Top 7 Fiber Optic Cable Manufacturers List and Guide: How To Solv…

Introduction: Navigating the Global Market for Fiber Optic Cable Manufacturers

Navigating the global market for fiber optic cable manufacturers presents a significant challenge for B2B buyers seeking reliable and high-quality solutions. As businesses across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia, increasingly rely on advanced communication networks, the demand for top-notch fiber optic cables has surged. This guide is designed to empower international buyers by providing a comprehensive overview of the diverse types of fiber optic cables available, their specific applications, and insights into supplier vetting and pricing strategies.

Within this guide, you will find detailed information on outdoor, indoor, and indoor/outdoor cable types, enabling you to make informed decisions tailored to your operational environment. We delve into the latest innovations in fiber optic technology, including high-density ribbon cables and microduct solutions, which are essential for meeting the growing bandwidth demands of modern networks. Additionally, we outline best practices for evaluating suppliers, ensuring that you partner with manufacturers who adhere to rigorous quality standards and offer competitive pricing.

By equipping you with the knowledge necessary to navigate the complexities of the fiber optic market, this guide aims to facilitate strategic purchasing decisions that align with your business goals. As you explore the wealth of information provided, you will be better positioned to enhance your network infrastructure and drive your organization’s success in an increasingly connected world.

Top 10 Fiber Optic Cable Manufacturers Manufacturers & Suppliers List

1. Corning – Fiber Optic Cables

Domain: corning.com

Registered: 1991 (34 years)

Introduction: Corning offers a variety of fiber optic cables designed for different environments and applications, including: Outdoor Cables (Aerial, Duct, Direct Buried, Microduct), Indoor/Outdoor Cables (Aerial, Duct, Direct Buried, Low Smoke Zero Halogen, Plenum, Riser), and Indoor Cables (LSZH, Plenum, Riser). Key product lines include ALTOS® Loose Tube Cables, MiniXtend® Micro Cables, RocketRibbon® Cables,…

2. Corning – Fiber Optic Cable

Domain: gcabling.com

Registered: 2021 (4 years)

Introduction: 1. Corning: Fiber Optic Cable Manufacturer, Optical Fiber Supplier, Headquarters: Corning, NY, Established: 1851, Employees: ~58,000, Annual Sales: $250 Million+, Main Products: Fibre Optic Cable, Optical Fiber, Fiber Connector. 2. Panduit: Fiber Optic Cable Manufacturer, Patch Cord Supplier, Headquarters: Tinley Park, IL, Established: 1955, Employees: 1000+, Annual Sales: $250 Million+, Main Prod…

3. OFS – Optical Fiber Solutions

Domain: ofsoptics.com

Registered: 2002 (23 years)

Introduction: OFS offers a range of optical fiber cable and connectivity solutions, including:

– Communications Optical Fibers

– Communications Fiber Optic Cables

– Communications Optical Connectivity

– Specialty Optical Connectivity

– Fiber Laser Modules & Components

– Fusion Splicers

– Specialty Optical Fiber

– Specialty Fiber Optic Cable

– Dispersion Compensating Modules

– FTTx Solutions

Key feat…

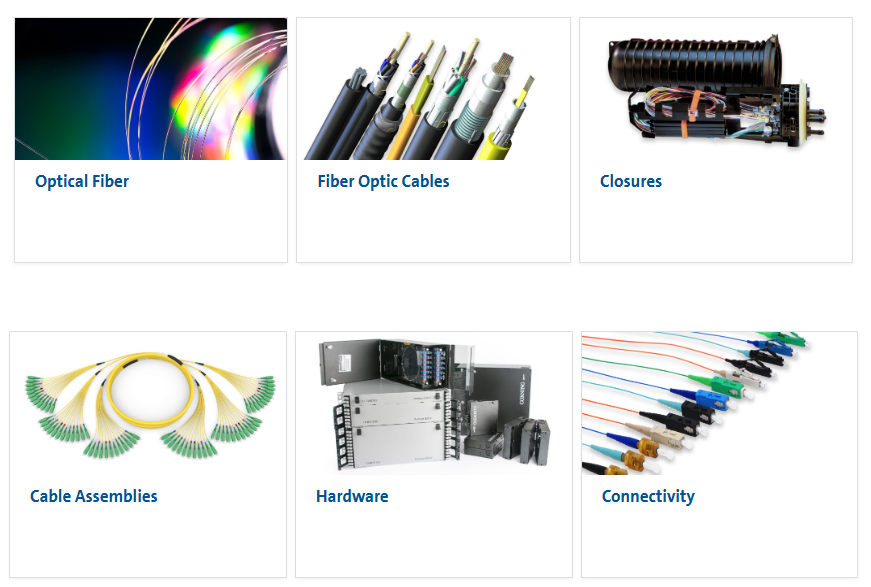

4. Fibertronics – Custom Cable Assemblies & Fiber Optic Solutions

Domain: fibertronics.com

Registered: 2000 (25 years)

Introduction: Custom Cable Assembly Manufacturing, Fiber Optic Cable Assemblies, Fiber Optic Patch Cables, Fiber Optic Pigtails, Fiber Optic Loopbacks, Custom Cable Assemblies, Mode Conditioning Cables, MPO/MMC Multi-Fiber Solutions, Splitters / Couplers, Flex Circuit Adapters & Attenuators, Adapter Plates, Adapters / Mating Sleeves, Attenuators, Connectors, Patch Panels and Splicing, Fiber Optic Patch Panels, …

5. OCC – Fiber, Copper, and Connectivity Solutions

Domain: occfiber.com

Registered: 1996 (29 years)

Introduction: OCC offers a wide range of products including Fiber, Copper, Hybrid cables, and connectivity solutions. Key product categories include:

1. **Fiber Products:**

– Commercial Enterprise Cables

– Harsh Environment Cables

– Indoor Cables (Data Center and Assembly)

– Indoor/Outdoor Cables

– Outdoor and Campus Cables

– Military Cables

– Broadcast Deployable Cables

– Mini…

6. Industrial Fiber Optics – Custom Fiber Optic Solutions

Domain: i-fiberoptics.com

Registered: 1998 (27 years)

Introduction: Industrial Fiber Optics specializes in manufacturing polymer and large-core silica optical fiber cable assemblies. Key products include:

– Customized Fiber Optic Connectors

– Custom Fiber Optic Assemblies

– Custom Light Pipes, LED Mounts, and Lens Caps

– Prototype Research & Fabrication Capabilities

– High-Quality Fiber Optic Connectors (POF and silica solutions)

– Complete Cable Assembly So…

7. OFS – Glass and Cable

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: OFS makes their glass in Norcross, GA and their cable in Carrollton, GA. Prysmian makes their glass in NC and their cable in Lexington, SC. CommScope uses OFS glass and makes their cable in NC. Corning makes their glass and cable in NC. AFL manufactures in Duncan, SC. Superior Essex cables are made in Bronwood, TX. Cleerline has its cable made in the USA. Hexatronic has a factory in the USA. Cable…

Understanding Fiber Optic Cable Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Loose Tube Cables | Contains multiple fibers in a loose tube, allowing for expansion and contraction. | Outdoor installations, long-distance networks | Pros: Flexible, high fiber count; Cons: More complex installation. |

| Ribbon Cables | Features multiple fibers arranged in a flat ribbon, enabling mass fusion splicing. | High-density networks, data centers | Pros: Space-efficient, faster installation; Cons: Requires specialized splicing equipment. |

| Indoor/Outdoor Cables | Flame-retardant and designed for both indoor and outdoor use. | Building-to-building connections, campus networks | Pros: Versatile, meets safety standards; Cons: May be more expensive than single-use cables. |

| Micro Cables | Smaller diameter cables designed for high-density environments and space-saving installations. | Data centers, urban environments | Pros: Lightweight, easy to install; Cons: Limited to specific applications. |

| Aerial Cables | Designed to be suspended from poles or buildings, often self-supporting. | Telecommunications, broadband networks | Pros: Cost-effective installation; Cons: Vulnerable to environmental factors. |

What Are Loose Tube Cables and Their B2B Suitability?

Loose tube cables are constructed to house multiple fibers in a protective tube, allowing for thermal expansion and contraction without compromising performance. This design makes them ideal for outdoor installations and long-distance networks, where environmental factors can vary significantly. B2B buyers should consider the flexibility and high fiber count of these cables, but be aware that their installation can be more complex, requiring skilled technicians.

How Do Ribbon Cables Enhance Network Efficiency?

Ribbon cables are characterized by their flat arrangement of fibers, which allows for mass fusion splicing. This feature makes them particularly advantageous for high-density networks, such as those found in data centers. The space efficiency and speed of installation are significant benefits for B2B buyers, although the need for specialized splicing equipment can be a drawback, potentially increasing initial setup costs.

Why Choose Indoor/Outdoor Cables for Versatile Applications?

Indoor/outdoor cables are specifically designed to meet the rigorous safety standards required for both environments. They are flame-retardant and suitable for building-to-building connections or campus networks. For businesses looking for versatility in their cabling solutions, these cables offer significant advantages. However, they may come at a higher price point compared to cables designed for single environments.

What Advantages Do Micro Cables Offer in High-Density Installations?

Micro cables are engineered for high-density applications, featuring a smaller diameter that allows for easier installation in tight spaces. They are particularly useful in urban environments and data centers where space is at a premium. While their lightweight design and ease of installation are appealing, B2B buyers should note that these cables may be limited to specific applications and environments.

How Do Aerial Cables Support Cost-Effective Telecommunications?

Aerial cables are designed for suspension from poles or buildings, often requiring no additional support structures. This characteristic makes them a cost-effective solution for telecommunications and broadband networks. While they simplify installation and reduce costs, businesses should consider the potential vulnerabilities to environmental factors, which may affect long-term performance and maintenance.

Key Industrial Applications of Fiber Optic Cable Manufacturers

| Industry/Sector | Specific Application of Fiber Optic Cable Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Backbone infrastructure for internet service providers | High-speed data transmission and enhanced bandwidth | Fiber type (single-mode/multi-mode), environmental ratings, and installation method |

| Industrial Automation | Connectivity for IoT devices and sensors | Improved data collection and real-time monitoring | Ruggedness, temperature tolerance, and cable flexibility |

| Healthcare | Networking for medical imaging and telemedicine | Reliable data transfer for critical medical applications | Compliance with health regulations and flame retardant materials |

| Transportation | Signal and communication systems in railways | Enhanced safety and operational efficiency | Resistance to environmental factors and installation ease |

| Military and Defense | Secure communication networks for operations | High data security and resilience in hostile environments | Compliance with military standards and durability |

How Are Fiber Optic Cables Used in Telecommunications?

In the telecommunications sector, fiber optic cables serve as the backbone infrastructure for internet service providers. They facilitate high-speed data transmission, enabling seamless internet access and communication services. This application addresses the growing demand for bandwidth, especially in regions undergoing digital transformation. Buyers must consider fiber types, such as single-mode for long distances and multi-mode for shorter runs, as well as environmental ratings to ensure durability in various climates.

What Role Do Fiber Optic Cables Play in Industrial Automation?

Fiber optic cables are crucial in industrial automation, providing connectivity for IoT devices and sensors that collect and transmit data in real time. This application enhances operational efficiency and enables predictive maintenance, which is vital for minimizing downtime. International buyers should focus on the ruggedness and temperature tolerance of cables, ensuring they can withstand harsh industrial environments while maintaining performance.

How Are Fiber Optic Cables Transforming Healthcare?

In the healthcare industry, fiber optic cables are integral to networking systems that support medical imaging and telemedicine applications. They ensure reliable data transfer, which is critical for diagnostics and patient monitoring. For B2B buyers in this sector, compliance with health regulations and the use of flame-retardant materials are essential considerations when sourcing cables, as they directly impact patient safety and operational reliability.

What Are the Benefits of Fiber Optic Cables in Transportation?

Fiber optic cables are increasingly being used in transportation systems, particularly for signal and communication systems in railways. They enhance safety and operational efficiency by providing real-time data transfer for monitoring and control systems. Buyers in this sector should prioritize cables that resist environmental factors, such as moisture and temperature extremes, and consider the ease of installation to minimize disruption during upgrades.

How Do Fiber Optic Cables Support Military and Defense Applications?

In military and defense contexts, fiber optic cables are employed to create secure communication networks essential for operations. They offer high data security and resilience, which are critical in hostile environments. For international buyers in defense, compliance with military standards and the durability of cables under extreme conditions are vital factors to evaluate when sourcing fiber optic solutions.

3 Common User Pain Points for ‘Fiber Optic Cable Manufacturers’ & Their Solutions

Scenario 1: Navigating Diverse Environmental Conditions for Fiber Optic Installation

The Problem: B2B buyers often encounter challenges when selecting fiber optic cables suitable for various environmental conditions, especially when operating in regions with extreme weather or unique geographical features. For instance, a telecommunications company in Saudi Arabia may need to install cables in both desert and urban areas, requiring different cable types for durability and performance. Buyers struggle to understand which products can withstand specific environmental factors, leading to potential installation failures, increased costs, and project delays.

The Solution: To effectively address these challenges, B2B buyers should prioritize working closely with fiber optic cable manufacturers who offer a comprehensive portfolio tailored for specific environments. When sourcing cables, it’s crucial to inquire about product specifications related to temperature resistance, moisture protection, and mechanical durability. For example, manufacturers like Corning provide specialized outdoor cables designed for direct burial or aerial installation, which can withstand harsh weather conditions. Buyers should also request samples and technical support to test compatibility with local conditions before making bulk purchases. Additionally, leveraging manufacturers’ expertise in installation techniques can help ensure that the right type of cable is deployed correctly, reducing risks associated with environmental factors.

Scenario 2: Understanding Fiber Cable Specifications and Standards

The Problem: International B2B buyers often face confusion regarding the various specifications and standards of fiber optic cables, which can lead to miscommunication and suboptimal purchasing decisions. For instance, a distributor in South America may not fully grasp the differences between single-mode and multimode cables, or the significance of fiber counts and material types. This lack of clarity can result in purchasing the wrong type of cable, ultimately affecting network performance and client satisfaction.

The Solution: To overcome these hurdles, B2B buyers should invest time in understanding the specific applications of different fiber optic cables and the relevant standards that govern their use. Manufacturers can assist by providing detailed product catalogs and educational resources that outline the specifications, such as fiber count, transmission distance, and bandwidth capabilities. Buyers should also engage in dialogue with manufacturers to clarify any uncertainties regarding the specifications. Additionally, attending industry workshops or webinars organized by manufacturers can enhance knowledge about fiber optics, enabling buyers to make informed decisions that align with their clients’ needs and project requirements.

Scenario 3: Managing Supply Chain and Inventory Challenges

The Problem: Another common pain point for B2B buyers in the fiber optic cable sector is managing supply chain disruptions and inventory shortages, particularly in regions with fluctuating demand or logistical challenges. For instance, a buyer in Africa might find it difficult to source the required fiber optic cables on time due to shipping delays or local supply issues, which can jeopardize project timelines and client relationships.

The Solution: To mitigate supply chain risks, B2B buyers should establish strong partnerships with reliable fiber optic cable manufacturers that have a proven track record of timely deliveries and adequate inventory management. It’s essential to engage in proactive communication with manufacturers about lead times, stock levels, and potential delays. Buyers should also consider diversifying their suppliers to avoid over-reliance on a single source, enabling them to maintain consistent supply flows. Implementing a just-in-time inventory strategy can also help manage stock levels efficiently, ensuring that necessary products are available without overcommitting financial resources. Additionally, utilizing technology solutions for inventory tracking can provide real-time insights into stock levels and help anticipate future needs, allowing buyers to plan purchases accordingly and avoid last-minute scrambles.

Strategic Material Selection Guide for Fiber Optic Cable Manufacturers

What Are the Key Materials for Fiber Optic Cable Manufacturing?

When selecting materials for fiber optic cables, manufacturers must consider various factors that impact performance, durability, and suitability for different applications. Here, we analyze four common materials used in fiber optic cable manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Glass Fiber

Key Properties:

Glass fiber is known for its excellent optical transmission properties, low attenuation, and high bandwidth capabilities. It typically operates effectively in a wide temperature range, making it suitable for diverse environments.

Pros & Cons:

The primary advantage of glass fiber is its superior performance in transmitting data over long distances. However, it is more fragile than other materials, making it susceptible to breakage during installation. The manufacturing process can be complex, which may lead to higher costs.

Impact on Application:

Glass fiber is compatible with various media and is often used in telecommunications and data centers. Its high transmission quality makes it ideal for applications requiring high bandwidth.

Considerations for International Buyers:

Buyers from regions such as Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, when sourcing glass fiber cables. The need for specialized installation techniques may also be a consideration.

2. Polyethylene (PE)

Key Properties:

Polyethylene is lightweight, flexible, and resistant to moisture and chemicals. It has a good temperature rating, typically ranging from -40°C to 80°C.

Pros & Cons:

The main advantage of PE is its durability and resistance to environmental factors, making it suitable for outdoor applications. However, its lower optical performance compared to glass fiber can limit its use in high-bandwidth applications.

Impact on Application:

PE is commonly used in outdoor cables, especially in direct burial and duct installations. Its properties make it suitable for harsh environments where moisture and chemicals are present.

Considerations for International Buyers:

When sourcing PE cables, buyers should check for compliance with local environmental regulations and standards. In regions like South America, where extreme weather conditions may be common, the durability of PE cables is a significant selling point.

3. Low Smoke Zero Halogen (LSZH)

Key Properties:

LSZH materials are designed to emit minimal smoke and no halogen when exposed to fire, making them safer for indoor installations. They have good fire resistance and moderate temperature ratings.

Pros & Cons:

The primary advantage of LSZH is its safety profile, which is crucial for indoor applications. However, these materials can be more expensive than standard PVC options, and their manufacturing can be more complex.

Impact on Application:

LSZH cables are ideal for environments where fire safety is a priority, such as commercial buildings and data centers. They are often required by local building codes in many regions.

Considerations for International Buyers:

Buyers in Europe and the Middle East, where stringent fire safety regulations exist, will find LSZH cables more suitable. Compliance with local standards is essential to avoid legal issues.

4. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used material due to its affordability and versatility. It has good mechanical strength and a temperature rating that typically ranges from -20°C to 60°C.

Pros & Cons:

The cost-effectiveness of PVC makes it a popular choice for many manufacturers. However, it is less fire-resistant than LSZH and can emit harmful gases when burned, limiting its use in certain applications.

Impact on Application:

PVC is commonly used in indoor cables where budget constraints are a concern. However, its use may be restricted in environments requiring high fire safety standards.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of PVC, especially in regions with strict environmental standards. Understanding the balance between cost and compliance is crucial for successful procurement.

Summary Table of Material Selection for Fiber Optic Cables

| Material | Typical Use Case for Fiber Optic Cable Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass Fiber | Telecommunications, Data Centers | Superior optical performance over long distances | Fragile, higher manufacturing complexity | High |

| Polyethylene (PE) | Outdoor installations, Direct burial | Durable, moisture-resistant | Lower optical performance than glass fiber | Medium |

| Low Smoke Zero Halogen (LSZH) | Indoor installations, Commercial buildings | High safety profile, minimal smoke emission | More expensive, complex manufacturing | High |

| Polyvinyl Chloride (PVC) | Indoor cables, Budget-sensitive applications | Cost-effective, versatile | Less fire-resistant, emits harmful gases when burned | Low |

This strategic material selection guide provides valuable insights for fiber optic cable manufacturers and international B2B buyers, ensuring informed decision-making in material procurement.

In-depth Look: Manufacturing Processes and Quality Assurance for Fiber Optic Cable Manufacturers

What Are the Main Stages in the Manufacturing Process of Fiber Optic Cables?

The manufacturing of fiber optic cables involves several critical stages, each crucial to ensuring the final product’s quality and performance. Here are the primary steps in the manufacturing process:

-

Material Preparation: This initial stage includes sourcing high-quality raw materials, primarily silica glass, which is drawn into fibers. The glass must meet stringent specifications for purity and consistency. Manufacturers often use advanced techniques like chemical vapor deposition (CVD) to create preforms that are the basis for fiber drawing.

-

Forming: The preform is heated to a high temperature and drawn into thin fibers. This process requires precision to achieve the desired diameter, typically around 125 micrometers for standard fibers. Advanced technologies like the MCVD (Modified Chemical Vapor Deposition) or OVD (Outside Vapor Deposition) are commonly employed to create fibers with specific optical properties.

-

Assembly: Once the fibers are drawn, they are assembled into cables. This involves grouping multiple fibers and encasing them in protective materials, which could include strength members, moisture barriers, and jackets that resist environmental factors. The assembly process is critical for ensuring the cable’s durability and performance in various applications.

-

Finishing: The final stage involves applying coatings and performing tests to ensure the fibers meet industry standards. This may include adding protective sheaths and labeling the cables according to specifications. Quality assurance measures are integrated into this stage to ensure that each cable is ready for deployment.

How Do Fiber Optic Manufacturers Ensure Quality Assurance?

Quality assurance is a pivotal aspect of the fiber optic cable manufacturing process. Here’s how manufacturers maintain high standards:

-

International Standards Compliance: Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that companies maintain consistent quality and continuously improve their processes.

-

Industry-Specific Certifications: In addition to ISO standards, fiber optic cable manufacturers often obtain certifications relevant to their markets. For instance, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Other certifications like API (American Petroleum Institute) may be necessary for specialized applications in the oil and gas industry.

-

Quality Control Checkpoints: Manufacturers implement various quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

– In-Process Quality Control (IPQC): During the manufacturing process, samples are regularly tested to monitor the quality of the fibers being produced. This includes checking for defects, consistency in diameter, and optical performance.

– Final Quality Control (FQC): At the end of the manufacturing process, finished products undergo rigorous testing to verify they meet all technical specifications and quality standards.

What Common Testing Methods Are Used for Fiber Optic Cables?

Various testing methods are employed to ensure the reliability and performance of fiber optic cables:

-

Optical Time Domain Reflectometry (OTDR): This technique is used to assess the integrity of the fiber and identify any faults or losses in the system. It provides a visual representation of the fiber’s performance characteristics over distance.

-

Insertion Loss Testing: This method measures the amount of signal loss that occurs when light passes through the fiber. It is essential for determining the efficiency of the fiber in transmitting data.

-

Return Loss Testing: This test assesses how much light is reflected back towards the source. High return loss values indicate better performance, as less light is being lost.

-

Environmental Testing: Cables are subjected to various environmental conditions, such as temperature variations, humidity, and mechanical stress, to ensure they can withstand real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of fiber optic cable manufacturers is essential:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide firsthand insight into their manufacturing processes and quality assurance practices. Buyers should look for evidence of compliance with international standards and certifications.

-

Quality Reports: Requesting detailed quality reports from suppliers, including results from testing methods, can help buyers assess the consistency and reliability of the products. These reports should include data on IQC, IPQC, and FQC findings.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This is particularly valuable when sourcing from manufacturers in different regions, ensuring that they meet the buyer’s expectations and standards.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers need to navigate various nuances when it comes to quality control and certification:

-

Understanding Local Standards: Different regions may have specific standards and regulations that must be adhered to. Buyers should familiarize themselves with local compliance requirements to ensure that the products are suitable for their markets.

-

Certifications Validity: It’s important to verify the validity and relevance of certifications claimed by suppliers. Some certifications may be more recognized in certain regions, impacting their acceptance in local markets.

-

Cultural and Regulatory Differences: Buyers should be aware of cultural differences that may affect manufacturing practices and quality assurance. Engaging with local experts or consultants can provide valuable insights into best practices and compliance expectations in specific regions.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing fiber optic cables, ensuring they select reliable suppliers that meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Fiber Optic Cable Manufacturers’

This guide aims to equip B2B buyers with a comprehensive checklist for sourcing fiber optic cable manufacturers. Whether you are seeking products for telecommunications, data centers, or other applications, following these steps will help you make informed decisions and ensure high-quality procurement.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline your technical requirements. This includes determining the type of fiber optic cable you need—such as single-mode or multimode—and the specific applications, like indoor versus outdoor use. Knowing your specifications helps you communicate effectively with suppliers and ensures that you receive products tailored to your needs.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify potential fiber optic cable manufacturers. Focus on companies with a solid reputation in the industry and experience in your desired applications. Utilize resources such as trade shows, industry publications, and online directories to compile a list of candidates. Prioritize manufacturers that have a proven track record in delivering quality products in your target region.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers possess relevant certifications and compliance with international standards. Look for certifications such as ISO 9001 for quality management and any specific industry standards pertinent to fiber optics. This step is vital as it assures you that the manufacturer adheres to quality control processes and industry regulations, reducing the risk of defects.

Step 4: Request Samples and Product Specifications

Once you have identified potential suppliers, request product samples and detailed specifications. Analyzing samples allows you to assess the quality, performance, and suitability of the cables for your applications. Additionally, ensure that the specifications align with your defined technical requirements, including fiber count, jacket material, and environmental ratings.

Step 5: Inquire About Lead Times and Production Capabilities

Understanding lead times is crucial for planning your projects. Ask suppliers about their production capabilities, including how quickly they can fulfill orders and whether they can scale production based on your needs. This information helps you assess whether the supplier can meet your timelines and adapt to fluctuations in demand.

Step 6: Review Warranty and Support Services

Evaluate the warranty and post-purchase support offered by manufacturers. A robust warranty policy indicates confidence in product quality, while strong customer support can facilitate issue resolution and provide technical assistance when needed. Look for manufacturers that offer comprehensive service agreements to ensure ongoing support throughout the product lifecycle.

Step 7: Negotiate Pricing and Payment Terms

Finally, engage in discussions regarding pricing and payment terms. Compare quotes from multiple manufacturers, but also consider the value offered, including product quality and service. Establishing clear payment terms is essential for maintaining a healthy supplier relationship and ensuring smooth transactions.

By following these steps, B2B buyers can effectively navigate the sourcing process for fiber optic cable manufacturers, ensuring they make informed choices that align with their technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for Fiber Optic Cable Manufacturers Sourcing

What Are the Key Cost Components in Fiber Optic Cable Manufacturing?

Understanding the cost structure of fiber optic cable manufacturing is crucial for B2B buyers. The primary components include:

-

Materials: Fiber optic cables are primarily composed of glass or plastic fibers, protective jackets, and additional materials for durability. The choice of materials significantly impacts costs, especially if high-performance specifications are required.

-

Labor: Skilled labor is essential in the manufacturing process, from fiber drawing to assembly. Labor costs can vary widely based on geographic location and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead costs, which can be a point of negotiation.

-

Tooling: Specialized equipment for fiber optic production can be capital-intensive. Tooling costs are amortized over production volume, meaning larger orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Ensuring product quality requires rigorous testing and inspection, which adds to the overall cost. Certifications like ISO can also affect pricing.

-

Logistics: Shipping and handling, particularly for international orders, can substantially influence overall costs. This includes not only freight but also customs clearance and duties.

-

Margin: Manufacturers typically add a profit margin that reflects their business model and market positioning.

How Do Price Influencers Impact Fiber Optic Cable Costs?

Several factors influence the pricing of fiber optic cables, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Understanding a manufacturer’s MOQ can help in planning procurement strategies.

-

Specifications and Customization: Customized cables tailored to specific applications can incur higher costs due to additional materials and production complexity. Buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications ensure better performance and reliability but can also increase costs. Buyers should assess whether the benefits justify the additional expense.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium, while newer entrants might offer lower prices to capture market share.

-

Incoterms: The chosen Incoterm can significantly impact total costs. For example, DDP (Delivered Duty Paid) includes all shipping and duty costs, while EXW (Ex Works) leaves the buyer responsible for all logistics, often leading to higher overall expenses.

What Are the Best Practices for Negotiating Fiber Optic Cable Prices?

When negotiating prices for fiber optic cables, B2B buyers can adopt several strategies:

-

Leverage Volume Discounts: Consider consolidating orders to meet minimum quantities for better pricing. This can be particularly effective for organizations planning long-term projects.

-

Explore Total Cost of Ownership (TCO): Evaluate not just the initial price but also long-term costs associated with installation, maintenance, and operational efficiency. A higher upfront cost may lead to lower total costs over time.

-

Assess Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional supply chain logistics that can affect pricing.

-

Request Multiple Quotes: Engaging several suppliers and comparing their offers can provide leverage in negotiations. It also helps in understanding the market price range.

-

Build Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms over time, as trust and familiarity develop.

Final Thoughts on Pricing Dynamics in Fiber Optic Cable Procurement

While this analysis provides a framework for understanding costs and pricing in fiber optic cable sourcing, prices can vary widely based on numerous factors. It’s advisable for buyers to conduct thorough market research and engage in transparent discussions with suppliers to ensure they secure the best possible deals tailored to their specific needs. Always remember to consider the total cost of ownership and the strategic value of the investment in fiber optic technology.

Alternatives Analysis: Comparing Fiber Optic Cable Manufacturers With Other Solutions

Understanding Alternatives to Fiber Optic Cable Manufacturers

In the rapidly evolving landscape of communication technologies, businesses often explore various solutions to meet their connectivity needs. While fiber optic cables are renowned for their high-speed data transmission and reliability, alternative technologies can also provide viable options depending on specific operational requirements. This section analyzes fiber optic cable manufacturers against other communication solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Fiber Optic Cable Manufacturers | Copper Cable Solutions | Wireless Communication Systems |

|---|---|---|---|

| Performance | High bandwidth, low latency | Moderate bandwidth, higher latency | Variable performance based on distance and interference |

| Cost | Higher initial investment | Lower initial cost | Moderate to high, depending on infrastructure |

| Ease of Implementation | Requires specialized installation | Easier to install | Quick deployment, minimal infrastructure needed |

| Maintenance | Low maintenance, durable | Moderate maintenance | High maintenance due to environmental factors |

| Best Use Case | Long-distance, high-demand applications | Short-distance, legacy systems | Mobile applications, temporary setups |

What Are the Advantages and Disadvantages of Copper Cable Solutions?

Copper cables, such as twisted pair and coaxial cables, have been staples in networking for decades. One of their primary advantages is cost-effectiveness; they are generally cheaper to purchase and install compared to fiber optics. Additionally, copper is easier to work with, requiring less specialized training for installation. However, copper cables fall short in terms of performance, especially over long distances, where they experience higher signal attenuation and interference. This makes them suitable for short-distance applications but less ideal for modern, high-speed networking needs.

How Do Wireless Communication Systems Compare?

Wireless communication systems, including Wi-Fi and cellular technologies, offer unmatched flexibility and ease of deployment. They are especially beneficial in environments where cabling is impractical or where mobility is essential. Wireless solutions can be set up quickly, making them ideal for temporary installations or in rapidly changing environments. However, their performance can be inconsistent due to factors like physical obstructions and interference from other devices. Additionally, wireless systems often face higher maintenance demands, especially in areas with high user density or challenging environmental conditions.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate communication solution, B2B buyers should assess their specific requirements, including the scale of their operations, budget constraints, and environmental considerations. Fiber optic cables excel in high-demand scenarios requiring fast, reliable connections over long distances, making them ideal for data centers and large enterprises. Conversely, copper solutions may suffice for localized applications where cost is a significant factor. Wireless systems offer flexibility and rapid deployment but may struggle with consistent performance in complex environments. By carefully evaluating these alternatives, businesses can align their connectivity solutions with their operational needs, ensuring optimal performance and cost-effectiveness.

Essential Technical Properties and Trade Terminology for Fiber Optic Cable Manufacturers

What Are the Key Technical Properties of Fiber Optic Cables for Manufacturers?

Understanding the essential technical properties of fiber optic cables is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications:

-

Material Grade: The primary material used in fiber optic cables is glass or plastic. Glass fibers offer lower attenuation and higher bandwidth, making them suitable for long-distance communication. Plastic fibers, while more flexible and easier to handle, typically have higher loss rates. For manufacturers, selecting the appropriate material grade impacts performance and durability.

-

Fiber Count: This specification indicates the number of fibers contained within a cable. Higher fiber counts allow for increased data transmission capabilities, which is vital for expanding network infrastructures. Manufacturers must consider the intended use and scalability when determining the required fiber count.

-

Attenuation: Measured in decibels per kilometer (dB/km), attenuation indicates the loss of signal strength as it travels through the fiber. Lower attenuation values are preferable as they ensure better performance over long distances. For manufacturers, understanding attenuation is essential for designing systems that meet specific performance criteria.

-

Bend Radius: The minimum radius that a fiber optic cable can be bent without incurring damage is known as the bend radius. Cables with a smaller bend radius are easier to install in tight spaces and reduce the risk of breakage. This property is particularly important for manufacturers focusing on installations in constrained environments.

-

Temperature Range: Fiber optic cables are designed to operate within specific temperature ranges. Understanding the operational environment is crucial for selecting the right cable type, especially for outdoor applications. Manufacturers need to ensure that the chosen cables can withstand the environmental conditions of the installation site.

What Are Common Trade Terms Used in the Fiber Optic Cable Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the fiber optic cable market. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the fiber optic industry, OEMs often supply cables and components for larger telecommunications companies. Understanding OEM relationships can help buyers identify reliable suppliers.

-

MOQ (Minimum Order Quantity): This specification indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage their inventory and budget effectively. It can also affect purchasing decisions, especially for smaller businesses.

-

RFQ (Request for Quotation): An RFQ is a formal process used by buyers to solicit price quotes from suppliers for specific quantities of products. This term is essential for B2B transactions, as it establishes a clear communication channel for pricing and delivery expectations.

-

Incoterms (International Commercial Terms): These are internationally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for managing shipping risks and costs, ensuring that both parties are clear on their obligations.

-

Fiber Optic Cable Types: Various types of fiber optic cables exist, including single-mode and multimode cables, each serving different applications. Single-mode cables are designed for long-distance communication, while multimode cables are used for shorter distances. Buyers must choose the appropriate type based on their specific network requirements.

By grasping these technical properties and trade terms, B2B buyers can better navigate the fiber optic cable market, ensuring they select the right products for their needs while optimizing their supply chain operations.

Navigating Market Dynamics and Sourcing Trends in the Fiber Optic Cable Manufacturers Sector

What Are the Key Trends Influencing the Fiber Optic Cable Market?

The global fiber optic cable market is experiencing significant growth, driven by the increasing demand for high-speed internet and telecommunications services. Key drivers include the proliferation of data centers, the expansion of 5G networks, and the rise in smart city initiatives. In regions like Africa and South America, where infrastructure development is critical, fiber optic cables are pivotal in bridging the digital divide, facilitating connectivity in remote areas.

Emerging trends in B2B sourcing include the adoption of advanced technologies such as artificial intelligence (AI) and the Internet of Things (IoT) for network management and optimization. These technologies allow manufacturers to streamline production processes and improve supply chain efficiency, making it easier for international buyers to source high-quality products. Additionally, the shift towards ribbon and micro cables is notable; these types offer higher fiber density and ease of installation, catering to the growing need for scalable solutions in densely populated urban areas.

International buyers must also be aware of fluctuating raw material costs and geopolitical factors that could impact supply chains. Engaging with multiple suppliers and diversifying sourcing strategies can mitigate risks associated with these market dynamics.

How Can Sustainability and Ethical Sourcing Impact Fiber Optic Cable Procurement?

Sustainability is increasingly becoming a focal point for B2B buyers in the fiber optic cable industry. Manufacturers are now prioritizing eco-friendly materials and production methods to minimize environmental impact. This includes using Low Smoke Zero Halogen (LSZH) materials in cable production, which reduce toxic emissions during fire incidents, thereby enhancing safety in urban environments.

Ethical sourcing is equally important, as stakeholders seek transparency in supply chains. Buyers should look for suppliers who are certified for sustainability and ethical practices, such as ISO 14001 for environmental management and certifications that indicate responsible sourcing of materials. This not only helps in compliance with regulations but also enhances brand reputation among environmentally conscious consumers and businesses.

Investing in suppliers with a commitment to sustainability can lead to long-term partnerships that not only meet current demands but also align with future regulatory trends and consumer expectations regarding environmental responsibility.

How Has the Fiber Optic Cable Industry Evolved Over Time?

The fiber optic cable industry has undergone a remarkable transformation since the introduction of the first low-loss optical fiber in the 1970s. Initially, these cables were primarily used in telecommunications, but advancements in technology have expanded their applications across various sectors, including healthcare, military, and data centers.

As the demand for faster and more reliable data transmission has grown, manufacturers have innovated to produce cables that are not only more efficient but also easier to install and maintain. The introduction of ribbon cables and micro cables exemplifies this evolution, enabling higher fiber counts and supporting the massive bandwidth required for modern applications.

In summary, understanding the market dynamics, prioritizing sustainability, and recognizing the historical context of fiber optic cables can provide international B2B buyers with a competitive edge in sourcing strategies and supplier relationships.

Frequently Asked Questions (FAQs) for B2B Buyers of Fiber Optic Cable Manufacturers

-

1. How do I choose the right fiber optic cable for my project?

Choosing the right fiber optic cable starts with understanding the specific requirements of your project. Consider factors such as the installation environment (outdoor, indoor, or indoor/outdoor), the required fiber count, and the type of fiber (single-mode or multimode). Evaluate the environmental conditions, such as temperature variations and exposure to moisture or chemicals. Manufacturers often provide guidance and recommendations based on these parameters, so consulting with them can help ensure you select a cable that meets your needs. -

2. What is the best type of fiber optic cable for outdoor installations?

For outdoor installations, loose tube cables are generally considered the best option due to their durability and resistance to environmental stresses. These cables are designed to withstand harsh conditions, such as extreme temperatures and moisture. Additionally, ribbon cables can be advantageous for projects requiring high fiber counts and efficient mass fusion splicing. It’s essential to assess the specific environmental challenges of your installation site to choose the most suitable cable type. -

3. What are the minimum order quantities (MOQ) for fiber optic cables?

Minimum order quantities for fiber optic cables can vary significantly among manufacturers. Typically, MOQs range from as low as 100 meters for standard cables to several kilometers for specialized or custom orders. It’s advisable to discuss your project requirements with manufacturers directly to negotiate MOQs that align with your needs. Some manufacturers may offer flexibility for larger orders or specific projects, so always inquire about potential exceptions. -

4. How can I vet potential fiber optic cable suppliers for reliability?

To vet potential suppliers, start by researching their reputation in the industry. Look for customer reviews, case studies, and testimonials. Verify their certifications and compliance with international standards, such as ISO and TIA/EIA. Request samples to assess the quality of their products firsthand. Additionally, consider their experience in international trade, especially if you’re sourcing from regions like Africa or South America, where local regulations might differ. -

5. What payment terms should I expect when sourcing fiber optic cables internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments upon order confirmation, and balance due before shipping. Letters of credit are also frequently used for international transactions to mitigate risk. Always clarify payment terms during negotiations to ensure they align with your cash flow and budget constraints. Establishing a clear agreement upfront can prevent misunderstandings later in the procurement process. -

6. How do I ensure quality assurance when purchasing fiber optic cables?

To ensure quality assurance, look for manufacturers that implement rigorous testing protocols for their cables. Request documentation of their quality control processes, including testing for performance metrics such as attenuation and bandwidth. Many reputable manufacturers provide certifications and compliance reports that demonstrate adherence to industry standards. Engaging third-party testing services can also provide an additional layer of assurance regarding product quality. -

7. What logistics considerations should I keep in mind when importing fiber optic cables?

When importing fiber optic cables, consider factors such as shipping methods, customs regulations, and import tariffs. Work with logistics providers experienced in international shipping to navigate these complexities. Ensure that your supplier can provide the necessary shipping documentation, including bills of lading and customs declarations, to facilitate smooth clearance. Additionally, factor in lead times for production and shipping to align with your project timelines. -

8. Can fiber optic cables be customized for specific applications?

Yes, many manufacturers offer customization options for fiber optic cables to meet specific application requirements. Customization can include variations in fiber counts, jacket materials, and lengths. If you have unique needs, discuss them with potential suppliers early in the procurement process. Providing detailed specifications will help manufacturers tailor their offerings, ensuring that the final product aligns with your project requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Fiber Optic Cable Manufacturers

The strategic sourcing of fiber optic cables is crucial for businesses aiming to optimize their telecommunications infrastructure. As the demand for high-speed internet connectivity continues to rise, selecting the right manufacturers becomes essential. This guide emphasizes the importance of understanding environmental factors, product specifications, and supplier capabilities when making sourcing decisions. By engaging with reputable manufacturers, such as Corning and OmniCable, buyers can ensure access to innovative solutions tailored to diverse applications, from outdoor installations to specialized indoor environments.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that not only offer high-quality products but also provide comprehensive support, including technical assistance and customized solutions. This proactive approach will enable businesses to stay ahead in a competitive market, addressing current needs while planning for future expansion.

Take the next step in enhancing your telecommunications strategy by exploring reliable fiber optic cable manufacturers that align with your operational goals. Embrace the potential of fiber optics to transform your communication capabilities and drive growth in your region.