wall applications and display solutions. These panels create engaging environments that enhance customer experiences while being easy to maintain. Buyers should seek suppliers who can offer quick turnaround times for projects, as well as a range of design options to fit the branding needs of various retail environments, especially in fast-paced markets in regions like Nigeria and Germany.

How Are ACP Panels Applied in Industrial Applications?

In industrial settings, ACP panels are used for machinery and equipment housing, providing a protective barrier that improves safety and operational efficiency. These panels can be customized for specific applications, ensuring they meet fire ratings and material certifications relevant to different industries. International buyers should prioritize sourcing from manufacturers who can demonstrate compliance with global safety standards, particularly in regions with stringent regulations.

3 Common User Pain Points for ‘ACP Panel Manufacturers’ & Their Solutions

Scenario 1: Delayed Deliveries Impacting Project Timelines

The Problem: B2B buyers often face significant delays in the delivery of aluminum composite panels (ACP), which can jeopardize project timelines and budgets. For instance, a construction firm in Nigeria may plan to complete a building facade using ACP, but when the panels arrive weeks late, it disrupts the entire construction schedule. This can lead to increased labor costs and strained relationships with clients who expect timely delivery.

The Solution: To mitigate delivery delays, buyers should establish a clear communication channel with their ACP manufacturers. Before placing an order, inquire about the manufacturer’s production capacity, lead times, and shipping logistics. Opt for manufacturers with a proven track record of on-time deliveries and consider those that offer diversified transportation methods, such as sea and air freight. Moreover, utilizing tools like order tracking can provide real-time updates on shipment status, allowing for proactive adjustments to project schedules if needed.

Scenario 2: Quality Assurance and Compliance Concerns

The Problem: Buyers frequently grapple with concerns over the quality and compliance of ACP products, especially when sourcing from international manufacturers. In regions like South America, where regulatory standards may vary, a buyer might receive panels that do not meet local fire safety regulations, posing a significant risk and potential liability for projects.

The Solution: To address quality assurance, buyers should prioritize manufacturers who provide detailed product certifications and test reports. Before finalizing a purchase, request documentation that proves compliance with international standards, such as ISO certifications, fire rating approvals, and material safety data sheets (MSDS). Engaging with manufacturers that offer warranties—ranging from 10 to 20 years—can also provide peace of mind. Additionally, consider conducting third-party inspections or audits of the manufacturing facilities to ensure adherence to quality and safety standards.

Scenario 3: Limited Customization Options Hindering Design Flexibility

The Problem: Many B2B buyers encounter restrictions when it comes to customizing ACP panels for specific design needs. For architects in Europe, the inability to obtain panels in unique colors or finishes can stifle creativity and limit project outcomes. This lack of flexibility can force buyers to compromise on their vision, ultimately impacting the aesthetic quality of the final product.

The Solution: Buyers should seek out ACP manufacturers that specialize in customizable solutions. When initiating discussions with potential suppliers, clearly outline your design requirements, including colors, finishes, and panel dimensions. Look for manufacturers who offer advanced capabilities, such as in-house coil coating or CNC machining, which can facilitate bespoke designs. Additionally, request samples to evaluate the look and feel of the materials before making a bulk purchase. Establishing a collaborative relationship with the manufacturer can also lead to innovative solutions that meet unique design challenges.

Strategic Material Selection Guide for ACP Panel Manufacturers

What Are the Key Materials for ACP Panel Manufacturers?

Aluminium Composite Panels (ACP) are increasingly popular in various industries due to their versatility and performance characteristics. When selecting materials for ACP manufacturing, it is essential to consider properties such as durability, cost, and suitability for specific applications. Below, we analyze four common materials used in ACP production, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminium Perform in ACP Panels?

Key Properties: Aluminium is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It can withstand a wide range of temperatures, making it suitable for various climates.

Pros & Cons: The primary advantage of aluminium is its durability and resistance to environmental factors. It is also relatively easy to fabricate and can be coated in various finishes. However, the initial cost can be higher compared to other materials, and it may require additional treatment to enhance its fire resistance.

Impact on Application: Aluminium’s properties make it ideal for architectural applications, signage, and interior design. Its compatibility with various coatings allows for aesthetic flexibility.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and the Middle East should ensure that the aluminium used meets local fire safety regulations.

What Role Does Polyethylene Play in ACP Manufacturing?

Key Properties: Polyethylene (PE) serves as the core material in many ACPs, providing a lightweight structure with good impact resistance and moderate thermal insulation.

Pros & Cons: The main advantage of PE is its cost-effectiveness and ease of processing. However, it has lower fire resistance compared to other core materials, which can be a significant drawback in certain applications.

Impact on Application: PE is commonly used in applications where weight is a concern, such as in signage and interior panels. However, its lower fire rating may limit its use in high-risk environments.

Considerations for International Buyers: Buyers should be aware of the fire safety standards in their region. For example, European buyers often prefer materials that meet stringent fire regulations, which may not be satisfied by standard PE cores.

How Does Mineral Core Material Enhance ACP Panels?

Key Properties: Mineral core materials, often made from non-combustible substances, offer superior fire resistance and sound insulation compared to PE.

Pros & Cons: The key advantage of mineral cores is their high fire rating, making them suitable for high-rise buildings and other applications requiring stringent safety standards. However, they are generally more expensive and heavier, which may increase shipping costs and installation complexity.

Impact on Application: Mineral core ACPs are ideal for external cladding in commercial buildings, where fire safety is a priority. Their sound insulation properties also make them suitable for urban environments.

Considerations for International Buyers: Buyers should ensure that the mineral core complies with local building codes and international standards. In regions like Europe, adherence to standards such as EN 13501-1 is critical.

What Advantages Do Composite Materials Offer in ACP Panels?

Key Properties: Composite materials, which may include combinations of metals and polymers, provide a balance of strength, weight, and aesthetic appeal.

Pros & Cons: The primary advantage of composites is their versatility, allowing manufacturers to tailor properties to specific applications. However, they can be more complex to manufacture and may require specialized equipment.

Impact on Application: Composite ACPs are often used in high-end architectural applications where aesthetics and performance are both critical. They can be designed to mimic natural materials while providing the durability of synthetic options.

Considerations for International Buyers: Buyers should consider the manufacturing capabilities of suppliers, especially in regions with less developed infrastructure. Additionally, understanding the local market’s preferences for aesthetics can guide material selection.

Summary Table of Material Selection for ACP Panel Manufacturers

| Material | Typical Use Case for ACP Panel Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminium | Architectural panels, signage | Durable and corrosion-resistant | Higher initial cost | High |

| Polyethylene | Interior panels, signage | Cost-effective and lightweight | Lower fire resistance | Low |

| Mineral Core | External cladding for commercial buildings | Excellent fire resistance | More expensive and heavier | High |

| Composite Materials | High-end architectural applications | Versatile and customizable | Complex manufacturing process | Medium |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions regarding material selection for ACP manufacturing. Understanding the properties and implications of each material can significantly impact project success and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ACP Panel Manufacturers

What Are the Main Stages of Manufacturing Aluminium Composite Panels?

The manufacturing of Aluminium Composite Panels (ACP) involves several critical stages that ensure the final product meets the necessary quality and performance standards. The process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, primarily aluminum sheets and a non-aluminum core material (often polyethylene or fire-resistant material). Suppliers must ensure that these materials meet industry standards and are suitable for the intended application. This includes checking for properties such as thickness, weight, and surface finish.

-

Forming: During the forming stage, the aluminum sheets are cut to size and shaped according to specific project requirements. Advanced techniques such as CNC machining, laser cutting, and die pressing are often employed to achieve precise dimensions. This stage is crucial as it impacts the panel’s overall structural integrity and aesthetic appeal.

-

Assembly: In the assembly phase, the prepared aluminum sheets are bonded to the core material using specialized adhesives. This process often requires controlled environments to ensure optimal bonding conditions, including temperature and humidity management. Some manufacturers may also utilize thermal bonding techniques, enhancing the panel’s strength and durability.

-

Finishing: The final stage involves applying finishes to the ACP, which may include coatings for UV resistance, color application, and protective layers. Techniques such as coil coating and powder coating are commonly used. This not only enhances the visual appeal of the panels but also improves their longevity and resistance to environmental factors.

How Do ACP Manufacturers Ensure Quality Control?

Quality assurance is paramount in the ACP manufacturing process to guarantee that the panels meet international standards and customer specifications. Manufacturers typically adhere to several internationally recognized standards, including ISO 9001, which focuses on quality management systems.

-

International and Industry-Specific Standards: Compliance with standards such as CE marking for European markets, API (American Petroleum Institute) for certain industrial applications, and various fire safety certifications is crucial. These standards ensure that the products meet safety, environmental, and performance criteria.

-

Quality Control Checkpoints: Manufacturers implement multiple quality control checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line. It includes inspections for material specifications, certifications, and supplier reliability.

– In-Process Quality Control (IPQC): During manufacturing, real-time inspections are conducted to monitor critical parameters, ensuring adherence to manufacturing specifications. This can include checks for dimensional accuracy, bonding strength, and surface finish.

– Final Quality Control (FQC): Before shipping, finished panels undergo rigorous testing to assess their performance under various conditions. This may include stress tests, fire resistance tests, and visual inspections for defects.

What Testing Methods Are Commonly Used in ACP Manufacturing?

Testing methods for ACPs are designed to evaluate their mechanical properties, durability, and safety. Common testing protocols include:

-

Mechanical Testing: These tests assess properties such as tensile strength, flexural strength, and impact resistance. Manufacturers often conduct these tests in accordance with ASTM (American Society for Testing and Materials) standards to ensure reliability.

-

Fire Testing: Given the importance of fire safety, ACPs are subjected to fire resistance tests to determine their reaction to fire and smoke development. Compliance with international fire safety standards, such as EN 13501-1 for European markets, is critical.

-

Environmental Testing: Panels are also tested for resistance to weathering, UV exposure, and corrosion. These tests help predict the longevity and performance of the panels in different climates, particularly for international buyers in diverse regions like Africa and South America.

How Can B2B Buyers Verify the Quality Control of ACP Suppliers?

For international B2B buyers, especially those from regions with varying regulatory environments, verifying the quality control processes of ACP manufacturers is essential. Here are actionable strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing practices and quality control systems. This allows buyers to assess compliance with international standards and the effectiveness of their quality management practices.

-

Requesting Quality Control Reports: Buyers should request detailed QC reports, including test results and certifications. These documents should outline the procedures followed during manufacturing and any third-party testing conducted.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can occur at various stages of production, from raw material inspection to final product evaluation.

-

Certifications Verification: Buyers should verify the authenticity of certifications claimed by the manufacturer. This may involve checking with certifying bodies to ensure the manufacturer maintains up-to-date certifications and adheres to the required standards.

What QC and Certification Nuances Should International Buyers Consider?

B2B buyers from different regions should be aware of specific nuances related to quality control and certification processes:

-

Regional Standards Compliance: Different regions have varying regulations. For instance, European buyers may prioritize CE marking and compliance with EN standards, while buyers in the Middle East may focus on local certifications such as the Gulf Standardization Organization (GSO).

-

Cultural Considerations: Understanding the cultural context of suppliers can influence negotiations and expectations regarding quality assurance. For example, suppliers in some regions may have different approaches to quality management, which could affect timelines and communication.

-

Long-Term Partnerships: Establishing long-term relationships with reliable manufacturers can lead to improved quality assurance over time. Continuous collaboration fosters transparency and accountability, which are crucial for maintaining high standards.

In conclusion, understanding the manufacturing processes and quality assurance protocols of ACP manufacturers is vital for B2B buyers seeking reliable suppliers. By focusing on these key aspects, buyers can make informed decisions that align with their project requirements and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ACP Panel Manufacturers’

Introduction

Sourcing aluminium composite panels (ACP) for your projects requires careful consideration and strategic planning. This guide provides a step-by-step checklist tailored for international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that you select reliable manufacturers who meet your specific requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Consider factors such as panel dimensions, thickness, color, fire resistance ratings, and surface finish. This clarity will not only streamline your communication with manufacturers but also help in comparing different offerings effectively.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify potential ACP manufacturers that align with your needs. Look for companies with a proven track record in your target regions, and assess their industry experience. Resources like trade publications, online directories, and industry associations can provide valuable insights into reputable manufacturers.

Step 3: Verify Supplier Certifications

It’s crucial to ensure that your chosen manufacturers possess the necessary certifications. Check for compliance with international quality standards such as ISO 9001, as well as specific product certifications like SGS or Intertek. These certifications are indicators of a supplier’s commitment to quality and safety, which are essential in construction materials.

Step 4: Evaluate Production Capabilities

Assess the production capabilities of potential suppliers. Investigate their manufacturing processes, technology, and capacity to handle your order volume. A supplier with advanced technology and flexibility can provide customized solutions and faster turnaround times, which are critical in meeting project deadlines.

Step 5: Request Samples for Quality Assurance

Before finalizing your order, request samples of the ACP products. Evaluating samples allows you to assess the quality, finish, and suitability for your specific applications. Pay attention to the panel’s weight, rigidity, and aesthetic appeal, as these factors can significantly impact your project’s success.

Step 6: Discuss Payment Terms and Conditions

Engage in discussions about payment terms with your shortlisted suppliers. Understand their accepted payment methods, such as letters of credit or bank transfers, and negotiate terms that align with your financial strategy. Clear communication on payment conditions can prevent misunderstandings and ensure a smooth transaction process.

Step 7: Establish Communication and Support Channels

Effective communication is vital throughout the sourcing process. Ensure that your suppliers have robust customer support and responsiveness to inquiries. A manufacturer with a dedicated sales and customer relationship management team can facilitate smoother interactions and assist in resolving any issues that may arise during production and delivery.

By following this checklist, you can navigate the complexities of sourcing ACP panels and secure a reliable manufacturer that meets your project’s requirements.

Comprehensive Cost and Pricing Analysis for ACP Panel Manufacturers Sourcing

What Are the Key Cost Components in ACP Panel Manufacturing?

When sourcing Aluminium Composite Panels (ACP), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly affect pricing. High-grade aluminum and core materials enhance durability and aesthetics but come at a premium. Suppliers often provide various options, and selecting the right material can lead to cost savings in the long run.

-

Labor: Skilled labor is necessary for manufacturing and quality control. In regions with higher labor costs, such as Western Europe, this can drive prices up. Conversely, sourcing from countries with lower labor costs may offer savings but could compromise quality if not managed carefully.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, which is often reflected in competitive pricing.

-

Tooling: The initial setup for production, including molds and machinery, contributes to the cost. Custom designs may require specialized tooling, increasing upfront expenses but potentially leading to a better fit for specific project needs.

-

Quality Control (QC): Investing in robust QC processes ensures that the final product meets industry standards and certifications. This is particularly important for international buyers who may require compliance with specific regulations.

-

Logistics: Shipping and handling can significantly impact overall costs, especially for international shipments. Factors like distance, mode of transport, and packaging requirements play a critical role in logistics expenses.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect ACP Panel Sourcing?

Several factors can influence the pricing of ACP panels, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating higher MOQs can yield better pricing structures.

-

Specifications and Customization: Custom features or unique specifications will typically increase costs. Buyers should assess whether the added features justify the increased investment.

-

Material Quality and Certifications: Products with certifications (e.g., fire ratings, environmental standards) command higher prices. Buyers should consider the implications of these certifications for their projects.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established manufacturers may charge more due to their proven track record, but they often provide superior quality and service.

-

Incoterms: Understanding the terms of shipping and delivery is essential. Different Incoterms can affect the overall cost structure and risk allocation between buyer and supplier.

What Buyer Tips Can Enhance Cost-Efficiency in ACP Panel Procurement?

For B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Leverage your purchasing power to negotiate better terms. Building a long-term relationship with suppliers can also lead to favorable pricing and terms in future transactions.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and potential replacement costs. A higher upfront cost may lead to lower TCO if the product lasts longer and requires less maintenance.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations and import duties can impact costs. Be sure to factor these into your budget when sourcing from overseas suppliers.

-

Conduct Market Research: Familiarize yourself with various suppliers and their offerings. This knowledge can empower you to make informed decisions and recognize when a price is fair or inflated.

Disclaimer

The prices and cost structures discussed are indicative and can vary significantly based on numerous factors, including market conditions, supplier negotiations, and specific project requirements. Always seek detailed quotations and conduct thorough due diligence when sourcing ACP panels.

Alternatives Analysis: Comparing ACP Panel Manufacturers With Other Solutions

Exploring Viable Alternatives to ACP Panel Manufacturers

When considering materials for architectural and construction projects, it’s essential to evaluate various solutions available in the market. Aluminium Composite Panels (ACP) are popular for their aesthetic appeal and versatility, but alternatives may offer unique advantages depending on specific project needs. This section compares ACP Panel Manufacturers with alternative solutions, providing actionable insights for international B2B buyers.

Comparison Table

| Comparison Aspect | ACP Panel Manufacturers | Fiber Cement Boards | High-Pressure Laminate (HPL) |

|---|---|---|---|

| Performance | Excellent durability and weather resistance | Good durability, resistant to moisture | High resistance to impact and scratches |

| Cost | Moderate to high cost | Generally lower cost | Moderate to high cost |

| Ease of Implementation | Requires professional installation | Easier to install; can be cut on-site | Requires specialized tools for installation |

| Maintenance | Low maintenance; periodic cleaning required | Low maintenance; periodic cleaning | Low maintenance; resistant to staining |

| Best Use Case | Commercial facades, signage, and interiors | Exterior cladding, residential buildings | Interior and exterior applications requiring high aesthetic quality |

Detailed Breakdown of Alternatives

What Are Fiber Cement Boards and Their Benefits?

Fiber cement boards are composed of cement, sand, and cellulose fibers, providing a robust alternative to ACPs. They offer good durability and moisture resistance, making them suitable for various climates, especially in humid regions. Fiber cement is often less expensive than ACP, making it a cost-effective choice for large-scale projects. However, they are heavier and may require more structural support, which can complicate installation.

How Do High-Pressure Laminates (HPL) Compare?

High-Pressure Laminate (HPL) consists of layers of resin and paper or fabric that are compressed under high pressure, resulting in a dense, durable surface. HPL is known for its resistance to scratches, impacts, and stains, making it ideal for high-traffic areas. Additionally, it offers a wide variety of aesthetic options. However, installation can be more complex and may require specialized tools, which could increase labor costs. HPL generally falls into a similar price range as ACP panels, depending on the design and finish selected.

Making the Right Choice: Which Solution Fits Your Needs?

Choosing the right material depends heavily on the specific requirements of your project. For high-end aesthetics and design flexibility, ACP panels may be the best option despite their higher cost. Alternatively, for projects focused on budget and ease of installation, fiber cement boards present a viable solution. If durability and resistance to wear are paramount, HPL could be the ideal choice. Consider factors such as climate, application type, and long-term maintenance costs to determine the best fit for your needs. Engaging with manufacturers directly can also provide insights into customization options that align with your project objectives.

By evaluating these alternatives against ACP panels, international B2B buyers can make informed decisions that enhance project outcomes and align with their strategic goals.

Essential Technical Properties and Trade Terminology for ACP Panel Manufacturers

What Are the Key Technical Properties of ACP Panels That Buyers Should Know?

When sourcing Aluminium Composite Panels (ACP), understanding the technical properties is crucial for ensuring that the products meet specific project requirements. Here are some essential properties to consider:

-

Material Grade

ACPs typically consist of a non-aluminum core sandwiched between two aluminum sheets. The grade of aluminum used (such as 1100, 3003, or 5005) affects the panel’s strength, durability, and resistance to corrosion. Selecting the right grade is essential, especially for applications in varying climatic conditions, as it influences the longevity and performance of the panels. -

Thickness

The thickness of ACP panels generally ranges from 3mm to 6mm, although custom thicknesses may be available. Thicker panels provide enhanced durability and resistance to impact, making them suitable for high-traffic areas. For buyers, understanding the thickness is critical in determining the panel’s suitability for specific applications like exterior facades or interior signage. -

Tolerance

Tolerance refers to the allowable variation in the panel dimensions. Tight tolerances ensure that the panels fit accurately during installation, reducing waste and ensuring a seamless appearance. Buyers should inquire about the manufacturer’s tolerance standards to avoid complications during installation and to ensure structural integrity. -

Fire Rating

ACPs are available with different fire ratings, which indicate how well the material resists combustion. Compliance with local fire safety regulations is essential, particularly for commercial buildings. Understanding the fire rating of ACP panels helps buyers select materials that not only meet safety standards but also fulfill aesthetic requirements. -

Surface Finish

The surface finish of ACPs can vary widely, from matte to high-gloss options. Specialty finishes, such as textured or metallic coatings, enhance aesthetic appeal and may provide additional functional benefits like UV resistance. Buyers should consider the desired finish in relation to the project’s design vision and maintenance requirements. -

Thermal Conductivity

This property determines how well the ACP panel insulates against temperature changes. High thermal resistance can lead to energy savings by reducing heating and cooling costs. For projects in regions with extreme temperatures, understanding thermal conductivity is vital for selecting the right materials.

What Are Common Trade Terms Used in ACP Panel Manufacturing?

Navigating the world of ACP panels involves familiarizing oneself with specific industry terminology. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are then sold under another company’s brand name. In the context of ACP panels, OEMs may provide custom panel solutions tailored to the specifications of other businesses, making it vital for buyers to clarify their needs and expectations. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to assess whether a supplier’s offerings align with their project size and budget. This term helps in negotiating bulk orders or exploring alternative suppliers if the MOQ is too high. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For ACP panel buyers, issuing an RFQ can facilitate competitive pricing and help in evaluating different suppliers’ capabilities and offerings. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms (such as FOB, CIF, or DDP) helps buyers understand shipping costs, risk transfer, and delivery obligations. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. In the ACP industry, lead times can vary based on production capacity and order complexity. Buyers should inquire about lead times to ensure that project timelines are met. -

Certification

Certifications (such as ISO, CE, or fire safety ratings) indicate that products meet certain standards of quality and safety. Buyers should prioritize suppliers who can provide relevant certifications, ensuring compliance with local regulations and enhancing the credibility of their projects.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right ACP panels that meet their project requirements while fostering successful supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the ACP Panel Manufacturers Sector

What Are the Key Trends Shaping the Global ACP Panel Manufacturing Market?

The global aluminium composite panel (ACP) market is witnessing a transformative phase influenced by several key drivers. The growing demand for lightweight, durable materials in construction and signage sectors is propelling the market forward. Additionally, advancements in manufacturing technologies, such as digital printing and automated processes, are enhancing product quality and customization capabilities. For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed sourcing decisions.

Emerging trends in the market include an increasing emphasis on quick turnaround times and just-in-time inventory management, which can significantly reduce costs and improve project timelines. Companies are leveraging e-commerce platforms and online marketplaces to streamline procurement processes, allowing for easier access to a global network of suppliers. The rise of digital tools also facilitates better communication between manufacturers and buyers, ensuring that projects align with specific requirements and timelines.

Moreover, the demand for innovative ACP solutions, such as fire-resistant and eco-friendly panels, is reshaping product offerings. As international regulations become more stringent, manufacturers are adapting to meet safety standards while providing aesthetically pleasing designs. This trend is particularly relevant for buyers in regions like Germany, where regulatory compliance is paramount. Understanding these market dynamics can empower B2B buyers to identify reliable suppliers who can meet their evolving needs.

How Important Is Sustainability and Ethical Sourcing for ACP Panel Manufacturers?

Sustainability has emerged as a critical consideration for B2B buyers in the ACP manufacturing sector. The environmental impact of production processes, including energy consumption and waste generation, necessitates a focus on sustainable practices. Buyers are increasingly seeking suppliers that prioritize eco-friendly materials and manufacturing methods, which not only reduce carbon footprints but also align with global sustainability goals.

Ethical sourcing is equally crucial, as it reflects a company’s commitment to social responsibility. B2B buyers should evaluate potential suppliers based on their supply chain transparency and labor practices. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) indicate a manufacturer’s dedication to sustainable practices. These certifications not only enhance a supplier’s credibility but also provide buyers with assurance that they are contributing to responsible sourcing.

Furthermore, the trend towards using recyclable materials in ACP production is gaining traction. Manufacturers are increasingly developing panels that incorporate recycled content, which can significantly lower environmental impacts. By prioritizing suppliers that offer ‘green’ certifications and sustainable materials, international B2B buyers can make choices that align with both their business objectives and ethical standards.

What Has Been the Evolution of the ACP Panel Manufacturing Industry?

The aluminium composite panel manufacturing industry has evolved significantly over the past few decades. Initially, ACPs were primarily utilized for their aesthetic appeal and lightweight properties in the architectural sector. However, as safety regulations became more stringent, the focus shifted towards enhancing the fire resistance and durability of these panels.

Advancements in technology have played a pivotal role in this evolution, with innovations in materials and production processes enabling manufacturers to create panels that not only meet regulatory standards but also cater to diverse design needs. Today, ACPs are used across various applications, including signage, transportation, and interior design, reflecting their versatility and growing importance in the global market.

As the industry continues to mature, B2B buyers can expect an ongoing emphasis on customization, sustainability, and compliance, ensuring that ACPs remain a vital component of modern construction and design projects.

Frequently Asked Questions (FAQs) for B2B Buyers of ACP Panel Manufacturers

-

1. How do I ensure the quality of ACP panels when sourcing from manufacturers?

To ensure the quality of Aluminium Composite Panels (ACP) when sourcing from manufacturers, request certifications such as ISO, SGS, or other relevant quality assurance documents. Additionally, ask for samples to evaluate material properties like durability, weight, and finish. It’s beneficial to conduct factory visits or arrange third-party inspections to verify production standards. Look for manufacturers with a proven track record and positive customer testimonials to further assure quality. -

2. What is the best way to vet ACP panel suppliers for reliability and quality?

The best way to vet ACP panel suppliers is to conduct thorough background research. Check their certifications, years of experience, and previous project portfolios. Engage in direct communication to assess their responsiveness and customer service. Utilize platforms like trade associations or industry directories to find reputable manufacturers. Additionally, consider requesting references from past clients to gauge reliability and performance. -

3. What customization options are typically available for ACP panels?

Customization options for ACP panels often include variations in color, finish, size, and thickness. Many manufacturers provide tailored solutions to meet specific project needs, such as unique designs or enhanced fire resistance. Discuss your requirements with potential suppliers to understand their capabilities and the types of customizations they can offer. Ensure you review samples of any custom work before finalizing orders. -

4. What is the minimum order quantity (MOQ) when purchasing ACP panels?

Minimum order quantities for ACP panels can vary significantly among manufacturers, typically ranging from a few hundred to several thousand square meters. It is essential to clarify MOQ with potential suppliers early in the negotiation process. Some manufacturers may offer flexibility based on your specific project needs or long-term partnership agreements, so discussing your requirements can often lead to more favorable terms. -

5. What payment terms should I expect when sourcing ACP panels internationally?

Payment terms when sourcing ACP panels can vary by supplier and region. Common options include advance payment, letters of credit (L/C), or payment upon delivery. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Be cautious of suppliers requesting full payment upfront, especially if they lack a solid reputation. Always ensure that payment methods are secure and traceable. -

6. How can I manage logistics and shipping for ACP panels from international suppliers?

To manage logistics for ACP panels, work closely with your supplier to understand shipping options and timelines. Ensure that they provide clarity on transport methods, including sea or air freight, and the associated costs. Consider partnering with a freight forwarder experienced in handling building materials to navigate customs regulations and ensure timely delivery. Always confirm the shipping terms, such as Incoterms, to avoid misunderstandings regarding responsibility and liability. -

7. What are the common quality assurance practices in ACP panel manufacturing?

Common quality assurance practices in ACP panel manufacturing include rigorous material inspections, adherence to production standards, and systematic testing of finished products. Manufacturers often implement a multi-step inspection process that includes incoming material checks, in-process quality control, and final product testing. Ensure the manufacturer you choose has a robust QA system in place to guarantee compliance with international standards and customer specifications. -

8. How do I handle potential disputes or issues with ACP panel suppliers?

Handling potential disputes with ACP panel suppliers requires clear communication and documentation. Establish a formal agreement that outlines specifications, delivery timelines, and payment terms to serve as a reference. In case of issues, address them promptly by reaching out to the supplier to seek resolution. If necessary, consider mediation or arbitration as stipulated in your contract. Maintaining a professional relationship and open lines of communication can often lead to quicker resolutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ACP Panel Manufacturers

What Are the Key Takeaways for B2B Buyers in Sourcing ACP Panels?

In conclusion, strategic sourcing of Aluminium Composite Panels (ACP) is vital for international buyers seeking quality, reliability, and innovation. Manufacturers with robust certifications and a proven track record, such as ISO compliance and multi-national project experience, demonstrate their commitment to quality and customer satisfaction. Moreover, flexible payment terms and efficient logistics options significantly enhance the procurement process, allowing for smoother transactions and timely project execution.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in well-researched sourcing strategies not only mitigates risks but also opens doors to innovative solutions tailored to specific industry needs. By partnering with manufacturers who prioritize quality, transparency, and collaboration, buyers can ensure they receive exceptional value that meets both budgetary constraints and project specifications.

What’s Next for International Buyers in the ACP Market?

As the demand for sustainable and aesthetically pleasing building materials continues to grow across Africa, South America, the Middle East, and Europe, now is the time for B2B buyers to reassess their sourcing strategies. Engage with leading ACP manufacturers, explore new product offerings, and leverage technology to streamline your supply chain. Embrace this opportunity to enhance your projects with superior materials that align with market trends and consumer expectations. Your next strategic partnership awaits—take the leap towards a more sustainable and efficient future in construction.