Top 8 Custom Glass Bottle Manufacturers List and Guide: How To So…

Introduction: Navigating the Global Market for Custom Glass Bottle Manufacturers

In today’s competitive landscape, sourcing custom glass bottle manufacturers presents unique challenges for international B2B buyers. With a myriad of options available, businesses must navigate complexities such as varying designs, material quality, production capabilities, and regulatory compliance across different regions. This guide aims to simplify the process by providing a comprehensive overview of custom glass bottle manufacturing, addressing key factors like types of bottles, their applications, supplier vetting strategies, and cost considerations.

Whether you’re in the beverage industry in South America, the cosmetics sector in Europe, or food packaging in the Middle East, understanding the nuances of sourcing custom glass bottles is crucial for enhancing your product offerings. This guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—by equipping them with actionable insights to make informed purchasing decisions.

From exploring innovative designs to assessing eco-friendly options, this resource is designed to help you identify reliable suppliers that align with your business goals. By leveraging the information within, you can ensure that your choice of glass packaging not only elevates your brand but also meets the increasing consumer demand for sustainable and aesthetically pleasing products.

Top 10 Custom Glass Bottle Manufacturers Manufacturers & Suppliers List

1. Glassnow – European-Inspired Glass Bottles

Domain: glassnow.com

Registered: 1997 (28 years)

Introduction: Glassnow offers a variety of glass bottles designed with European influences, available in multiple sizes, shapes, colors, and styles. The product range includes cork finish glass bottles, threaded finish glass bottles, dropper bottles, and glass tubes. Key features include eco-friendly options made from 100% recycled glass, BPA-free materials, and the ability to customize with screen printing and…

2. TricorBraun – Wholesale Glass Bottles & Jars

Domain: tricorbraun.com

Registered: 1998 (27 years)

Introduction: Wholesale & Bulk Glass Bottles and Jars available at TricorBraun. Product categories include: Glass Bottles (Beer Bottles & Growlers, Boston Round Glass Bottles, Glass Dropper Bottles, Glass Liquor & Spirit Bottles, Glass Packer Bottles, Glass Sauce Bottles), Glass Jars (Glass Candle Jars, Glass Canning Jars, Glass Spice Jars, Glass Straight Sided Jars, Glass Wide Mouth Jars), Glass Carboys & Jugs…

3. ESTAL – Custom Glass Bottles

Domain: estal.com

Registered: 2002 (23 years)

Introduction: ESTAL specializes in the design and manufacture of custom glass bottles, emphasizing premium packaging made from 100% recyclable glass. Their product offerings include various collections such as Wildly Crafted Spirits, Wild Glass (100% Post Consumer Recycled Glass), Rude Collection (100% Post Consumer Recycled Glass for Spirits), Prima Collection (100% Post Consumer Recycled Glass for Wines), Bub…

4. Custom Glass Bottles – Cost Analysis

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom glass bottle design, approximately 50 cl in size. Estimated manufacturing cost for 1000 bottles in the US is around $10-15 per bottle, with a mold cost of no less than $5,000. In China, mold costs could be under $1,000, with bottle costs ranging from $2-5. Considerations for material change to hard plastic include higher non-recurring engineering (NRE) costs but lower part costs, with poten…

5. Imperial Packaging – Spirits Bottles

Domain: imperial-packaging.com

Registered: 2005 (20 years)

Introduction: Spirits Bottles available in various sizes and designs, sourced from high-quality manufacturers. Key products include:

– Amsterdam 750 ml: Rectangle Base/Oval Shoulder, Flint, Bar Top, Glass

– Antica Farmacia: 1 L, 200 ml, 500 ml, 750 ml – all Round, Flint, Bar Top, Glass

– Arizona: 1.75 L, 1 L, 375 ml, 50 ml, 700 ml, 750 ml – all Round, Flint, Bar Top, Glass

– Atlanta: 350 ml, 500 ml, 700 ml,…

6. Rockwood Glass – Custom Glass Bottles

Domain: custom-glass-bottle.com

Registered: 2023 (2 years)

Introduction: Rockwood Glass specializes in custom glass bottle manufacturing, producing over 500 million classic and exclusive bottles annually for premium brands in the spirits and beverages sector. Their extensive range of glass bottles includes:

– Vodka bottles

– Gin bottles

– Brandy, Cognac, and Whisky bottles

– Rum bottles

– Tequila bottles

– Mezcal bottles

– Water and beverage bottles

– Decanters

– Eccen…

7. Burch Bottle – Custom Glass Options

8. Berlin Packaging – Wholesale Glass Bottles

Domain: berlinpackaging.com

Registered: 1997 (28 years)

Introduction: Berlin Packaging offers wholesale glass bottles ranging from 5 ml to 1-gallon sizes in colors such as amber, green, and cobalt blue. Available shapes include Boston round, oval, growlers, and wine bottles. The company provides additional services like label design and warehouse storage, and manages the supply chain, including tracking delivery and ensuring product quality.

Understanding Custom Glass Bottle Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Glass Bottles | Wide range of sizes and shapes, often mass-produced | Food and beverage, cosmetics, cleaning | Pros: Cost-effective, readily available. Cons: Limited customization options. |

| Custom-Molded Glass Bottles | Unique designs tailored to brand specifications | High-end beverages, luxury products | Pros: Brand differentiation, tailored aesthetics. Cons: Higher production costs, longer lead times. |

| Recycled Glass Bottles | Made from post-consumer glass, eco-friendly | Sustainable brands, organic products | Pros: Eco-friendly, enhances brand image. Cons: May have variable quality, limited design options. |

| Specialty Glass Bottles | Designed for specific uses (e.g., UV protection, airtight) | Pharmaceuticals, specialty foods | Pros: Enhanced functionality, tailored performance. Cons: Often more expensive, niche market. |

| Decorative Glass Bottles | Aesthetic focus with unique shapes and colors | Gift items, home décor, artisan products | Pros: Eye-catching, great for branding. Cons: May not be practical for all applications, higher costs. |

What Are the Characteristics of Standard Glass Bottles?

Standard glass bottles are typically mass-produced in various sizes and shapes, making them widely available and cost-effective for businesses. These bottles often come with standard neck finishes, such as 28mm or 43mm, allowing for easy compatibility with common closures. B2B buyers in industries like food and beverage or cleaning products often prefer these bottles for their affordability and quick turnaround times. However, buyers should note that the customization options may be limited, which can affect branding efforts.

How Do Custom-Molded Glass Bottles Stand Out?

Custom-molded glass bottles are crafted specifically to meet the unique branding requirements of a company. This type of manufacturing allows businesses to create distinctive shapes and designs that can enhance product visibility on shelves. Suitable for high-end beverages and luxury products, these bottles offer significant brand differentiation. However, B2B buyers should consider the higher production costs and longer lead times associated with custom molds, which may impact inventory management.

What Are the Benefits of Using Recycled Glass Bottles?

Recycled glass bottles are made from post-consumer materials, making them an excellent choice for brands focusing on sustainability. These bottles appeal to environmentally conscious consumers and can enhance a brand’s image as eco-friendly. They are commonly used in organic products and sustainable brands. However, buyers should be aware that recycled glass may come with variable quality and limited design options, which can influence consumer perception.

What Makes Specialty Glass Bottles Unique?

Specialty glass bottles are designed for specific applications, such as providing UV protection or airtight seals. This makes them ideal for pharmaceuticals and specialty foods where product integrity is crucial. B2B buyers should consider the enhanced functionality these bottles offer, as well as their tailored performance for niche markets. However, the costs associated with specialty bottles tend to be higher, which may not be feasible for all businesses.

Why Choose Decorative Glass Bottles for Branding?

Decorative glass bottles are characterized by their unique shapes and vibrant colors, making them perfect for gift items and artisan products. These bottles can significantly enhance brand appeal and consumer attraction due to their aesthetic focus. While they are great for branding, B2B buyers should weigh their practicality against higher costs and limited functionality in certain applications.

Key Industrial Applications of Custom Glass Bottle Manufacturers

| Industry/Sector | Specific Application of Custom Glass Bottle Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom bottles for sauces, dressings, and beverages | Enhances product appeal and preserves freshness | Compliance with food safety regulations; sustainable sourcing options |

| Cosmetics and Personal Care | Glass containers for skincare and grooming products | Elevates brand perception and customer experience | Variety of designs and sizes; compatibility with various closures |

| Pharmaceuticals | Bottles for liquid medicines and supplements | Ensures product integrity and safety | Compliance with pharmaceutical regulations; tamper-evident features |

| Home and Garden | Bottles for essential oils and home fragrance products | Differentiates products in a competitive market | Customization options for branding; resistance to chemical reactions |

| Craft Brewing and Distilling | Custom liquor and beer bottles | Attracts consumers and enhances brand identity | Unique design capabilities; options for eco-friendly materials |

How are Custom Glass Bottle Manufacturers Used in the Food and Beverage Industry?

Custom glass bottles are pivotal in the food and beverage sector, specifically for sauces, dressings, and beverages. These bottles not only enhance the visual appeal of products but also preserve the freshness and flavor integrity of the contents. B2B buyers in this sector should prioritize compliance with food safety regulations and explore sustainable sourcing options, as eco-friendly packaging is increasingly demanded by consumers.

What Role Do Custom Glass Bottles Play in Cosmetics and Personal Care?

In the cosmetics and personal care industry, custom glass containers serve as a premium packaging solution for skincare and grooming products. These bottles elevate brand perception and enhance the overall customer experience. Buyers should seek manufacturers that offer a variety of designs and sizes, ensuring compatibility with various closures to meet their specific product requirements.

Why Are Custom Glass Bottles Essential for the Pharmaceutical Sector?

Custom glass bottles are crucial for the pharmaceutical industry, particularly for liquid medicines and supplements. They ensure product integrity and safety, which are paramount in this sector. International B2B buyers must consider compliance with stringent pharmaceutical regulations and look for features like tamper-evident closures to guarantee consumer safety.

How Do Custom Glass Bottles Enhance Home and Garden Products?

In the home and garden sector, custom bottles are often used for essential oils and home fragrance products. These glass containers help differentiate products in a competitive market and provide a superior aesthetic appeal. Buyers should focus on customization options for branding, as well as the bottles’ resistance to chemical reactions, which is essential for maintaining product quality.

What Benefits Do Custom Glass Bottles Offer to Craft Brewing and Distilling?

Custom glass bottles play a significant role in the craft brewing and distilling industry. They not only attract consumers with unique designs but also enhance brand identity. B2B buyers should consider manufacturers that offer unique design capabilities and options for eco-friendly materials, as sustainability is becoming a key factor in consumer purchasing decisions.

3 Common User Pain Points for ‘Custom Glass Bottle Manufacturers’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs

The Problem: B2B buyers often face challenges when trying to communicate their specific requirements for custom glass bottles. This includes variations in size, shape, color, and design features that align with their branding. Miscommunication can lead to delays in production, increased costs, or receiving products that do not meet expectations. For instance, a cosmetics company may need a unique bottle shape that reflects its brand identity but struggles to convey these specifications to the manufacturer, resulting in prototypes that are far from the envisioned design.

The Solution: To mitigate this issue, buyers should invest time in thorough pre-production discussions with their chosen manufacturers. Start by preparing a detailed brief that includes sketches, samples of desired colors, and descriptions of the intended use of the bottles. Utilize 3D modeling tools or mock-ups to visualize the final product. Establish a clear line of communication with the manufacturer to discuss capabilities and limitations regarding customizations. Additionally, consider requesting samples of similar products to ensure that the manufacturer can deliver on quality and design standards before committing to a large order.

Scenario 2: Managing Supply Chain and Delivery Timelines

The Problem: Timely delivery of custom glass bottles is critical for B2B buyers, especially when launching new products or adhering to retail deadlines. However, many manufacturers face challenges in their supply chains due to raw material shortages, production delays, or logistical issues. This can result in extended lead times that jeopardize product launches, causing frustration and financial losses for buyers who rely on precise timing.

The Solution: To address this pain point, buyers should adopt a proactive approach to supply chain management by establishing strong relationships with their manufacturers. Begin by discussing potential lead times and any known risks associated with the production schedule. Implement a project management tool to track progress and set clear milestones for delivery. Additionally, consider diversifying suppliers to ensure backup options are available in case of unexpected delays. Regularly reviewing and adjusting inventory levels can also help mitigate the impact of delays on business operations.

Scenario 3: Ensuring Compliance with International Standards

The Problem: B2B buyers, particularly those operating across multiple regions, often struggle with compliance regarding packaging regulations and standards for glass products. Different countries have varying requirements for safety, labeling, and environmental impact, which can complicate sourcing efforts. A buyer in South America may find that their chosen manufacturer does not meet the EU regulations for food-safe packaging, leading to additional costs and time spent on rework or repackaging.

The Solution: To navigate compliance challenges, buyers must conduct thorough research into the regulations governing their target markets. Engage with manufacturers who are well-versed in international standards and can provide documentation proving compliance with local laws. Request certifications for safety and quality assurance, and don’t hesitate to ask for guidance on best practices for labeling and packaging. Establish a compliance checklist specific to each market, and consider working with a legal advisor specializing in international trade to ensure that all products meet the necessary standards before shipment. This proactive approach will not only save time and resources but also enhance the buyer’s reputation in their respective markets.

Strategic Material Selection Guide for Custom Glass Bottle Manufacturers

What Are the Key Materials Used in Custom Glass Bottle Manufacturing?

In the realm of custom glass bottle manufacturing, selecting the right material is crucial for ensuring product performance, safety, and marketability. Below, we analyze four common materials used in the industry, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Soda-Lime Glass

Key Properties: Soda-lime glass is the most commonly used type of glass for bottle manufacturing. It has a moderate temperature resistance (up to about 500°F) and good chemical resistance, making it suitable for various applications.

Pros & Cons: This material is relatively inexpensive and easy to manufacture, allowing for high-volume production. However, it is less durable than other types of glass, making it more susceptible to breakage. Additionally, its lower thermal shock resistance limits its use in applications involving extreme temperature changes.

Impact on Application: Soda-lime glass is compatible with a wide range of products, including beverages, cosmetics, and food items. However, it may not be suitable for products requiring high-pressure containment.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local regulations regarding food safety and packaging standards. Common standards include ASTM and DIN, which provide guidelines for material safety and performance.

2. Borosilicate Glass

Key Properties: Borosilicate glass is known for its high thermal resistance and low thermal expansion, allowing it to withstand extreme temperature changes without cracking.

Pros & Cons: The primary advantage of borosilicate glass is its durability and resistance to thermal shock, making it ideal for applications like laboratory bottles and food containers. However, it is more expensive to produce compared to soda-lime glass, which can impact overall project budgets.

Impact on Application: This type of glass is particularly well-suited for products that require high-temperature sterilization, such as food and beverage containers. Its chemical resistance also makes it compatible with acidic or alkaline substances.

Considerations for International Buyers: Buyers should be aware of specific certifications required for borosilicate glass in their regions, especially in Europe, where stringent regulations govern food safety and packaging materials.

3. Flint Glass

Key Properties: Flint glass is characterized by its clarity and brilliance, making it aesthetically appealing. It has good chemical resistance and can be produced in various colors.

Pros & Cons: The primary advantage of flint glass is its visual appeal, which enhances product presentation. However, it is more fragile than other types of glass, leading to higher breakage rates during transportation and handling.

Impact on Application: Flint glass is often used for premium products, such as high-end spirits and perfumes, where appearance is crucial. However, its lower durability may limit its use in more demanding applications.

Considerations for International Buyers: Buyers should consider the environmental impact of flint glass production and ensure that suppliers adhere to sustainability practices, particularly in regions where eco-friendly packaging is prioritized.

4. Colored Glass

Key Properties: Colored glass is created by adding metal oxides during the manufacturing process, resulting in a variety of hues. It provides UV protection, which can be beneficial for light-sensitive products.

Pros & Cons: The main advantage of colored glass is its ability to protect contents from UV degradation, making it ideal for products like oils and certain beverages. However, it can be more expensive and may complicate recycling processes.

Impact on Application: Colored glass is commonly used in the cosmetics and beverage industries, particularly for products that require light protection. Its aesthetic appeal can also enhance brand recognition.

Considerations for International Buyers: International buyers should be mindful of regulations regarding colored glass, especially in Europe, where certain pigments may be restricted. Compliance with local recycling laws is also essential.

Summary Table of Material Selection

| Material | Typical Use Case for Custom Glass Bottle Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Soda-Lime Glass | Beverages, cosmetics, food items | Cost-effective and easy to manufacture | Less durable, lower thermal shock resistance | Low |

| Borosilicate Glass | Laboratory bottles, high-temperature food containers | High thermal resistance and durability | More expensive to produce | High |

| Flint Glass | Premium spirits, perfumes | Aesthetically pleasing and clear | More fragile, higher breakage rates | Medium |

| Colored Glass | Cosmetics, UV-sensitive beverages | Provides UV protection and enhances branding | More expensive, complicates recycling processes | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions that align with their product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for Custom Glass Bottle Manufacturers

What Are the Key Stages in the Manufacturing Process of Custom Glass Bottles?

The manufacturing process for custom glass bottles is intricate and comprises several key stages. Each stage is crucial for ensuring that the final product meets both aesthetic and functional requirements.

Material Preparation: What Materials Are Used in Glass Bottle Manufacturing?

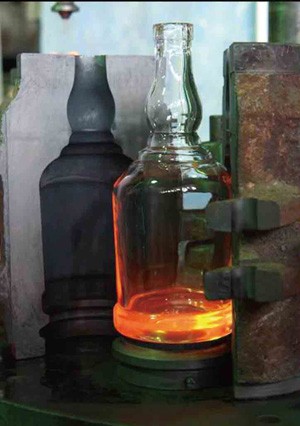

The first step in the manufacturing process involves preparing the raw materials. The primary components for glass bottles include silica sand, soda ash, and limestone. Depending on the desired characteristics of the glass, manufacturers may also incorporate recycled glass to enhance sustainability. The materials are mixed and melted in a furnace at high temperatures, typically around 1,700 degrees Celsius (3,092 degrees Fahrenheit), to create molten glass.

How Are Custom Glass Bottles Formed?

Once the glass is molten, it is ready for forming. This stage can be accomplished through various techniques, including:

- Blow Molding: Used for creating bottles with complex shapes. Air is blown into a pre-formed glass parison, allowing it to take the shape of the mold.

- Press Molding: This technique involves pressing molten glass into a mold, which is ideal for producing uniform bottles.

- Injection Molding: While less common for bottles, this method is used for specific designs that require high precision.

The choice of forming technique affects not only the appearance of the bottle but also its structural integrity and durability.

What Happens During the Assembly Stage of Glass Bottle Manufacturing?

After the bottles are formed, they undergo an assembly stage. This often involves adding components such as caps, labels, and other closures. Customization options, such as screen printing or embossing, are also applied during this stage, allowing brands to enhance their product’s visibility on shelves.

What Finishing Techniques Are Employed in Custom Glass Bottle Production?

Finishing processes are crucial for ensuring that the bottles meet quality standards. Techniques such as annealing are used to relieve internal stresses in the glass, enhancing its strength and thermal resistance. Additional finishing touches can include polishing, coating for UV protection, and applying decorative elements that align with brand identity.

What Quality Assurance Practices Are Essential in Custom Glass Bottle Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final product is safe, functional, and meets the specified design criteria.

Which International Standards Should B2B Buyers Be Aware Of?

Custom glass bottle manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific standards like CE marking for products sold in the European market and API standards for pharmaceutical packaging may apply. Understanding these standards is essential for B2B buyers to ensure compliance and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

The quality control (QC) process typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials before they enter production.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to ensure that the production methods are consistent and meet specified standards.

- Final Quality Control (FQC): Once the bottles are completed, a thorough inspection is conducted to check for defects in appearance, dimensions, and functionality.

These checkpoints are vital for identifying issues early in the production process, reducing waste, and ensuring product reliability.

What Common Testing Methods Are Used to Ensure Quality in Glass Bottles?

Testing methods may include:

- Visual Inspection: A manual check for defects such as cracks, bubbles, or irregularities in the glass.

- Dimensional Testing: Ensuring that the bottles meet specified measurements for compatibility with closures and labeling.

- Pressure Testing: For bottles intended to hold carbonated beverages, pressure testing ensures they can withstand internal pressure without failure.

- Chemical Resistance Testing: Essential for bottles used in food and pharmaceutical applications, this testing ensures that the glass does not react with its contents.

How Can B2B Buyers Verify the Quality Control Processes of Custom Glass Bottle Manufacturers?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate manufacturing practices, QA systems, and compliance with international standards.

- Requesting QC Reports: Suppliers should provide documentation of their quality control processes, including testing results and certifications.

- Third-Party Inspections: Engaging third-party inspectors can offer an unbiased assessment of the supplier’s manufacturing and quality assurance practices.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing custom glass bottles, international buyers must navigate various certification requirements based on their region. For example, products exported to Europe may require CE marking, while those intended for the U.S. market must comply with FDA regulations. Buyers from regions such as Africa and South America should also be aware of local standards and certifications that may impact their procurement process.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Critical for B2B Buyers?

For B2B buyers looking to procure custom glass bottles, a deep understanding of the manufacturing processes and quality assurance practices is vital. This knowledge not only helps ensure that products meet safety and quality standards but also fosters stronger supplier relationships and enhances brand reputation in the marketplace. By engaging with manufacturers that prioritize quality and sustainability, buyers can secure packaging solutions that align with their business goals and consumer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Custom Glass Bottle Manufacturers’

This guide provides a structured approach for B2B buyers looking to source custom glass bottle manufacturers. By following these actionable steps, you can ensure that you select the right partner to meet your specific needs and enhance your product offerings.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for custom glass bottles, including size, shape, color, and any specific design elements. This step is crucial as it sets the foundation for your sourcing process, ensuring that potential suppliers can meet your needs. Consider the end use of the bottles to determine features like neck finish and capacity.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in custom glass bottles. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential partners. Pay attention to their production capabilities, range of products, and market reputation, as this will help you narrow down your options.

Step 3: Verify Supplier Certifications

Ensure that the manufacturers you are considering have the necessary certifications for quality and safety standards. Look for certifications such as ISO 9001 for quality management and FDA approval for food-grade materials. These certifications indicate a commitment to maintaining high production standards and compliance with regulations.

Step 4: Evaluate Supplier Experience and Portfolio

Review the experience of potential suppliers in your industry. Request case studies or samples of previous work to assess their capabilities. A manufacturer with a proven track record in producing similar products is more likely to deliver satisfactory results, reducing the risk of costly errors or delays.

Step 5: Request Quotes and Compare Pricing

Obtain detailed quotes from shortlisted suppliers, ensuring that they include all costs associated with production, shipping, and any additional services. Comparing pricing is essential to identify the most cost-effective options, but also consider the value offered in terms of quality and service. Look for transparency in pricing to avoid hidden costs later.

Step 6: Assess Production Capacity and Lead Times

Inquire about the supplier’s production capacity and lead times to ensure they can meet your demand. Understanding their production capabilities will help you gauge whether they can handle your order volume and timelines. Ensure that the supplier can accommodate your needs, especially during peak seasons or promotional launches.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful partnership. Ensure that the manufacturer provides clear channels for support and communication throughout the sourcing process. Establishing a good rapport can lead to smoother transactions and the ability to address any issues that may arise during production.

By following these steps, you can effectively navigate the process of sourcing custom glass bottle manufacturers, ensuring that you find a partner that aligns with your business goals and product requirements.

Comprehensive Cost and Pricing Analysis for Custom Glass Bottle Manufacturers Sourcing

What Are the Key Cost Components in Custom Glass Bottle Manufacturing?

Understanding the cost structure of custom glass bottle manufacturing is essential for B2B buyers. The primary cost components include:

-

Materials: The type of glass used (e.g., recycled, soda-lime) significantly influences costs. Specialty glass, such as borosilicate, is generally more expensive due to its enhanced properties.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled artisans for custom designs may command higher wages, impacting overall production costs.

-

Manufacturing Overhead: This includes utilities, maintenance of machinery, and factory rent. Efficient manufacturing processes can reduce overhead costs, which is particularly important for bulk orders.

-

Tooling: Custom molds and tooling are significant initial investments. The cost can vary widely depending on the complexity and size of the bottle designs. High-quality molds may lead to better production efficiency and lower defect rates.

-

Quality Control (QC): Implementing rigorous QC processes ensures product consistency and adherence to safety standards, but it adds to the overall costs. Certifications (such as ISO or food safety standards) may also incur additional expenses.

-

Logistics: Shipping and handling costs can vary significantly based on the destination, weight, and volume of the order. Buyers should consider both domestic and international freight options.

-

Margin: Manufacturers typically add a margin to cover risks, market fluctuations, and profit. This can vary based on the supplier’s business model and market position.

How Do Price Influencers Affect Custom Glass Bottle Costs?

Several factors can influence the pricing of custom glass bottles:

-

Volume/MOQ: Bulk orders usually qualify for discounted pricing, whereas smaller orders may incur higher per-unit costs. Understanding a supplier’s minimum order quantity (MOQ) can help in negotiations.

-

Specifications and Customization: The level of customization, including size, color, and design intricacies, directly affects pricing. More complex designs or unique colors typically lead to higher costs.

-

Materials and Quality: The choice of materials impacts both the cost and the perceived quality of the final product. Higher-quality materials not only enhance product aesthetics but can also justify premium pricing.

-

Supplier Factors: The reputation and reliability of the manufacturer can influence costs. Established suppliers may charge more due to their proven track record, while newer companies may offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of delivery (such as FOB, CIF, etc.) is crucial. These terms dictate who is responsible for shipping costs and risks, which can significantly affect the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Conduct Comprehensive Market Research: Understand the average pricing for similar products in your target market. This knowledge empowers you during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, storage, and potential wastage costs. A lower upfront price may lead to higher long-term expenses.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet MOQs for better pricing. This approach can lead to significant savings.

-

Build Relationships with Suppliers: Establishing a good rapport with manufacturers can lead to better terms and pricing flexibility over time.

-

Stay Informed on Tariffs and Regulations: Changes in trade policies can affect costs. Staying updated allows for proactive adjustments to sourcing strategies.

Conclusion

While indicative prices for custom glass bottles can range widely based on the factors discussed, understanding the underlying cost structure and price influencers can significantly enhance your purchasing strategy. By leveraging these insights, B2B buyers can negotiate more effectively, ensuring they achieve the best possible value for their custom glass bottle needs.

Alternatives Analysis: Comparing Custom Glass Bottle Manufacturers With Other Solutions

Exploring Alternatives to Custom Glass Bottle Manufacturers

In the competitive landscape of packaging solutions, businesses often seek alternatives to custom glass bottle manufacturers. Understanding the pros and cons of various options can help B2B buyers make informed decisions tailored to their unique needs. Below, we compare custom glass bottle manufacturers with two viable alternatives: plastic bottle manufacturers and aluminum can suppliers.

| Comparison Aspect | Custom Glass Bottle Manufacturers | Plastic Bottle Manufacturers | Aluminum Can Suppliers |

|---|---|---|---|

| Performance | High durability, premium feel | Lightweight, versatile | Excellent preservation, recyclable |

| Cost | Higher initial investment | Generally lower cost | Moderate, depending on volume |

| Ease of Implementation | Moderate, requires design input | Easy, many stock options | Moderate, requires specific machinery |

| Maintenance | Low, long-lasting materials | Low, but can degrade over time | Low, corrosion-resistant |

| Best Use Case | High-end products, branding focus | Everyday consumer goods | Beverages, food products |

What Are the Pros and Cons of Plastic Bottle Manufacturers?

Plastic bottle manufacturers offer a lightweight and versatile alternative to glass. They are generally less expensive and easier to source, with many stock options available. However, they may not convey the same premium feel as glass and can be perceived as less environmentally friendly due to the use of petroleum-based materials. Additionally, while they are durable, they are prone to degradation over time, especially when exposed to heat or UV light, which can affect the quality of the contents.

How Do Aluminum Can Suppliers Compare to Glass Bottle Manufacturers?

Aluminum can suppliers provide a robust option for businesses, particularly in the beverage industry. They offer excellent preservation qualities, making them ideal for carbonated drinks. Aluminum cans are also fully recyclable, which appeals to environmentally conscious consumers. However, they may not be suitable for all products, especially those that benefit from the aesthetic qualities of glass. Additionally, the initial setup costs for canning lines can be significant, which may deter smaller businesses.

What Should B2B Buyers Consider When Choosing Packaging Solutions?

When selecting the right packaging solution, B2B buyers should evaluate their product type, target market, and budget. Custom glass bottles are ideal for high-end products that require a premium appearance and durability. In contrast, plastic bottles may be suitable for lower-cost consumer goods where weight and cost are critical factors. Aluminum cans are excellent for beverages that require a longer shelf life and strong brand recognition. Each option has its unique advantages and limitations, so buyers should prioritize their specific needs to make the most effective choice.

Essential Technical Properties and Trade Terminology for Custom Glass Bottle Manufacturers

What Are the Key Technical Properties of Custom Glass Bottles?

When sourcing custom glass bottles, understanding the technical specifications is crucial for ensuring product quality and compatibility with your needs. Here are several essential properties to consider:

-

Material Grade

The most common materials for glass bottles include soda-lime glass and borosilicate glass. Soda-lime glass is widely used for its cost-effectiveness and versatility, suitable for many applications, including food and beverage packaging. Borosilicate glass, known for its thermal resistance, is ideal for laboratory and high-heat applications. Selecting the right material grade can affect durability, safety, and regulatory compliance. -

Capacity

The capacity of glass bottles is typically measured in milliliters (ml) or ounces (oz). Understanding your product’s volume requirements is essential for ensuring proper packaging and customer satisfaction. For instance, beverage manufacturers often choose between 250ml and 750ml bottles depending on market preferences. Capacity impacts not only logistics and storage but also marketing strategies, as different sizes can appeal to various consumer demographics. -

Neck Finish and Closure Compatibility

The neck finish refers to the design and dimensions of the bottle’s opening, which directly affects closure options, such as caps or corks. Common neck finishes include 28mm and 43mm threads, with compatibility varying by bottle type. Ensuring the right neck finish is critical for maintaining product integrity and ease of use. This detail is particularly important for industries like cosmetics and food, where leakage or contamination must be avoided. -

Tolerance

Tolerance is the allowable deviation in the dimensions of the bottle. Precise tolerances are essential for ensuring that bottles fit standard closures and that they can be easily filled and packaged. Typical tolerances can range from ±0.5mm to ±2mm, depending on the bottle’s design and purpose. Inconsistent tolerances can lead to production inefficiencies and increased costs, making it a vital specification to discuss with manufacturers. -

Weight

The weight of the bottle impacts shipping costs, handling, and customer perception. Lightweight bottles can reduce transportation expenses, while heavier bottles may convey a sense of quality and durability. It’s important to find a balance that meets both cost and branding objectives, especially in competitive markets. -

Color and Finish Options

Glass bottles come in various colors and finishes, which can influence product presentation and branding. Options like frosted, clear, or colored glass can enhance visual appeal and protect contents from UV light. This aspect is particularly significant for products sensitive to light, such as oils and certain beverages.

What Are Common Trade Terms in the Custom Glass Bottle Industry?

Familiarizing yourself with industry jargon can help streamline communication with suppliers and ensure a smoother procurement process. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that manufactures products that are sold under another company’s brand. For custom glass bottles, an OEM might produce bottles based on your specific design requirements. Understanding OEM relationships can facilitate better collaboration and innovation in product development. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for buyers, as it affects budgeting and inventory management. It’s essential to negotiate MOQ that aligns with your production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers for specific products or services. In the context of custom glass bottles, an RFQ allows buyers to compare pricing, lead times, and terms from multiple manufacturers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping, insurance, and customs duties. Familiarity with Incoterms helps buyers manage risks and expectations regarding delivery timelines and costs. -

Lead Time

Lead time refers to the duration from placing an order to receiving the products. It encompasses production time, shipping, and potential delays. Understanding lead times is crucial for inventory planning and meeting market demands. -

Customization Options

This term encompasses the various ways a manufacturer can tailor products to meet specific client requirements. Customization may include size, shape, color, and labeling options. Knowing available customization options allows buyers to better align product offerings with consumer preferences and branding strategies.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when partnering with custom glass bottle manufacturers, leading to successful product launches and sustained market presence.

Navigating Market Dynamics and Sourcing Trends in the Custom Glass Bottle Manufacturers Sector

What Are the Key Market Dynamics and Trends in Custom Glass Bottle Manufacturing?

The global market for custom glass bottles is experiencing significant shifts driven by factors such as consumer preference for sustainable packaging, the rise of e-commerce, and advancements in manufacturing technologies. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that can provide tailored solutions to meet diverse market demands. The demand for innovative designs and functionalities, such as enhanced durability and aesthetic appeal, is shaping the landscape of custom glass bottle manufacturing.

Emerging technologies, such as 3D printing and automation, are streamlining the design and production processes, enabling manufacturers to offer more personalized products at competitive prices. This trend is particularly beneficial for small to medium enterprises (SMEs) that require smaller batch productions without compromising on quality. Furthermore, the integration of digital platforms for sourcing and procurement is becoming prevalent, allowing buyers to access a wider range of options and make informed decisions quickly.

As markets in regions like Vietnam and Saudi Arabia expand, understanding local regulations and preferences is crucial for successful sourcing. Buyers are advised to partner with manufacturers who not only comply with international quality standards but also possess a robust understanding of local market dynamics.

How Is Sustainability Shaping the Custom Glass Bottle Manufacturing Sector?

Sustainability is a cornerstone of the custom glass bottle manufacturing sector, impacting sourcing decisions and supplier selection. The environmental impact of packaging waste has led many brands to seek out eco-friendly materials and practices. Custom glass bottles are often perceived as a premium choice due to their recyclability and reduced carbon footprint when compared to plastic alternatives.

Ethical sourcing is becoming increasingly important, with B2B buyers favoring manufacturers who demonstrate transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and the use of recycled glass materials not only appeal to environmentally conscious consumers but also enhance brand reputation. Manufacturers that prioritize sustainable practices can differentiate themselves in a competitive market, attracting buyers who are committed to reducing their environmental impact.

The shift towards sustainability is not just a trend; it reflects a broader commitment to corporate social responsibility. By choosing suppliers who adhere to ethical sourcing principles, businesses can align their operations with consumer values, fostering loyalty and trust in their brand.

How Has the Custom Glass Bottle Manufacturing Sector Evolved Over Time?

The evolution of custom glass bottle manufacturing can be traced back to ancient civilizations that utilized glass for storage and decoration. In the modern era, the sector has undergone substantial transformation, driven by technological advancements and changing consumer preferences. The introduction of automated production lines in the mid-20th century significantly increased efficiency and reduced costs, making glass packaging more accessible to a broader range of industries.

In recent years, the focus has shifted towards customization and sustainability, reflecting a growing demand for unique packaging solutions that resonate with consumers. The development of innovative designs and the ability to produce smaller quantities have opened new avenues for brands to differentiate themselves in a crowded marketplace. As we move forward, the integration of digital technologies and sustainable practices will likely continue to shape the future of custom glass bottle manufacturing, making it an exciting field for B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of Custom Glass Bottle Manufacturers

-

1. How do I choose the right custom glass bottle manufacturer for my business?

Choosing the right custom glass bottle manufacturer involves several key factors. Start by assessing their experience and expertise in your industry, as well as their ability to meet specific design requirements. Check their portfolio for previous work and client testimonials. It’s also crucial to evaluate their production capabilities, including minimum order quantities (MOQs) and lead times. Finally, consider their certifications and quality assurance processes to ensure compliance with international standards. -

2. What are the typical minimum order quantities (MOQs) for custom glass bottles?

Minimum order quantities (MOQs) for custom glass bottles can vary significantly depending on the manufacturer. Generally, MOQs range from 1,000 to 10,000 units for custom designs. However, some manufacturers may offer lower MOQs for stock items. It’s advisable to discuss your specific needs with potential suppliers to determine if they can accommodate smaller orders, especially if you are a startup or testing a new product line. -

3. What customization options are available for glass bottles?

Custom glass bottles can be tailored in various ways, including shape, size, color, and closure types. Manufacturers often offer options for screen printing, labeling, and embossing to enhance branding. Additionally, you can choose eco-friendly materials or recycled glass to appeal to environmentally conscious consumers. Collaborating closely with the manufacturer during the design phase will help ensure your vision aligns with their capabilities. -

4. What payment terms should I expect when sourcing custom glass bottles internationally?

Payment terms for international orders of custom glass bottles typically include a deposit upfront, often ranging from 30% to 50% of the total order value, with the balance due before shipment. Some suppliers may offer flexible payment options, including letters of credit or payment upon delivery. It’s essential to clarify these terms in advance and ensure they are documented in your contract to avoid any misunderstandings. -

5. How can I ensure the quality of custom glass bottles before shipment?

To ensure the quality of custom glass bottles, request samples before finalizing your order. Most reputable manufacturers will provide prototypes or pre-production samples for your approval. Additionally, inquire about their quality assurance processes, including inspections at various production stages. Consider conducting third-party quality checks if you are sourcing from overseas, as this can provide an additional layer of assurance regarding product standards. -

6. What are the logistics considerations for importing custom glass bottles?

When importing custom glass bottles, logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling glass products to mitigate risks of breakage. Familiarize yourself with the customs requirements of your destination country, including documentation and duties. Establishing a good relationship with your supplier can also help streamline the logistics process and address any challenges that arise. -

7. How do international tariffs affect the cost of custom glass bottles?

International tariffs can significantly impact the cost of custom glass bottles, especially if you are importing from countries with high import duties. It’s important to research the tariff rates applicable to your products and factor these costs into your overall budget. Some manufacturers may offer guidance on navigating tariffs and suggest strategies to minimize costs, such as bulk purchasing or sourcing materials locally. -

8. What are the best practices for vetting a custom glass bottle supplier?

To effectively vet a custom glass bottle supplier, start by conducting thorough research on their reputation and reliability. Look for reviews and testimonials from previous clients and verify their industry certifications. Request references and follow up with past customers about their experiences. Additionally, assess their communication responsiveness and willingness to collaborate on your project. A reputable supplier should be transparent about their processes and open to addressing your concerns.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Custom Glass Bottle Manufacturers

In navigating the dynamic landscape of custom glass bottle manufacturing, strategic sourcing emerges as a pivotal element for international B2B buyers. By prioritizing partnerships with manufacturers who offer diverse designs, sustainable materials, and competitive pricing, businesses can enhance their product offerings and brand identity. Emphasizing eco-friendly packaging not only aligns with global sustainability trends but also resonates with increasingly environmentally-conscious consumers.

Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage the unique advantages of sourcing from established manufacturers that understand local market nuances and compliance requirements. This approach not only mitigates risks associated with supply chain disruptions but also fosters innovation through collaborative design processes.

Looking ahead, the demand for custom glass bottles is poised to grow as industries continue to recognize the aesthetic and functional benefits of glass packaging. Now is the time for B2B buyers to engage with manufacturers, explore innovative packaging solutions, and solidify their supply chains. By doing so, they can ensure their products stand out in a competitive marketplace and meet evolving consumer preferences.