Top 8 Led Tape Manufacturers List and Guide: How To Solve Scenari…

Introduction: Navigating the Global Market for LED Tape Manufacturers

In the dynamic landscape of lighting solutions, sourcing the right LED tape manufacturers can pose significant challenges for international B2B buyers. With a plethora of options spanning across various regions, including Africa, South America, the Middle East, and Europe, navigating this market requires a comprehensive understanding of the diverse offerings available. This guide aims to equip buyers with essential insights into the myriad types of LED tape products, their applications, and the critical factors to consider during supplier vetting processes.

From static white and color-changing LED tapes to specialized products like dim-to-warm and high-density options, the selection can be overwhelming. Additionally, understanding the pricing structures, lead times, and warranty terms is crucial for making informed purchasing decisions. This guide delves into these aspects, providing a clear framework to evaluate potential suppliers effectively.

By addressing these key challenges, this resource empowers B2B buyers to confidently select LED tape manufacturers that align with their project requirements and quality standards. Whether you are in Brazil looking for vibrant lighting solutions or in Saudi Arabia seeking energy-efficient options, this comprehensive guide serves as your roadmap to successful sourcing in the global LED tape market. Embrace the possibilities that LED technology offers, and let this guide illuminate your path toward informed purchasing decisions.

Top 10 Led Tape Manufacturers Manufacturers & Suppliers List

1. Alloy LED – LED Products

Domain: alloyled.wpcomstaging.com

Registered: 2018 (7 years)

Introduction: Alloy LED offers a variety of LED products including Tape and Strip Lights (Static White, Color Changing & Multicolor, Dim-to-Warm, Line Voltage), COB Tape Lights, Neon Lights, LED Sheets, TapeMate Connectors, Channels (Surface-Mount, In-Wall, Mud-In, In-Ground, Recessed, Closet, Suspended), Fixtures (Surface-Mount, In-Wall, Mud-In, In-Ground, Recessed, Closet, Suspended), Pucks & Discs, Controls …

2. Diode LED – LED Tape and Strip Lights

Domain: diodeled.com

Registered: 2009 (16 years)

Introduction: Diode LED offers a range of LED Tape and Strip Lights suitable for various applications including indoor, outdoor, and RGB options. Key features include:

– Multiple families: VALENT®, BLAZE™, STREAMLITE™, and more.

– Lumen range from 100+ to 800+ lumens per foot.

– Color options include RGBW, Tunable White, Warm Dim, and various color temperatures from 2000K to 6300K.

– IP ratings for indoor (…

3. LED Supply – Versatile LED Strips

Domain: ledsupply.com

Registered: 2002 (23 years)

Introduction: LED Strips available in various types including Low Voltage (12V & 24V), Plug & Play, Rope Lights, and Specialty Kits. Options include single-color, RGB, RGBW, and tunable white. Features include waterproof models (IP65, IP68), dimmable solutions, and wireless control options. Ideal for applications such as under-cabinet lighting, cove lighting, stairs, bars, signage, displays, and vehicles. Produ…

4. Enttec – LED Strip Solutions

Domain: enttec.com

Registered: 1999 (26 years)

Introduction: Brilliant quality LED Strip made to match your lighting effect. Available in 10m reels, with options including RGB, RGBW, and white varieties. Designed for low, medium, or high output brightness. Quality-checked by a specialist engineering team. 24V indoor-use LED strips, easy to control, ideal for wall washes and uniform designs. RGBW LED strip (9VLW) priced at $270.00, RGB LED strip (9VL4) price…

5. Glowback – Commercial-Grade LED Strips

Domain: glowbackledstore.com

Registered: 2013 (12 years)

Introduction: Shop Commercial-Grade LED Strips | Architectural LED Lighting Solutions. Free shipping on orders over $200. Key product categories include: UL Listed White LED Strips (2200K-6500K), LED Strips for Outdoor Use, DOT-FREE COB LED Strips, VIVID RGB+White RGBW LED Strip Lighting, Designer Grade LED Strips, Vivid-Color Changing Commercial RGB LED Strips, DOTLESS Ultra High Density LED Strip Lighting, an…

6. Kelvix – LED Strip and Tape Light

Domain: kelvix.com

Registered: 2005 (20 years)

Introduction: Kelvix offers a range of LED lighting products including: LED Strip and Tape Light, Specialty Strip and Tape Light Fixtures, Flexible Neon, Flexible Sheets, Channels, Power Supplies, Controls & Dimmers, and Accessories. Key products include Endurawave, FlexFit (available in Static White and RGBW), and Uniform Static White options. The company provides application engineering services, project mana…

7. EllumiGlow – LED Strip Lights

Domain: ellumiglow.com

Registered: 2009 (16 years)

Introduction: LED strip lights available in various lengths and colors, suitable for indoor and outdoor use, with options for waterproof and non-waterproof designs. Features include easy installation, flexibility for different applications, and energy efficiency.

8. HitLights – LED Strip Lights & Power Supplies

Domain: hitlights.com

Registered: 2011 (14 years)

Introduction: HitLights offers a variety of LED products including Single Color LED Strip Lights, Multi-Color LED Strip Lights, LED Strip Kits, and Bundle Collections. They provide Transformers such as Non-Dimmable Power Supplies and Dimmable Drivers. Mounting Supplies include Aluminum Channels and Mounting Tape. The company also has a Professional Partner Program for electricians, LED installers, home remodele…

Understanding LED Tape Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Static White LED Tape | Fixed color temperature; high CRI options available | Indoor lighting, architectural design | Pros: Consistent color, high efficiency. Cons: Limited flexibility in color options. |

| Color Changing LED Tape | RGB/RGBW capabilities; dynamic color control | Event lighting, retail displays | Pros: Versatile applications, customizable ambiance. Cons: Potentially higher cost. |

| Dim-to-Warm LED Tape | Gradually changes color temperature when dimmed | Hospitality, residential settings | Pros: Creates warm, inviting environments. Cons: May require compatible dimmers. |

| COB (Chip-on-Board) LED Tape | Higher LED density for seamless light; low profile | Commercial spaces, cove lighting | Pros: Smooth illumination, compact design. Cons: Higher initial investment. |

| Neon LED Tape | Flexible design mimicking traditional neon lights | Signage, creative installations | Pros: Eye-catching aesthetics, flexible installation. Cons: May require specialized connectors. |

What are the Characteristics and Suitability of Static White LED Tape?

Static white LED tape is characterized by its fixed color temperature, typically available in various Kelvin ratings to suit different lighting needs. This type of tape is ideal for applications requiring consistent lighting, such as indoor spaces, architectural features, and task lighting. When purchasing, B2B buyers should consider the color rendering index (CRI) to ensure high-quality illumination, which is crucial for showcasing products or creating a specific ambiance.

How Does Color Changing LED Tape Enhance B2B Applications?

Color changing LED tape, often featuring RGB or RGBW capabilities, allows users to dynamically alter the color and intensity of the light. This flexibility makes it particularly beneficial for event lighting, retail environments, and entertainment venues where ambiance changes are desired. Buyers should evaluate the control systems available, such as DMX or wireless options, to ensure compatibility with their specific project requirements.

What Makes Dim-to-Warm LED Tape a Popular Choice for Hospitality?

Dim-to-warm LED tape offers a unique feature that adjusts the color temperature from cool to warm as the light dims, creating a cozy atmosphere. This is particularly advantageous in hospitality and residential settings, where mood lighting plays a significant role in customer experience. Buyers should ensure that their dimming systems are compatible, as this can affect performance and lighting quality.

Why Choose COB LED Tape for Commercial Spaces?

COB (Chip-on-Board) LED tape is distinguished by its high density of LEDs, providing seamless and uniform lighting without visible hotspots. This makes it suitable for cove lighting and other applications where aesthetics and light quality are paramount. B2B buyers should consider the installation requirements and potential for customization, as COB solutions often come with a higher upfront cost but can yield significant long-term energy savings.

What are the Benefits of Neon LED Tape for Creative Installations?

Neon LED tape mimics the appearance of traditional neon lighting while offering greater flexibility and lower energy consumption. It is widely used in signage and creative installations due to its vibrant colors and adaptability to various shapes. Buyers should be aware of the installation requirements, including the need for specialized connectors and mounting options, to ensure successful project execution.

Key Industrial Applications of LED Tape Manufacturers

| Industry/Sector | Specific Application of LED Tape Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Commercial | Store Displays and Signage Lighting | Enhances product visibility and customer engagement | Brightness, color temperature, and customization options for branding |

| Hospitality | Ambient and Accent Lighting in Hotels | Improves guest experience and ambiance | Durability, energy efficiency, and design flexibility |

| Architectural Lighting | Cove and Wall Wash Lighting | Adds depth and aesthetic appeal to spaces | IP ratings for moisture resistance, ease of installation |

| Automotive | Interior and Exterior Vehicle Lighting | Enhances safety and aesthetics in vehicle design | Compliance with automotive standards, voltage compatibility |

| Entertainment | Stage and Event Lighting | Creates dynamic visual experiences for audiences | Color changing capabilities, DMX control compatibility |

How Are LED Tape Manufacturers Used in Retail and Commercial Applications?

In the retail and commercial sector, LED tape is extensively utilized for store displays and signage lighting. By providing bright, uniform illumination, these tape lights enhance product visibility, drawing customers’ attention and improving engagement. International B2B buyers should consider brightness levels, color temperature options, and customization capabilities to align with their branding strategies. Furthermore, the ability to integrate these lights into existing display systems can streamline installation and enhance overall aesthetics.

What Role Does LED Tape Play in the Hospitality Industry?

In the hospitality industry, LED tape is crucial for creating ambient and accent lighting in hotels and restaurants. This lighting not only enhances the guest experience but also contributes to the overall ambiance of the establishment. B2B buyers in this sector need to focus on durability and energy efficiency, as well as design flexibility, to ensure that the lighting can withstand varying conditions while meeting aesthetic demands. Selecting options with adjustable color temperatures can also allow for different atmospheres throughout the day.

Why Is Architectural Lighting Important for Cove and Wall Wash Applications?

Architectural lighting, particularly cove and wall wash applications, significantly benefits from LED tape solutions. These lights add depth and aesthetic appeal to spaces, creating visually engaging environments. For buyers, key considerations include the IP ratings of the products, which ensure moisture resistance in various settings, and the ease of installation. Flexible designs that can be customized to fit unique architectural features are also critical for achieving desired lighting effects.

How Is LED Tape Used in Automotive Lighting?

In the automotive industry, LED tape plays a vital role in both interior and exterior vehicle lighting. It enhances safety through improved visibility while also contributing to the overall aesthetics of vehicle design. B2B buyers need to ensure that the products comply with automotive standards and are compatible with the specific voltage requirements of their vehicles. Additionally, the ability to offer color-changing options can appeal to customers looking for customizable features in their vehicles.

What Benefits Does LED Tape Provide for Entertainment Lighting?

LED tape is widely used in the entertainment sector for stage and event lighting, where it creates dynamic visual experiences that captivate audiences. The versatility of LED tape allows for intricate designs and color-changing capabilities, essential for theatrical productions and concerts. Buyers should prioritize products that are compatible with DMX control systems, enabling seamless integration with existing lighting setups. Additionally, the durability and ease of setup are critical factors for fast-paced event environments.

3 Common User Pain Points for ‘LED Tape Manufacturers’ & Their Solutions

Scenario 1: Managing Inconsistent Quality in LED Tape Products

The Problem: B2B buyers often face challenges with inconsistent quality when sourcing LED tape products. Variability in manufacturing processes can lead to discrepancies in brightness, color temperature, and overall performance. This inconsistency not only impacts the final product quality but can also lead to increased project costs, delays, and potential damage to the buyer’s reputation. Buyers may find themselves navigating through numerous suppliers, each promising high quality, yet delivering subpar products.

The Solution: To mitigate quality concerns, buyers should prioritize sourcing from reputable LED tape manufacturers with a proven track record of quality assurance. It is essential to request certifications, such as ISO 9001, which indicates adherence to quality management principles. Furthermore, buyers should engage in a thorough vetting process that includes reviewing product samples and performance specifications. Establishing a clear communication channel with manufacturers about quality expectations and tolerances can also enhance product consistency. By forming strategic partnerships with manufacturers who offer warranties and return policies, buyers can safeguard their investments and ensure project timelines remain intact.

Scenario 2: Navigating Complex Technical Specifications

The Problem: Many B2B buyers encounter difficulties in understanding the technical specifications of LED tape products. With various options available—such as different voltage ratings, color temperatures, and IP ratings—buyers may struggle to select the appropriate products for specific applications. This can lead to costly mistakes, such as using an inappropriate LED tape that does not meet the project requirements, ultimately resulting in wasted resources and time.

The Solution: Buyers can overcome these technical challenges by investing time in education and training on LED tape specifications. Manufacturers often provide comprehensive product guides and resources that clarify technical terms and applications. Buyers should also leverage support from manufacturers’ technical teams to gain insights on the best product fit for their projects. Creating a checklist that includes key specifications needed for different projects can streamline the selection process. Additionally, attending industry trade shows or webinars can further enhance knowledge and help buyers stay updated on the latest trends and innovations in LED technology.

Scenario 3: Addressing Supply Chain and Delivery Challenges

The Problem: Supply chain disruptions can severely impact the availability of LED tape products, leading to delays in project timelines. Buyers often face uncertainty regarding lead times, particularly when sourcing from international manufacturers. This unpredictability can result in last-minute project changes, increased costs, and strained relationships with clients and stakeholders.

The Solution: To effectively manage supply chain challenges, buyers should diversify their supplier base. Working with multiple LED tape manufacturers can reduce reliance on a single source, allowing for greater flexibility in delivery timelines. Buyers should also establish clear agreements regarding lead times and inventory levels, ensuring that manufacturers understand the urgency of their projects. Utilizing inventory management systems can help track stock levels and forecast demand accurately. Additionally, implementing a just-in-time (JIT) inventory strategy can minimize excess stock and enhance cash flow. Regular communication with suppliers about potential delays and proactive planning can further alleviate supply chain risks and ensure smoother project execution.

Strategic Material Selection Guide for LED Tape Manufacturers

What Are the Key Materials Used in LED Tape Manufacturing?

When selecting materials for LED tape manufacturing, it is crucial to consider the properties and performance implications of each option. Here, we analyze four common materials used in the production of LED tapes, focusing on their characteristics, advantages, disadvantages, and considerations for international B2B buyers.

1. Flexible PCB (Printed Circuit Board)

Key Properties: Flexible PCBs are known for their excellent thermal conductivity and lightweight nature. They can withstand temperatures up to 130°C and are resistant to mechanical stress, making them suitable for various applications.

Pros & Cons: The primary advantage of flexible PCBs is their adaptability to different shapes and sizes, allowing for innovative designs. However, they can be more expensive to manufacture than rigid alternatives, which may impact overall production costs.

Impact on Application: Flexible PCBs are ideal for applications requiring intricate designs, such as under-cabinet lighting or curved installations. They are compatible with various media and can be easily integrated into complex lighting systems.

Considerations for International Buyers: Compliance with international standards like IPC-6013 is essential. Buyers from regions like Africa and South America may need to consider local manufacturing capabilities to ensure cost-effectiveness.

2. Silicone Encapsulation

Key Properties: Silicone materials are known for their high-temperature resistance (up to 200°C) and excellent UV stability. They also provide a waterproof barrier, making them suitable for outdoor applications.

Pros & Cons: The primary advantage of silicone encapsulation is its durability and protection against environmental factors. However, the cost of silicone can be higher than other encapsulation materials, which may affect pricing strategies.

Impact on Application: Silicone-encapsulated LED tapes are particularly effective in outdoor and wet environments, ensuring longevity and reliability. They are compatible with various substrates, enhancing versatility.

Considerations for International Buyers: Buyers should ensure that silicone materials meet regional compliance standards, such as ASTM D2240 for hardness. In the Middle East, where high temperatures are common, silicone’s thermal properties are a significant advantage.

3. Aluminum Profiles

Key Properties: Aluminum is lightweight, highly conductive, and resistant to corrosion. It can handle temperatures ranging from -40°C to 80°C, making it suitable for a variety of environments.

Pros & Cons: The key advantage of aluminum profiles is their ability to dissipate heat effectively, prolonging the life of the LED tape. However, they can be more expensive than plastic alternatives and may require additional processing.

Impact on Application: Aluminum profiles are commonly used in commercial and residential lighting applications, providing structural support and aesthetic appeal. They enhance the overall performance of LED tapes by improving heat management.

Considerations for International Buyers: Compliance with standards like EN 573 for aluminum alloys is crucial. Buyers in Europe, particularly, may prioritize aluminum for its recyclability and sustainability.

4. Polycarbonate (PC)

Key Properties: Polycarbonate is known for its high impact resistance and transparency. It can withstand temperatures up to 120°C and has good UV resistance, making it suitable for various applications.

Pros & Cons: The main advantage of polycarbonate is its lightweight nature and ease of fabrication. However, it may not offer the same level of heat dissipation as aluminum, which can limit its effectiveness in high-power applications.

Impact on Application: Polycarbonate is often used for protective covers and diffusers in LED tape applications. Its clarity allows for optimal light transmission, making it ideal for decorative lighting.

Considerations for International Buyers: Buyers should verify that polycarbonate materials comply with local regulations regarding safety and environmental impact. In regions like Brazil, where humidity levels can be high, ensuring moisture resistance is essential.

Summary Table

| Material | Typical Use Case for LED Tape Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB | Intricate designs, curved installations | Adaptability to various shapes | Higher manufacturing costs | High |

| Silicone Encapsulation | Outdoor and wet environments | Durability and environmental protection | Higher material costs | Med |

| Aluminum Profiles | Commercial and residential lighting | Effective heat dissipation | More expensive than plastic alternatives | High |

| Polycarbonate (PC) | Protective covers and diffusers | Lightweight and easy to fabricate | Limited heat dissipation | Med |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, aiding in informed decision-making for LED tape manufacturing.

In-depth Look: Manufacturing Processes and Quality Assurance for LED Tape Manufacturers

What Are the Main Stages in the Manufacturing Process of LED Tape?

The manufacturing process for LED tape lights involves several critical stages, each of which plays a crucial role in ensuring the final product meets quality and performance standards.

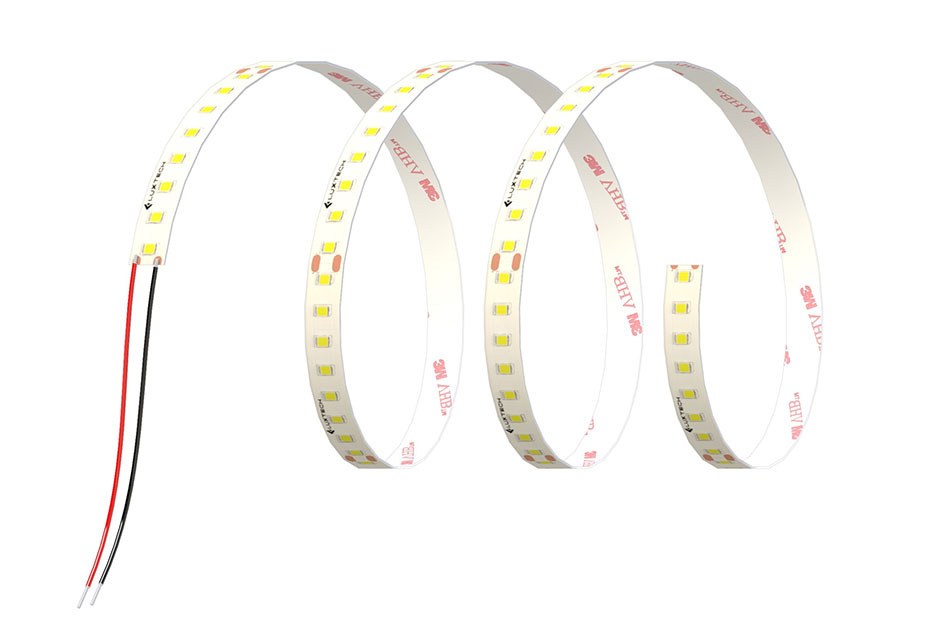

Material Preparation

The first stage involves sourcing and preparing high-quality materials, including LED chips, circuit boards, adhesive backing, and encapsulation materials. Suppliers often procure LED chips from reputable manufacturers, ensuring they meet specific lumen output and color temperature requirements. The circuit boards are fabricated using advanced techniques like surface mount technology (SMT), which allows for precise placement of LED components.

Forming and Assembly

Once materials are prepared, the next stage is forming and assembly. This includes:

-

PCB Assembly: LED chips are mounted onto the printed circuit boards using automated pick-and-place machines. This process is critical for ensuring precise alignment and soldering of components.

-

Wiring and Connections: After assembly, wires and connectors are soldered to the PCB. This step requires attention to detail, as improper connections can lead to performance issues.

-

Adhesive Application: A strong adhesive backing is applied to facilitate easy installation by end-users. This step often involves automated systems to ensure uniform application.

Finishing Touches

The final stage includes various finishing processes that enhance the aesthetic and functional qualities of the LED tape:

-

Encapsulation: To protect the LEDs from moisture and dust, a protective coating is applied. This is particularly important for products designed for outdoor use, where environmental exposure is a concern.

-

Cutting and Testing: After encapsulation, the LED tape is cut to specified lengths. Each batch typically undergoes rigorous testing to ensure functionality and performance specifications are met.

What Quality Control Measures Are Essential for LED Tape Manufacturers?

Quality control (QC) is integral to the manufacturing process, ensuring that every product meets international standards and customer expectations.

Which International Standards Should LED Tape Manufacturers Adhere To?

Compliance with international standards is vital for building trust with B2B buyers. Common certifications include:

-

ISO 9001: This standard focuses on quality management systems and helps manufacturers ensure consistent quality in their processes.

-

CE Marking: Essential for products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

-

RoHS Compliance: Ensures that hazardous materials are minimized in the manufacturing process, crucial for environmental sustainability.

What Are the Key QC Checkpoints in LED Tape Manufacturing?

Quality assurance in LED tape manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): Before production begins, all raw materials are inspected for defects or non-compliance with specifications.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are checked at various stages to ensure that the assembly and soldering processes are performed correctly.

-

Final Quality Control (FQC): Once the product is fully assembled, each unit undergoes comprehensive testing for electrical performance, light output, and color accuracy. This stage may also include visual inspections for any cosmetic defects.

What Testing Methods Are Commonly Used to Ensure Quality in LED Tape Production?

Several testing methods are employed to validate the quality of LED tape lights:

-

Photometric Testing: Measures light output and distribution, ensuring that the product meets specified lumen requirements.

-

Thermal Testing: Evaluates heat dissipation to prevent overheating, which can significantly reduce the lifespan of LED products.

-

Electrical Testing: Assesses voltage and current levels to verify that the LED tape operates within specified parameters.

-

Environmental Testing: Especially for outdoor products, this includes IP rating tests to ensure water and dust resistance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s QC processes is crucial to ensure product reliability and compliance with local regulations. Here are some actionable steps:

-

Supplier Audits: Conduct thorough audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

-

Request Quality Reports: Ask for detailed quality assurance reports that outline the QC checkpoints and testing methodologies employed in their manufacturing process.

-

Third-Party Inspections: Engage third-party inspection services that can provide unbiased assessments of product quality, ensuring adherence to specified standards before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing LED tape from international manufacturers, buyers should consider regional certification requirements and market-specific standards. For example, products intended for the European market must comply with CE marking, while those for the U.S. market may require UL certification.

Understanding these nuances can help buyers avoid costly compliance issues and ensure that the products they purchase meet the necessary legal and safety requirements in their respective markets.

In conclusion, the manufacturing and quality assurance processes for LED tape lights are complex and critical to delivering reliable, high-performance products. By focusing on robust manufacturing practices and stringent quality control measures, LED tape manufacturers can meet the diverse needs of B2B buyers across various global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘LED Tape Manufacturers’

Introduction

Sourcing LED tape manufacturers can be a complex process, especially for international buyers navigating diverse markets. This practical checklist is designed to guide you through the essential steps to ensure a successful procurement experience, helping you identify reliable suppliers who meet your technical, quality, and logistical needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining your technical requirements for LED tape. Consider factors such as voltage, color temperature, brightness (lumens), and environmental ratings (e.g., IP ratings for moisture resistance). A well-defined specification not only streamlines the sourcing process but also helps suppliers provide accurate quotations and product recommendations tailored to your project.

- Voltage Options: Ensure you specify whether you need 12V or 24V LED tapes, as this can affect compatibility with existing systems.

- Color Temperature Range: Determine the required color temperatures (e.g., warm white, cool white, RGB) to match your design vision.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize online directories, trade shows, and industry forums to compile a list of manufacturers with a solid reputation in the LED market. Prioritize suppliers known for their product quality, reliability, and innovation.

- Industry Reputation: Look for reviews and testimonials from other buyers, especially those in your region or industry.

- Product Range: Ensure the supplier offers a diverse selection of LED tape options that align with your specifications.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that suppliers have the necessary certifications and compliance with international quality standards. This step ensures that the products you receive are safe and meet regulatory requirements in your target markets.

- Key Certifications: Look for certifications such as UL, CE, or RoHS, which indicate adherence to safety and environmental standards.

- Quality Assurance Processes: Inquire about their quality control measures to ensure consistent product quality.

Step 4: Request Samples

Before making a large purchase, request samples of the LED tape products you are considering. Testing samples allows you to evaluate the quality, brightness, color accuracy, and flexibility of the tapes in real-world conditions.

- Testing Environment: Assess samples in the actual environment where they will be installed to gauge performance.

- Comparison: Compare samples from multiple suppliers to make informed decisions based on quality and performance.

Step 5: Review Terms and Conditions

Carefully review the terms and conditions of the purchase agreement with potential suppliers. Understanding payment terms, delivery schedules, and warranty policies can prevent misunderstandings later.

- Payment Options: Check for flexible payment terms that suit your budget and cash flow.

- Warranty and Returns: Ensure the supplier has a clear warranty policy and a return process for defective products.

Step 6: Establish Communication Channels

Effective communication is vital for successful collaboration with your chosen supplier. Establish clear channels for ongoing discussions about orders, specifications, and any potential issues.

- Point of Contact: Designate a specific contact person for both you and the supplier to streamline communication.

- Regular Updates: Schedule regular check-ins to discuss project progress and address any concerns promptly.

Step 7: Plan for Logistics and Shipping

Finally, consider the logistics of shipping and handling your LED tape orders. Assess the supplier’s capabilities in terms of shipping options, lead times, and delivery methods to ensure timely receipt of your products.

- Shipping Options: Discuss available shipping methods that align with your deadlines and budget.

- Customs and Duties: Be aware of any import duties or customs regulations that may apply to your order based on your location.

By following this checklist, you can navigate the complexities of sourcing LED tape manufacturers effectively, ensuring that you choose a supplier that meets your specific needs and expectations.

Comprehensive Cost and Pricing Analysis for LED Tape Manufacturers Sourcing

What Are the Key Cost Components for LED Tape Manufacturers?

When evaluating the cost structure of LED tape manufacturing, several key components come into play. These include:

-

Materials: The primary materials for LED tape include LED chips, circuit boards, and adhesive backing. The quality and sourcing of these materials can significantly affect overall costs. High-quality materials typically yield better performance and longevity, justifying a higher price point.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, which can increase labor costs but also enhance product reliability.

-

Manufacturing Overhead: This encompasses the costs associated with running a production facility, including utilities, rent, and maintenance. Manufacturers with advanced technology and efficient processes may have lower overhead costs, which can be passed on to buyers.

-

Tooling: Initial setup costs for molds and other manufacturing tools can be significant, especially for custom designs. These costs are amortized over production runs, so larger orders can benefit from lower per-unit tooling costs.

-

Quality Control (QC): Ensuring product reliability through rigorous quality control processes is essential, especially for B2B buyers who require dependable products. QC processes incur costs but are vital for minimizing returns and defects.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping methods, and packaging requirements. Buyers should consider these costs as part of the total pricing structure.

-

Margin: Manufacturers typically add a profit margin to the total costs, which can vary based on competition, market demand, and brand positioning.

How Do Price Influencers Impact LED Tape Pricing?

Several factors influence the pricing of LED tape, particularly for international B2B buyers:

-

Volume/MOQ: Larger orders often lead to discounted prices. Manufacturers may have Minimum Order Quantities (MOQs) that can affect pricing structures, so negotiating for higher volumes can yield better rates.

-

Specifications and Customization: Customized products or specialized specifications typically carry higher costs due to the additional resources required for development and production. Buyers should weigh the benefits of customization against the potential cost increases.

-

Materials and Quality Certifications: The choice of materials and certifications (e.g., UL, CE) can significantly impact costs. Higher-quality, certified products often come at a premium but offer improved safety and efficiency.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may command higher prices, but they often provide better service and assurance of quality.

-

Incoterms: The terms of shipping and delivery (Incoterms) can affect the total cost. Understanding who is responsible for shipping, insurance, and tariffs is crucial for international transactions.

What Buyer Tips Can Enhance Cost Efficiency in LED Tape Sourcing?

To optimize costs when sourcing LED tape, international buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when placing large orders. Building a relationship can also lead to better terms and potential discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like energy efficiency, lifespan, and potential maintenance costs. A higher upfront cost may be offset by lower operational costs over time.

-

Understand Pricing Nuances for International Transactions: Be aware of additional costs such as tariffs, taxes, and currency fluctuations when importing products. Working with suppliers who have experience in international shipping can help mitigate these risks.

-

Research Local Regulations and Standards: Different regions have varying compliance requirements for lighting products. Understanding these can prevent costly delays or non-compliance penalties.

Disclaimer on Indicative Prices

Pricing for LED tape can vary widely based on the aforementioned factors, and the figures provided by manufacturers may be subject to change based on market conditions and supplier negotiations. It’s advisable for buyers to request updated quotes and detailed breakdowns of costs to make informed purchasing decisions.

Alternatives Analysis: Comparing LED Tape Manufacturers With Other Solutions

Exploring Alternatives to LED Tape Manufacturers

When considering lighting solutions for commercial and residential applications, B2B buyers often evaluate various options beyond LED tape. While LED tape is favored for its versatility and energy efficiency, alternative technologies can offer distinct advantages depending on specific project requirements. This analysis compares LED tape manufacturers to other viable solutions: LED panel lights and traditional incandescent lighting.

| Comparison Aspect | LED Tape Manufacturers | LED Panel Lights | Traditional Incandescent Lighting |

|---|---|---|---|

| Performance | High luminous efficacy, customizable lengths, and colors | Uniform light distribution, energy-efficient | High brightness but low energy efficiency |

| Cost | Generally moderate initial cost with long-term savings | Higher upfront cost, lower operating cost | Low initial cost, high energy consumption |

| Ease of Implementation | Requires careful installation, often needs professional assistance | Simple installation, typically surface-mounted | Easy to install, standard fittings available |

| Maintenance | Low maintenance, long lifespan (up to 50,000 hours) | Low maintenance, long lifespan (up to 50,000 hours) | Frequent replacement (typically 1,000 hours) |

| Best Use Case | Accent lighting, under-cabinet applications, cove lighting | Offices, commercial spaces, and schools | Residential applications, temporary setups |

What Are the Pros and Cons of LED Panel Lights?

LED panel lights are a popular alternative to LED tape, especially in environments requiring even lighting across large areas, such as offices and commercial spaces. The primary advantage of LED panels is their uniform light distribution, which minimizes shadows and glare, enhancing visibility. They are energy-efficient, reducing electricity costs over time. However, LED panels usually come with a higher upfront cost compared to LED tape, and their installation may require professional expertise for optimal results.

How Does Traditional Incandescent Lighting Compare?

Traditional incandescent lighting has been a long-standing choice for many applications due to its warm glow and instant brightness. It is easy to install and generally has a lower initial cost. However, incandescent bulbs have a significantly shorter lifespan and higher energy consumption, making them less cost-effective in the long run. They are best suited for residential settings or temporary applications where budget constraints are a priority.

Conclusion: How Should B2B Buyers Choose the Right Lighting Solution?

When selecting a lighting solution, B2B buyers should consider their specific needs, including the intended application, budget constraints, and maintenance capabilities. LED tape manufacturers excel in versatility and energy efficiency, making them ideal for decorative and functional lighting in diverse settings. LED panel lights offer superior uniformity for commercial applications, while traditional incandescent options may suffice for short-term residential use. By weighing these factors, buyers can make informed decisions that align with their project goals and operational requirements.

Essential Technical Properties and Trade Terminology for LED Tape Manufacturers

What Are the Key Technical Properties of LED Tape for Manufacturers?

1. Lumen Output

Lumen output measures the amount of visible light emitted by the LED tape. It is crucial for B2B buyers to understand lumen output as it determines the brightness of the lighting solution. Higher lumen ratings are essential for applications requiring substantial illumination, such as commercial spaces or outdoor environments. Selecting the appropriate lumen output ensures that the lighting meets the specific requirements of a project, enhancing customer satisfaction and reducing the likelihood of returns or complaints.

2. Color Temperature

Color temperature, measured in Kelvin (K), indicates the hue of the light emitted by the LED tape. Common ranges include warm white (2700K-3000K), neutral white (3500K-4100K), and cool white (5000K-6500K). Understanding color temperature is vital for applications where ambiance is critical, such as hospitality or residential projects. A proper selection can significantly influence the aesthetic appeal and functionality of the lighting design.

3. IP Rating (Ingress Protection)

The IP rating defines the level of protection provided against dust and water ingress. For instance, an IP65 rating indicates that the LED tape is dust-tight and protected against water jets. This property is particularly important for buyers in regions with varying climates or for applications in outdoor settings. Selecting LED tapes with appropriate IP ratings ensures durability and longevity, which are key considerations for project cost-effectiveness.

4. Voltage and Power Consumption

LED tapes typically operate on low voltages, such as 12V or 24V, and understanding their power consumption is essential for energy efficiency. B2B buyers need to consider the total wattage of the LED tape to ensure compatibility with existing electrical systems and to optimize energy usage. This is especially relevant in regions where energy costs are high or sustainability is a priority.

5. CRI (Color Rendering Index)

CRI measures the ability of a light source to accurately render colors in comparison to natural light. A CRI of 80 or higher is generally recommended for most applications, while specialized settings may require higher values. This property is essential for buyers in retail or healthcare sectors, where accurate color representation impacts product visibility and patient comfort.

What Are Common Trade Terms Used in the LED Tape Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the LED tape industry, OEM partnerships allow manufacturers to design custom lighting solutions tailored to specific client needs. This term is important for B2B buyers looking for unique, branded products that differentiate them in the market.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is critical for buyers to assess inventory and cash flow needs. Low MOQs may benefit smaller businesses or startups, while larger firms may negotiate higher quantities for cost savings.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This term is vital for B2B buyers as it formalizes the procurement process, allowing them to compare offers from multiple manufacturers and select the best value based on quality and cost.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international trade terms used to define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps buyers understand their obligations regarding shipping, insurance, and tariffs, which is crucial for international transactions, particularly for buyers in regions like Africa and South America.

5. Dimming Capability

This term refers to the ability of LED tape to adjust brightness levels, often achieved through compatible drivers or controllers. Dimming capability enhances energy efficiency and allows for customizable lighting environments. B2B buyers should consider this feature for projects requiring flexible lighting solutions, such as commercial spaces or residential areas.

Understanding these technical properties and trade terminologies equips B2B buyers with the knowledge to make informed decisions when sourcing LED tape products, ensuring they meet both functional and aesthetic project requirements.

Navigating Market Dynamics and Sourcing Trends in the LED Tape Manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the LED Tape Manufacturing Sector?

The global LED tape market is experiencing significant growth, driven by an increasing demand for energy-efficient lighting solutions and advancements in LED technology. Key trends include the rise of smart lighting systems that integrate with IoT devices, allowing for remote control and automation. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, as businesses seek innovative solutions to enhance operational efficiency and reduce energy costs.

Moreover, the diversification of product offerings is notable, with manufacturers expanding their lines to include color-changing, dim-to-warm, and tunable white options. These enhancements not only provide aesthetic flexibility but also cater to varying consumer preferences across different markets. The focus on customization is becoming increasingly important, as buyers look for tailored solutions that meet specific project requirements.

Another market dynamic is the competitive landscape, where manufacturers are leveraging advanced technologies such as COB (Chip on Board) and RGBW (Red, Green, Blue, White) systems to differentiate their products. Buyers should pay attention to the reliability and warranty offerings from suppliers, as these factors can significantly influence long-term project success. Lastly, sustainability is shaping purchasing decisions, with businesses increasingly favoring suppliers who demonstrate a commitment to eco-friendly practices.

How Is Sustainability Influencing Sourcing Decisions in the LED Tape Sector?

Sustainability is a critical consideration for B2B buyers in the LED tape manufacturing sector. The environmental impact of products is under scrutiny, with companies seeking suppliers who prioritize sustainable materials and ethical sourcing practices. This trend is particularly relevant in emerging markets, where regulatory frameworks are evolving to support greener initiatives.

Buyers should look for manufacturers that offer “green” certifications, such as Energy Star, RoHS, or ISO 14001, which indicate compliance with environmental standards. Additionally, the use of recyclable and low-impact materials in manufacturing processes is becoming a key differentiator among suppliers. By opting for sustainable products, businesses not only contribute to environmental conservation but also enhance their brand reputation, appealing to eco-conscious consumers.

Ethical supply chains are gaining traction, with companies increasingly aware of the social implications of their sourcing decisions. Manufacturers that demonstrate transparency in their supply chains and ethical labor practices are more likely to attract international buyers. As the demand for sustainable and ethically sourced products continues to rise, B2B buyers should prioritize partnerships with manufacturers that align with these values.

What Is the Brief Evolution of LED Tape Manufacturing?

The evolution of LED tape manufacturing can be traced back to the early 2000s when LED technology began to emerge as a viable alternative to traditional lighting solutions. Initially, LED strips were limited in functionality and brightness, primarily serving decorative purposes in residential applications. However, advancements in LED technology led to significant improvements in efficiency, brightness, and color capabilities.

By the late 2010s, the market saw a surge in demand for LED tape lights in commercial and industrial applications, driven by their energy-saving properties and versatility. Manufacturers began to innovate with features such as color-changing capabilities, smart lighting integration, and customizable lengths, further expanding their appeal.

Today, LED tape lights are a staple in various sectors, including retail, hospitality, and architecture, reflecting a shift towards dynamic lighting solutions that enhance aesthetic and functional aspects of spaces. As the market continues to evolve, manufacturers are expected to further innovate, focusing on sustainability and technology integration to meet the demands of a diverse global market.

Frequently Asked Questions (FAQs) for B2B Buyers of LED Tape Manufacturers

-

How do I choose the right LED tape for my project?

Choosing the right LED tape involves assessing your project’s specific requirements. Consider the application—whether it’s for indoor accent lighting, outdoor installations, or industrial use. Evaluate critical factors such as lumen output, color temperature, and IP rating for moisture resistance. Additionally, review the flexibility and ease of installation of the tape, especially for intricate designs. Engaging with manufacturers for samples can also help you evaluate the quality and performance before making a bulk purchase. -

What is the best LED tape for commercial applications?

For commercial applications, look for high-density LED tapes like those offering 800+ lumens per foot, ensuring bright and effective illumination. Options like RGBW or tunable white LED tapes are ideal for versatility in lighting design, catering to different moods and settings. Additionally, consider products with high CRI (Color Rendering Index) values above 90 for accurate color representation. Manufacturer warranties of 5 years or more can also indicate reliability and long-term performance. -

What are common minimum order quantities (MOQs) for LED tape?

Minimum order quantities (MOQs) for LED tape can vary significantly between manufacturers, typically ranging from 50 to 500 meters. Some suppliers may have lower MOQs for specific products or during promotional periods. It’s advisable to clarify MOQs before proceeding with negotiations, especially if you’re looking to test products or develop a long-term partnership. Discussing customization options may also influence MOQs, as tailored solutions often require different production runs. -

How can I ensure quality when sourcing LED tape from international manufacturers?

To ensure quality, conduct thorough research on potential suppliers, focusing on their certifications (such as ISO 9001) and quality assurance processes. Request samples to evaluate the product firsthand, and inquire about their testing methods for reliability and performance. Additionally, check customer reviews and case studies to gauge satisfaction levels. Establishing a clear communication channel can also facilitate discussions about quality expectations and standards. -

What payment terms should I expect when buying LED tape internationally?

Payment terms can vary, but common practices include upfront payments, partial payments, or letters of credit. Many manufacturers require a deposit of 30-50% before production, with the balance due upon shipment or delivery. It’s crucial to negotiate terms that suit your financial capabilities while ensuring security for both parties. Always clarify the currency used for transactions, as exchange rates can impact overall costs. -

What are the shipping options for LED tape products?

Shipping options for LED tape products generally include air freight, sea freight, and express courier services. Air freight is faster but more expensive, suitable for urgent orders, while sea freight is cost-effective for larger quantities but takes longer. Express services can be used for smaller shipments requiring quick delivery. It’s essential to discuss logistics with your supplier to choose the most efficient and economical shipping method based on your location and timeline. -

What customization options are available for LED tape?

Many manufacturers offer customization options for LED tape, including different colors, lengths, and adhesive backing types. You may also request variations in brightness, IP ratings, or the addition of specific features like dimming capabilities or color-changing technology. Discuss your project needs with the manufacturer to explore tailored solutions that meet your unique requirements and enhance the overall design. -

How can I track my order once it’s shipped?

Most reputable manufacturers provide tracking information once your order has been shipped. This can typically be accessed via a tracking number linked to the shipping carrier. Establish a clear communication channel with your supplier to receive updates on your shipment status. Some manufacturers may also offer online portals where you can track your order in real time, providing peace of mind regarding delivery timelines and logistics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for LED Tape Manufacturers

In the rapidly evolving landscape of LED tape manufacturing, strategic sourcing emerges as a crucial factor for international B2B buyers. By partnering with reputable manufacturers, buyers can access a diverse array of high-quality products, including static white, color-changing, and dim-to-warm options. Understanding the value of customization, such as build-to-order solutions and specific IP ratings for various environments, can significantly enhance project outcomes.

Moreover, leveraging suppliers that prioritize quick response times and robust inventory management ensures that projects remain on schedule and within budget. Buyers should also consider the warranty offerings and product certifications, as these indicators of reliability can safeguard investments.

Looking ahead, the demand for innovative lighting solutions is set to increase, particularly in emerging markets across Africa, South America, and the Middle East. As sustainable practices gain traction, LED tape manufacturers are well-positioned to meet this demand with energy-efficient products. International buyers are encouraged to explore partnerships with forward-thinking manufacturers who are committed to quality, service, and innovation. Engaging with these suppliers will not only fulfill immediate project needs but also pave the way for future growth and collaboration in the global marketplace.