Top 8 Dental Chair Manufacturers List and Guide: How To Solve Sce…

Introduction: Navigating the Global Market for dental chair manufacturers

In the ever-evolving landscape of dental care, sourcing high-quality dental chairs that ensure patient comfort and clinician efficiency presents a significant challenge for international B2B buyers. With diverse requirements across regions such as Africa, South America, the Middle East, and Europe, the selection process can be daunting. This guide aims to simplify your journey through the global market for dental chair manufacturers by providing a comprehensive overview of types, applications, supplier vetting processes, and cost considerations.

From ergonomic designs that enhance clinician posture to innovative features that cater to specific dental procedures, understanding the nuances of available options is crucial. Buyers will benefit from actionable insights on identifying reputable manufacturers, assessing product quality, and making cost-effective decisions that align with their practice’s needs.

By equipping you with the knowledge to navigate this complex landscape, this guide empowers you to make informed purchasing decisions. Whether you are establishing a new practice or upgrading existing equipment, our expert recommendations and market analysis will help you select the right dental chairs that meet both your operational requirements and budgetary constraints. Dive in to discover how to elevate your dental practice with the right equipment, ensuring both patient satisfaction and clinical success.

Top 10 Dental Chair Manufacturers Manufacturers & Suppliers List

1. Henry Schein – Dental Chairs

Domain: henryscheinequipmentcatalog.com

Registered: 2011 (14 years)

Introduction: Dental chairs designed for optimal patient experience and clinician support. Features include ergonomic design, good posture support, ample legroom, seamless patient positioning, and unobstructed access to the oral cavity. Standout features include thin, flexible backrests and dual-articulating headrests. Brands available include A-dec, DCI Edge, Midmark, and more.

2. Patterson – Patient Dental Chairs

3. TPC – Dental Operatory Packages

Domain: capitaldentalequipment.com

Registered: 2011 (14 years)

Introduction: TPC MP2015 – 600LED Mirage Hydraulic Chair Mount Operatory Package As Low As: $ 11,520.00; TPC MSP3500 Dental Mirage Swing Mount Operatory Packages As Low As: $ 11,330.00; MP2015-550 LED Dental Operatory Package As Low As: $ 11,320.00; TPC Mirage Orthodontic Dental Chair Package Model MOP3000 As Low As: $ 10,290.00; Flight Dental Systems A12 Patient Dental Chair As Low As: $ 10,042.00; Laguna Dent…

4. XO Care – Digital Dental Units

Domain: xo-care.com

Registered: 2001 (24 years)

Introduction: Dental units: XO FLOW, XO FLEX, XO SEAT & STOOL, XO WORKTOP, XO ODONTOSURGE, XO ODONTOSON 360, XO ODONTOSCALER, XO ODONTOCURE, XO SUCTION DISINFECTION, XO WATER DISINFECTION, XO FABRIC MAKEUP, XO GENTLE DISINFECTION. XO FLOW is a digital dental unit known for its modular configuration and flexibility, suitable for various dental care needs. XO FLEX is a classic ergonomic dental chair designed for …

5. Burkhart Dental – Dental Chairs

Domain: burkhartdental.com

Registered: 1997 (28 years)

Introduction: Dental Chairs available from various manufacturers including Royal Dental Group, Pelton & Crane, Midmark, Forest Dental, DentalEZ, DCI, and A-dec. Specific models mentioned are: Alliant Dental Chair, Pelton & Crane 1706 Dental Chair, MTI 721 Oral Surgery Chair, Midmark Elevance Dental Chair, Midmark 641 Barrier-Free Oral Procedure Chair, Forest Dental 3900 Operatory Chair, Firstar FDC50 Chair, Den…

6. DentalEZ – Professional Dental Equipment

Domain: dentalez.com

Registered: 1997 (28 years)

Introduction: Professional Dental Equipment and Supplies including:

– Dental Handpieces:

– Electric Dental Handpieces

– High-Speed, Air-Driven Dental Handpieces

– Low-speed, Air-Driven Dental Handpieces

– Hygiene Dental Handpieces

– Dental Hand Instruments

– Dental Burs

– Dental Utility Room Equipment:

– Dental Compressors

– Dry Dental Vacuums

– Separation Tanks

– Dental …

7. ADS Dental – Ergonomic Dental Chairs

Domain: adsdental.com

Registered: 2012 (13 years)

Introduction: ADS provides various dental chairs, including hydraulic chairs, electromechanical chairs, pediatric dental chairs, orthodontic chairs, and surgical chairs. The design covers all functions from simple to luxurious, with an ergonomic design that provides efficiency for dentists and comfort for patients. The durable design ensures reliable quality, and the affordable price range offers better choices…

8. FSROSON – Dental Units & Accessories

Domain: fsroson.com

Registered: 2005 (20 years)

Introduction: Dental Units: Flagship Model A3, Affordable Luxury Model S9, Smart Model A3S, Fashion Model A3L, Professional Model S6, Hot-Selling Model S3, Elite Model N2 PRO, Classic Model N2+, Classic Model N1, Customized Model A3L. Dental Stool, Dental Light, Upholstery, Built-in Dental Scaler, Electric Motor, Built-in Dental Curing Light, Intraoral Camera, Dental Handpiece, Dental Air Compressor, Dental Com…

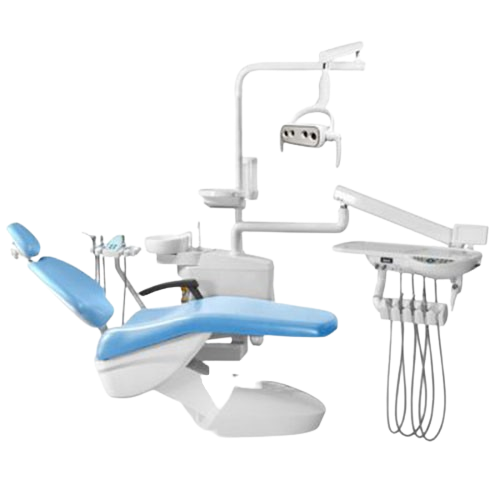

Understanding dental chair manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Dental Chairs | Operated by hydraulic systems for smooth adjustments | General dentistry, oral surgery | Pros: Smooth operation, reliable; Cons: Potential for hydraulic leaks. |

| Electromechanical Dental Chairs | Powered by electric motors, offering precise positioning | Orthodontics, pediatric dentistry | Pros: High precision, programmable settings; Cons: Higher initial cost. |

| Specialty Dental Chairs | Designed for specific procedures (e.g., oral surgery) | Specialty clinics, oral surgery practices | Pros: Tailored for specific needs; Cons: Limited versatility. |

| Modular Dental Units | Customizable configurations with interchangeable parts | Multi-specialty clinics | Pros: Flexible design, adaptable to various needs; Cons: Can be complex to set up. |

| Ergonomic Dental Chairs | Focus on comfort and posture for both patients and dentists | General dentistry, long procedures | Pros: Reduces strain and discomfort; Cons: May come at a premium price. |

What Are Hydraulic Dental Chairs and Their Applications?

Hydraulic dental chairs utilize hydraulic systems to facilitate smooth height and positioning adjustments. They are ideal for general dentistry and oral surgery due to their reliability and ease of use. When purchasing, buyers should consider the maintenance requirements of hydraulic systems, as leaks can occur, potentially leading to costly repairs.

How Do Electromechanical Dental Chairs Enhance Precision?

Electromechanical dental chairs are powered by electric motors, offering precise control over chair positioning. They are particularly beneficial in orthodontics and pediatric dentistry, where accurate adjustments are crucial. Buyers should weigh the higher initial investment against the long-term benefits of programmable settings and reduced physical strain during procedures.

What Makes Specialty Dental Chairs Unique?

Specialty dental chairs are designed for specific procedures, such as oral surgery, and often include features tailored to those needs. They are primarily used in specialty clinics and oral surgery practices. While they provide targeted functionality, buyers must consider their limited versatility and whether they align with the clinic’s service offerings.

How Do Modular Dental Units Provide Flexibility?

Modular dental units feature customizable configurations that allow practices to adapt the setup as needed. This flexibility is particularly advantageous for multi-specialty clinics that require varying equipment for different procedures. However, the complexity of setup and potential for higher costs should be factored into purchasing decisions.

Why Are Ergonomic Dental Chairs Important for Comfort?

Ergonomic dental chairs are designed to enhance comfort and promote good posture for both patients and dental professionals. They are essential in general dentistry and during lengthy procedures, helping to reduce strain and fatigue. While they may come at a premium price, the investment is often justified by improved workflow and patient satisfaction.

Key Industrial Applications of dental chair manufacturers

| Industry/Sector | Specific Application of dental chair manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Ergonomic dental chairs for general dentistry | Enhances patient comfort and improves practitioner ergonomics | Ensure compatibility with existing equipment and space |

| Orthodontic Practices | Specialized orthodontic chairs with adjustable features | Facilitates precise patient positioning for treatment | Look for customizable options to fit specific treatment needs |

| Oral Surgery Facilities | Surgical dental chairs with enhanced support and access | Increases operational efficiency during complex procedures | Prioritize durability and ease of cleaning for hygiene |

| Mobile Dental Units | Compact and portable dental chairs | Expands service capabilities in underserved areas | Verify weight and transportability for field operations |

| Educational Institutions | Training dental chairs for simulation and practice | Prepares students for real-world clinical settings | Consider chairs that replicate various dental scenarios |

How Are Dental Chairs Used in Dental Clinics?

In dental clinics, ergonomic dental chairs are essential for providing a comfortable environment for patients while allowing practitioners to maintain optimal posture. These chairs are designed to support long hours of work without causing strain, thereby enhancing the overall patient experience. For international buyers, particularly in regions like Africa and South America, sourcing chairs that are durable and easy to maintain is crucial due to varying infrastructure and service capabilities.

What Role Do Specialized Orthodontic Chairs Play?

Orthodontic practices utilize specialized chairs that feature adjustable components to accommodate various treatment modalities. These chairs allow orthodontists to position patients accurately for procedures such as braces adjustments and aligner fittings. Buyers from the Middle East and Europe should look for manufacturers that offer customization options, ensuring that the chair meets specific procedural requirements and patient demographics.

Why Are Surgical Dental Chairs Important for Oral Surgery Facilities?

Oral surgery facilities require surgical dental chairs that provide enhanced support and accessibility to ensure safety and efficiency during complex procedures. These chairs often come equipped with features such as adjustable height, tilt functions, and additional support for the patient’s head and neck. Buyers should prioritize sourcing chairs that are easy to clean and maintain, especially in regions where hygiene standards are critical.

How Do Mobile Dental Units Benefit Underserved Areas?

Mobile dental units equipped with compact and portable dental chairs play a vital role in expanding dental services to underserved areas. These units allow practitioners to provide essential dental care in remote locations, thus addressing accessibility issues. Buyers should assess the weight and transportability of the chairs to ensure they can withstand the rigors of mobile operations, especially in regions with challenging terrains like Nigeria and Vietnam.

What Are the Benefits of Training Dental Chairs in Educational Institutions?

Educational institutions utilize training dental chairs that mimic real-world clinical environments, allowing students to practice and refine their skills. These chairs often incorporate features that replicate various dental procedures, providing a comprehensive learning experience. International buyers should seek manufacturers that offer durable, versatile chairs to support diverse training scenarios, ensuring that students are well-prepared for their future careers in dentistry.

3 Common User Pain Points for ‘dental chair manufacturers’ & Their Solutions

Scenario 1: Ensuring Ergonomic Design for Patient and Practitioner Comfort

The Problem: B2B buyers often face challenges in selecting dental chairs that adequately cater to both patient comfort and clinician ergonomics. Inadequate design can lead to discomfort for patients during procedures, potentially affecting their overall experience and satisfaction. Furthermore, dental professionals may experience physical strain due to poorly designed chairs, leading to long-term health issues and reduced productivity. This dual concern makes it critical for buyers to find chairs that strike the right balance.

The Solution: When sourcing dental chairs, prioritize manufacturers that emphasize ergonomic design. Look for features such as adjustable height, lumbar support, and articulating headrests that allow for optimal positioning. Engaging with manufacturers that offer customization options can be beneficial, as it allows you to tailor the chair to your specific practice needs. Additionally, consider requesting samples or demonstrations to evaluate how different designs affect both patient and practitioner comfort. Investing in ergonomic dental chairs may have a higher initial cost, but it can enhance patient retention and reduce practitioner absenteeism due to discomfort.

Scenario 2: Navigating Budget Constraints While Maintaining Quality

The Problem: Many B2B buyers, especially in emerging markets, struggle with budget constraints when purchasing dental chairs. The challenge lies in finding high-quality products that do not compromise on essential features due to financial limitations. This scenario often leads to buyers settling for inferior options that could result in higher long-term costs due to maintenance and replacement needs.

The Solution: To navigate budget constraints effectively, consider creating a comprehensive list of must-have features versus nice-to-have features. This prioritization will help you identify essential qualities that align with your budget. Work with dental chair manufacturers that offer flexible financing options or leasing programs, which can make high-quality chairs more accessible. Additionally, explore group purchasing agreements with other dental practices to gain bulk discounts. Prioritize manufacturers that provide warranties and after-sales support, ensuring that your investment is safeguarded and that maintenance costs are minimized over time.

Scenario 3: Managing Integration with Existing Dental Equipment

The Problem: B2B buyers often encounter difficulties when integrating new dental chairs with existing equipment. This can lead to workflow disruptions and inefficiencies, particularly in busy practices where time is of the essence. The incompatibility of new chairs with current systems can also cause frustration among staff, affecting overall productivity and patient care.

The Solution: Before making a purchase, conduct a thorough assessment of your existing equipment and how new dental chairs will fit into your operational workflow. Engage with dental chair manufacturers that offer comprehensive compatibility assessments or have a wide range of products designed to work seamlessly with various dental units and instruments. Make sure to ask about the specifications regarding power sources, attachment options, and any necessary adaptors. Additionally, consider manufacturers that provide installation services and training for your staff to facilitate a smooth transition. By ensuring compatibility upfront, you can avoid costly downtime and maintain a streamlined practice environment.

Strategic Material Selection Guide for dental chair manufacturers

When selecting materials for dental chairs, manufacturers must consider a variety of factors that impact product performance, durability, and compliance with international standards. Below is an analysis of several common materials used in dental chair manufacturing, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel in Dental Chair Manufacturing?

Steel is often chosen for its strength and durability, making it a popular choice for the structural components of dental chairs. It typically exhibits excellent temperature and pressure ratings, allowing it to withstand the rigors of daily use in a dental practice. Additionally, steel is resistant to corrosion when treated properly, which is essential for maintaining hygiene in a clinical environment.

Pros: Steel offers high durability and strength, which contributes to the longevity of dental chairs. It is also relatively easy to manufacture and can be molded into various shapes.

Cons: The primary disadvantage of steel is its weight, which can make dental chairs cumbersome to adjust. Additionally, untreated steel can corrode over time, necessitating protective coatings that can increase costs.

Impact on Application: Steel’s robustness makes it suitable for high-traffic environments, but manufacturers must ensure that the steel is treated to prevent corrosion, especially in humid climates.

Considerations for International Buyers: Compliance with standards such as ASTM for material quality is crucial. Buyers from regions like Africa and South America should also consider the availability of local suppliers for steel components to reduce shipping costs.

How Does Upholstery Material Affect Patient Comfort and Chair Durability?

Upholstery materials, such as vinyl and synthetic leather, are critical for patient comfort and the overall aesthetic of dental chairs. These materials are designed to be easy to clean and maintain, which is vital in a clinical setting where hygiene is paramount.

Pros: Upholstery materials are generally more comfortable for patients and can be produced in various colors and textures to match the clinic’s decor. They are also resistant to stains and can withstand frequent cleaning.

Cons: While durable, some upholstery materials may degrade over time with exposure to harsh cleaning agents or UV light. Additionally, high-quality upholstery can increase the overall cost of the chair.

Impact on Application: The choice of upholstery can significantly affect patient experience, influencing their perception of care quality. It is essential for manufacturers to select materials that balance comfort with durability.

Considerations for International Buyers: Buyers should be aware of local preferences for upholstery materials, as cultural factors may influence choices. Compliance with regulations regarding chemical safety in upholstery materials is also important.

What Are the Benefits and Limitations of Plastic Components in Dental Chairs?

Plastic is frequently used in dental chairs for components like armrests and headrests due to its lightweight nature and ease of molding into ergonomic shapes. Plastics can also be treated for UV resistance and durability.

Pros: Plastics are lightweight and can be produced in various colors, making them visually appealing. They are also resistant to moisture and easy to clean, enhancing their suitability for dental environments.

Cons: While plastics can be durable, they may not have the same strength as metals, making them less suitable for load-bearing applications. Over time, some plastics can become brittle or discolored.

Impact on Application: Plastic components can enhance the ergonomics of dental chairs, but manufacturers must ensure that the plastic used meets safety and durability standards.

Considerations for International Buyers: Buyers should verify that plastic materials comply with local regulations regarding safety and environmental impact. Additionally, preferences for aesthetics may vary by region, influencing material choices.

How Do Composite Materials Enhance the Functionality of Dental Chairs?

Composite materials, which combine plastics and other materials, are increasingly used in dental chair manufacturing. These materials can offer a balance of strength, flexibility, and aesthetic appeal.

Pros: Composites can be engineered to provide specific properties, such as enhanced strength or improved resistance to chemicals. They can also be molded into complex shapes, allowing for innovative designs.

Cons: The manufacturing process for composites can be more complex and costly compared to traditional materials. Additionally, not all composites are created equal, and quality can vary significantly.

Impact on Application: Composites can improve the overall functionality of dental chairs, particularly in terms of weight distribution and patient comfort.

Considerations for International Buyers: Buyers should assess the certifications of composite materials to ensure they meet international standards. Awareness of local market trends regarding composite use can also guide purchasing decisions.

Summary Table of Material Selection for Dental Chair Manufacturers

| Material | Typical Use Case for dental chair manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High durability and strength | Heavy and can corrode if untreated | Medium |

| Upholstery | Chair covering and padding | Comfortable and easy to clean | May degrade with harsh cleaning agents | Medium to High |

| Plastic | Armrests and headrests | Lightweight and visually appealing | Less strength than metals | Low to Medium |

| Composite | Complex chair designs | Customizable properties and aesthetics | Higher manufacturing complexity | Medium to High |

This guide provides a strategic overview of material selection for dental chair manufacturers, emphasizing the importance of balancing performance, cost, and compliance with international standards. By understanding these materials, B2B buyers can make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for dental chair manufacturers

What Are the Key Stages in the Manufacturing Process of Dental Chairs?

The manufacturing of dental chairs involves several crucial stages, each designed to ensure that the final product meets the ergonomic, aesthetic, and functional requirements of dental practices. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material preparation, where high-quality materials are sourced. Dental chairs typically require a combination of metals (such as steel or aluminum for the frame), plastics (for components like armrests and upholstery), and upholstery fabrics that are durable and easy to clean. Manufacturers often conduct rigorous material inspections to ensure compliance with health and safety regulations, particularly since dental chairs are used in clinical environments.

Forming: How Are Dental Chairs Shaped?

Once materials are prepared, the forming stage begins. This stage involves various techniques, such as welding for the frame, molding for plastic components, and cutting for upholstery. Advanced manufacturers may employ computer numerical control (CNC) machines to achieve precision in shaping metal parts. The use of robotic arms for welding and assembly can also enhance consistency and reduce human error, which is critical in maintaining product quality.

Assembly: What Does the Assembly Process Entail?

The assembly stage is where all the components come together. This involves attaching the seat, backrest, and armrests to the frame, integrating hydraulic systems for height adjustment, and installing electrical components for features such as lighting and patient controls. Quality assurance checks are often performed at this stage to ensure that each chair meets design specifications and functions correctly.

Finishing: What Are the Final Touches on Dental Chairs?

After assembly, dental chairs undergo a finishing process that includes painting, coating, and upholstering. The finishing stage not only enhances the aesthetic appeal of the chair but also adds protective layers that improve durability and resistance to chemicals and wear. Manufacturers may apply antimicrobial coatings to enhance hygiene, which is an essential feature for dental environments.

How is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral throughout the manufacturing process, ensuring that each dental chair meets international standards and specific industry requirements. For B2B buyers, understanding the QA processes can provide confidence in the products they are purchasing.

What International Standards Should B2B Buyers Be Aware Of?

Most reputable dental chair manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE marking (Conformité Européenne) for the European market and API (American Petroleum Institute) standards for certain components may apply. These certifications indicate that the products have undergone rigorous testing and meet safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are crucial in the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): Assessing raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Monitoring the manufacturing process at various stages to identify any deviations from quality standards.

-

Final Quality Control (FQC): Conducting comprehensive inspections and tests on finished products before they are shipped to customers.

These checkpoints help to catch potential issues early and ensure that only high-quality products reach the market.

What Testing Methods Are Commonly Used in Dental Chair Manufacturing?

Testing methods are essential in validating the performance and safety of dental chairs. Common testing procedures include:

-

Load Testing: Assessing the structural integrity of the chair under various weights to ensure it can accommodate different patient sizes.

-

Ergonomic Testing: Evaluating the chair’s design to ensure it meets ergonomic standards for both patients and dental professionals.

-

Durability Testing: Subjecting the chair to simulated long-term use to evaluate wear and tear on materials and mechanisms.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is vital for ensuring product reliability. Here are several methods to consider:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers can request audits of the manufacturing facilities to assess compliance with quality standards. An on-site audit allows buyers to review the manufacturing process, observe QA practices, and check documentation related to certifications.

How Can Buyers Access Quality Control Reports?

Requesting QC reports from suppliers can provide insights into testing outcomes and compliance with international standards. These reports should detail the methods used, results obtained, and any corrective actions taken for non-compliant products.

Are Third-Party Inspections Recommended?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct thorough evaluations of the manufacturing processes and product quality, providing unbiased reports that can help buyers make informed purchasing decisions.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from diverse regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific regional regulations and standards that may affect product quality. For example, some countries may have stricter hygiene and safety regulations, which could influence the choice of materials and manufacturing processes.

Furthermore, buyers should consider the logistics of international shipping and how it impacts product integrity. Ensuring that suppliers have robust packaging and handling procedures in place is essential to prevent damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices of dental chair manufacturers is crucial for B2B buyers. By focusing on the stages of production, quality control measures, and verification methods, buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dental chair manufacturers’

To ensure a successful procurement process for dental chairs, international B2B buyers must navigate a complex landscape filled with diverse options and varying supplier capabilities. This practical sourcing guide provides a step-by-step checklist to help buyers identify and select the right dental chair manufacturers for their needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to establish clear technical specifications for the dental chairs required. Consider factors such as ergonomics, adjustability, material quality, and technology integration. This clarity will streamline communication with potential manufacturers and ensure that the products meet your clinical and operational requirements.

Step 2: Conduct Market Research

Thorough market research is critical for understanding the landscape of dental chair manufacturers. Investigate brands, models, and features that are well-reviewed by professionals in your target regions. Pay attention to regional preferences, as ergonomic designs and technological advancements may vary based on local practices and patient demographics.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of quality and reliability, and don’t hesitate to seek out customer testimonials or industry awards that can attest to their reputation.

Step 4: Verify Supplier Certifications and Compliance

Ensure that potential manufacturers comply with relevant international standards and certifications, such as ISO or CE markings. These certifications indicate that the products meet quality and safety requirements, which is particularly important in healthcare settings. Additionally, check if they adhere to local regulations in your target markets.

Step 5: Assess Customization Options

Consider whether the manufacturer offers customization options for their dental chairs. Customization can range from upholstery choices to specific features tailored to your practice’s needs. A supplier that provides flexible solutions can help you create a more personalized and functional treatment environment for both patients and staff.

Step 6: Analyze Cost and Payment Terms

Once you’ve shortlisted potential suppliers, analyze their pricing structures and payment terms. Compare costs not only based on initial purchase price but also consider factors such as warranty, after-sales service, and potential hidden costs like shipping or installation fees. Understanding the total cost of ownership will aid in making a financially sound decision.

Step 7: Request Demonstrations and Trials

If possible, request product demonstrations or trials before finalizing your purchase. This hands-on experience allows you to evaluate the comfort, functionality, and ease of use of the dental chairs. Engaging your clinical team in this process can provide valuable insights into how well the products meet the practical demands of your practice.

By following this structured approach, B2B buyers can navigate the complexities of sourcing dental chair manufacturers effectively, ensuring that their investment enhances both patient comfort and clinical efficiency.

Comprehensive Cost and Pricing Analysis for dental chair manufacturers Sourcing

What Are the Key Cost Components in Sourcing Dental Chairs?

When sourcing dental chairs, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: High-quality materials such as upholstery, metal frames, and electronic components significantly influence the overall cost. Dental chairs made from durable and easy-to-clean materials may command a premium but can offer better longevity.

-

Labor: The labor cost associated with manufacturing dental chairs varies by region. In countries with lower wage standards, labor costs may be less, but this can sometimes impact the quality of craftsmanship. Understanding the labor market of the manufacturing country is crucial.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling and molds can be significant, especially for customized designs. Manufacturers often amortize these costs over larger production runs, so the price per unit decreases with higher volumes.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the dental chairs meet safety and performance standards. Investing in QC can raise initial costs but may reduce long-term expenses associated with returns or repairs.

-

Logistics: Transportation and shipping costs can vary greatly depending on the origin of the chairs and the destination. Understanding the logistics involved, including potential customs duties and tariffs, is crucial for accurate cost estimation.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary based on market demand, brand reputation, and competitive landscape.

How Do Price Influencers Affect Dental Chair Costs?

Several factors can significantly influence the pricing of dental chairs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can often lead to discounted pricing. Buyers should consider negotiating for better rates based on their purchasing volume.

-

Specifications and Customization: Chairs with advanced features or custom designs typically cost more. Buyers should assess whether the additional features justify the higher price.

-

Materials and Quality Certifications: Chairs made from premium materials or those that meet specific quality certifications (e.g., ISO, CE) often come at a higher price point, reflecting their enhanced durability and safety.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established brands with a proven track record may charge more, but they often provide better support and reliability.

-

Incoterms: The terms of shipping and delivery (Incoterms) can affect overall costs. Buyers should clarify which party is responsible for shipping fees, insurance, and customs duties to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Cost-Effective Pricing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-effectiveness:

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and after-sales support. Flexibility in these areas can lead to better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a dental chair, including maintenance, energy consumption, and replacement parts. A lower upfront cost may not always equate to better value if ongoing costs are high.

-

Research Market Prices: Conduct market research to understand typical pricing ranges for different chair models and brands. Being informed can strengthen your negotiation position.

-

Leverage Local Partnerships: Collaborating with local distributors or agents can help navigate the complexities of import regulations and logistics, potentially reducing costs.

-

Stay Informed on Trends: Keeping abreast of industry trends and emerging technologies can provide insights into future pricing shifts and help in making timely purchasing decisions.

Conclusion: Understanding Pricing Nuances

While indicative prices for dental chairs can range widely—from approximately $4,100 for basic models to over $11,500 for high-end units—it’s essential to note that actual costs will vary based on the factors discussed. Buyers should conduct thorough analyses of their specific needs and market conditions to ensure they make the most informed purchasing decisions.

Alternatives Analysis: Comparing dental chair manufacturers With Other Solutions

Understanding Alternatives to Dental Chair Manufacturers

In the competitive landscape of dental practices, selecting the right equipment is crucial for efficiency and patient satisfaction. While traditional dental chairs have long been the standard, emerging alternatives offer innovative solutions that may meet the needs of modern dental environments. This analysis explores how dental chair manufacturers compare to other viable options, such as portable dental units and tele-dentistry solutions.

| Comparison Aspect | Dental Chair Manufacturers | Portable Dental Units | Tele-Dentistry Solutions |

|---|---|---|---|

| Performance | High, designed for ergonomic use and patient comfort. | Moderate, suitable for basic procedures; may lack advanced features. | Variable, depends on technology and practitioner engagement. |

| Cost | Generally high, ranging from $4,100 to $11,520. | Lower initial investment, often between $1,500 to $5,000. | Low to moderate, depending on software and hardware used. |

| Ease of Implementation | Requires dedicated space; installation can be complex. | Easy to set up; often mobile and user-friendly. | Requires reliable internet and tech-savvy personnel. |

| Maintenance | Regular maintenance needed; parts can be expensive. | Low maintenance; generally more robust due to portability. | Minimal physical maintenance; software updates required. |

| Best Use Case | Ideal for established practices needing ergonomic solutions. | Perfect for mobile clinics or practices with space constraints. | Best for initial consultations or follow-ups, enhancing access. |

What Are the Advantages and Disadvantages of Portable Dental Units?

Portable dental units are designed for flexibility and mobility, making them an attractive choice for practices that require adaptability. They are particularly beneficial for outreach programs, home visits, or clinics with limited space. The lower cost of entry makes them accessible for startups or practices looking to expand services without significant capital investment. However, their performance may not match that of traditional chairs, especially for complex procedures, and they may lack some advanced features found in high-end dental chairs.

How Do Tele-Dentistry Solutions Compare to Traditional Dental Chairs?

Tele-dentistry solutions leverage technology to facilitate remote consultations and follow-ups, significantly expanding access to dental care. This method can enhance patient engagement and convenience, especially in regions with limited access to dental professionals. While the cost of tele-dentistry can be lower compared to traditional chair setups, its effectiveness heavily relies on technology and communication skills. However, it may not replace the need for in-person treatments, particularly for complex procedures that require physical examination and intervention.

Conclusion: How Should B2B Buyers Choose the Right Dental Solution?

When selecting the appropriate solution for their dental practice, B2B buyers must consider their specific needs, budget, and operational context. Traditional dental chairs offer durability and ergonomic benefits, ideal for established practices focused on patient experience. In contrast, portable dental units provide flexibility and cost-effectiveness, suitable for mobile operations or new practices. Tele-dentistry serves as a complementary approach, enhancing patient access but not replacing the need for physical treatments. Buyers should weigh these factors carefully to make an informed decision that aligns with their practice goals and patient needs.

Essential Technical Properties and Trade Terminology for dental chair manufacturers

What Are the Key Technical Properties of Dental Chairs That Buyers Should Consider?

When sourcing dental chairs, understanding their technical properties is crucial for making informed purchasing decisions. Here are several critical specifications:

1. Material Grade

The material used in dental chairs significantly affects durability, comfort, and maintenance. Common materials include high-grade plastics, metals, and upholstery fabrics that are resistant to wear and tear, disinfectants, and stains. For B2B buyers, selecting chairs made from high-quality materials can reduce long-term costs associated with replacements and repairs.

2. Weight Capacity

Most dental chairs are designed with a specific weight limit, typically ranging from 300 to 600 pounds. Understanding the weight capacity is vital for ensuring the chair can accommodate all patients comfortably and safely. This specification also influences the structural design and stability of the chair, which is essential for both patient and clinician safety.

3. Adjustment Range

The ability to adjust the chair’s height, backrest angle, and leg support is crucial for ergonomic comfort. An extensive adjustment range allows for optimal positioning of patients and practitioners, facilitating better access to the oral cavity. For manufacturers, offering a wide range of adjustments can enhance the chair’s appeal to diverse dental practices.

4. Hydraulic vs. Electromechanical Operation

Dental chairs can be operated using hydraulic or electromechanical systems. Hydraulic chairs are often more durable and can support heavier weights, while electromechanical options provide smoother and more precise movements. Buyers should consider the operational requirements of their practice when choosing between these systems, as they impact efficiency and ease of use.

5. Warranty and Service Support

A robust warranty and service support system are essential for B2B buyers. Many manufacturers offer warranties ranging from 1 to 10 years, covering various components of the dental chair. Understanding the terms of the warranty can guide buyers in assessing the long-term value of their investment.

What Trade Terminology Should Buyers Understand When Sourcing Dental Chairs?

Familiarizing yourself with industry terminology can streamline the procurement process. Here are some common terms you might encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For dental chair buyers, sourcing from an OEM can ensure that they are getting high-quality, compatible components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for budget planning and inventory management. Some manufacturers might have high MOQs, which could impact smaller dental practices that need to manage cash flow carefully.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products or services. This process helps buyers compare pricing and terms across different manufacturers, enabling them to make cost-effective decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international transactions, ensuring clarity on who bears the risk and cost at each stage of the shipping process.

5. Ergonomics

In the context of dental chairs, ergonomics refers to the design principles that ensure comfort and efficiency for both patients and dental professionals. Understanding ergonomic specifications can lead to better health outcomes for practitioners and enhanced patient experiences.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing dental chairs more effectively, ensuring that their investments meet both operational needs and patient care standards.

Navigating Market Dynamics and Sourcing Trends in the dental chair manufacturers Sector

What Are the Current Market Dynamics and Key Trends in Dental Chair Manufacturing?

The dental chair manufacturing sector is experiencing significant transformation driven by technological advancements, changing consumer expectations, and evolving healthcare regulations. A key global driver is the increasing emphasis on patient comfort and safety, which influences the design and functionality of dental chairs. Manufacturers are adopting innovations like ergonomic designs, advanced materials, and integrated digital technologies that enhance both the patient experience and clinical outcomes.

Emerging trends include the rise of tele-dentistry and digital workflows, which have prompted manufacturers to create chairs that can accommodate advanced imaging and diagnostic equipment. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding local market needs is crucial. Buyers are increasingly looking for customizable solutions that align with their specific operational requirements and patient demographics. Additionally, the market is witnessing a growing demand for cost-effective yet high-quality products, making it essential for manufacturers to balance affordability with advanced features.

Furthermore, sustainability is becoming a pivotal consideration in the purchasing decisions of dental practices. As buyers become more environmentally conscious, they are seeking suppliers who prioritize sustainable practices and materials. This trend underscores the importance for manufacturers to innovate while adhering to eco-friendly practices, ensuring they remain competitive in a rapidly evolving landscape.

How Can Sustainability and Ethical Sourcing Impact Dental Chair Manufacturing?

Sustainability and ethical sourcing have emerged as vital considerations for dental chair manufacturers, reflecting a broader shift in the global marketplace. The environmental impact of production processes is under scrutiny, pushing manufacturers to adopt practices that reduce waste, lower emissions, and use sustainable materials. Eco-friendly certifications, such as ISO 14001 or Green Seal, are becoming increasingly important for manufacturers aiming to demonstrate their commitment to environmental stewardship.

Incorporating recyclable materials and developing energy-efficient manufacturing processes not only enhances a company’s brand reputation but also aligns with the growing demand from B2B buyers for responsible sourcing. Buyers are increasingly favoring suppliers who can provide transparency about their supply chain and demonstrate compliance with ethical labor practices. This shift is particularly relevant in regions like Africa and South America, where buyers are advocating for social responsibility in procurement.

Moreover, the market for ‘green’ dental chairs is expanding, with innovations such as chairs made from sustainable woods, low-emission upholstery materials, and non-toxic finishes. For international B2B buyers, investing in sustainable dental chairs can enhance their brand image, attract environmentally-conscious patients, and ensure compliance with local regulations regarding waste and materials.

What is the Evolution of Dental Chair Manufacturing?

The evolution of dental chair manufacturing has been marked by significant technological advancements and a growing focus on patient-centered design. Initially, dental chairs were simple, static structures; however, advancements in hydraulic and electric systems have revolutionized their functionality. The introduction of ergonomic designs has also been pivotal, as manufacturers recognized the importance of clinician comfort and posture in promoting long-term health.

As digital dentistry began to emerge, manufacturers adapted by integrating technology into their products, allowing for enhanced patient monitoring and treatment capabilities. This evolution reflects a broader trend towards the digitization of healthcare, as dental practices seek to improve efficiency and patient outcomes. Today, dental chairs not only serve as a critical piece of equipment in treatment rooms but also play a vital role in shaping the overall patient experience.

Understanding this evolution is essential for international B2B buyers, as it informs their purchasing decisions and highlights the importance of investing in modern, innovative solutions that meet the demands of contemporary dental practices.

Frequently Asked Questions (FAQs) for B2B Buyers of dental chair manufacturers

-

How do I choose the right dental chair for my practice?

Choosing the right dental chair involves assessing your specific needs, including the types of procedures you perform, the size of your practice, and your budget. Look for features such as ergonomic design, adjustability, and ease of cleaning. It’s also essential to consider the chair’s compatibility with other equipment and the overall workflow in your operatory. Research different manufacturers and request demonstrations to evaluate the comfort and functionality of various models. -

What are the key features to look for in a dental chair?

When selecting a dental chair, prioritize ergonomic design, adjustable height, and flexible positioning capabilities to enhance both patient comfort and clinician accessibility. Look for features like dual-articulating headrests, easy-to-clean upholstery, and integrated dental unit compatibility. Additional considerations include weight capacity, warranty duration, and the availability of customization options to fit your specific practice needs. -

What is the typical lead time for ordering dental chairs internationally?

Lead times for international orders of dental chairs can vary significantly based on the manufacturer, model, and shipping logistics. Generally, you can expect a lead time of 4 to 12 weeks, including production and transit. It’s crucial to communicate with suppliers about their timelines and ensure that they can meet your deadlines, particularly if you’re planning a new practice setup or renovation. -

How can I ensure the quality of dental chairs from manufacturers?

To ensure quality, request certifications and compliance documentation from manufacturers, including ISO standards and safety regulations. Conduct supplier audits if possible and seek testimonials from other buyers. Additionally, consider manufacturers that offer warranties and after-sales support, as these can be indicators of their commitment to quality. Testing the chair firsthand or visiting a showroom can also help you assess quality before purchase. -

What are the common payment terms for international dental chair purchases?

Payment terms for international purchases can vary widely. Most manufacturers require a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some may offer financing options or extended payment plans. Always clarify payment terms upfront, including currency, payment methods (such as wire transfer or credit card), and any additional fees that may apply, such as for customs or duties. -

What is the minimum order quantity (MOQ) for dental chairs?

Minimum order quantities (MOQs) can differ based on the manufacturer and the specific chair model. Some manufacturers may have an MOQ of one unit, while others might require bulk orders of 5 to 10 units to offset production costs. Be sure to inquire about MOQs when sourcing potential suppliers to align with your purchasing strategy and budget constraints. -

How can I customize dental chairs to suit my practice’s needs?

Many dental chair manufacturers offer customization options, including upholstery colors, materials, and additional features like integrated lights or suction systems. When considering customization, communicate your specific requirements clearly to the supplier and ask for a detailed breakdown of available options. Be aware that customization may impact lead times and pricing, so factor these into your decision-making process. -

What logistics considerations should I keep in mind when importing dental chairs?

When importing dental chairs, consider shipping methods (air vs. sea), customs regulations, and potential tariffs. Ensure that your supplier provides the necessary documentation for customs clearance, such as invoices and certificates of origin. It’s also advisable to work with logistics partners experienced in handling medical equipment to navigate any complexities and ensure timely delivery to your location.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental chair manufacturers

In conclusion, strategic sourcing of dental chairs is essential for international B2B buyers aiming to enhance their dental practices. As highlighted throughout this guide, prioritizing ergonomic design, advanced technology, and supplier reliability can significantly impact both patient comfort and practitioner efficiency. Buyers should evaluate key factors such as product quality, warranty options, and customization capabilities to make informed purchasing decisions.

The dental equipment market is evolving, with increasing demand for innovative solutions that cater to diverse practice needs across regions such as Africa, South America, the Middle East, and Europe. Engaging with reputable manufacturers not only ensures access to high-quality products but also fosters long-term partnerships that can lead to improved operational outcomes.

Looking ahead, we encourage B2B buyers to leverage this guide as a resource for exploring potential suppliers and making strategic investments in dental chairs that align with their practice goals. By doing so, you will not only elevate the standard of care offered to your patients but also position your practice for future growth in a competitive market. Take the next step today—connect with leading manufacturers and explore the latest innovations in dental chair technology.