Top 7 Piston Pump Manufacturers List and Guide: How To Solve Scen…

Introduction: Navigating the Global Market for Piston Pump Manufacturers

In today’s competitive global market, sourcing reliable piston pump manufacturers can be a daunting task for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexity of hydraulic systems, combined with the critical role that piston pumps play in various industries—from construction and manufacturing to aerospace and automotive—demands that buyers make informed decisions to ensure operational efficiency and cost-effectiveness.

This comprehensive guide delves into the multifaceted world of piston pump manufacturers, providing insights into the different types of pumps available, their specific applications, and the essential factors to consider when vetting suppliers. We will explore the intricacies of both axial and radial piston pumps, discuss the importance of performance specifications, and highlight key considerations such as pressure ratings and compatibility with existing systems. Furthermore, we will guide you through the cost implications of purchasing piston pumps, ensuring that you can balance quality with budget constraints.

By equipping international B2B buyers with actionable insights and practical knowledge, this guide empowers you to navigate the complexities of sourcing piston pumps effectively. Whether you are based in Germany, Saudi Arabia, or any other region, understanding these critical elements will enhance your purchasing strategy, ultimately driving productivity and success in your operations.

Top 10 Piston Pump Manufacturers Manufacturers & Suppliers List

1. Kawasaki – Axial Piston Pumps

Domain: kawasakihydraulics.com

Registered: 2019 (6 years)

Introduction: Kawasaki has been producing axial piston pumps for over 50 years, leading in pump efficiency and performance. Key product series include: K3VLS (medium duty, load sensing control, 50-150cc displacements, 280 bar continuous pressure, 350 bar max), K3VL (swash plate type, 28-200cc displacements, 320 bar continuous pressure), K3V/K5V/K7V (63-212cc displacements, 350 bar continuous pressure), K3VG (63…

2. Arozone – Piston Pumps & Packages

Domain: arozone.com

Registered: 2000 (25 years)

Introduction: Piston Pumps and Packages for Transfer & Extrusion, including 2-Ball Piston Pumps, 4-Ball Piston Pumps, and Chop-Check Piston Pumps. Also includes Piston Pump Parts & Accessories.

3. Bailey Hydraulics – Hydraulic Piston Pumps

Domain: baileyhydraulics.com

Registered: 2013 (12 years)

Introduction: Hydraulic Piston Pumps available from brands such as Fluidyne and OMFB. Key specifications include: PSI ratings up to 5800, GPM ratings ranging from 15.7 to 52.3, RPM ranging from 500 to 3300, various outlet port sizes (1″ UNC Thread, 3/4″ UNC Thread), cubic inch displacement (CID) options from 1.10 to 6.71, and multiple mounting options including 2 bolt A, B, C flanges, ISO 80MM 4B, and SAE-C 4B….

4. Aurora Prosci – Piston Pump OEM

Domain: auroraprosci.com

Registered: 2018 (7 years)

Introduction: The Piston Pump OEM is a family of maintenance-free OEM pumps designed for precise fluid dispensing, particularly for analytical instruments. It features a lifespan of 10 million cycles, reducing maintenance costs. Available dispense volumes range from 25 µL to 5000 µL, with specific options including 25 µL, 50 µL, 100 µL, 250 µL, 500 µL, 1000 µL, 2500 µL, and 5000 µL. The pump head materials incl…

5. All World – Piston Pumps

Domain: allworldmachinery.com

Registered: 2002 (23 years)

Introduction: Piston pumps are designed to transport liquids or fluids through the reciprocating movements of pistons inside a cylinder, building positive pressure for a steady flow of liquid. All World offers a selection of piston pumps from manufacturers like Daikin, available at competitive prices and prompt delivery. Key features include various control methods (e.g., combination control, power match contro…

6. Motion – Hydraulic Axial Piston Pumps

Domain: motion.com

Registered: 1994 (31 years)

Introduction: Motion offers hydraulic axial piston pumps that feature axial pistons generating axial forces to drive fluid flow, ensuring optimal performance and versatility. The product range includes various brands such as VICKERS BY DANFOSS, Nachi America Inc, Danfoss Hydrostatic, Yuken, and others. Key specifications include displacement values ranging from 10.5 cc/rev to 141 cc/rev, maximum flow rates, inl…

7. Sprayer Supplies – Piston Pumps

Understanding Piston Pump Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Axial Piston Pumps | Compact design, high efficiency, variable or fixed displacement | Construction, aerospace, industrial machinery | Pros: High efficiency, adaptable; Cons: Can be complex and more expensive. |

| Radial Piston Pumps | Piston arrangement perpendicular to the drive shaft, high pressure | Heavy machinery, hydraulic presses, marine systems | Pros: High pressure capabilities; Cons: Larger footprint, potentially higher maintenance. |

| Hydraulic Hand Pumps | Manual operation, low-pressure output, simple design | Small-scale applications, maintenance tasks | Pros: Cost-effective, easy to use; Cons: Limited pressure and flow capabilities. |

| Electric Hydraulic Pumps | High pressure output, often automated, electric-powered | Automation, manufacturing, precision tasks | Pros: Consistent performance, minimal manual input; Cons: Higher initial investment. |

| Pneumatic Piston Pumps | Utilizes compressed air, lightweight, versatile | Automotive, packaging, assembly lines | Pros: Lightweight, fast operation; Cons: Dependent on air supply, may require additional equipment. |

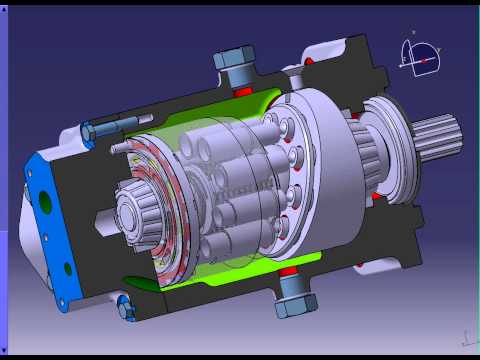

What Are the Characteristics of Axial Piston Pumps?

Axial piston pumps feature pistons arranged parallel to the drive shaft, allowing for a compact and efficient design. They are particularly well-suited for high-pressure and high-flow applications, making them ideal for industries like construction and aerospace. When considering an axial piston pump, B2B buyers should evaluate the required pressure ratings, compatibility with existing systems, and whether a fixed or variable displacement model is more appropriate for their needs.

How Do Radial Piston Pumps Stand Out?

Radial piston pumps are distinguished by their unique arrangement of pistons that radiate outward from a central drive shaft. This design enables them to achieve extremely high pressure outputs, making them ideal for heavy-duty applications such as hydraulic presses and marine systems. Buyers should assess the operational pressures required for their applications and consider the space constraints, as radial pumps may occupy more room compared to other types.

What Should Buyers Know About Hydraulic Hand Pumps?

Hydraulic hand pumps are manually operated devices that convert minimal force into hydraulic power. They are commonly used in smaller-scale applications where portability and cost-effectiveness are key considerations. While they are easy to use and maintain, buyers must be aware that these pumps are limited in terms of pressure and flow output. Assessing the specific application requirements will help determine if a hand pump meets the operational needs.

What Advantages Do Electric Hydraulic Pumps Offer?

Electric hydraulic pumps provide high pressure outputs and are often integrated into automated systems for manufacturing and precision tasks. Their consistent performance and ease of use make them appealing for businesses looking to enhance efficiency. However, potential buyers should consider the higher initial investment and ensure that their facility can support the required electrical infrastructure.

Why Choose Pneumatic Piston Pumps?

Pneumatic piston pumps leverage compressed air to operate, making them lightweight and versatile for various applications, such as automotive assembly lines. They are known for their fast operation and responsiveness. However, B2B buyers should consider the dependency on an air supply and any additional equipment that may be necessary to maintain optimal performance, which could impact overall cost and efficiency.

Key Industrial Applications of Piston Pump Manufacturers

| Industry/Sector | Specific Application of Piston Pump Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Heavy Machinery | Hydraulic systems in excavators and loaders | Enhanced lifting capacity and operational efficiency | Pressure ratings, displacement options, and compatibility with existing systems |

| Oil and Gas | Hydraulic fracturing and drilling operations | Increased productivity and precise control under extreme conditions | Durability, high-pressure capabilities, and service support |

| Automotive Manufacturing | Assembly line automation and hydraulic presses | Improved precision and speed in manufacturing processes | Customization options, energy efficiency, and reliability |

| Agriculture | Crop harvesting machinery and irrigation systems | Maximized productivity and reduced operational downtime | Adaptability to varying loads and environmental conditions |

| Aerospace and Defense | Hydraulic actuation systems in aircraft | High reliability and performance in critical applications | Compliance with safety standards and pressure specifications |

How Are Piston Pumps Used in Construction and Heavy Machinery?

In the construction sector, piston pumps play a crucial role in hydraulic systems of heavy machinery such as excavators and loaders. These pumps efficiently convert mechanical energy into hydraulic energy, enabling the equipment to lift and maneuver heavy loads with precision. For international buyers, especially in regions like Africa and the Middle East, sourcing high-pressure hydraulic pumps with robust durability is essential to withstand harsh working conditions and ensure minimal downtime.

What Role Do Piston Pumps Play in the Oil and Gas Industry?

Piston pumps are integral to hydraulic fracturing and drilling operations in the oil and gas industry. They provide the necessary pressure to inject fluids into the ground, facilitating the extraction of oil and gas. The reliability and efficiency of these pumps can significantly impact productivity, making it vital for businesses to consider pumps that can operate under extreme conditions. Buyers should prioritize sourcing pumps with high-pressure capabilities and excellent service support to address potential operational challenges.

How Are Piston Pumps Utilized in Automotive Manufacturing?

In automotive manufacturing, piston pumps are utilized in assembly line automation and hydraulic presses, which are essential for shaping and assembling parts. These pumps enhance the precision and speed of manufacturing processes, leading to improved productivity. For B2B buyers in Europe, such as Germany, it is crucial to source pumps that offer customization options to meet specific operational needs while ensuring energy efficiency to reduce costs.

Why Are Piston Pumps Important in Agriculture?

In the agricultural sector, piston pumps are commonly found in crop harvesting machinery and irrigation systems. They help maximize productivity by providing consistent hydraulic power to operate various agricultural equipment. Buyers from South America should consider pumps that can adapt to varying loads and environmental conditions to ensure reliable operation throughout the growing season.

What Applications Do Piston Pumps Have in Aerospace and Defense?

Piston pumps are vital in hydraulic actuation systems used in aerospace applications, including aircraft. Their high reliability and performance are crucial for ensuring safety and efficiency in flight operations. International buyers in this sector must focus on sourcing pumps that comply with stringent safety standards and possess specific pressure specifications to meet the rigorous demands of aerospace applications.

3 Common User Pain Points for ‘Piston Pump Manufacturers’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Piston Pump for Specific Applications

The Problem: B2B buyers often face the challenge of selecting the most suitable piston pump from a vast array of options. With various types of piston pumps—axial and radial—each designed for different applications and performance requirements, the decision-making process can be overwhelming. Buyers may struggle to match the pump specifications, such as displacement, pressure rating, and compatibility with existing systems. This uncertainty can lead to costly mistakes, including purchasing pumps that underperform or fail to integrate effectively into their machinery.

The Solution: To alleviate this issue, buyers should start with a comprehensive assessment of their application requirements. This includes understanding the necessary pressure ratings, flow rates, and the specific operating conditions of their machinery. Engaging with manufacturers early in the process can provide insights into the best-suited pump types for their needs. Buyers should also request detailed product datasheets and consult with engineers from the manufacturer to clarify technical specifications and compatibility with existing hydraulic systems. Utilizing simulation software to model the pump’s performance in their specific application can further ensure the right selection, ultimately leading to improved operational efficiency and reduced costs.

Scenario 2: High Maintenance Costs Due to Inefficient Pump Systems

The Problem: Many businesses experience high maintenance costs due to the inefficiency of their hydraulic systems, often stemming from using outdated or poorly matched piston pumps. These inefficiencies can manifest as increased energy consumption, frequent breakdowns, and the need for constant repairs, which significantly disrupt operations and inflate operational costs. Buyers may find it challenging to identify the root causes of inefficiencies and may not know how to upgrade or replace their systems effectively.

The Solution: To address these maintenance challenges, buyers should conduct a thorough evaluation of their current hydraulic systems. This includes analyzing pump performance data to identify inefficiencies. Collaborating with piston pump manufacturers can provide access to modern, energy-efficient models designed to reduce operational costs. Buyers should inquire about variable displacement pumps that adapt to system demands, ensuring optimal performance. Additionally, investing in predictive maintenance technologies can help monitor pump conditions and predict failures before they occur, thereby minimizing downtime and maintenance expenses. Establishing a partnership with a reliable manufacturer for ongoing support and training on system optimization can further enhance long-term operational efficiency.

Scenario 3: Challenges in Global Supply Chain and Availability of Components

The Problem: B2B buyers in regions such as Africa and South America often face supply chain disruptions that impact the availability of piston pump components and replacement parts. Delays in obtaining critical components can halt production lines, leading to significant losses. Buyers may also struggle with navigating international shipping and customs regulations, which adds complexity to the procurement process.

The Solution: To mitigate these supply chain issues, buyers should establish relationships with multiple piston pump manufacturers and suppliers to ensure a diversified sourcing strategy. This can help reduce dependency on a single supplier and create a buffer against supply chain disruptions. Buyers should also consider local manufacturers or distributors that can provide quicker access to essential components. Implementing a just-in-time inventory system can help manage parts availability more effectively. Additionally, staying informed about global shipping trends and collaborating with logistics experts can facilitate smoother procurement processes. By proactively managing supply chain relationships and inventory levels, buyers can significantly reduce the impact of disruptions on their operations.

Strategic Material Selection Guide for Piston Pump Manufacturers

What Are the Key Materials Used in Piston Pump Manufacturing?

When selecting materials for piston pumps, manufacturers must consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials: cast iron, aluminum, stainless steel, and composite materials, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Cast Iron Perform in Piston Pump Applications?

Cast iron is a traditional choice for piston pump housings due to its excellent wear resistance and ability to withstand high pressures. It typically has a temperature rating of up to 300°C and can handle pressures exceeding 200 bar. However, cast iron is relatively heavy, which can impact the overall weight of the pump system.

Pros: Cast iron is durable and cost-effective, making it suitable for heavy-duty applications. Its excellent vibration-damping properties also contribute to smoother operation.

Cons: The primary limitation is its weight, which can be a disadvantage in mobile applications. Additionally, cast iron is prone to corrosion if not properly coated, which may necessitate additional maintenance.

For international buyers, compliance with standards such as ASTM A48 for cast iron is crucial. Buyers in regions like Europe may prefer cast iron due to its availability and established manufacturing practices.

What Are the Advantages of Aluminum in Piston Pumps?

Aluminum is increasingly popular in piston pump manufacturing due to its lightweight nature and good corrosion resistance. With a temperature rating of around 150°C and pressure capabilities of up to 250 bar, aluminum pumps are ideal for applications requiring mobility and efficiency.

Pros: The lightweight nature of aluminum reduces the overall weight of the pump, making it suitable for portable applications. Its corrosion resistance minimizes maintenance needs, especially in harsh environments.

Cons: Aluminum is generally more expensive than cast iron and may not withstand extreme pressures as well. Additionally, its lower strength compared to steel can limit its use in high-load applications.

For buyers in regions like Africa and South America, where portability is often a key consideration, aluminum pumps can offer significant advantages. Compliance with standards such as ISO 9001 for quality assurance is also important.

How Does Stainless Steel Compare for Piston Pump Use?

Stainless steel is favored for its exceptional corrosion resistance and strength, making it suitable for harsh environments and applications involving aggressive fluids. It typically operates at temperatures up to 400°C and can handle pressures exceeding 300 bar.

Pros: The durability and corrosion resistance of stainless steel make it ideal for food processing, pharmaceuticals, and other sensitive applications. Its strength also allows for compact designs.

Cons: The primary drawback is the high cost of stainless steel, which can significantly increase manufacturing expenses. Additionally, the complexity of machining stainless steel can lead to longer production times.

International buyers, particularly in the Middle East and Europe, often prefer stainless steel for its compliance with stringent hygiene and safety standards, such as FDA regulations and EN 10088 for stainless steel grades.

What Role Do Composite Materials Play in Piston Pump Manufacturing?

Composite materials, including reinforced plastics and carbon-fiber composites, are emerging as alternatives in piston pump design. They offer excellent corrosion resistance and can operate at temperatures up to 120°C with pressure ratings around 150 bar.

Pros: Composites are lightweight and can be molded into complex shapes, allowing for innovative designs. Their resistance to corrosion and chemicals makes them suitable for various applications.

Cons: The main limitation is their relatively low temperature and pressure ratings compared to metals. Additionally, the manufacturing process can be more complex and costly.

For international buyers, particularly in Europe, compliance with environmental regulations regarding composite materials is essential. The growing trend towards sustainability makes composites an attractive option for eco-conscious manufacturers.

Summary Table of Material Selection for Piston Pump Manufacturers

| Material | Typical Use Case for Piston Pump Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Heavy-duty industrial applications | Durable and cost-effective | Heavy and prone to corrosion | Low |

| Aluminum | Portable hydraulic systems | Lightweight and corrosion-resistant | Higher cost and lower strength | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional corrosion resistance | High cost and complex machining | High |

| Composite Materials | Innovative designs in various applications | Lightweight and moldable | Lower temperature and pressure ratings | Medium |

This analysis provides valuable insights for B2B buyers in selecting the right materials for piston pumps, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for Piston Pump Manufacturers

What Are the Key Stages in the Manufacturing Process of Piston Pumps?

The manufacturing process of piston pumps is intricate and involves several critical stages designed to ensure optimal performance and reliability. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing of piston pumps is material preparation. High-quality materials such as steel, aluminum, and specialized alloys are sourced, ensuring they meet the required specifications for strength and durability. Advanced manufacturers often conduct material testing to verify properties such as tensile strength and corrosion resistance. This step is crucial, as the materials must withstand high pressures and harsh operating conditions.

What Techniques Are Used in the Forming Stage?

Once materials are prepared, the forming stage begins. This phase often employs techniques such as machining, forging, and casting.

- Machining involves precision processes like turning, milling, and grinding to create the exact dimensions required for each component, such as the cylinder block and pistons.

- Forging is used to shape metals into desired forms while enhancing their strength through deformation.

- Casting may be utilized for complex shapes that cannot be easily machined.

These techniques ensure that each part of the piston pump meets strict dimensional tolerances and performance specifications.

How Are Piston Pumps Assembled?

The assembly stage is where individual components come together to form the complete piston pump. This process requires skilled labor and specialized equipment to ensure precision.

Key considerations during assembly include:

- Alignment: Ensuring that all moving parts are aligned correctly to prevent wear and tear.

- Sealing: Implementing effective sealing solutions to prevent hydraulic fluid leaks.

- Integration of Control Systems: For variable displacement pumps, integrating electronic control systems is essential for performance optimization.

Highly automated assembly lines may be used to enhance efficiency while maintaining quality standards.

What Finishing Processes Are Essential for Piston Pumps?

After assembly, finishing processes such as surface treatment and quality inspection are performed. Surface treatments, including anodizing and coating, are applied to enhance corrosion resistance and reduce friction. This not only prolongs the life of the pump but also improves its efficiency.

What Quality Assurance Measures Are Implemented by Piston Pump Manufacturers?

Quality assurance is paramount in the manufacturing of piston pumps, as these components must operate reliably in demanding environments. Manufacturers adhere to various international and industry-specific standards to ensure product quality.

Which International Standards Are Relevant for Piston Pump Quality Assurance?

ISO 9001 is one of the most recognized standards for quality management systems globally. Compliance with ISO 9001 ensures that manufacturers have a systematic approach to managing their processes, leading to consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications are critical. These certifications demonstrate that the products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage inspects raw materials and components upon arrival to ensure they meet specifications before manufacturing begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues in real-time.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products ensure that they meet all specified standards and performance criteria before shipment.

What Testing Methods Are Commonly Used for Piston Pumps?

Various testing methods are employed to verify the functionality and reliability of piston pumps. Common tests include:

- Hydraulic Testing: Pumps are subjected to high-pressure conditions to ensure they can operate effectively under specified loads.

- Performance Testing: This involves measuring flow rates, pressure outputs, and efficiency to confirm that the pump meets performance specifications.

- Durability Testing: Simulating long-term operational conditions helps assess the wear and tear of components over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to ensure that their suppliers maintain high-quality standards. Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices.

Buyers should request:

- Quality Management System Documentation: This includes certifications, process maps, and quality manuals.

- Inspection and Testing Reports: Reviewing these reports can confirm that the supplier adheres to required standards and conducts thorough testing.

- Third-Party Inspection Reports: Engaging independent inspectors can provide an unbiased assessment of the supplier’s quality practices.

What Are the Quality Control Considerations for International Buyers?

For international buyers, understanding regional quality standards and certifications is crucial. Different markets may have specific requirements regarding materials, safety, and performance.

For example, buyers from Germany may prioritize TÜV certifications, while those in Saudi Arabia might focus on local compliance standards. It’s essential for buyers to communicate their specific requirements clearly and ensure that suppliers can meet these standards.

In conclusion, the manufacturing processes and quality assurance measures for piston pumps are integral to delivering reliable, high-performance products. B2B buyers should carefully evaluate suppliers based on their adherence to international standards and robust quality control practices to ensure they receive products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Piston Pump Manufacturers’

Introduction

Sourcing piston pumps for industrial applications requires a strategic approach to ensure you select the right manufacturer that meets your specific needs. This checklist serves as a practical guide for B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process, minimize risks, and enhance operational efficiency.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential for effective sourcing. This includes understanding the type of piston pump needed—whether axial or radial—along with specifications such as pressure ratings, flow rates, and power sources.

– Consider application needs: Different industries may require pumps with specific capabilities, such as variable displacement for energy efficiency.

– Identify compatibility: Ensure that the chosen pump can integrate seamlessly with your existing hydraulic systems.

Step 2: Research and Shortlist Potential Manufacturers

Conduct thorough research to identify manufacturers with a strong reputation in the industry. Look for companies with a proven track record in producing high-performance piston pumps.

– Utilize online directories and trade platforms: Websites and industry-specific platforms can provide valuable insights and reviews.

– Examine case studies: Focus on manufacturers that have successfully delivered solutions in your industry or similar applications.

Step 3: Evaluate Supplier Certifications and Standards

Verify that potential suppliers adhere to relevant industry standards and possess necessary certifications. This is crucial for ensuring product quality and compliance with safety regulations.

– Look for ISO certifications: ISO 9001 certification indicates a commitment to quality management systems.

– Check compliance with industry standards: Depending on your industry, certifications such as API or ASME may be essential.

Step 4: Request Detailed Product Information

Engage with shortlisted manufacturers to obtain comprehensive product information. This should include technical datasheets, performance curves, and warranty details.

– Analyze product specifications: Ensure the products meet your defined technical requirements.

– Inquire about after-sales support: Understand the level of technical support, maintenance services, and warranty options offered.

Step 5: Assess Manufacturing Capabilities and Lead Times

Understanding a manufacturer’s production capacity and lead times is vital for planning your projects effectively. This will help you align procurement with your operational timelines.

– Inquire about production processes: Assess whether the manufacturer uses advanced technology and quality control measures.

– Request lead time estimates: Ensure that the delivery timelines align with your project schedules.

Step 6: Negotiate Pricing and Terms of Sale

Once you have identified a suitable manufacturer, proceed to negotiate pricing and terms. This is a critical step that can significantly impact your overall procurement budget.

– Consider total cost of ownership: Evaluate factors such as maintenance costs, energy efficiency, and potential downtime.

– Discuss payment terms: Ensure that the payment structure is favorable and aligns with your cash flow needs.

Step 7: Conduct Final Evaluations and Make a Decision

Before finalizing your purchase, conduct a final evaluation of your top choices. This may include site visits, discussions with current customers, and reviewing contracts thoroughly.

– Verify references: Speak with other clients to gauge their satisfaction with the manufacturer’s products and services.

– Review all contractual obligations: Ensure that all terms are clearly defined to avoid future disputes.

By following this checklist, you can effectively navigate the complex landscape of sourcing piston pumps, ensuring that your procurement process is both efficient and aligned with your operational goals.

Comprehensive Cost and Pricing Analysis for Piston Pump Manufacturers Sourcing

What Are the Key Cost Components for Piston Pump Manufacturing?

When sourcing piston pumps, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel, aluminum alloys, and specialized composites are common in piston pump production. Premium materials enhance durability and performance, but they also increase costs.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Skilled labor is often required for assembly, welding, and quality control, especially in markets like Germany, where precision engineering is paramount.

-

Manufacturing Overhead: This includes the costs associated with running the factory, such as utilities, rent, and equipment maintenance. Manufacturers often pass these costs onto buyers, making it crucial to consider overhead when evaluating suppliers.

-

Tooling: Custom tooling for specific piston pump designs can be a significant upfront investment. This cost varies depending on the complexity of the pump design and can affect lead times.

-

Quality Control (QC): Implementing rigorous QC processes is essential for ensuring product reliability. Costs associated with testing and certification can add to the overall price but are critical for industries that demand high standards, such as aerospace and defense.

-

Logistics: Transportation costs, especially for international shipments, can fluctuate based on distance, shipping method, and customs duties. Incoterms play a vital role in determining who bears these costs.

-

Margin: Manufacturers will typically add a margin to their pricing to ensure profitability. This can vary widely depending on the manufacturer’s position in the market and their operational efficiency.

How Do Price Influencers Impact Piston Pump Costs?

Several factors influence the pricing of piston pumps, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced unit costs. Manufacturers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized pumps tailored to specific applications can significantly raise prices. Buyers should weigh the need for custom features against potential cost savings from standard models.

-

Materials and Quality Certifications: The use of high-grade materials and compliance with international quality standards (ISO, CE, etc.) can increase costs. Buyers should assess whether the certifications are necessary for their application to avoid paying for unnecessary features.

-

Supplier Factors: The reputation and reliability of the manufacturer can also impact pricing. Established manufacturers may charge a premium due to their proven track record, while lesser-known suppliers might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms can help buyers negotiate better deals and avoid unexpected expenses.

What Buyer Tips Can Enhance Cost Efficiency in Piston Pump Sourcing?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a strong relationship can lead to better pricing and flexibility in terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost but also maintenance, operational efficiency, and potential downtime associated with the piston pumps. Investing in higher-quality pumps may yield long-term savings.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, and the Middle East should be aware of additional costs such as tariffs, taxes, and currency fluctuations that can impact overall pricing.

-

Research and Compare: Use platforms and resources to compare different manufacturers and their offerings. This will provide insights into market rates and help identify competitive pricing.

Disclaimer for Indicative Prices

Pricing for piston pumps can vary significantly based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers and conduct thorough market research to obtain the most accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing Piston Pump Manufacturers With Other Solutions

Understanding Alternative Solutions to Piston Pump Manufacturers

When selecting hydraulic systems for industrial applications, it is essential to consider a range of options that can meet the specific needs of your operations. Piston pump manufacturers provide robust solutions for high-pressure applications, but other technologies may offer advantages depending on the context. Below, we compare piston pumps with alternative hydraulic solutions to help B2B buyers make informed decisions.

| Comparison Aspect | Piston Pump Manufacturers | Gear Pump | Diaphragm Pump |

|---|---|---|---|

| Performance | High efficiency, variable displacement; suitable for high-pressure applications | Good for low to moderate pressures; consistent flow | Limited to lower pressures; excellent for corrosive fluids |

| Cost | Generally higher upfront costs; long-term savings through efficiency | Lower initial investment; less energy-efficient | Moderate cost; economical for specific applications |

| Ease of Implementation | Requires precise installation and integration with hydraulic systems | Easier to install; fewer components | Simple installation; flexible mounting options |

| Maintenance | Requires regular maintenance; parts can be expensive | Generally low maintenance; fewer moving parts | Low maintenance; parts are often replaceable |

| Best Use Case | Heavy machinery, construction, aerospace, and manufacturing | Automotive applications, hydraulic lifts, and conveyor systems | Chemical processing, food and beverage, and wastewater treatment |

What Are the Advantages and Disadvantages of Gear Pumps?

Gear pumps are often a popular alternative to piston pumps, particularly for applications that require consistent flow at lower pressures. They are simpler in design, featuring fewer moving parts, which results in lower maintenance costs. However, their efficiency diminishes at higher pressures, making them less suitable for heavy-duty applications. Buyers should consider gear pumps for automotive or hydraulic lift systems where high pressure is not a critical requirement.

How Do Diaphragm Pumps Compare to Piston Pumps?

Diaphragm pumps offer a unique solution for applications involving corrosive or sensitive materials, such as in the chemical or food processing industries. Their design allows them to handle a wide range of fluids without contamination. While they are easier to install and maintain, diaphragm pumps generally operate at lower pressures compared to piston pumps. This makes them less versatile for heavy-duty applications but an excellent choice for specific use cases where fluid integrity is paramount.

How Can B2B Buyers Choose the Right Hydraulic Solution?

Selecting the right hydraulic solution requires a thorough understanding of your operational needs, including pressure requirements, fluid types, and maintenance capabilities. B2B buyers should evaluate the total cost of ownership, including installation and ongoing maintenance expenses, alongside initial purchase costs. By carefully assessing the specific demands of their applications, buyers can choose between piston pumps and alternative technologies such as gear or diaphragm pumps to optimize performance and efficiency. Ultimately, the right choice will depend on balancing performance needs with cost-effectiveness and ease of maintenance.

Essential Technical Properties and Trade Terminology for Piston Pump Manufacturers

What Are the Key Technical Properties of Piston Pumps for Manufacturers?

Understanding the critical specifications of piston pumps is essential for B2B buyers looking to make informed decisions. Here are several key technical properties that should be considered:

-

Displacement

Displacement refers to the volume of fluid that the pump can move per cycle, typically measured in cubic centimeters (cc) or liters. This specification is crucial as it directly impacts the pump’s efficiency and performance in various applications. Buyers need to assess the required displacement to ensure that the pump can handle the specific workload and pressure requirements of their systems. -

Pressure Rating

The pressure rating indicates the maximum pressure the pump can safely operate under, usually expressed in pounds per square inch (PSI) or bar. This property is vital for applications that demand high pressure, such as in construction equipment or hydraulic machinery. Selecting a pump with an appropriate pressure rating ensures reliability and reduces the risk of equipment failure. -

Material Grade

The material grade of components, such as the pump casing and pistons, affects durability and resistance to wear and corrosion. Common materials include aluminum, cast iron, and high-grade steel. For B2B buyers, understanding material specifications helps in selecting pumps that will withstand harsh operational environments, thereby extending the equipment’s lifespan. -

Efficiency

Efficiency is a measure of how well the pump converts input energy into hydraulic energy, often expressed as a percentage. High-efficiency pumps minimize energy consumption and operational costs, making them more appealing for long-term investment. Buyers should prioritize efficiency ratings to optimize their hydraulic systems. -

Mounting Options

The design and availability of various mounting options (e.g., flanged, foot-mounted) are important for installation flexibility. Compatibility with existing systems can save time and costs associated with retrofitting. Buyers must consider these options to ensure seamless integration into their machinery. -

Flow Rate

Flow rate measures how much fluid the pump can deliver in a given time, typically in liters per minute (L/min) or gallons per minute (GPM). This property is essential for matching the pump’s output to the demands of specific applications, ensuring that machinery operates efficiently without delays.

Which Trade Terms Should Piston Pump Manufacturers Know?

Navigating the technical landscape of piston pumps also involves understanding key trade terminology. Here are several important terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, working with OEMs ensures the quality and compatibility of components, which is critical for maintaining system integrity. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs helps buyers plan their purchasing strategies and manage inventory effectively, ensuring they meet production demands without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific products or services. It is an essential tool for buyers to gauge market pricing and supplier capabilities, enabling them to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and insurance obligations, ensuring smoother international transactions. -

Hydraulic Circuit

A hydraulic circuit refers to the interconnected components in a hydraulic system that work together to transmit power. Understanding hydraulic circuits is crucial for buyers to ensure compatibility and efficiency in their applications. -

Closed Center System

This term describes a hydraulic system where the pump maintains a constant pressure, and flow is directed to the actuator only when needed. Recognizing the differences between closed and open systems helps buyers select the right pump configuration for their operational needs.

By understanding these technical properties and trade terms, B2B buyers can better navigate the complexities of purchasing piston pumps, ensuring they choose the right equipment for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the Piston Pump Manufacturers Sector

What Are the Key Market Dynamics and Trends Influencing Piston Pump Manufacturers?

The global market for piston pumps is witnessing robust growth driven by several key factors. As industries across Africa, South America, the Middle East, and Europe continue to expand, the demand for efficient hydraulic solutions is on the rise. Heavy-duty machinery in construction, agriculture, and manufacturing sectors heavily relies on piston pumps for enhanced operational efficiency. The increasing focus on automation and advanced manufacturing technologies is further propelling the adoption of hydraulic systems, making piston pumps integral to modern industrial applications.

Emerging technologies such as IoT and AI are shaping the way piston pumps are sourced and integrated into systems. Predictive maintenance powered by IoT allows manufacturers to monitor pump performance in real-time, reducing downtime and maintenance costs. Additionally, the shift towards variable displacement pumps is gaining traction, as these systems offer better energy efficiency and adaptability to varying workload demands, enhancing overall system performance.

Furthermore, international B2B buyers should be aware of regional market dynamics. In Europe, stringent regulations regarding energy efficiency and emissions are pushing manufacturers to innovate and adopt greener technologies. Conversely, in emerging markets, the focus is often on cost-effective solutions that do not compromise on performance. Understanding these regional nuances is critical for buyers looking to source piston pumps effectively.

How Is Sustainability Shaping the Sourcing of Piston Pumps?

Sustainability has become a cornerstone of sourcing strategies in the piston pump manufacturing sector. The environmental impact of hydraulic systems, particularly in energy consumption and waste generation, is prompting manufacturers to adopt greener practices. International buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 or adherence to eco-friendly materials.

Moreover, the demand for ethically sourced materials is rising. Buyers should evaluate the supply chain for transparency, ensuring that materials used in piston pumps are sourced responsibly, with minimal environmental impact. This includes assessing the lifecycle of products and the possibility of recycling or reusing components to reduce waste.

The adoption of ‘green’ technologies, such as pumps designed for lower energy consumption and reduced noise levels, is also becoming a key consideration for B2B buyers. By aligning sourcing decisions with sustainability goals, companies can not only comply with regulations but also enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of Piston Pump Development in the B2B Sector?

The evolution of piston pumps dates back to the early 20th century, primarily driven by the demands of the burgeoning industrial sector. Initially developed for basic hydraulic applications, these pumps have undergone significant advancements in design and technology. The introduction of variable displacement pumps in the 1960s marked a pivotal moment, allowing for more efficient energy use and better adaptability to varying operational conditions.

As industries evolved, so did the complexity and capabilities of piston pumps. Innovations such as load-sensing technology and electronic displacement control have transformed these pumps into sophisticated components essential for modern machinery. Today, piston pumps are recognized not just for their functionality but also for their role in enhancing productivity and efficiency across diverse sectors, making them a vital consideration for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of Piston Pump Manufacturers

-

1. How do I select the right piston pump for my application?

Selecting the appropriate piston pump requires a thorough understanding of your specific application needs. Consider the required pressure ratings, flow rates, and the type of hydraulic system you are using (open or closed center). Assess whether you need a fixed or variable displacement pump based on efficiency requirements. Additionally, evaluate the pump’s compatibility with existing equipment, including dimensions and mounting options. Consulting with manufacturers can provide insights into the best configurations for your operational demands. -

2. What factors should I consider when vetting piston pump manufacturers?

When vetting piston pump manufacturers, prioritize their industry experience, reputation, and certifications. Review their product range to ensure they offer the specific type of piston pump you need. Investigate customer reviews and testimonials to gauge satisfaction levels. Furthermore, inquire about their manufacturing processes, quality assurance protocols, and after-sales support. A strong partnership with a reliable supplier can significantly impact your operational efficiency and maintenance costs. -

3. What are common customization options available for piston pumps?

Most piston pump manufacturers offer various customization options to meet specific operational requirements. Customizations may include alterations in displacement size, pressure ratings, and mounting configurations. You may also request specific materials for enhanced durability or modifications for unique hydraulic circuit integrations. Discussing your requirements with manufacturers can lead to tailored solutions that improve performance and efficiency in your applications. -

4. What is the typical minimum order quantity (MOQ) for piston pumps?

Minimum order quantities for piston pumps can vary significantly among manufacturers and depend on the complexity and customization of the product. Generally, MOQs can range from a few units to several dozen, especially for specialized or custom-designed pumps. It is crucial to discuss your needs directly with manufacturers to determine their specific MOQ policies and whether they can accommodate smaller orders or trial runs for new customers. -

5. What payment terms should I expect when sourcing piston pumps internationally?

Payment terms can differ widely based on the manufacturer and the buyer’s relationship. Common terms include full payment upfront, partial payment with the balance upon delivery, or payment within a specific period post-delivery (e.g., Net 30 or Net 60). Always clarify payment options, including acceptable methods (e.g., bank transfers, letters of credit) and any potential fees associated with international transactions. Establishing clear payment agreements upfront can prevent misunderstandings later in the procurement process. -

6. How do I ensure the quality of piston pumps before purchasing?

Ensuring the quality of piston pumps involves several steps. Request product certifications and compliance documentation to confirm adherence to international standards. Review the manufacturer’s quality assurance processes, including testing and inspection procedures. If possible, request samples or visit the manufacturing facility to assess production practices firsthand. Additionally, consider seeking third-party inspections or audits for added assurance of quality before making a bulk purchase. -

7. What logistics considerations should I keep in mind when importing piston pumps?

Logistics is crucial when importing piston pumps, particularly regarding shipping methods, timelines, and costs. Evaluate the manufacturer’s shipping options and whether they provide support for customs clearance. Consider the potential impact of tariffs, duties, and taxes on your total costs. Additionally, assess the reliability of shipping partners and their track record with international deliveries to minimize delays or damages during transit. -

8. How can I establish a long-term relationship with a piston pump manufacturer?

Building a long-term relationship with a piston pump manufacturer involves consistent communication and mutual understanding. Start by clearly articulating your needs and expectations, which helps manufacturers tailor their offerings. Regularly provide feedback on product performance and service quality. Engage in joint planning sessions for future projects and consider collaborating on innovations or improvements. Establishing trust and transparency will foster a productive partnership that can adapt to your evolving business requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Piston Pump Manufacturers

In summary, strategic sourcing in the piston pump manufacturing sector is essential for B2B buyers aiming to enhance operational efficiency and reduce costs. The diversity of hydraulic piston pumps, including axial and radial types, offers a range of solutions tailored to various industrial applications, from construction to aerospace. By focusing on key criteria such as pump efficiency, compatibility with existing systems, and the ability to adapt to specific operational demands, buyers can make informed decisions that drive productivity and performance.

As international markets continue to evolve, particularly in Africa, South America, the Middle East, and Europe, the emphasis on quality and reliability in hydraulic solutions will only intensify. Engaging with reputable manufacturers and suppliers who prioritize innovation and customer service can significantly impact the success of your projects.

Looking ahead, B2B buyers are encouraged to leverage strategic sourcing as a pathway to future-proof their operations. By aligning with trusted piston pump manufacturers, you can ensure your equipment meets the rigorous demands of your industry while also embracing advancements in technology. Take action now to explore partnerships that will elevate your operational capabilities and drive sustainable growth in your business.