Top 7 Aluminium Composite Panel Manufacturers List and Guide: How…

Introduction: Navigating the Global Market for Aluminium Composite Panel Manufacturers

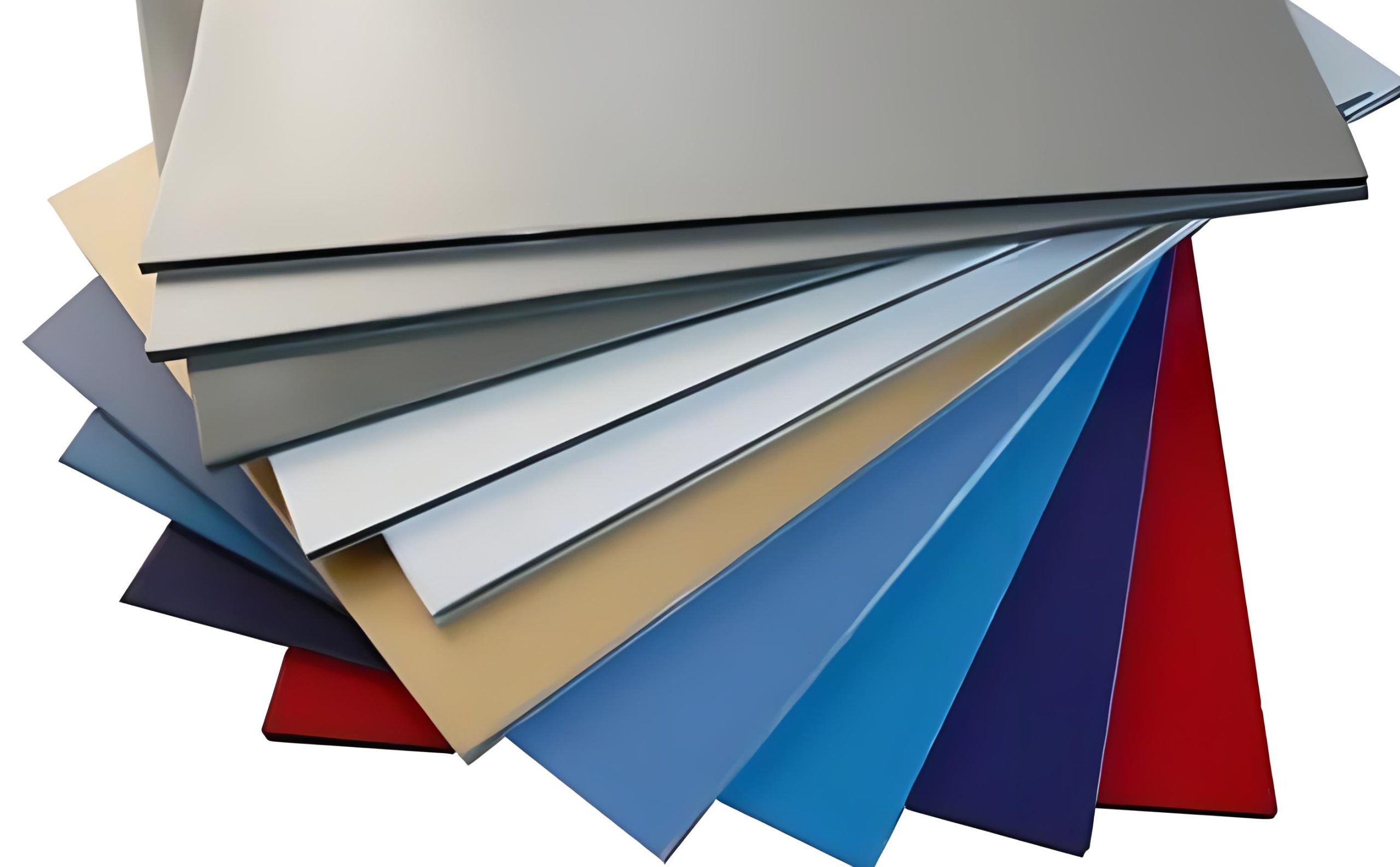

In the ever-evolving landscape of construction materials, sourcing high-quality aluminium composite panels (ACPs) poses a significant challenge for international B2B buyers. With diverse applications ranging from architectural façades to signage and interior finishes, understanding the intricacies of ACP manufacturing and supplier capabilities is crucial for making informed decisions. This guide provides an in-depth exploration of the global market for aluminium composite panel manufacturers, examining various types of ACPs, their applications, and essential supplier vetting processes.

As you navigate this complex market, you will gain insights into crucial factors such as cost considerations, material specifications, and compliance with international standards. By identifying key players in regions like Africa, South America, the Middle East, and Europe—including major markets such as Saudi Arabia and Germany—you can streamline your procurement process and mitigate risks associated with supplier selection.

This comprehensive resource empowers B2B buyers to make strategic purchasing decisions, ensuring you select reliable manufacturers who meet your project requirements while adhering to sustainability and quality benchmarks. With actionable insights and expert guidance, this guide is your go-to reference for navigating the global aluminium composite panel landscape effectively.

Top 10 Aluminium Composite Panel Manufacturers Manufacturers & Suppliers List

1. Metoree – Aluminum Composite Panels

Domain: us.metoree.com

Registered: 2020 (5 years)

Introduction: Aluminum panels are composite panels consisting of a nonflammable synthetic resin sheet sandwiched between thin sheets of aluminum. They are treated with various surface treatments for enhanced corrosion resistance. The core material typically includes nonflammable and strong substances like polypropylene or foamed polyethylene. Aluminum panels are widely used in building exteriors and interiors, …

2. Alutec – Aluminium Composite Panels (ACP)

Domain: alutec.us

Registered: 2017 (8 years)

Introduction: Aluminium Composite Panels (ACP) ALUTEC® consists of two aluminum sheets attached to a low-density polyethylene core with fire-retardant material. It features PVDF paint for color durability of up to 20 years against UV exposure. Alutec offers over 40 colors across three brands: Alutec® (11 colors, 4 mm thickness), Alucomex® (30 colors, 4 mm thickness with textures like wood and marble), and Alusi…

3. ALUCOBOND – ALUCOBOND PLUS

Domain: alucobondusa.com

Registered: 2004 (21 years)

Introduction: ALUCOBOND is a lightweight aluminum composite panel known for its durability, design flexibility, and exceptional performance in both exterior and interior applications. Key products include:

1. **ALUCOBOND PLUS**: High-quality aluminum composite panel available in 91 colors and finishes, ideal for exterior cladding.

2. **ALUCOBOND EasyFix**: An innovative attachment system for easy fabrication…

4. VancoPanel – Aluminium Composite Panels

Domain: vancopanel.com

Registered: 2008 (17 years)

Introduction: Aluminium Composite Panel (ACP) products including: Fire-rated Aluminium Composite Panel, PVDF Aluminium Composite Panel, PE Aluminium Composite Panel, Brush Aluminium Composite Panel, Wooden Aluminium Composite Panel, Marble Aluminium Composite Panel, Metal Composite Panel, Billboard Aluminium Coil. Quality warranty of 10-20 years, ISO production & management system, SGS, Cisro, Exova, and Intert…

5. Nglantz – Aluminum Composite Panels

6. MakerStock – Aluminum Composite Panels (White)

Domain: makerstock.com

Registered: 2012 (13 years)

Introduction: Aluminum Composite Panels (ACP) – White

Price:

– $6.25 for 1/8″ / 3mm / 12″ x 12″

– $9.45 for 1/8″ / 3mm / 12″ x 20″

– $10.45 for 1/8″ / 3mm / 12″ x 24″

– $15.75 for 1/8″ / 3mm / 18″ x 24″

– $20.25 for 1/8″ / 3mm / 24″ x 24″

– $29.75 for 1/8″ / 3mm / 24″ x 36″

– $8.45 for 1/4″ / 6mm / 12″ x 12″

– $13.95 for 1/4″ / 6mm / 12″ x 20″

– $15.95 for 1/4″ / 6mm / 12″ x 24″

– $23.45 for 1/4″ / 6mm / 18″ …

7. Mordor Intelligence – Aluminum Composite Panels (ACP) Companies

Domain: mordorintelligence.com

Registered: 2013 (12 years)

Introduction: Aluminum Composite Panel (ACP) companies include 3A Composites GmbH, Jyi Shyang Industrial Co., Ltd., Arconic, Alstrong Enterprises India (Pvt) Ltd, Alubond U.S.A., Alucoil, Eurobond, GUANGZHOU XINGHE ACP CO. LTD, Interplast (Harwal Group of Companies), Mitsubishi Chemical Corporation, Mulford, Qatar National Aluminium Panel Company, Yaret Industrial Group Co. Ltd, and YingJia Aluminium Co. Ltd. T…

Understanding Aluminium Composite Panel Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Aluminium Composite Panels | Composed of two aluminum sheets with a low-density polyethylene core; cost-effective. | Commercial buildings, residential properties, signage. | Pros: Affordable, versatile; Cons: Limited fire resistance compared to other types. |

| Fire-Retardant Aluminium Composite Panels | Incorporate fire-retardant materials; meet stringent safety standards. | High-rise buildings, hospitals, schools. | Pros: Enhanced safety, compliance with regulations; Cons: Higher cost. |

| Eco-Friendly Aluminium Composite Panels | Made from recycled materials; focus on sustainability. | Green buildings, eco-friendly projects. | Pros: Reduced environmental impact; Cons: May have limited design options. |

| Decorative Aluminium Composite Panels | Various finishes and textures available; customizable aesthetics. | Retail spaces, corporate offices, luxury developments. | Pros: High aesthetic appeal; Cons: Can be more expensive. |

| Industrial Aluminium Composite Panels | Designed for heavy-duty applications; thicker and more durable. | Warehouses, factories, transport vehicles. | Pros: Exceptional durability; Cons: Heavier and may require more complex installation. |

What are the characteristics and suitability of Standard Aluminium Composite Panels for B2B buyers?

Standard Aluminium Composite Panels are the most common type, featuring a combination of two aluminum sheets enclosing a low-density polyethylene core. They are highly versatile and cost-effective, making them suitable for a wide range of applications, including commercial buildings and signage. B2B buyers often choose these panels for their affordability and ease of installation. However, it’s important to note that their fire resistance is limited compared to other variations, which may not meet the requirements for high-rise or safety-critical structures.

Why are Fire-Retardant Aluminium Composite Panels essential for safety in B2B applications?

Fire-Retardant Aluminium Composite Panels are specifically designed to enhance safety in construction. These panels include fire-retardant materials that comply with stringent safety standards, making them ideal for high-rise buildings, hospitals, and educational institutions. For B2B buyers, investing in these panels is crucial for projects where fire safety is a priority. While they typically come at a higher price point, the peace of mind and regulatory compliance they provide can outweigh the costs.

How do Eco-Friendly Aluminium Composite Panels contribute to sustainability in construction?

Eco-Friendly Aluminium Composite Panels are manufactured using recycled materials, aligning with the growing demand for sustainable building practices. These panels are particularly suited for green buildings and eco-conscious projects. B2B buyers looking to minimize their environmental footprint will find these panels appealing. However, it’s essential to consider that the variety of finishes and designs may be more limited compared to standard options, which could impact aesthetic choices.

What advantages do Decorative Aluminium Composite Panels offer for branding and aesthetics?

Decorative Aluminium Composite Panels are characterized by a wide array of finishes and textures, allowing for significant customization. They are ideal for retail spaces, corporate offices, and luxury developments where aesthetics play a crucial role. B2B buyers can leverage these panels to enhance brand identity and visual appeal. However, the cost may be higher than standard panels, and buyers should evaluate their budget against the desired aesthetic outcomes.

In what scenarios are Industrial Aluminium Composite Panels the best choice for B2B buyers?

Industrial Aluminium Composite Panels are engineered for heavy-duty applications, featuring thicker and more robust materials. They are ideal for warehouses, factories, and transport vehicles that require exceptional durability. B2B buyers in sectors that demand resilience and longevity will find these panels advantageous. However, their weight can complicate installation, and buyers should be prepared for potentially higher logistical costs.

Key Industrial Applications of Aluminium Composite Panel Manufacturers

| Industry/Sector | Specific Application of Aluminium Composite Panel Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Façade cladding for commercial and residential buildings | Enhances aesthetic appeal, durability, and energy efficiency | Compliance with local building codes and fire standards |

| Signage & Advertising | Outdoor and indoor signage solutions | High visibility, customizability, and weather resistance | Color options, thickness, and printability for branding |

| Transportation | Trailer and cargo siding | Lightweight, corrosion resistance, and structural integrity | Compatibility with vehicle specifications and regulations |

| Healthcare | Wall paneling in hospitals and clinics | Hygiene, fire resistance, and easy maintenance | Compliance with health and safety regulations |

| Retail & Hospitality | Interior finishes for shops and hotels | Improved customer experience and brand representation | Custom finishes and colors to align with brand identity |

How Are Aluminium Composite Panels Used in Construction and Architecture?

Aluminium composite panels (ACP) are widely used in the construction and architecture sectors for façade cladding on both commercial and residential buildings. They provide an attractive appearance while offering durability and energy efficiency. ACPs help solve common problems such as weather resistance and maintenance costs. International buyers must ensure compliance with local building codes, especially concerning fire safety and insulation standards, to avoid costly project delays.

What Role Do Aluminium Composite Panels Play in Signage and Advertising?

In the signage and advertising industry, aluminium composite panels are utilized for both outdoor and indoor signage solutions. Their lightweight nature and high visibility make them an ideal choice for businesses looking to enhance their brand presence. ACPs can be customized with various colors and finishes, which is essential for effective branding. Buyers should consider the specific thickness and printability of panels to ensure they meet the visual and durability requirements of their advertising campaigns.

Why Are Aluminium Composite Panels Important for Transportation Applications?

In the transportation sector, aluminium composite panels are increasingly used for trailer and cargo siding. Their lightweight properties help improve fuel efficiency, while their corrosion resistance ensures longevity in harsh conditions. For international buyers, it is crucial to verify compatibility with vehicle specifications and local regulations to ensure compliance and safety. This can prevent operational disruptions and enhance the performance of the vehicles.

How Are Aluminium Composite Panels Beneficial in Healthcare Settings?

Aluminium composite panels are essential in healthcare facilities, where they are used for wall paneling in hospitals and clinics. These panels offer advantages like hygiene, fire resistance, and ease of maintenance, which are critical in a healthcare environment. Buyers in this sector must prioritize compliance with health and safety regulations to ensure that the materials used are suitable for sensitive environments, thereby safeguarding patient health and well-being.

What Advantages Do Aluminium Composite Panels Offer in Retail and Hospitality?

In the retail and hospitality industries, aluminium composite panels are used for interior finishes in shops and hotels. They significantly enhance customer experience by providing aesthetically pleasing environments that reflect brand identity. Buyers should focus on obtaining custom finishes and colors that align with their branding strategies to maximize impact. Additionally, the ease of installation and maintenance of ACPs can lead to reduced operational costs, making them a practical choice for businesses in these sectors.

3 Common User Pain Points for ‘Aluminium Composite Panel Manufacturers’ & Their Solutions

Scenario 1: Navigating Quality and Compliance Challenges

The Problem: B2B buyers often face difficulties ensuring that the aluminium composite panels (ACP) they source meet the necessary international quality standards and compliance regulations. This is particularly challenging for companies operating in regions with strict building codes, such as Germany and Saudi Arabia, where non-compliance can lead to costly project delays or legal repercussions. The varying quality of materials from different manufacturers can also create uncertainty about the durability and safety of the products.

The Solution: To mitigate these challenges, buyers should prioritize sourcing from manufacturers with well-documented certifications and proven track records. Buyers can request detailed product specifications, compliance certificates (e.g., ASTM, NFPA), and test reports to ensure that the panels meet local and international standards. Engaging with manufacturers that offer transparency about their quality control processes and allow for third-party audits can provide additional assurance. Additionally, establishing a direct line of communication with the manufacturer’s technical team can facilitate clarification on material properties and compliance, ensuring that the buyer’s specific project requirements are met.

Scenario 2: Managing Cost Constraints in Project Budgets

The Problem: Many B2B buyers in the construction sector grapple with tight budgets that necessitate cost-effective solutions without compromising quality. The initial costs of high-quality aluminium composite panels can be daunting, especially for large-scale projects. Buyers may feel pressured to choose cheaper alternatives, which could lead to higher maintenance costs and reduced longevity in the long run.

The Solution: To address budget constraints effectively, buyers should conduct a thorough cost-benefit analysis before making purchasing decisions. This analysis should consider not only the initial purchase price but also the long-term implications of durability, maintenance, and energy efficiency. Buyers can seek out manufacturers that offer flexible pricing structures, bulk purchase discounts, or financing options. Furthermore, engaging in direct negotiations with manufacturers can sometimes yield better pricing or value-added services, such as design consultations or delivery logistics, ultimately aligning with the buyer’s financial capabilities while ensuring quality is not sacrificed.

Scenario 3: Overcoming Design Limitations and Aesthetic Concerns

The Problem: When it comes to architectural projects, aesthetics play a crucial role. B2B buyers often struggle with the limited aesthetic options available from standard aluminium composite panels, which can hinder the creative vision for a project. Buyers in markets like Europe, where design trends are continually evolving, may find it challenging to source panels that meet specific aesthetic requirements without compromising on functionality.

The Solution: Buyers should proactively engage with manufacturers that offer a wide range of customization options, including finishes, colors, and textures. Many modern ACP manufacturers provide advanced design capabilities, allowing for bespoke solutions that align with the buyer’s creative vision. It’s advisable to request samples of different finishes and textures to evaluate how they will look in the intended environment. Additionally, collaborating with the manufacturer’s design team can lead to innovative solutions that merge aesthetic appeal with functional requirements. Emphasizing the importance of aesthetics in initial communications with manufacturers can help ensure that the resulting products enhance the overall design while meeting performance criteria.

Strategic Material Selection Guide for Aluminium Composite Panel Manufacturers

What Are the Key Materials Used in Aluminium Composite Panels for Manufacturers?

Aluminium composite panels (ACPs) are increasingly popular in construction and design due to their versatility, durability, and aesthetic appeal. The selection of materials used in ACPs significantly impacts their performance and suitability for various applications. Here, we analyze four common materials used in ACP manufacturing: Low-Density Polyethylene (LDPE), Fire-Retardant (FR) Core, Mineral Core, and Aluminum Alloy.

How Does Low-Density Polyethylene (LDPE) Perform in ACPs?

Low-Density Polyethylene (LDPE) is a widely used core material in ACPs. It offers excellent flexibility and is lightweight, making it easy to handle and install. LDPE panels typically have a temperature rating of up to 80°C (176°F) and are resistant to moisture and chemicals, which enhances their longevity.

Pros: LDPE panels are cost-effective and provide good insulation properties. They are also easy to fabricate, allowing for a wide range of design options.

Cons: However, LDPE is less fire-resistant compared to other core materials, which may limit its use in high-risk environments. Additionally, while it offers decent durability, it may not withstand extreme weather conditions as effectively as other options.

Impact on Application: LDPE is suitable for interior applications and facades in low to moderate fire-risk areas.

Considerations for International Buyers: Buyers must ensure compliance with local fire safety regulations, especially in regions like the Middle East and Europe, where stringent standards exist.

What Are the Benefits of Using Fire-Retardant (FR) Core in ACPs?

Fire-Retardant (FR) cores are engineered to enhance the fire safety of ACPs. These cores can withstand higher temperatures and have a reduced flame spread index, making them suitable for high-rise buildings and public spaces.

Pros: The primary advantage of FR cores is their enhanced fire safety, which is critical for compliance with international building codes. They also offer good mechanical properties and durability.

Cons: The manufacturing process for FR panels can be more complex, leading to higher costs. Additionally, they may be heavier than LDPE panels, which could affect installation logistics.

Impact on Application: FR panels are ideal for applications in commercial buildings, schools, and hospitals where fire safety is paramount.

Considerations for International Buyers: Buyers should look for products certified to standards such as ASTM E84 and NFPA 285, particularly in regions with strict fire safety regulations.

Why Choose a Mineral Core for Aluminium Composite Panels?

Mineral core ACPs are designed for maximum fire resistance and are often used in high-performance applications. These panels typically contain a non-combustible mineral core that meets rigorous fire safety standards.

Pros: Mineral core panels offer superior fire resistance and are often required in high-rise buildings and public infrastructure. They also provide excellent durability and weather resistance.

Cons: The cost of mineral core panels is generally higher than other options, and they may require specialized installation techniques due to their weight.

Impact on Application: These panels are particularly suited for applications in urban environments where fire safety and aesthetic appeal are critical.

Considerations for International Buyers: Compliance with local and international fire safety standards is essential, especially in Europe and the Middle East.

What Role Does Aluminum Alloy Play in ACP Manufacturing?

Aluminum alloy is the outer layer of ACPs, providing strength and durability. Different alloys can be used, depending on the desired mechanical properties and corrosion resistance.

Pros: Aluminum alloys are lightweight, corrosion-resistant, and can be finished in various colors and textures, enhancing aesthetic appeal. They also provide excellent structural integrity.

Cons: The cost of high-grade aluminum alloys can be significant, and they may require additional treatments to enhance corrosion resistance in harsh environments.

Impact on Application: Aluminum alloy is suitable for a wide range of applications, including façades, signage, and interior design.

Considerations for International Buyers: Buyers should consider the alloy grade and finish, ensuring compliance with local standards such as DIN in Germany and other relevant regulations.

Summary Table of Material Selection for Aluminium Composite Panels

| Material | Typical Use Case for Aluminium Composite Panel Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene | Interior applications, low to moderate fire-risk areas | Cost-effective, good insulation | Limited fire resistance | Low |

| Fire-Retardant Core | High-rise buildings, public spaces | Enhanced fire safety | Higher cost, heavier weight | Med |

| Mineral Core | Urban environments, high-performance applications | Superior fire resistance | Higher cost, specialized installation | High |

| Aluminum Alloy | Façades, signage, and interior design | Lightweight, corrosion-resistant | Higher cost for high-grade alloys | Med to High |

This guide provides a comprehensive overview of the key materials used in aluminium composite panels, highlighting their properties, advantages, and considerations for international B2B buyers. By understanding these factors, manufacturers can make informed decisions that align with project requirements and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for Aluminium Composite Panel Manufacturers

What are the Key Stages in the Manufacturing Process of Aluminium Composite Panels?

The manufacturing of Aluminium Composite Panels (ACPs) involves several critical stages that ensure the final product meets the high standards required in various applications, including architectural façades, signage, and industrial uses. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality raw materials. ACPs typically consist of two aluminum sheets and a core material, often made from low-density polyethylene (LDPE) or fire-retardant (FR) materials. Suppliers must ensure that these materials conform to international quality standards. This stage also involves cutting the aluminum sheets and preparing the core to the required dimensions.

-

Forming: In this phase, the aluminum sheets are treated to enhance their adhesion properties, often through a process like chemical etching or cleaning. The core material is then sandwiched between the two aluminum sheets and subjected to pressure to bond them together. This is often accomplished using techniques such as adhesive bonding or heat lamination, which solidify the structure and ensure durability.

-

Assembly: After forming, the panels are cut to size and may undergo various assembly processes depending on the specific requirements of the project. This may include the addition of features like grooves or attachment points for installation. Advanced manufacturing techniques, such as CNC machining, may be employed to ensure precision in these processes.

-

Finishing: The final stage involves applying coatings or finishes to the panels. This can include painting, anodizing, or applying protective films. High-quality paints, such as PVDF (Polyvinylidene Fluoride), are often used to provide color and weather resistance, ensuring the panels maintain their aesthetic appeal over time. Custom finishes can also be provided to meet specific design requirements.

How is Quality Assurance Implemented in Aluminium Composite Panel Manufacturing?

Quality assurance (QA) is an essential aspect of ACP manufacturing, as it ensures that the products meet specified performance criteria and comply with relevant international standards.

-

International Standards: Many ACP manufacturers adhere to standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards helps assure B2B buyers that the manufacturer has established processes for consistent quality. Additionally, certifications such as CE (Conformité Européenne) for products sold in Europe and ASTM standards in North America provide further assurance regarding product safety and performance.

-

Quality Control Checkpoints: Quality control is typically implemented at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection checks the quality of raw materials before they enter the production line. Materials that do not meet specified standards are rejected.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that each stage adheres to quality standards. This includes checking dimensions, bond strength, and surface finishes.

– Final Quality Control (FQC): After the panels are completed, a final inspection is conducted to verify that they meet all specifications. This may include visual inspections, dimensional checks, and performance testing. -

Common Testing Methods: To ensure that ACPs meet fire safety and durability requirements, various testing methods are employed, such as:

– Fire Resistance Testing: To assess how the panels perform under fire conditions, manufacturers may conduct tests according to ASTM E84 or NFPA 285 standards.

– Weathering Tests: These tests evaluate how the panels withstand exposure to UV light, moisture, and temperature fluctuations.

– Mechanical Testing: This may include tests for tensile strength, impact resistance, and rigidity, ensuring that the panels can withstand the stresses of installation and use.

How Can B2B Buyers Verify the Quality Control Processes of ACP Manufacturers?

B2B buyers looking to source ACPs should take proactive steps to verify the quality control processes of potential suppliers. Here are some strategies:

-

Audits and Inspections: Conducting on-site audits of manufacturing facilities can provide valuable insights into the quality control processes in place. Buyers can assess whether the manufacturer adheres to established quality standards and examine their manufacturing practices firsthand.

-

Requesting Quality Control Reports: Manufacturers should be willing to provide detailed reports on their quality control procedures, including results from IQC, IPQC, and FQC. This documentation can help buyers understand how the manufacturer ensures product quality at each stage of production.

-

Third-Party Inspections and Certifications: Engaging third-party inspection services can add an additional layer of assurance. These independent entities can evaluate the manufacturer’s processes and products, providing unbiased assessments of quality compliance.

-

Understanding Certification Nuances: Different regions may have specific certification requirements. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may look for compliance with local standards. Understanding these nuances can help buyers make informed decisions when selecting a supplier.

What are the Quality Control Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider various factors when evaluating ACP manufacturers:

-

Regulatory Compliance: Buyers must ensure that the products meet local building codes and safety regulations. Understanding the specific requirements in each region can help mitigate risks associated with non-compliance.

-

Cultural and Logistical Challenges: Different regions may have varying expectations regarding quality and service. Buyers should communicate clearly with manufacturers about their quality requirements and timelines to avoid misunderstandings.

-

Sustainability Practices: Increasingly, buyers are looking for manufacturers that prioritize sustainability. Inquire about recycling practices, waste management, and the environmental impact of the production processes. Manufacturers committed to sustainability may have certifications that can enhance their credibility.

By understanding the manufacturing processes and quality assurance practices of aluminium composite panel manufacturers, B2B buyers can make informed decisions that align with their project requirements, ensuring high-quality outcomes for their construction or signage projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Aluminium Composite Panel Manufacturers’

Introduction

Navigating the procurement process for aluminium composite panels (ACP) can be complex, especially for international B2B buyers. This guide provides a structured checklist to streamline your sourcing efforts, ensuring you select a reputable manufacturer that meets your project requirements. By following these steps, you can make informed decisions and establish successful partnerships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the required panel dimensions, thickness, core materials, and fire resistance ratings. This will help you communicate your needs effectively and ensure that suppliers can meet your project’s safety and performance standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential manufacturers. Look for companies with a solid reputation in the industry, preferably those with certifications from recognized standards (e.g., ASTM, NFPA). Utilize online resources, trade shows, and industry publications to gather insights on their capabilities and product offerings.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it is essential to verify their certifications and compliance with international standards. This ensures that the panels meet safety, quality, and environmental regulations. Request documentation such as environmental product declarations and quality control certificates to validate their claims.

Step 4: Evaluate Product Range and Customization Options

Assess the manufacturer’s product range to ensure they offer the types of panels that suit your project. Look for options in various finishes, colors, and textures to align with your design vision. Additionally, inquire about customization capabilities, as some projects may require bespoke solutions.

- Consider finishes: Check if the manufacturer offers finishes that withstand harsh weather conditions, especially if you are sourcing for regions with extreme climates.

- Customization: Ensure they can accommodate specific color requests or unique designs.

Step 5: Request Samples

Request samples of the panels you are considering to evaluate their quality and aesthetic appeal. Testing samples will allow you to assess the material’s durability, color fidelity, and overall finish. This step is crucial for ensuring that the product meets your expectations before making a bulk order.

Step 6: Discuss Lead Times and Logistics

Engage in discussions regarding lead times for production and delivery. Understanding the supplier’s capacity to meet your timelines is vital, especially for projects with tight schedules. Additionally, clarify logistics arrangements, including shipping methods, costs, and any potential customs issues, particularly for international shipments.

Step 7: Negotiate Terms and Establish a Contract

Once you’ve selected a supplier, negotiate terms including pricing, payment schedules, and warranty conditions. A well-defined contract will protect both parties and outline responsibilities, ensuring clarity throughout the project. Make sure to include clauses for quality assurance and recourse in case of defects or delays.

By following these steps, B2B buyers can confidently navigate the procurement process for aluminium composite panels, ensuring they partner with reliable manufacturers that meet their project needs.

Comprehensive Cost and Pricing Analysis for Aluminium Composite Panel Manufacturers Sourcing

What Are the Key Cost Components in Sourcing Aluminium Composite Panels?

When sourcing aluminium composite panels (ACPs), understanding the cost structure is crucial for international B2B buyers. The primary components influencing the cost include:

-

Materials: The choice of materials, particularly the type of aluminium and core material (e.g., low-density polyethylene vs. mineral-filled), significantly impacts pricing. Premium materials that enhance fire resistance or provide better aesthetics typically come at a higher cost.

-

Labor: Labor costs vary by region and manufacturer. Countries with higher labor costs may reflect this in their pricing, while manufacturers in regions with lower wages can offer more competitive rates.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, thereby lowering the overall cost of the panels.

-

Tooling: Initial setup costs for specialized equipment or molds can be substantial, especially for custom designs. These costs are often amortized over large production runs, making them less significant per unit when ordering higher volumes.

-

Quality Control (QC): Rigorous QC measures ensure product reliability and adherence to international standards. Manufacturers that invest heavily in QC may charge more, but this investment can lead to long-term savings through reduced defects and returns.

-

Logistics: Transporting panels, especially internationally, can add significant costs. Factors such as distance, mode of transport, and shipping terms (Incoterms) will affect the final pricing.

-

Margin: Finally, the manufacturer’s profit margin will influence the price. This can vary widely based on the brand’s market position, reputation, and the perceived value of its products.

How Do Price Influencers Affect the Cost of Aluminium Composite Panels?

Several factors can influence the pricing of ACPs, making it essential for buyers to consider these when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically lead to better pricing. Manufacturers often have set MOQs, which can affect the cost per unit significantly.

-

Specifications and Customization: Custom finishes, thickness, and dimensions can increase costs. Standard products are usually cheaper than bespoke solutions.

-

Materials and Certifications: Panels with certifications (e.g., fire safety ratings) or made from higher-quality materials may command a premium. Buyers should assess the value of these certifications in their specific application.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record may charge more due to their proven quality and service.

-

Incoterms: Understanding shipping terms is vital for calculating total costs. Different Incoterms (e.g., FOB, CIF) can shift responsibility and costs from the seller to the buyer, affecting the overall price structure.

What Are Some Effective Tips for Negotiating Prices on ACPs?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, employing strategic negotiation tactics can lead to significant savings:

-

Understand Total Cost of Ownership (TCO): Consider not just the initial purchase price but also long-term costs such as maintenance, durability, and potential replacement. A higher upfront cost may lead to lower TCO if the panels last longer or require less upkeep.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ requirements. This can lead to better pricing and lower shipping costs.

-

Research Market Prices: Familiarize yourself with market rates for ACPs in your region. This knowledge can bolster your negotiation position.

-

Explore Alternative Suppliers: Don’t hesitate to compare multiple suppliers. Different manufacturers may offer varying prices and terms, allowing you to find the best deal that meets your needs.

-

Clarify Specifications: Ensure all specifications are clear before finalizing contracts. Misunderstandings can lead to unexpected costs down the line.

Conclusion and Disclaimer on Pricing

While the information provided gives a comprehensive overview of the cost and pricing structure for aluminium composite panels, it is essential to recognize that prices can fluctuate based on market conditions, supplier changes, and geographic factors. Therefore, buyers should treat any indicative prices as a starting point for negotiation and conduct thorough research tailored to their specific needs and locations.

Alternatives Analysis: Comparing Aluminium Composite Panel Manufacturers With Other Solutions

Understanding Alternatives in Aluminium Composite Panel Solutions

In the ever-evolving landscape of construction materials, aluminium composite panels (ACP) stand out for their versatility and aesthetic appeal. However, it’s essential for B2B buyers to consider alternative solutions that may meet their project requirements more effectively or economically. This analysis compares aluminium composite panels to two viable alternatives: High-Pressure Laminate (HPL) and Glass Reinforced Plastic (GRP), focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Aluminium Composite Panel Manufacturers | High-Pressure Laminate (HPL) | Glass Reinforced Plastic (GRP) |

|---|---|---|---|

| Performance | Excellent durability, fire resistance, and aesthetic variety | Good durability, moderate fire resistance | High durability and impact resistance |

| Cost | Moderate to high cost depending on customization | Generally lower cost than ACP | Higher initial cost, but low maintenance |

| Ease of Implementation | Requires specialized installation techniques | Easier to install with standard tools | Requires specific skills for installation |

| Maintenance | Low maintenance but requires periodic cleaning | Low maintenance, resistant to fading | Very low maintenance, high resistance to chemicals |

| Best Use Case | High-rise buildings, corporate offices, and retail facades | Interior walls, furniture, and exterior cladding | Industrial applications, marine environments, and architectural elements |

Detailed Breakdown of Alternatives

High-Pressure Laminate (HPL)

High-Pressure Laminate (HPL) is a composite material made from layers of paper and resin, subjected to high pressure and temperature. HPL is often used for interior applications, including wall coverings and furniture surfaces, but can also be applied externally.

Pros: HPL is typically more cost-effective than aluminium composite panels, making it an attractive option for budget-sensitive projects. It offers a wide variety of finishes and colors, and its installation is relatively straightforward, requiring standard tools.

Cons: While HPL possesses good durability, its fire resistance is moderate compared to ACP, which can be a crucial factor in high-rise or commercial buildings. Additionally, HPL is less suitable for high-stress environments due to potential surface damage.

Glass Reinforced Plastic (GRP)

Glass Reinforced Plastic (GRP) is a composite material that consists of a polymer matrix reinforced with glass fibers. GRP is known for its strength-to-weight ratio, making it a popular choice in various industrial applications.

Pros: GRP offers outstanding impact resistance and durability, making it suitable for environments subject to harsh conditions, such as marine or industrial settings. Its resistance to chemicals and corrosion is superior, ensuring longevity with minimal maintenance.

Cons: The initial cost of GRP can be higher than that of aluminium composite panels, which may deter some buyers. Moreover, the installation process requires specialized skills, which can increase labor costs and project timelines.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating materials for construction projects, B2B buyers should consider specific project requirements, including budget, environmental conditions, and aesthetic goals. Aluminium composite panels offer a blend of durability, fire resistance, and aesthetic variety, making them ideal for high-visibility applications. However, alternatives like HPL and GRP may provide better cost efficiency or performance in specialized scenarios. Conducting a thorough needs assessment and consulting with material experts can help buyers make informed decisions that align with their project objectives.

Essential Technical Properties and Trade Terminology for Aluminium Composite Panel Manufacturers

What Are the Key Technical Properties of Aluminium Composite Panels?

Aluminium Composite Panels (ACPs) are renowned for their versatility and aesthetic appeal in various architectural applications. Understanding their technical properties is essential for B2B buyers looking to make informed purchasing decisions. Here are critical specifications to consider:

-

Material Grade

The material grade of ACPs typically refers to the quality of the aluminum used in the panels. Common grades include 5005 and 3003, with 5005 offering better corrosion resistance and color retention. Selecting the appropriate material grade ensures durability and longevity, which is crucial for minimizing replacement and maintenance costs. -

Core Composition

The core of an ACP can significantly influence its performance. Common core materials include low-density polyethylene (LDPE) and fire-retardant (FR) materials. The choice of core impacts the panel’s fire resistance, insulation properties, and overall weight. For projects in regions with strict fire regulations, opting for FR cores is essential to comply with safety standards. -

Thickness and Tolerance

ACPs are available in various thicknesses, commonly ranging from 3mm to 6mm. Tolerance refers to the allowable deviation from specified dimensions. This specification is vital for ensuring that panels fit correctly during installation, reducing the risk of costly adjustments or structural issues. Buyers should assess project requirements to determine the ideal thickness and tolerance levels. -

Weather Resistance

Weather resistance encompasses the panel’s ability to withstand environmental factors, including UV exposure, moisture, and temperature fluctuations. Manufacturers often use coatings like Polyvinylidene Fluoride (PVDF) to enhance this property. Selecting weather-resistant panels is crucial for maintaining aesthetics and functionality over time, especially in regions with extreme climates. -

Fire Rating

Fire ratings are critical for compliance with local building codes and safety regulations. ACPs are classified under various fire ratings, such as A2 (non-combustible) or B1 (limited combustibility). Understanding these classifications is essential for projects where fire safety is a primary concern, as they dictate the appropriate applications for the panels. -

Impact Resistance

This property measures the panel’s ability to withstand physical impacts without sustaining damage. High-impact resistance is particularly important for applications in public spaces or industrial environments where panels may be exposed to heavy use or potential vandalism.

What Are Common Trade Terminologies Used in the Aluminium Composite Panel Industry?

Familiarity with industry jargon can streamline communication and negotiations between buyers and manufacturers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. In the ACP industry, OEMs might manufacture panels for construction firms that brand them as their own. Understanding OEM relationships can help buyers identify quality manufacturers and ensure product consistency. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory and budget effectively. It can also impact project timelines, especially if a buyer requires a specific quantity for a large-scale project. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. This process allows buyers to compare costs, terms, and specifications from multiple manufacturers. Crafting a clear and detailed RFQ can facilitate better responses and help in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and reduce risks associated with cross-border transactions. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. This timeframe can vary based on the manufacturer’s production capacity and the complexity of the order. Understanding lead times is essential for project planning and ensuring timely completion of construction schedules. -

Certification

Certification refers to the formal recognition that a product meets specific standards set by regulatory bodies. Common certifications for ACPs include ASTM, CE, and ISO. Buyers should prioritize certified products to ensure compliance with safety and quality standards, particularly in regulated markets.

By grasping these technical properties and trade terms, B2B buyers can navigate the aluminium composite panel market more effectively, ensuring they make informed decisions that align with their project requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the Aluminium Composite Panel Manufacturers Sector

What Are the Key Trends Driving the Aluminium Composite Panel Market?

The global aluminium composite panel (ACP) market is experiencing robust growth, driven by several factors, including urbanization, rising construction activities, and increasing demand for aesthetically pleasing building materials. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are witnessing a surge in infrastructure development, which is expected to continue in the coming years. This is especially evident in countries such as Saudi Arabia and Germany, where ambitious architectural projects are underway.

Emerging technologies are reshaping sourcing trends in the ACP sector. Digital platforms are facilitating easier access to suppliers and manufacturers, enabling buyers to compare products, prices, and certifications quickly. Innovations such as 3D modeling and virtual reality are enhancing design capabilities, allowing architects and builders to visualize the end product before procurement. Additionally, the industry is seeing a move towards customization, with manufacturers offering a wide range of finishes and colors to meet specific project requirements.

Moreover, sustainability is becoming a crucial consideration for international buyers. Increasing regulations on building materials and environmental impacts are prompting manufacturers to adopt eco-friendly practices and materials. As a result, companies that prioritize sustainable sourcing and production methods will likely gain a competitive edge in this evolving market landscape.

How Are Sustainability and Ethical Sourcing Shaping the Aluminium Composite Panel Sector?

Sustainability and ethical sourcing are no longer optional in the aluminium composite panel industry; they have become essential to corporate responsibility and consumer demand. The environmental impact of construction materials has garnered significant attention, pushing manufacturers to adopt practices that minimize waste and reduce carbon footprints. For instance, many companies are implementing recycling programs and utilizing recycled materials in their ACP products, contributing to a circular economy.

B2B buyers are increasingly seeking suppliers that can provide certifications demonstrating their commitment to sustainability. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO (International Organization for Standardization) standards are valuable indicators of a manufacturer’s environmental performance. These certifications not only enhance a company’s reputation but also align with the growing preference among consumers for products that are environmentally friendly.

Ethical supply chains are also gaining traction. Buyers are now more inclined to partner with manufacturers that ensure fair labor practices and transparency in their sourcing processes. This shift is particularly relevant in regions where supply chain integrity is under scrutiny. By choosing suppliers that prioritize ethical practices, businesses can bolster their brand image while contributing positively to global sustainability efforts.

How Has the Aluminium Composite Panel Industry Evolved Over Time?

The aluminium composite panel industry has undergone significant evolution since its inception in the mid-20th century. Initially, ACPs were primarily used in commercial buildings due to their lightweight nature and versatility. Over the years, advancements in technology have enhanced their aesthetic appeal, durability, and fire resistance, expanding their applications to residential buildings, signage, and interior design.

The introduction of various coatings and finishes has allowed for a broader range of colors and textures, catering to the diverse tastes of architects and builders. Furthermore, the rise of environmental awareness has led to a focus on sustainable materials and practices, prompting manufacturers to innovate continuously. Today, the industry is characterized by a commitment to quality, safety, and sustainability, reflecting the changing demands of the global market and the increasing expectations of B2B buyers.

In summary, understanding the market dynamics and sourcing trends in the aluminium composite panel sector is crucial for international buyers. Staying informed about sustainability practices and the evolution of materials will empower businesses to make strategic procurement decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of Aluminium Composite Panel Manufacturers

-

How do I choose the right aluminium composite panel supplier for my project?

Choosing the right aluminium composite panel (ACP) supplier involves evaluating several key factors. First, assess the supplier’s industry experience and reputation by reviewing customer testimonials and case studies. Next, consider the range of products offered, including finishes, colors, and customization options. Verify the supplier’s certifications and compliance with international standards, particularly for fire safety and environmental impact. Additionally, inquire about their logistics capabilities, lead times, and after-sales support to ensure they can meet your project’s specific needs effectively. -

What are the key specifications to look for in aluminium composite panels?

When sourcing aluminium composite panels, focus on specifications such as panel thickness, core material, and fire rating. Look for panels with a durable exterior finish, such as PVDF, which provides long-lasting color retention and UV resistance. Ensure the panels meet relevant international fire safety standards, such as ASTM E84 or NFPA 285, especially for high-rise buildings. Additionally, consider the panel’s weight and rigidity, as these factors influence installation ease and overall structural performance in your application. -

What customization options are available for aluminium composite panels?

Most aluminium composite panel manufacturers offer extensive customization options. These may include a variety of colors, textures, and finishes to match specific design requirements. Some suppliers provide the ability to create custom colors based on RAL, Pantone, or NCS standards, as well as the possibility to replicate a specific finish from a physical sample. Additionally, inquire about panel sizes, thicknesses, and the potential for bespoke branding solutions, ensuring that the final product aligns with your project’s vision. -

What are the typical minimum order quantities (MOQs) for aluminium composite panels?

Minimum order quantities (MOQs) for aluminium composite panels can vary significantly between manufacturers. Generally, MOQs may range from a few hundred to several thousand square meters, depending on the supplier’s production capabilities and the specific panel specifications. It’s essential to discuss your project requirements with potential suppliers to determine if they can accommodate smaller orders or if they have flexible options for bulk purchasing, especially if you are working on multiple projects simultaneously. -

What payment terms should I expect when ordering aluminium composite panels internationally?

Payment terms for international orders of aluminium composite panels typically include options such as upfront deposits, letters of credit, or payment upon delivery. Many suppliers may require a deposit of 30-50% before production begins, with the balance due upon shipment or receipt of goods. It’s crucial to clarify payment terms during negotiations to avoid any misunderstandings. Additionally, consider the impact of currency exchange rates and international transaction fees, which can affect overall project costs. -

How can I ensure quality assurance when sourcing aluminium composite panels?

To ensure quality assurance when sourcing aluminium composite panels, request detailed product specifications and certifications from the manufacturer. Look for suppliers who conduct rigorous internal testing and are compliant with international quality standards. Many reputable manufacturers provide environmental product declarations and have third-party audits. Additionally, consider requesting samples before placing a large order to assess the material’s quality firsthand, and inquire about their warranty policies for added peace of mind. -

What are the logistics considerations for importing aluminium composite panels?

When importing aluminium composite panels, logistics considerations include shipping methods, delivery times, and customs regulations. Determine the most cost-effective shipping options based on your location and project timeline. Collaborating with a logistics provider familiar with importing construction materials can help navigate customs procedures smoothly. Also, factor in storage solutions upon arrival, as well as the need for timely delivery to align with your construction schedule, ensuring minimal delays in project execution. -

What fire safety standards should aluminium composite panels meet for my region?

Fire safety standards for aluminium composite panels vary by region and are critical for compliance in construction projects. In Europe, panels should adhere to EN 13501-1 classification, while in the U.S., they must meet ASTM E84 and NFPA 285 standards. For markets in the Middle East and Africa, local building codes may also dictate specific requirements. Always consult with your supplier to confirm that their panels meet the necessary fire safety certifications relevant to your project location, ensuring compliance and safety.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Aluminium Composite Panel Manufacturers

In the evolving landscape of aluminium composite panel manufacturing, strategic sourcing has emerged as a crucial factor for international buyers seeking quality and innovation. The insights from leading manufacturers highlight the importance of selecting suppliers that prioritize sustainability, advanced technology, and diverse product offerings. Buyers should focus on manufacturers that provide not only high-quality panels but also value-added services such as custom finishes, efficient assembly systems, and robust technical support.

As the demand for sustainable construction materials rises, sourcing from manufacturers committed to environmentally friendly practices will not only enhance project credibility but also align with global sustainability goals. By leveraging certifications and rigorous quality control processes, businesses can mitigate risks and ensure compliance with international standards.

Looking ahead, international B2B buyers from regions like Africa, South America, the Middle East, and Europe should actively engage with manufacturers that embrace innovation and adaptability. Investing in strategic partnerships will position companies to capitalize on emerging trends and market opportunities in the aluminium composite panel sector. Seize the opportunity to elevate your projects by choosing suppliers that meet your specific needs and contribute to a sustainable future.