Top 7 Electrical Generator Manufacturers List and Guide: How To S…

Introduction: Navigating the Global Market for Electrical Generator Manufacturers

In an increasingly interconnected world, sourcing reliable electrical generators poses a significant challenge for international B2B buyers. With diverse power needs across industries, from data centers in Germany to agricultural operations in Nigeria, selecting the right generator can directly impact operational efficiency and business continuity. This comprehensive guide on electrical generator manufacturers is designed to simplify your purchasing journey by offering in-depth insights into various types of generators, their applications, and the factors that influence pricing.

We will explore essential topics such as supplier vetting processes, key features to consider when assessing generator performance, and the latest technologies driving innovation in the market. Additionally, we will provide actionable strategies for evaluating potential suppliers based on quality, reliability, and service support, ensuring you make informed decisions tailored to your regional needs, whether in Africa, South America, the Middle East, or Europe.

By leveraging this guide, B2B buyers will gain the knowledge necessary to navigate the complex landscape of electrical generator manufacturers. Ultimately, this resource empowers you to select the most suitable power solutions that align with your business goals, ensuring uninterrupted operations and a sustainable energy future.

Top 10 Electrical Generator Manufacturers Manufacturers & Suppliers List

1. Generac – Reliable Power Solutions

2. Cummins – Solutions

Domain: cummins.com

Registered: 1990 (35 years)

Introduction: Cummins offers a range of generator sets powered by diesel, natural gas, and alternative fuels, designed for efficiency, quality, reliability, and performance. Diesel generator sets range from 15 to 3,750 kVA, while natural gas generator sets range from 13 to 2,000 kW. All generator sets are capable of running on Hydrotreated Vegetable Oil (HVO). Cummins provides integrated power solutions for var…

3. Generator Brands – Custom Solutions

4. Caterpillar – Electric Power Solutions

5. Perkins – Electric Power Generation Solutions

Domain: perkins.com

Registered: 1998 (27 years)

Introduction: Electric Power Generation solutions from Perkins include a wide range of diesel engines designed for various applications. Key product series include: 400 Series, 904 Series, 1100 Series, 1200 Series, 1500 Series, 1700 Series, 2000 Series, 2200 Series, 2400 Series, 2500 Series, 2800 Series, 4000 Series, and 5000 Series. Perkins focuses on innovative solutions, sustainability, and the development o…

6. PGMA – Portable Generators

Domain: pgmaonline.com

Registered: 2009 (16 years)

Introduction: Portable generators are engine-driven power generators designed for multiple uses and portability, though not necessarily with wheels. They are intended for use in emergencies (e.g., power outages), recreation (e.g., campsites and outdoor events), and professional settings (e.g., worksite applications). PGMA defines portable generators as excluding trailer-mounted generators, generators in motor h…

7. Power Systems – Generators & Accessories

Domain: powersystems.rehlko.com

Registered: 2024 (1 years)

Introduction: Power Systems Engines, Diesel Generators, Gaseous Generators, Mobile Generators, Marine Generators, ATS (Automatic Transfer Switches), Accessories, Controllers, Parts & Services, Fluid Analysis Program, Training, Warranty & Services.

Understanding Electrical Generator Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diesel Generators | High fuel efficiency, robust construction, portable options | Construction, mining, emergency backup power | Pros: Reliable performance, lower fuel costs. Cons: Higher emissions compared to gas alternatives. |

| Natural Gas Generators | Cleaner emissions, lower operational costs | Commercial buildings, healthcare, data centers | Pros: Environmentally friendly, cost-effective. Cons: Limited availability in remote areas. |

| Bi-Fuel Generators | Operate on diesel and natural gas, flexible fuel options | Industrial applications, rental services | Pros: Versatile fuel use, reduced operational costs. Cons: Complexity in fuel switching. |

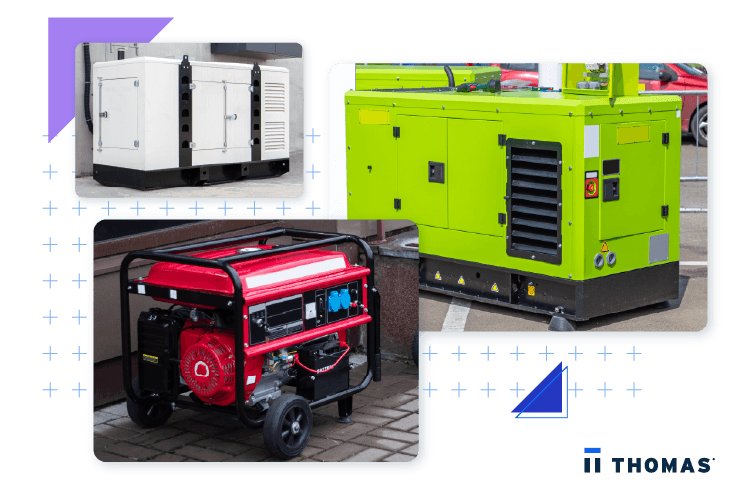

| Mobile Generators | Compact design, easy transport, quick deployment | Events, construction sites, temporary power needs | Pros: Portable, easy setup. Cons: Limited power capacity compared to stationary units. |

| Hybrid Generators | Combines traditional and renewable energy sources | Remote locations, green initiatives | Pros: Sustainable, reduced fuel dependency. Cons: Higher initial investment. |

What Are the Characteristics of Diesel Generators for B2B Use?

Diesel generators are renowned for their durability and efficiency, making them a staple in heavy-duty applications such as construction and mining. They are capable of delivering high power outputs, often ranging from 15 kVA to several thousand kVA, which suits large-scale operations. When considering a diesel generator, B2B buyers should evaluate factors such as fuel availability, emissions regulations, and the specific power needs of their applications.

How Do Natural Gas Generators Benefit Commercial Applications?

Natural gas generators are increasingly popular due to their cleaner emissions and lower operational costs. They are particularly suitable for commercial buildings, healthcare facilities, and data centers, where power reliability is critical. B2B buyers should assess the infrastructure for natural gas supply and the potential for long-term savings, as these generators often have lower maintenance costs compared to diesel counterparts.

What Are the Advantages of Bi-Fuel Generators for Industrial Applications?

Bi-fuel generators offer flexibility by utilizing both diesel and natural gas, allowing for operational adaptability. They are ideal for industrial applications where power demands fluctuate, such as in rental services or large manufacturing facilities. Buyers should consider the complexity of managing dual fuel systems and the potential for fuel cost savings, as well as the environmental benefits of cleaner emissions.

Why Choose Mobile Generators for Temporary Power Needs?

Mobile generators are designed for portability and rapid deployment, making them essential for events, construction sites, and emergency situations. Their compact design allows for easy transport, but they typically have lower power capacities than stationary generators. B2B buyers should evaluate the specific power requirements of their temporary applications and the trade-offs between mobility and output capacity.

What Makes Hybrid Generators a Sustainable Choice?

Hybrid generators combine traditional fuel sources with renewable energy, catering to businesses focused on sustainability. They are particularly effective in remote locations where fuel supply is limited, and they help reduce dependency on fossil fuels. However, the initial investment can be higher. B2B buyers should analyze the long-term benefits of reduced fuel costs and environmental impact against the upfront costs associated with hybrid systems.

Key Industrial Applications of Electrical Generator Manufacturers

| Industry/Sector | Specific Application of Electrical Generator Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Data Centers | Continuous power supply during outages and peak demand | Ensures uptime, protects sensitive data, and maintains service reliability | Capacity to meet load requirements, fuel efficiency, and service support availability |

| Healthcare | Emergency power for critical medical equipment | Guarantees patient safety and operational continuity in emergencies | Compliance with health regulations, reliability, and maintenance services |

| Telecommunications | Backup power for cell towers and network infrastructure | Prevents service interruptions and revenue loss during outages | Robustness against environmental conditions, capacity to support multiple sites |

| Construction | Portable power for tools and machinery on-site | Enhances productivity and ensures work continuity in remote areas | Mobility, fuel type flexibility, and ease of transport and setup |

| Agriculture | Power for irrigation systems and processing facilities | Supports crop production and operational efficiency | Adaptability to various fuel sources, reliability under diverse conditions |

How Are Electrical Generators Used in Data Centers?

In data centers, electrical generators are critical for providing continuous power supply during outages or peak demand periods. These facilities house sensitive equipment that must remain operational at all times to protect valuable data. Buyers from regions like Africa and Europe should prioritize generators that offer high capacity, fuel efficiency, and robust service support to ensure uptime and prevent costly disruptions. Additionally, generators must comply with local emissions standards to avoid regulatory issues.

What Role Do Electrical Generators Play in Healthcare?

Healthcare facilities rely heavily on electrical generators to maintain power for critical medical equipment during emergencies. These generators must be highly reliable, as they ensure patient safety and operational continuity. International buyers, particularly from the Middle East and South America, should consider generators that meet stringent health regulations and offer comprehensive maintenance services. The ability to provide seamless power transitions is also vital for these applications.

How Are Electrical Generators Essential for Telecommunications?

In the telecommunications sector, electrical generators provide backup power for cell towers and network infrastructure, preventing service interruptions that could lead to significant revenue loss. The generators must be robust enough to withstand harsh environmental conditions, particularly in remote locations. Buyers should evaluate the generator’s capacity to support multiple sites and its adaptability to various fuel sources, ensuring reliability and operational efficiency.

Why Are Electrical Generators Important in Construction?

For construction projects, portable generators are essential for powering tools and machinery on-site, especially in remote areas where grid power may be unavailable. These generators enhance productivity by ensuring work continuity, even in adverse conditions. Buyers should look for mobility, fuel type flexibility, and ease of transport and setup when sourcing generators for construction applications, particularly in developing regions where infrastructure may be limited.

What Benefits Do Electrical Generators Offer in Agriculture?

In agriculture, electrical generators are used to power irrigation systems and processing facilities, supporting crop production and operational efficiency. The reliability of these generators is crucial, as any downtime can directly impact harvests and profitability. Buyers should consider generators that can adapt to various fuel sources and operate reliably under diverse environmental conditions, ensuring that agricultural operations can continue uninterrupted.

3 Common User Pain Points for ‘Electrical Generator Manufacturers’ & Their Solutions

Scenario 1: Navigating Complex Power Requirements for Diverse Applications

The Problem: B2B buyers often face significant challenges when it comes to determining the appropriate generator size and type for their specific operational needs. This complexity can stem from diverse applications, such as powering data centers, healthcare facilities, or industrial operations, each with unique power demands. Misjudging these requirements can lead to costly downtime, inefficient operations, or even safety risks. Moreover, understanding the compatibility of generators with existing systems and future scalability can be overwhelming, especially in regions with varying power supply conditions.

The Solution: To effectively navigate these complexities, B2B buyers should leverage advanced generator sizing tools and consult with experienced electrical generator manufacturers. Tools like Cummins’ GenSize™ or Power Suite™ provide tailored recommendations based on specific project requirements. Buyers should engage in detailed discussions with manufacturers to outline their operational needs, including peak load expectations, backup power requirements, and fuel preferences. Additionally, conducting a thorough site assessment to understand local power conditions will help in selecting a generator that meets both current and future needs. By taking these proactive steps, buyers can ensure they invest in a generator that optimally supports their business operations.

Scenario 2: Overcoming Maintenance and Reliability Concerns

The Problem: Reliability is a paramount concern for B2B buyers, particularly in sectors where power outages can result in significant financial losses or safety hazards. However, many manufacturers may not provide adequate support or information regarding the maintenance and longevity of their generators. This lack of clarity can leave buyers feeling uncertain about the reliability of their investment, leading to anxiety about potential equipment failures and the associated costs of downtime and repairs.

The Solution: To mitigate these concerns, B2B buyers should prioritize manufacturers that offer comprehensive maintenance plans and transparent service agreements. It’s essential to ask potential suppliers about their after-sales support, including availability of spare parts, service schedules, and warranty conditions. Buyers should also look for manufacturers that provide training for in-house maintenance teams, which can empower them to conduct routine checks and minor repairs. Establishing a robust relationship with the manufacturer can ensure that support is readily available when needed, ultimately enhancing the generator’s reliability and extending its operational lifespan.

Scenario 3: Addressing Sustainability and Compliance Challenges

The Problem: As global regulations on emissions become more stringent, B2B buyers in sectors like healthcare and telecommunications are increasingly pressured to adopt sustainable power solutions. However, many traditional generator options may not comply with these regulations, creating a dilemma for buyers who wish to balance operational efficiency with environmental responsibility. This challenge is particularly pronounced in developing regions where alternative fuel sources may not be readily available, complicating the transition to greener technologies.

The Solution: Buyers should seek out manufacturers that offer a range of fuel options, including natural gas, biodiesel, and renewable energy solutions, such as Hydrotreated Vegetable Oil (HVO). Engaging with suppliers who are committed to sustainability can provide access to innovative technologies that align with regulatory requirements and corporate social responsibility goals. Additionally, buyers can consider investing in hybrid systems that integrate renewable energy sources with traditional generators, ensuring a reliable power supply while minimizing environmental impact. Conducting a lifecycle analysis of potential generator options will also help buyers understand the long-term benefits of choosing sustainable solutions, ultimately leading to more informed purchasing decisions.

Strategic Material Selection Guide for Electrical Generator Manufacturers

What Materials Are Commonly Used in Electrical Generators and Their Key Properties?

Electrical generator manufacturers often rely on a variety of materials to ensure optimal performance, durability, and compliance with international standards. Understanding the properties, pros and cons, and specific considerations for these materials is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Steel Contribute to Generator Performance?

Steel is a primary material used in the construction of generator frames, enclosures, and components. Its key properties include high tensile strength, excellent durability, and good resistance to deformation under stress. Steel can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros: Steel is relatively cost-effective and widely available, which simplifies sourcing for manufacturers. Its robustness translates to long-lasting products, which is a significant advantage in harsh operating environments.

Cons: Steel is prone to corrosion if not properly treated or coated, which can lead to reduced lifespan in humid or coastal regions. Additionally, manufacturing processes involving steel can be complex, requiring specialized equipment for cutting and welding.

Impact on Application: Steel is compatible with various media, including fuel and lubricants, but its corrosion susceptibility necessitates careful consideration in environments with high moisture or chemical exposure.

What Role Does Aluminum Play in Generator Design?

Aluminum is often used for components such as housings and heat exchangers due to its lightweight nature and excellent thermal conductivity. Its key properties include corrosion resistance and a good strength-to-weight ratio, making it ideal for portable and mobile generators.

Pros: The lightweight characteristic of aluminum aids in reducing overall generator weight, enhancing mobility. Additionally, aluminum’s natural resistance to corrosion extends the life of components exposed to the elements.

Cons: While aluminum is generally less expensive than high-grade steel, it can be more costly than standard steel in some markets. Its lower strength compared to steel may limit its use in high-stress applications.

Impact on Application: Aluminum is well-suited for applications requiring thermal management, such as cooling systems, but may not be appropriate for high-pressure environments without reinforcement.

How Does Copper Enhance Electrical Efficiency in Generators?

Copper is extensively used in electrical windings and connections due to its excellent electrical conductivity. The key properties of copper include high thermal and electrical conductivity, as well as good corrosion resistance.

Pros: The superior conductivity of copper leads to improved efficiency and lower energy losses in generators, which is critical for performance. Its resistance to corrosion ensures reliable long-term operation.

Cons: Copper is relatively expensive compared to other conductive materials, which can increase the overall cost of generator manufacturing. Additionally, copper components can be heavier, potentially impacting the design of portable generators.

Impact on Application: Copper is essential for applications involving electrical transmission and is compatible with various insulation materials, but its cost may be a consideration for budget-sensitive projects.

What Benefits Does Plastic Offer for Generator Components?

Plastics are increasingly being used for non-structural components such as covers, insulators, and fuel tanks. Key properties of plastics include lightweight, corrosion resistance, and flexibility.

Pros: The use of plastics can significantly reduce the weight of generators, making them easier to transport and install. Plastics are also resistant to many chemicals, which adds to their versatility in various environments.

Cons: Plastics may not withstand high temperatures or mechanical stress as effectively as metals, which can limit their use in high-performance applications. Additionally, the long-term durability of plastics can vary based on the specific type used.

Impact on Application: Plastics are suitable for applications where weight reduction is critical, but their thermal and mechanical limitations must be considered in high-stress scenarios.

Summary of Material Selection for Electrical Generators

| Material | Typical Use Case for Electrical Generator Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frames, enclosures, structural components | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Housings, heat exchangers, portable units | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Copper | Electrical windings and connections | Excellent electrical conductivity | Higher cost and weight compared to alternatives | High |

| Plastic | Covers, insulators, fuel tanks | Lightweight and chemical resistant | Limited thermal and mechanical performance | Low |

This guide provides essential insights into the strategic selection of materials for electrical generator manufacturing, helping B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Electrical Generator Manufacturers

What Are the Key Stages in the Manufacturing Process for Electrical Generators?

The manufacturing of electrical generators involves several meticulous stages that ensure the final product meets performance standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Electrical Generators?

Material preparation begins with sourcing high-quality raw materials, such as steel for frames and copper for windings. Suppliers should be vetted for compliance with international standards to ensure material integrity. Once sourced, materials undergo rigorous inspection to check for defects or inconsistencies. This step is crucial, as the performance and longevity of the generator depend heavily on the quality of materials used.

What Techniques Are Used in the Forming Process?

Forming techniques vary based on the components being produced. Common methods include stamping, machining, and welding. For instance, stamping is often used to create sheet metal components, while machining is crucial for precision parts like engine blocks. Advanced technologies like CNC (Computer Numerical Control) machining can enhance accuracy and reduce waste, leading to cost savings in mass production.

How Does the Assembly Process Work for Electrical Generators?

The assembly process is where all individual components come together to form a complete generator. This stage typically involves several sub-assemblies, including the engine, alternator, and control systems. Skilled technicians follow detailed assembly instructions, often utilizing automated systems to enhance precision. A critical aspect of this stage is to ensure that all components are compatible and function harmoniously, which is vital for the generator’s efficiency and reliability.

What Finishing Techniques Are Applied to Electrical Generators?

Finishing techniques are applied to enhance durability and aesthetics. Common practices include surface treatment to prevent corrosion, painting for visual appeal, and applying protective coatings. Each finishing technique must be tailored to the specific environmental conditions in which the generator will operate, especially for regions with harsh climates, like Africa and the Middle East.

What Quality Assurance Standards Should Electrical Generator Manufacturers Follow?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product adheres to both international and industry-specific standards. One of the most recognized standards is ISO 9001, which outlines criteria for a quality management system (QMS). Adhering to ISO 9001 helps manufacturers improve efficiency and customer satisfaction.

In addition to ISO standards, many electrical generator manufacturers comply with certifications such as CE marking for products sold in Europe and API (American Petroleum Institute) standards for oil and gas applications. These certifications indicate that the products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Generator Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. The aim is to confirm that materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring is essential. IPQC involves regular inspections and testing of components as they are formed and assembled, ensuring any defects are identified and rectified promptly.

-

Final Quality Control (FQC): Once assembly is complete, FQC involves comprehensive testing of the finished product. This may include performance testing under various loads, noise level assessments, and safety inspections to verify compliance with relevant standards.

What Testing Methods Are Commonly Used for Electrical Generators?

Various testing methods are employed to ensure the quality and reliability of electrical generators:

-

Load Testing: This simulates real-world conditions by applying load to the generator and monitoring its performance over time. It helps identify any potential issues before the generator is deployed.

-

Vibration Analysis: This technique detects mechanical issues by monitoring vibrations during operation, helping to predict failures before they occur.

-

Thermal Imaging: Used to identify overheating components, thermal imaging can reveal problems that are not visible to the naked eye.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in international markets, verifying a supplier’s QC practices is crucial. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards. This involves reviewing their manufacturing processes, quality control measures, and compliance with certifications.

-

Request Quality Reports: Suppliers should provide documentation of their QC processes and results from testing. This transparency is vital for building trust and ensuring product reliability.

-

Engage Third-Party Inspectors: Employing independent inspectors can provide an unbiased evaluation of the supplier’s quality practices. This is particularly important when dealing with overseas suppliers where language and cultural barriers may complicate direct communication.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

-

Regulatory Compliance: Different regions may have specific regulations regarding electrical equipment. Buyers must ensure that suppliers meet these regional standards to avoid legal issues and ensure product safety.

-

Cultural Differences in Quality Expectations: Quality perceptions may vary across cultures. It is essential for buyers to communicate their expectations clearly and understand the local manufacturing practices of their suppliers.

-

Logistical Challenges: International shipping can impact product quality. B2B buyers should consider the logistics involved in transporting electrical generators and ensure that suppliers have robust packaging and handling processes to minimize damage.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing electrical generators, ensuring they select suppliers who meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Electrical Generator Manufacturers’

In the competitive landscape of electrical generator procurement, making informed decisions is crucial for B2B buyers. This guide provides a comprehensive checklist designed to streamline the sourcing process for electrical generator manufacturers, ensuring you select the best options to meet your operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, it’s essential to articulate your specific requirements. Consider factors such as power output (kVA or kW), fuel type (diesel, natural gas, or alternative fuels), and any regulatory compliance needs relevant to your region. Clear specifications will help you narrow down potential suppliers who can meet your precise demands.

Step 2: Research and Identify Reputable Manufacturers

Take time to compile a list of established electrical generator manufacturers. Look for companies with a proven track record in your industry, favorable customer reviews, and certifications that align with international standards. Resources like industry reports, trade publications, and online reviews can provide insights into the reliability and reputation of these manufacturers.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. A solid supplier should be able to provide evidence of past successful projects and satisfied customers, which can give you confidence in their capabilities.

Step 4: Verify Supplier Certifications

Ensure that the manufacturers you are considering possess the necessary certifications and standards compliance. Look for ISO certifications, emissions certifications, and other relevant accreditations that demonstrate their commitment to quality and environmental responsibility. This step is crucial, especially if your operations are subject to regulatory scrutiny.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that outline pricing, lead times, warranty terms, and after-sales support. Compare these quotations carefully, taking note of any hidden costs or conditions that may affect the total cost of ownership. This step will help you identify the most cost-effective solutions while ensuring quality.

Step 6: Assess After-Sales Support and Maintenance Services

Inquire about the after-sales support and maintenance services offered by the manufacturers. A reliable supplier should provide comprehensive service packages that include installation, routine maintenance, and emergency support. Understanding the level of support available will ensure your generators operate efficiently and minimize downtime.

Step 7: Conduct a Site Visit if Possible

If feasible, conduct a site visit to the manufacturer’s facility. This will give you the opportunity to assess their production processes, quality control measures, and overall operational capabilities. A site visit can also strengthen your relationship with the supplier and provide valuable insights that may not be evident through virtual communication.

By following this checklist, B2B buyers can enhance their sourcing strategy for electrical generators, ensuring they choose a manufacturer that aligns with their technical requirements and business goals.

Comprehensive Cost and Pricing Analysis for Electrical Generator Manufacturers Sourcing

Understanding the cost structure and pricing dynamics of electrical generator manufacturers is crucial for international B2B buyers looking to make informed sourcing decisions. This analysis delves into the various cost components and price influencers that affect generator pricing, along with practical tips for buyers to enhance negotiation and procurement strategies.

What Are the Key Cost Components for Electrical Generators?

When evaluating the pricing of electrical generators, several cost components come into play:

-

Materials: The choice of materials significantly impacts the cost. High-quality components, such as robust engines and durable alternators, are essential for reliability but can increase the price. The trend towards sustainable materials, such as those compatible with renewable fuel sources, is also influencing costs.

-

Labor: Labor costs can vary widely depending on the manufacturer’s location and the complexity of the generator design. Regions with higher labor costs may lead to increased pricing, while manufacturers in countries with lower wages might offer more competitive rates.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize overhead, impacting the final pricing.

-

Tooling: Custom generators often require specialized tooling, which can be a significant upfront investment. This cost is usually amortized over the production volume, affecting per-unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure that generators meet industry standards. While this adds to the cost, it ultimately enhances product reliability and reduces the risk of failures.

-

Logistics: Transportation and handling costs must be factored in, especially for international shipments. Incoterms will dictate who bears these costs, influencing the overall pricing structure.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and the perceived value of the generator.

How Do Price Influencers Affect Electrical Generator Costs?

Several factors can influence the pricing of electrical generators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing due to economies of scale. Buyers should aim for volume commitments to negotiate better rates.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should weigh the necessity of custom features against standard options that may offer better value.

-

Materials and Quality Certifications: Generators that comply with international quality standards (e.g., ISO certifications) may carry a premium. However, investing in certified products can reduce long-term operational risks.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established brands may command higher prices due to perceived quality, while lesser-known manufacturers may offer more competitive rates.

-

Incoterms: Understanding Incoterms is crucial for cost management in international transactions. These terms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, which can significantly affect total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Generator Sourcing?

-

Negotiate Effectively: Leverage volume orders and long-term contracts to negotiate better pricing and terms. Establishing a relationship with suppliers can also provide insights into potential discounts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, maintenance, and potential downtime when assessing generator options. A lower upfront cost may lead to higher TCO if the generator is less reliable.

-

Understand Pricing Nuances in Different Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import tariffs that could affect pricing.

-

Request Detailed Quotes: When sourcing, request comprehensive quotes that break down costs. This transparency will help identify areas for negotiation and assess the competitiveness of the offer.

Disclaimer on Indicative Prices

Prices for electrical generators can vary significantly based on specifications, supplier, and market conditions. This analysis provides general insights and should not be interpreted as definitive pricing. Buyers are encouraged to obtain detailed quotations from multiple suppliers to ensure accurate comparisons.

Alternatives Analysis: Comparing Electrical Generator Manufacturers With Other Solutions

Understanding Alternatives to Electrical Generator Manufacturers

In the quest for reliable power solutions, B2B buyers must consider various options beyond traditional electrical generator manufacturers. While generators are a popular choice for ensuring continuous power supply, alternative solutions can also effectively meet energy needs. This section compares electrical generator manufacturers with two viable alternatives: solar power systems and battery storage solutions.

| Comparison Aspect | Electrical Generator Manufacturers | Solar Power Systems | Battery Storage Solutions |

|---|---|---|---|

| Performance | High output, consistent power | Variable based on sunlight | Provides power during outages |

| Cost | High initial investment, ongoing fuel costs | Moderate initial investment, low operating costs | High initial investment, cost-effective over time |

| Ease of Implementation | Requires professional setup and maintenance | Moderate setup complexity, needs space for panels | Simple installation, compact designs |

| Maintenance | Regular maintenance required | Low maintenance, occasional cleaning | Minimal maintenance, battery replacement needed |

| Best Use Case | Industrial applications, emergency power | Remote locations, off-grid living | Backup power for homes and businesses |

What Are the Pros and Cons of Solar Power Systems?

Solar power systems harness sunlight to generate electricity, making them an increasingly popular alternative to traditional generators. One of the main advantages of solar systems is their low operating costs once installed, as they rely on a renewable energy source. They are particularly beneficial in regions with abundant sunlight, which enhances their performance. However, their effectiveness can be inconsistent due to weather variations and nighttime limitations, requiring supplementary systems or storage solutions to provide reliable power during these times.

How Do Battery Storage Solutions Work?

Battery storage solutions offer a modern approach to energy management by storing electricity for use during peak demand or outages. These systems are compact and can be easily integrated into existing power setups, making them user-friendly for both residential and commercial applications. Their main advantage is the ability to provide immediate backup power, ensuring continuity during blackouts. However, the initial investment can be substantial, and batteries have a finite lifespan, necessitating eventual replacement.

Conclusion: How Should B2B Buyers Choose the Right Power Solution?

When selecting the ideal power solution, B2B buyers must assess their specific operational needs, budget constraints, and environmental considerations. Electrical generators remain a robust option for industries requiring high output and reliability. In contrast, solar power systems offer a sustainable and cost-effective alternative for businesses looking to reduce energy costs and carbon footprints. Meanwhile, battery storage solutions provide a modern backup option, ensuring power availability during outages. By evaluating these alternatives against their unique requirements, buyers can make informed decisions that align with their operational goals and sustainability objectives.

Essential Technical Properties and Trade Terminology for Electrical Generator Manufacturers

What Are the Key Technical Properties of Electrical Generators?

Understanding the technical specifications of electrical generators is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential technical properties to consider:

-

Power Output (kW or kVA)

Power output is a critical specification that indicates the generator’s capacity to supply electrical power. Measured in kilowatts (kW) or kilovolt-amperes (kVA), this metric determines how many devices or systems the generator can support simultaneously. For instance, a generator rated at 100 kW can power equipment requiring 100 kW of electrical load. Buyers must assess their power requirements to select a generator that meets their operational needs. -

Fuel Type and Efficiency

The type of fuel a generator uses—diesel, natural gas, or alternative fuels like hydrotreated vegetable oil (HVO)—affects its efficiency and operational cost. Diesel generators are known for their durability and high power output, while natural gas generators are often favored for their lower emissions and cleaner operation. Understanding fuel efficiency (measured in liters or gallons per hour) helps buyers calculate long-term operational costs and environmental impact. -

Noise Level (dB)

Noise level is a significant consideration, especially in urban or residential areas. Measured in decibels (dB), this specification informs buyers about the generator’s operational sound. Generators with lower dB ratings are often essential for businesses that operate in noise-sensitive environments, such as hospitals or schools. Selecting a quieter generator can enhance community relations and comply with local regulations. -

Durability and Material Grade

The materials used in the generator’s construction, such as steel or aluminum, dictate its durability and lifespan. High-grade materials can withstand harsh environmental conditions, reducing maintenance costs and increasing reliability. Buyers should inquire about the material specifications to ensure that the generator can perform under their specific operational conditions. -

Control Systems and Automation

Modern generators come equipped with advanced control systems that facilitate automation, remote monitoring, and diagnostics. These systems allow operators to manage power output, monitor fuel consumption, and perform self-diagnostics. Understanding the capabilities of these control systems can help buyers choose generators that enhance operational efficiency and reduce downtime.

What Are Common Trade Terms Used in the Electrical Generator Industry?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some key terms B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company under its brand name. In the generator industry, OEMs are critical for ensuring quality and compatibility of components. Buyers often seek OEM products to guarantee reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory costs and assess whether a supplier can meet their purchasing needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotations from suppliers for specific products or services. This term is crucial in the procurement process, as it allows buyers to compare prices, terms, and specifications from multiple vendors to make cost-effective decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers navigate shipping costs, risks, and delivery responsibilities when sourcing generators from global manufacturers. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the generator industry, knowing the lead time is crucial for project planning and ensuring that operations are not disrupted due to delayed equipment availability.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and make more informed decisions when sourcing electrical generators.

Navigating Market Dynamics and Sourcing Trends in the Electrical Generator Manufacturers Sector

What Are the Key Market Dynamics and Trends in Electrical Generator Manufacturing?

The electrical generator manufacturing sector is experiencing significant transformations driven by global demand for reliable power solutions, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key drivers include rapid urbanization, industrial expansion, and the growing reliance on data centers and renewable energy sources. As businesses in these regions look to secure energy independence and reliability, the trend toward integrated power solutions that combine generators with renewable energy technologies is gaining traction.

Emerging technologies, such as IoT and AI, are revolutionizing the sourcing strategies within this sector. For instance, manufacturers are increasingly adopting smart monitoring systems that allow for predictive maintenance, optimizing performance and reducing downtime. Moreover, there is a notable shift toward flexible fuel options, with many companies now offering generators that can run on a variety of fuels, including diesel, natural gas, and biofuels. This flexibility is crucial for buyers in regions where fuel availability can be inconsistent.

In terms of market dynamics, international B2B buyers must navigate a landscape influenced by fluctuating fuel prices, regulatory changes related to emissions, and the need for compliance with international standards. As a result, buyers are encouraged to establish relationships with manufacturers that not only deliver high-quality products but also demonstrate an understanding of local market conditions and regulatory frameworks.

How Is Sustainability Shaping the Sourcing of Electrical Generators?

Sustainability is no longer a peripheral consideration but a core aspect of sourcing in the electrical generator sector. The environmental impact of generator operations, particularly in terms of emissions and fuel consumption, is prompting manufacturers to innovate and offer greener solutions. Many companies are now developing generators that can operate on renewable fuels, such as Hydrotreated Vegetable Oil (HVO) and natural gas, which contribute to lower carbon footprints.

Moreover, ethical sourcing has become paramount for B2B buyers. The supply chain’s transparency is critical; buyers are increasingly demanding that manufacturers adhere to ethical labor practices and sustainable sourcing of materials. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming essential for manufacturers aiming to appeal to environmentally conscious buyers.

Investing in generators that come with sustainability certifications not only enhances a company’s brand reputation but also aligns with global initiatives aimed at reducing greenhouse gas emissions. For buyers in regions with stringent environmental regulations, sourcing from manufacturers committed to sustainability can also mitigate compliance risks.

What Is the Historical Context of Electrical Generator Manufacturing?

The electrical generator manufacturing sector has evolved significantly since its inception in the late 19th century. Initially, generators were primarily used for lighting and basic power needs, but advancements in technology have transformed them into sophisticated systems capable of meeting diverse energy demands. The introduction of diesel and gas-powered generators in the mid-20th century marked a pivotal moment, allowing for greater efficiency and reliability.

As industries grew and urbanization accelerated, the demand for more robust power solutions emerged. The late 20th and early 21st centuries saw a shift towards portable and mobile generators, catering to the needs of construction, telecommunications, and emergency services. Today, the focus has shifted towards integrating renewable energy sources and developing smart technologies, positioning the electrical generator manufacturing sector at the forefront of the global energy transition. This historical evolution underscores the importance of understanding market dynamics and sourcing trends for B2B buyers seeking to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of Electrical Generator Manufacturers

-

How do I choose the right electrical generator for my business needs?

Selecting the appropriate electrical generator involves assessing your power requirements, including voltage, wattage, and type of load (continuous vs. standby). Consider the operational environment, fuel availability (diesel, natural gas, or renewable options), and compliance with local emissions regulations. Utilize tools provided by manufacturers, such as sizing calculators, to ensure you select a generator that meets your specific power demands. Additionally, consult with experts or conduct a site assessment to understand any unique challenges your location may present. -

What is the best type of fuel for industrial generators?

The best type of fuel for industrial generators largely depends on your operational requirements and local availability. Diesel generators are known for their reliability and efficiency, making them ideal for heavy-duty applications. Natural gas generators offer cleaner emissions and are often more cost-effective in urban areas. Renewable fuels, such as Hydrotreated Vegetable Oil (HVO), are gaining popularity for their sustainability benefits. Evaluate the cost, availability, and environmental impact of each fuel type before making a decision. -

What are the typical minimum order quantities (MOQs) when purchasing generators?

Minimum order quantities can vary significantly among manufacturers and are influenced by the type of generator, customization options, and market demand. For standard models, MOQs may range from 1 to 10 units, while custom solutions may require larger orders to justify production costs. It’s advisable to communicate directly with manufacturers to negotiate MOQs that align with your business needs, especially if you’re a smaller buyer or looking for a trial order. -

How can I vet suppliers for electrical generators?

When vetting suppliers, consider their industry reputation, years of experience, and client testimonials. Request references from previous customers and conduct background checks on their financial stability and compliance with international standards. It’s also beneficial to assess their after-sales support, including warranty policies and service availability. Visiting manufacturing facilities or engaging in trade shows can provide firsthand insight into their operations and product quality. -

What payment terms should I expect when sourcing generators internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some manufacturers may offer credit terms for established businesses. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment, especially in international transactions. Always clarify payment terms in your contract to avoid misunderstandings. -

What quality assurance measures should I look for in generator manufacturers?

Quality assurance is critical when sourcing electrical generators. Look for manufacturers with ISO certifications and adherence to international standards such as ISO 9001, which demonstrates a commitment to quality management systems. Inquire about their testing procedures, including load testing and performance evaluations. Additionally, ask about warranty terms and the availability of spare parts to ensure long-term reliability and support for the generators you purchase. -

How do logistics and shipping impact the purchase of electrical generators?

Logistics and shipping are crucial factors in sourcing electrical generators, especially for international transactions. Consider the shipping methods available, such as sea or air freight, and their respective costs and delivery times. Understand import regulations in your country, including duties and taxes that may apply. Collaborate with your supplier to coordinate shipping schedules and ensure that the generators are packaged appropriately to prevent damage during transit. -

Can I customize generators to meet specific operational requirements?

Yes, many manufacturers offer customization options to meet specific operational needs. This can include modifications in size, power output, fuel type, and control systems. Discuss your requirements with the manufacturer early in the sourcing process to understand the feasibility and associated costs. Custom solutions may involve longer lead times, so plan accordingly to ensure that your operational timelines are met. Always request detailed specifications and documentation for any customized equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Electrical Generator Manufacturers

As the global demand for reliable and efficient power solutions continues to rise, strategic sourcing for electrical generators has never been more critical. By prioritizing quality, efficiency, and sustainability, businesses can ensure they are equipped to meet their operational needs while adhering to environmental standards. Key considerations include selecting manufacturers with a robust support network, such as Cummins and Caterpillar, known for their advanced technology and comprehensive service offerings.

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, should leverage these insights to make informed purchasing decisions. Collaborating with reputable manufacturers not only guarantees superior products but also enhances long-term operational resilience.

Looking ahead, the evolution of energy sources—especially the integration of renewable options—will shape the future landscape of electrical generators. It is essential for buyers to stay abreast of these trends and consider how innovative power solutions can drive efficiency and sustainability in their operations. Embrace strategic sourcing today to empower your business for tomorrow’s challenges.