Top 8 Metal Part Manufacturers List and Guide: How To Solve Scena…

Introduction: Navigating the Global Market for Metal Part Manufacturers

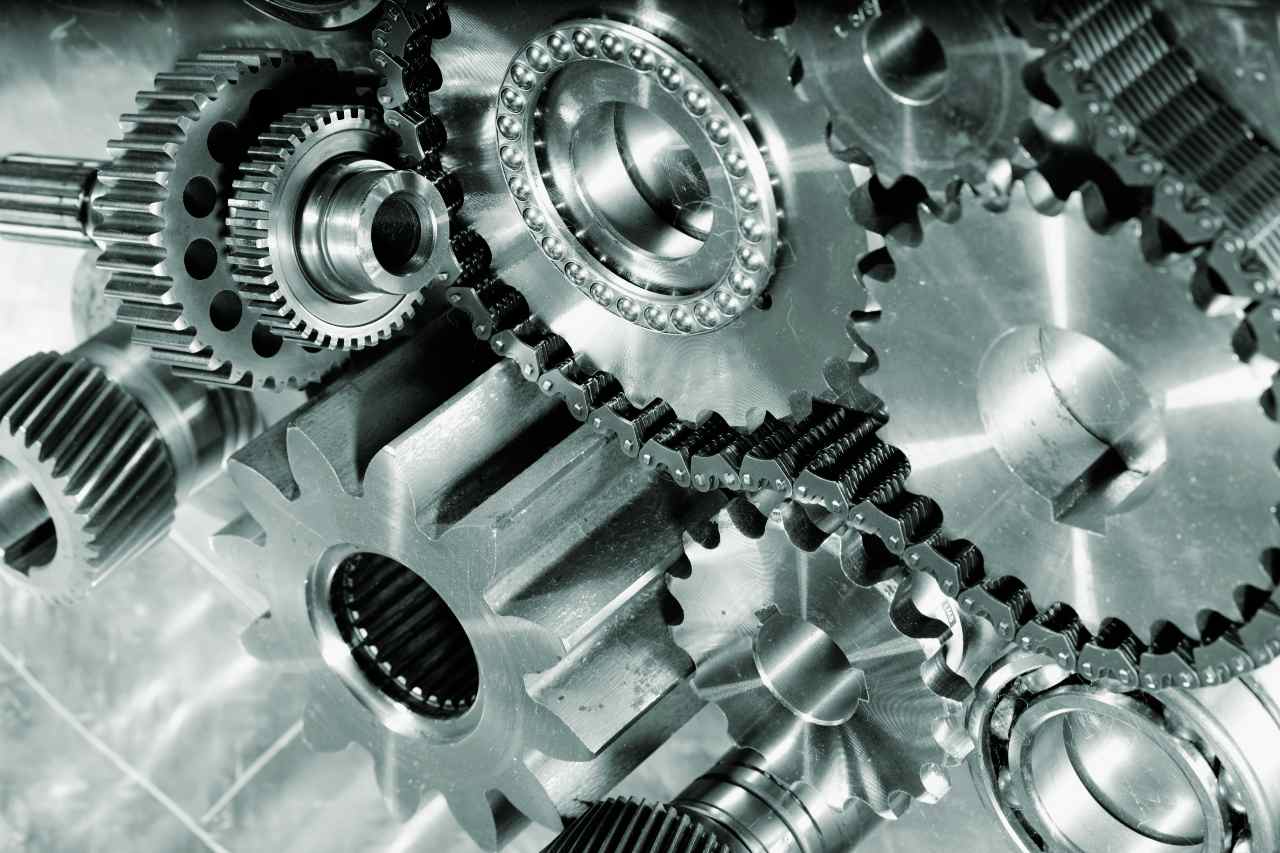

In the ever-evolving landscape of global manufacturing, sourcing metal parts can often present significant challenges for international B2B buyers. From navigating complex supply chains to ensuring quality and compliance with regional standards, the process can be daunting. This guide on metal part manufacturers aims to demystify these challenges, offering insights into the diverse types of metal components, their applications across various industries, and effective strategies for supplier vetting.

Within these pages, we will explore essential considerations such as cost factors, production capabilities, and the latest technologies in metal fabrication. Buyers from Africa, South America, the Middle East, and Europe—regions characterized by distinct market dynamics—will find actionable information tailored to their unique needs. By empowering you with the knowledge to make informed purchasing decisions, this guide serves as a valuable resource for optimizing your sourcing strategy.

Whether you are looking for custom sheet metal fabrication, precision CNC machining, or high-volume stamping, understanding the landscape of metal part manufacturing will not only enhance your procurement process but also improve your overall supply chain efficiency. Join us as we navigate this critical sector, ensuring that you are equipped with the right tools and insights to succeed in your metal parts sourcing endeavors.

Top 10 Metal Part Manufacturers Manufacturers & Suppliers List

1. SendCutSend – Custom Sheet Metal Fabrication

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: SendCutSend offers custom sheet metal fabrication services including laser cutting, CNC routing, waterjet cutting, anodizing, bending & forming, countersinking, dimple forming, hardware insertion, plating, powder coating, tapping, tumbling, and deburring. They provide instant pricing for custom parts uploaded in STEP, DXF, or EPS formats, with no minimum quantities and free US shipping on orders o…

2. eMachineShop – Custom Steel Parts Fabrication

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: Custom steel parts fabrication services offered by eMachineShop, including CNC steel cutting, with over 15 years of experience. Features include free CAD software for design, free shipping in the USA, no minimum order quantity, and a 100% quality guarantee. Various machining options available: CNC Milling, Waterjet Cutting, CNC Turning, EDM, Laser Cutting, and Plasma Cutting. Secondary manufacturi…

3. Dalsin Industries – Metal Fabrication & Enclosures

Domain: dalsinind.com

Registered: 1998 (27 years)

Introduction: American Made Metal Parts & Products include enclosures, boxes, door panels, and solar power cabinets. Dalsin Industries offers a range of metal fabrication services such as sheet metal fabrication, laser sheet metal cutting, MIG and TIG welding, robotic welding, automated sheet metal punching, and panel bending. They work with various materials including aluminum, carbon steel, stainless steel, c…

4. MW Components – Custom Springs

Domain: mwcomponents.com

Registered: 2017 (8 years)

Introduction: MW Components offers a wide range of US-made metal components, including:

1. **Springs**:

– Custom Springs

– Hot Wound Springs

– Coiled Springs

– Compression Springs

– Extension Springs

– Torsion Springs

– Automotive Springs

– Drawbar Springs

– Constant Force Springs

– Belleville Washers / Disc Springs

– Flat Springs

– Machined Springs

– POP Display Solution…

5. Atlas Metal Parts – Metal Stamping & Fabrication Solutions

Domain: atlasmetalparts.com

Registered: 2001 (24 years)

Introduction: Atlas Metal Parts specializes in metal stamping and fabrication, offering a range of services including:

– Stamping: Capable of handling 100 Tons to 1,500 Tons with coil feed and blanks.

– Fabrication: Utilizing laser, brake press, shear, and turret punch press.

– Tool & Die: Production, maintenance, repair, and storage of tooling.

– Welding: MIG/TIG, robotic, and spot welding, with AWS certificat…

6. Protolabs – Metal Fabrication Services

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Protolabs offers a range of metal fabrication services, utilizing both soft and hard metals. Soft metals include aluminum, magnesium, brass, and copper, with specific aluminum alloys such as 6061-T651 and 7075-T651. 6061 aluminum is known for its corrosion resistance and weldability, making it suitable for low-fatigue applications like structural components and automotive parts. 7075 aluminum is s…

7. Protocase – Custom Sheet Metal Parts

Domain: protocase.com

Registered: 2001 (24 years)

Introduction: Custom sheet metal parts and precision components built in 2-3 days with no minimum order quantity. Protocase offers a wide range of products including brackets, plates, frames, arms, bus bars, and fixtures. Customers can choose from various materials, hardware, fasteners, and powdercoat colors. Additional services include direct digital printing and silkscreen for graphics. Design options include…

8. G.E. Mathis Company – Precision Metal Fabrication

Domain: gemathis.com

Registered: 1997 (28 years)

Introduction: G.E. Mathis Company specializes in precision metal fabrication with over 120 years of experience. Key services include:

– Metal Fabrication

– Sheet Metal Fabrication

– Stainless Steel Fabrication

– Metal Cutting (Laser Cutting, CNC Plasma Cutting)

– Metal Forming (Press Brake Forming, Bending)

– Metal Welding

– HARDOX® Wearparts Fabrication

– Contract Manufacturing

– Custom OEM Solutions

Capabili…

Understanding Metal Part Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Sheet Metal Fabrication | Quick turnaround, low minimum order quantities, versatile materials | Prototyping, industrial equipment, HVAC systems | Pros: Fast delivery, cost-effective for small runs. Cons: Limited to specific processes. |

| CNC Machining | Precision machining, complex geometries, high-volume production | Aerospace components, automotive parts, medical devices | Pros: High precision, repeatability. Cons: Higher setup costs for low volume. |

| Metal Stamping | High-volume production, tight tolerances, cost-effective for bulk | Electrical enclosures, automotive parts, appliances | Pros: Economical for large runs, efficient. Cons: Not ideal for low volume or complex designs. |

| Tool & Die Making | Custom tooling, in-house design, prototyping capabilities | Manufacturing fixtures, specialized components | Pros: Tailored solutions, reduces production risk. Cons: Longer lead times for tooling. |

| Wire EDM | High precision for conductive materials, intricate designs | Aerospace, medical, and automotive applications | Pros: Exceptional detail, minimal material waste. Cons: Slower than traditional machining methods. |

What are the Key Characteristics of Custom Sheet Metal Fabrication?

Custom sheet metal fabrication stands out due to its rapid production capabilities and flexibility in order quantities. It allows businesses to create tailored components quickly, making it ideal for prototyping or low-volume needs in industries such as HVAC and industrial equipment. Buyers should consider the specific materials available and the range of finishing options that can enhance the final product. While this method is cost-effective for small runs, it may not be suitable for high-volume production due to the associated costs.

How Does CNC Machining Benefit B2B Buyers?

CNC machining is characterized by its ability to produce intricate designs with high precision and repeatability. This manufacturing type is particularly advantageous for sectors like aerospace, automotive, and medical devices, where tolerances are critical. Buyers should evaluate the machining capabilities, including the range of materials processed and the complexity of parts that can be manufactured. Although CNC machining can entail higher setup costs, the long-term benefits of precision and quality often outweigh these initial investments, especially for larger production runs.

What Makes Metal Stamping a Preferred Choice for High-Volume Production?

Metal stamping is a highly efficient manufacturing process for producing parts in bulk with tight tolerances. This method is commonly used in the production of electrical enclosures, automotive components, and household appliances. Buyers should assess the potential cost savings associated with high-volume orders and the speed of production. While metal stamping offers excellent economies of scale, it may not be the best fit for low-volume or highly complex parts due to its setup requirements and limitations in design flexibility.

Why is Tool & Die Making Important in Metal Manufacturing?

Tool and die making is essential for creating custom tooling that meets specific manufacturing needs. This process typically involves in-house design and prototyping, which can significantly reduce production risks for specialized components. Industries that benefit from tool and die making include manufacturing fixtures and other customized parts. However, buyers should be aware of the longer lead times associated with tooling and the necessity for upfront investment in design, which can be a barrier for some projects.

How Does Wire EDM Enhance Precision in Metal Part Manufacturing?

Wire EDM (Electrical Discharge Machining) is known for its ability to create highly detailed components from conductive materials, making it a go-to solution for industries requiring precision, such as aerospace and medical. This method excels in producing intricate shapes with minimal material waste. Buyers should consider the specific applications of wire EDM and its capability to handle complex geometries. While it offers exceptional precision, the process can be slower than traditional machining methods, which may impact production timelines for some projects.

Key Industrial Applications of Metal Part Manufacturers

| Industry/Sector | Specific Application of Metal Part Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft assembly | Enhances safety and performance of aircraft systems | Certification standards, material quality, lead times |

| Automotive | Custom metal stamping for vehicle parts | Reduces weight and improves fuel efficiency | Volume requirements, tooling costs, delivery schedules |

| Energy & Utilities | Fabrication of structural components for turbines | Increases energy efficiency and reliability | Material specifications, regulatory compliance, durability |

| Medical Devices | Manufacturing of surgical instruments | Ensures precision and sterility in medical procedures | Biocompatibility, quality certifications, traceability |

| Construction | Metal framing and structural supports | Provides strength and durability for buildings | Material sourcing, cost-effectiveness, local regulations |

How Are Metal Part Manufacturers Supporting the Aerospace Industry?

In the aerospace sector, metal part manufacturers produce precision components that are critical for aircraft assembly. These parts, such as brackets and fittings, must meet stringent safety and performance standards. For international buyers, particularly from Europe and the Middle East, it’s essential to source components that comply with aerospace certifications like AS9100. This ensures reliability and minimizes risks associated with aircraft operations.

What Role Do Metal Part Manufacturers Play in Automotive Production?

In the automotive industry, custom metal stamping is a vital application that produces vehicle parts such as chassis components and brackets. This process helps reduce weight and improve fuel efficiency, aligning with the industry’s shift towards sustainability. Buyers from Africa and South America should consider the manufacturer’s ability to handle high-volume orders and maintain quality control, as well as their experience with various materials, which can significantly impact production timelines and costs.

How Are Metal Part Manufacturers Contributing to Energy & Utilities?

Metal part manufacturers fabricate structural components for turbines and other energy systems, enhancing energy efficiency and reliability. These components often require specialized materials that can withstand extreme conditions. International buyers must focus on sourcing manufacturers that understand local regulatory compliance and can provide durable solutions to meet the demands of the energy sector, especially in regions with varying environmental challenges.

Why Are Metal Part Manufacturers Essential for Medical Devices?

In the medical device industry, manufacturers create surgical instruments and implants that require high precision and sterility. The importance of biocompatibility and adherence to health regulations cannot be overstated, especially for international buyers in Europe and Africa. It is crucial to partner with manufacturers who hold relevant certifications, ensuring that products meet safety standards and can be traced back through the supply chain.

How Do Metal Part Manufacturers Support Construction Projects?

In construction, metal part manufacturers produce metal framing and structural supports that provide essential strength and durability for buildings. The sourcing of these materials must consider cost-effectiveness and compliance with local building regulations. For international buyers, especially in emerging markets, understanding the supply chain and potential import/export tariffs is vital to ensure timely project completion and budget adherence.

3 Common User Pain Points for ‘Metal Part Manufacturers’ & Their Solutions

Scenario 1: Navigating Long Lead Times in Production

The Problem:

B2B buyers often face frustration when dealing with metal part manufacturers that have lengthy production lead times. This delay can be particularly challenging for companies operating in fast-paced industries like automotive or electronics, where time-to-market is critical. When a manufacturer estimates a delivery time of several weeks, it not only affects project timelines but can also lead to increased costs and lost sales opportunities. Buyers may find themselves caught in a cycle of waiting and uncertainty, unsure of when they will receive the necessary components to continue their operations.

The Solution:

To mitigate the issue of long lead times, buyers should prioritize manufacturers known for their expedited services. When sourcing suppliers, look for those that offer rapid prototyping and have the capability for quick turnaround on orders. Utilize platforms that provide instant pricing and ordering capabilities, enabling you to upload designs and receive quotes within minutes. Additionally, establishing a relationship with a manufacturer that can offer flexibility in production schedules will enhance responsiveness. Communicating your timelines and project requirements upfront allows manufacturers to allocate resources effectively and prioritize your orders. Regular follow-ups and utilizing tracking systems can also help keep you informed on the status of your order, reducing anxiety associated with uncertainty.

Scenario 2: Managing Quality Control Across Borders

The Problem:

For international B2B buyers, ensuring consistent quality in metal parts can be a significant pain point, especially when sourcing from manufacturers in different countries. Variations in manufacturing standards, material quality, and production techniques can lead to discrepancies in product quality. These inconsistencies can result in costly rework, increased waste, and potential damage to the buyer’s reputation in their market. Buyers may struggle to establish effective quality control processes when working with overseas suppliers.

The Solution:

To address quality control challenges, buyers should implement a robust vetting process when selecting metal part manufacturers. This includes requesting samples and conducting thorough audits of the manufacturer’s facilities, quality management systems, and certifications. Establish clear quality specifications and performance standards in your contracts, and consider utilizing third-party inspection services to evaluate products before shipment. Utilizing technology such as digital inspections and real-time monitoring can also enhance quality assurance efforts. Building strong communication channels with your manufacturer allows for quick resolution of any quality issues that may arise, ensuring that both parties are aligned on expectations.

Scenario 3: Difficulty in Customization and Design Iterations

The Problem:

Another common pain point for B2B buyers is the challenge of customizing metal parts to meet specific design requirements. Many manufacturers have rigid production processes that do not easily accommodate design changes or custom requests, leading to frustration for buyers who need tailored solutions. This limitation can hinder innovation and adaptability, especially in industries that require unique components for specialized applications.

The Solution:

To overcome challenges related to customization, buyers should seek out metal part manufacturers that specialize in flexible production capabilities and are open to collaborative design processes. Engaging with manufacturers that use advanced technologies such as CNC machining and 3D printing can facilitate quick adjustments to designs without significant delays. Buyers should communicate their specific needs clearly and consider using design software that allows for easy modifications and simulations. Establishing a partnership approach with manufacturers, where both parties work together in the design phase, can foster innovation and lead to better end products. Additionally, leveraging prototyping services can provide valuable insights and facilitate faster iterations before moving into full-scale production, ensuring that the final product meets all specifications.

Strategic Material Selection Guide for Metal Part Manufacturers

What Are the Key Properties of Carbon Steel for Metal Part Manufacturing?

Carbon steel is one of the most widely used materials in metal part manufacturing due to its excellent mechanical properties. It exhibits high tensile strength, making it suitable for applications that require durability and resistance to deformation under stress. Carbon steel also has good weldability and machinability, allowing for versatile manufacturing processes. However, its corrosion resistance is limited, necessitating protective coatings or treatments in certain environments.

Pros and Cons of Carbon Steel

The primary advantages of carbon steel include its low cost and high strength-to-weight ratio, making it an economical choice for various applications. However, its susceptibility to rusting can be a significant drawback, especially in humid or corrosive environments. This limitation can increase maintenance costs and affect the longevity of the final product.

Impact on Application

Carbon steel is commonly used in structural applications, automotive components, and machinery parts. Its performance can be affected by exposure to specific media, such as saltwater or acidic substances, which can lead to accelerated corrosion.

Considerations for International Buyers

For international B2B buyers, compliance with standards such as ASTM A36 or DIN 17100 is crucial for ensuring quality and performance. Buyers from regions like Africa and South America may also need to consider local climate conditions when selecting carbon steel, as these can influence corrosion rates.

How Does Stainless Steel Compare in Terms of Performance and Suitability?

Stainless steel is renowned for its corrosion resistance, which is attributed to the presence of chromium. This material maintains its strength at high temperatures and is less likely to rust or stain, making it ideal for applications in harsh environments. Additionally, stainless steel is available in various grades, allowing manufacturers to select the appropriate type for specific applications.

Pros and Cons of Stainless Steel

The key advantage of stainless steel is its durability and low maintenance requirements. However, it tends to be more expensive than carbon steel, which could be a consideration for budget-conscious manufacturers. The manufacturing complexity can also be higher, requiring specialized tools and techniques for cutting and welding.

Impact on Application

Stainless steel is widely used in the food processing, medical, and aerospace industries due to its hygienic properties and ability to withstand extreme conditions. Its compatibility with various media, including chemicals and high-pressure environments, makes it a preferred choice for critical applications.

Considerations for International Buyers

International buyers should ensure compliance with standards such as ASTM A240 or EN 10088 for stainless steel. In regions like Europe and the Middle East, where regulatory requirements are stringent, understanding these standards is essential for market entry.

What Are the Advantages of Aluminum in Metal Part Manufacturing?

Aluminum is a lightweight metal with excellent corrosion resistance and thermal conductivity. Its low density makes it an attractive option for applications where weight savings are critical, such as in the aerospace and automotive sectors. Aluminum can also be easily formed and machined, providing flexibility in design.

Pros and Cons of Aluminum

The primary advantage of aluminum is its lightweight nature, which contributes to energy efficiency in transportation applications. However, its lower strength compared to steel can be a limitation in high-stress applications. Additionally, aluminum can be more expensive than carbon steel, impacting cost-sensitive projects.

Impact on Application

Aluminum is particularly well-suited for applications involving exposure to moisture or chemicals, as it does not rust. Its compatibility with various media makes it ideal for marine and chemical processing applications.

Considerations for International Buyers

For B2B buyers, understanding the specific aluminum grades, such as 6061 or 7075, is crucial for selecting the right material. Compliance with standards like ASTM B221 or EN 485 is also important, especially for buyers in Europe and North America.

How Does Titanium Stand Out in Terms of Performance and Cost?

Titanium is known for its exceptional strength-to-weight ratio and outstanding corrosion resistance. It performs well under extreme temperatures and is biocompatible, making it suitable for medical applications. However, titanium is significantly more expensive than other metals, which can limit its use in cost-sensitive projects.

Pros and Cons of Titanium

The key advantage of titanium is its durability and resistance to corrosion, making it ideal for high-performance applications. On the downside, its high cost and the complexity of machining can be significant barriers for manufacturers.

Impact on Application

Titanium is often used in aerospace, medical implants, and high-performance automotive applications due to its strength and lightweight properties. Its compatibility with various environments, including marine and chemical applications, enhances its appeal.

Considerations for International Buyers

International buyers should be aware of standards such as ASTM B348 or ISO 5832 for titanium. Understanding these standards is crucial for compliance and ensuring product quality, particularly for buyers from regions with stringent regulations, such as Europe.

| Material | Typical Use Case for Metal Part Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components, automotive parts | Low cost and high strength | Limited corrosion resistance | Low |

| Stainless Steel | Food processing, medical devices | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive applications | Lightweight and easy to form | Lower strength compared to steel | Medium |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | Very high cost and machining complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for Metal Part Manufacturers

What Are the Main Stages of Manufacturing for Metal Part Manufacturers?

The manufacturing process for metal parts typically involves several key stages, each critical to ensuring the final product meets the desired specifications. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting and preparing the raw materials necessary for production. Common materials include various grades of steel, aluminum, brass, and titanium. Techniques such as cutting, shearing, and deburring are employed to ensure the materials are in the correct dimensions and free from contaminants. Proper material selection is vital, as it directly impacts the performance and durability of the final product.

-

Forming: This stage encompasses a range of techniques used to shape the prepared materials into the desired form. Key methods include:

– Laser Cutting: Utilized for precision cuts in various materials, allowing for intricate designs and high tolerances.

– CNC Machining: Offers versatility in shaping parts through processes like turning, milling, and drilling, ideal for complex geometries.

– Metal Stamping: Involves pressing metal sheets into specific shapes using dies, often used for high-volume production.

– Welding: Critical for joining different components, ensuring structural integrity and strength. -

Assembly: Once the individual parts are formed, they may require assembly. This can include processes such as hardware insertion, fastening, and sub-assembly. Effective assembly techniques are crucial for ensuring that the final product operates as intended, particularly in complex components used in industries like aerospace or automotive.

-

Finishing: The final stage focuses on enhancing the product’s appearance and resistance to wear and corrosion. Common finishing techniques include:

– Anodizing: Primarily for aluminum parts, this process increases corrosion resistance and provides a decorative finish.

– Powder Coating: A method that applies a protective layer of paint, offering durability and aesthetic appeal.

– Plating: Involves depositing a layer of metal onto the surface to improve corrosion resistance or electrical conductivity.

How Do Quality Assurance Practices Impact Metal Part Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet international standards and customer expectations. For international B2B buyers, understanding QA practices is essential for selecting reliable suppliers.

-

International Standards and Certifications: Many metal part manufacturers adhere to globally recognized standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE marking for European markets or API standards for oil and gas components are crucial indicators of compliance and quality assurance.

-

Quality Control Checkpoints: The QA process typically involves several checkpoints throughout production:

– Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early, minimizing waste and rework.

– Final Quality Control (FQC): This final inspection verifies that the finished product meets all specifications before shipping. -

Common Testing Methods: Manufacturers employ various testing methods to verify quality, including:

– Dimensional Inspection: Using tools like calipers and coordinate measuring machines (CMM) to ensure parts meet specified tolerances.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiography assess material integrity without causing damage.

– Destructive Testing: Involves testing samples to failure to understand material properties and performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is critical to ensuring product reliability and compliance with regulatory standards.

-

Audits and Assessments: Conducting audits of potential suppliers can provide insights into their quality management practices. This includes reviewing documentation, observing processes, and assessing compliance with international standards.

-

Quality Reports and Documentation: Suppliers should provide detailed reports on their quality control procedures, including inspection results and compliance certifications. This documentation is vital for buyers to assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control measures. This is particularly important for buyers from regions with stringent regulatory requirements.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of quality control can be challenging for international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe.

-

Regional Compliance Requirements: Different regions have varying compliance standards. Buyers must understand local regulations and ensure their suppliers meet these requirements. For example, European buyers may require CE marking for certain products, while Middle Eastern buyers may focus on local certifications.

-

Cultural Considerations: Differences in business practices and communication styles can affect quality assurance. Establishing clear expectations and fostering open communication with suppliers can help bridge these gaps.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain practices, including sourcing materials and subcontracting. This transparency is crucial for assessing potential risks and ensuring that all components meet quality standards.

Conclusion

Understanding the manufacturing processes and quality assurance practices of metal part manufacturers is essential for B2B buyers looking to source reliable products. By familiarizing themselves with the stages of manufacturing, quality control practices, and verification methods, buyers can make informed decisions that ensure their needs are met while minimizing risks associated with sourcing from international suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Metal Part Manufacturers’

Introduction

Navigating the procurement process for metal part manufacturing can be complex, especially for international B2B buyers. This step-by-step checklist is designed to guide you through essential actions, ensuring you select a reliable and capable supplier that meets your specific needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical specifications is crucial for ensuring that the supplier can meet your requirements. This includes details such as dimensions, tolerances, materials, and any necessary certifications. Precise specifications help prevent misunderstandings and ensure that the final product aligns with your project goals.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in the types of metal parts you need. Look for manufacturers with a solid reputation in your industry, which can be assessed through online reviews, industry forums, and trade associations. A strong track record in your specific market can indicate a supplier’s reliability and expertise.

Step 3: Evaluate Supplier Capabilities

Once you’ve shortlisted potential suppliers, evaluate their manufacturing capabilities. This includes assessing their machinery, technology, and processes to ensure they align with your requirements. Consider their production capacity, lead times, and whether they offer additional services like prototyping or assembly, which can streamline your sourcing process.

Step 4: Verify Supplier Certifications

Certifications are critical indicators of quality and compliance. Verify if the supplier holds relevant certifications such as ISO 9001 or industry-specific standards. These certifications demonstrate a commitment to quality management and can provide reassurance regarding the reliability of their manufacturing processes.

Step 5: Request Samples and Prototypes

Before finalizing your decision, request samples or prototypes of the parts you need. This step allows you to assess the quality and precision of the supplier’s work. Evaluate the samples against your specifications to ensure they meet your standards, which can prevent costly mistakes later in the production process.

Step 6: Discuss Terms and Conditions

Engage in open discussions regarding pricing, payment terms, and delivery schedules. Understanding the terms upfront can help avoid disputes later on. Be sure to clarify aspects such as minimum order quantities, shipping options, and warranties, which are vital for managing your budget and timelines effectively.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan that outlines how you will interact with the supplier throughout the project lifecycle. Determine points of contact, preferred communication channels, and frequency of updates to ensure that any issues are addressed promptly and collaboratively.

By following this checklist, you can streamline the sourcing process for metal part manufacturing, reducing risks and enhancing the likelihood of a successful partnership.

Comprehensive Cost and Pricing Analysis for Metal Part Manufacturers Sourcing

What Are the Key Cost Components in Metal Part Manufacturing?

When sourcing metal parts, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common options like steel, aluminum, and specialized alloys vary widely in price. Bulk purchasing can often lead to discounts, so consider your volume needs carefully.

-

Labor: Labor costs encompass wages for skilled workers involved in fabrication, machining, assembly, and quality control. Regions with lower labor costs may offer more competitive pricing, but this can come at the expense of quality or reliability.

-

Manufacturing Overhead: This includes expenses related to facility operation, maintenance, and utilities. Efficient manufacturing processes can help reduce overhead and improve profit margins.

-

Tooling: Custom tooling can be a substantial upfront investment but is essential for high-volume production. Tooling costs should be amortized over the expected production volume to gauge their impact on unit pricing.

-

Quality Control (QC): Ensuring the quality of metal parts is critical. QC processes, including inspections and testing, add to the overall cost but are necessary to avoid costly defects and rework.

-

Logistics: Shipping costs can vary significantly based on distance, weight, and shipping method. Understanding Incoterms is essential for determining who bears these costs and responsibilities.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This varies by market conditions and supplier strategy.

How Do Pricing Influencers Affect Metal Part Sourcing?

Several factors influence the pricing of metal parts, especially in a B2B context:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes generally lower the per-unit cost due to economies of scale. Conversely, low MOQ may lead to higher prices per unit.

-

Specifications and Customization: Unique specifications or highly customized parts often lead to increased costs. It’s essential to balance design needs with budget constraints.

-

Material Quality and Certifications: Parts requiring specific certifications (e.g., ISO, ASTM) typically incur higher costs due to additional processing and testing.

-

Supplier Factors: The supplier’s reputation, location, and reliability can influence pricing. Established suppliers may charge more but offer greater assurance of quality and service.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital. They dictate cost responsibilities and can significantly affect the total cost of ownership.

What Are Effective Buyer Tips for Negotiating Metal Part Prices?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiate on Volume: If feasible, consolidate orders to meet higher volume thresholds that can unlock better pricing.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial price. TCO includes shipping, handling, potential tariffs, and long-term maintenance costs. A lower upfront cost may lead to higher TCO.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in countries with lower production costs may offer competitive rates, but ensure they meet your quality standards.

-

Request Transparent Quotes: Ask suppliers for detailed breakdowns of their quotes. This transparency can help you identify areas for negotiation or cost-saving.

-

Build Relationships: Developing a strong relationship with your suppliers can lead to better pricing and terms over time. Trust and communication often yield favorable outcomes.

Disclaimer for Indicative Prices

Prices for metal parts can fluctuate based on market conditions, material availability, and specific project requirements. The figures mentioned in various pricing examples are indicative and should be confirmed with suppliers for accuracy based on current market dynamics.

Alternatives Analysis: Comparing Metal Part Manufacturers With Other Solutions

Exploring Alternatives to Metal Part Manufacturing

When sourcing metal parts, B2B buyers have several options to consider. While traditional metal part manufacturers offer a robust solution for high-quality, custom metal components, alternative methods may provide unique benefits depending on specific project requirements. This section will compare metal part manufacturers with 3D printing and injection molding, two viable alternatives in the manufacturing landscape.

| Comparison Aspect | Metal Part Manufacturers | 3D Printing | Injection Molding |

|---|---|---|---|

| Performance | High precision and quality; suitable for complex geometries | Versatile; ideal for prototypes and complex designs | Excellent for high-volume production; consistent quality |

| Cost | Higher upfront costs; price decreases with volume | Generally lower for low volumes; material costs can be high | High initial setup costs; cost-effective for mass production |

| Ease of Implementation | Requires detailed CAD files; longer lead times for setup | Simple design modifications; quick turnaround | Complex tooling setup; less flexibility once in production |

| Maintenance | Regular maintenance of machines required; skilled labor needed | Minimal maintenance; easy to adapt to new designs | Tooling maintenance can be costly and time-consuming |

| Best Use Case | Custom parts for various industries (aerospace, automotive) | Rapid prototyping, small batch production, custom designs | High-volume production of uniform parts (consumer goods) |

What Are the Advantages and Disadvantages of 3D Printing?

3D printing, or additive manufacturing, has gained traction for its ability to produce complex geometries that would be difficult or impossible to achieve with traditional methods. The primary advantage is its flexibility; designs can be altered quickly, making it ideal for prototyping and small production runs. However, the cost of materials can be prohibitive for larger projects, and the speed of production may not match that of traditional methods for high-volume needs.

How Does Injection Molding Compare?

Injection molding is a highly efficient manufacturing process for producing large quantities of identical parts. Its primary advantage lies in its cost-effectiveness for mass production, which significantly reduces the per-unit cost once the initial tooling is created. However, the upfront costs and time associated with creating molds can be substantial, making it less suitable for low-volume projects. Additionally, design changes after the mold is created can lead to further expenses and delays.

Conclusion: Which Manufacturing Solution Should You Choose?

Choosing between metal part manufacturers, 3D printing, and injection molding depends largely on your specific project needs. If you require high precision and quality for complex designs, traditional metal part manufacturers may be the best choice, especially for industries such as aerospace or automotive. On the other hand, if you’re looking for rapid prototyping or small batch production, 3D printing offers significant advantages in flexibility and speed. For large-scale production of uniform components, injection molding is likely the most cost-effective option. Ultimately, understanding the strengths and weaknesses of each method will empower B2B buyers to make informed decisions that align with their manufacturing goals.

Essential Technical Properties and Trade Terminology for Metal Part Manufacturers

What Are the Key Technical Properties Relevant to Metal Part Manufacturing?

Understanding the technical properties of metal parts is crucial for B2B buyers, as these specifications directly impact product performance, durability, and overall cost-effectiveness. Here are several critical specifications to consider:

-

Material Grade

Material grade refers to the classification of metal based on its chemical composition and mechanical properties. Common grades include carbon steel, stainless steel, and aluminum alloys, each suited for different applications. For buyers, selecting the right material grade ensures that the part can withstand environmental conditions and stresses, which is particularly important in industries like automotive and aerospace. -

Tolerance

Tolerance specifies the allowable deviation from a part’s specified dimensions. It is essential for ensuring that parts fit together correctly during assembly. Tight tolerances are necessary for high-precision applications, while looser tolerances may suffice for less critical components. Understanding tolerance helps buyers assess manufacturing capabilities and ensure compatibility with existing systems. -

Finish

The finish of a metal part refers to its surface treatment, which can include processes such as anodizing, plating, or powder coating. The choice of finish affects corrosion resistance, aesthetic appeal, and wear resistance. Buyers should consider finishes that not only meet functional requirements but also align with branding and customer expectations. -

Yield Strength

Yield strength is the maximum stress that a material can withstand without permanent deformation. It is a key indicator of a material’s ability to perform under load. For B2B buyers, understanding yield strength is vital for ensuring that the components will perform reliably under operational conditions, particularly in high-stress applications. -

Weight

The weight of a metal part is an important consideration, especially in industries where weight affects performance, such as aerospace and automotive. Lighter parts can lead to improved fuel efficiency and overall performance. Buyers should evaluate weight specifications alongside material selection to achieve optimal performance.

What Are the Common Trade Terms in Metal Part Manufacturing?

Familiarity with industry jargon is essential for effective communication and negotiation in the metal part manufacturing sector. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure access to high-quality, specialized components that meet specific operational requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for buyers, as it can affect inventory levels and cash flow. Buyers should negotiate MOQs that align with their production needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing information from suppliers for specific products or services. This process is crucial for obtaining competitive pricing and understanding the capabilities of potential vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, facilitating smoother transactions across borders. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. Understanding lead times is critical for inventory management and production scheduling, allowing buyers to align their supply chain processes with operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they procure the right metal parts for their applications while fostering effective supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the Metal Part Manufacturers Sector

What Are the Current Market Dynamics and Key Trends in Metal Part Manufacturing?

The metal part manufacturing sector is witnessing significant transformation driven by globalization, technological advancements, and changing consumer demands. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer rapid prototyping and just-in-time manufacturing capabilities. The rise of digital tools, including CAD software and instant pricing platforms, facilitates quicker decision-making and enhances the efficiency of the sourcing process. For example, companies that allow customers to upload designs for instant quotes are gaining traction, as they reduce lead times and improve customer satisfaction.

Another key trend is the increasing demand for customization. As businesses strive for differentiation in competitive markets, manufacturers that can offer tailored solutions are better positioned to attract B2B clients. Additionally, the shift towards automation and Industry 4.0 technologies is reshaping production processes, enabling manufacturers to achieve higher precision and lower operational costs. This trend is particularly relevant for regions like Germany, known for its advanced manufacturing capabilities, as well as emerging markets in Nigeria and Brazil that are looking to modernize their production facilities.

How Is Sustainability Shaping Sourcing Decisions in Metal Part Manufacturing?

Sustainability is no longer a mere buzzword; it has become a crucial factor in B2B sourcing decisions. Companies are increasingly aware of the environmental impact of their supply chains and are seeking partners that prioritize ethical sourcing practices. The use of recycled materials and the implementation of energy-efficient manufacturing processes are becoming standard expectations among discerning buyers. Certifications such as ISO 14001 and LEED are gaining importance, as they signify a commitment to environmental stewardship.

Moreover, the demand for ‘green’ materials is on the rise. Manufacturers that can provide eco-friendly alternatives—such as aluminum alloys with a high recycled content or bio-based plastics—are likely to capture the interest of international buyers committed to reducing their carbon footprint. Transparency in sourcing and production processes is also critical; buyers prefer suppliers who can clearly demonstrate their sustainability efforts and ethical practices. This trend not only enhances brand reputation but also aligns with the growing regulatory pressures surrounding environmental compliance across various regions.

How Has the Metal Part Manufacturing Sector Evolved Over Time?

The evolution of the metal part manufacturing sector has been marked by significant technological advancements and shifts in consumer demand. Initially characterized by manual processes and limited customization, the industry has transformed through the adoption of CNC machining, laser cutting, and automation technologies. These innovations have not only improved production efficiency but have also enabled manufacturers to meet increasingly complex specifications and tighter tolerances.

Historically, the sector has seen a gradual shift from local to global sourcing, driven by the need for cost efficiency and access to specialized skills. Countries such as Germany have led the charge with their focus on precision engineering, while emerging markets are rapidly developing their capabilities to compete on the international stage. Today, the combination of advanced manufacturing technologies and a growing emphasis on sustainability is shaping a new era for metal part manufacturers, creating opportunities for international B2B buyers to engage with suppliers that can meet their evolving needs.

Frequently Asked Questions (FAQs) for B2B Buyers of Metal Part Manufacturers

-

How do I ensure the quality of metal parts from a manufacturer?

To guarantee the quality of metal parts, begin by vetting the manufacturer’s certifications, such as ISO 9001 or industry-specific standards. Request samples or prototypes to evaluate craftsmanship and material quality before placing a larger order. Establish clear quality assurance protocols, including inspections at various production stages. Additionally, consider working with manufacturers that offer full traceability of materials used, as this can further enhance confidence in their quality control processes. -

What is the best way to customize metal parts for my specific needs?

The best approach to customization is to engage in open communication with the manufacturer from the outset. Provide detailed specifications, including dimensions, material types, and any required finishing processes. Many manufacturers offer design support, so consider sharing CAD files or sketches for precise guidance. Be prepared to discuss your production volume, as this may influence customization options and pricing. Additionally, inquire about their capabilities in handling complex designs and integrating necessary features. -

What are the typical minimum order quantities (MOQ) for metal parts?

Minimum order quantities (MOQ) can vary significantly among manufacturers. Some may have no MOQ, especially for custom parts, while others might require a minimum number based on production efficiency or setup costs. It’s essential to clarify these terms early in negotiations. If your needs are for low-volume production, look for manufacturers specializing in prototyping or those that can accommodate smaller runs without compromising on quality or cost. -

How can I effectively vet international metal part suppliers?

To vet international suppliers, start by researching their reputation through online reviews and industry referrals. Verify their certifications and compliance with international quality standards. Conduct video calls to assess their facilities and capabilities. Request documentation of previous projects similar to yours, and consider using third-party inspection services to evaluate their products before shipment. Building a relationship with the supplier can also provide insights into their reliability and commitment to service. -

What payment terms should I expect when working with metal part manufacturers?

Payment terms can vary widely, but common practices include upfront deposits, progress payments, or full payment upon delivery. Many manufacturers offer flexible terms, especially for established relationships. Be sure to discuss payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Understanding the payment structure is crucial for budgeting and cash flow management, especially for large international orders. -

What logistics considerations should I keep in mind when sourcing metal parts internationally?

When sourcing metal parts internationally, consider shipping costs, customs duties, and delivery timelines. Work with manufacturers who have experience with international shipping to ensure compliance with local regulations. Evaluate the shipping methods available, such as air freight for speed or sea freight for cost-efficiency. Additionally, establish a clear communication plan regarding tracking shipments and handling any potential delays or issues that may arise during transit. -

How do I manage communication with international suppliers effectively?

Effective communication with international suppliers involves establishing a clear line of contact and using tools that facilitate collaboration across time zones. Schedule regular updates through video calls or emails, and ensure that language barriers are minimized by using straightforward language or translation services if necessary. Document all agreements and specifications to avoid misunderstandings. Utilizing project management tools can also help keep everyone aligned on timelines and deliverables. -

What quality assurance processes should I implement when working with metal part manufacturers?

Implementing quality assurance processes involves setting clear standards and benchmarks for the parts you are sourcing. Collaborate with the manufacturer to establish inspection points throughout the production process, including initial samples, in-process checks, and final inspections. Consider using third-party quality assurance services for independent verification. Additionally, maintain open lines of communication for feedback and adjustments, ensuring that any quality issues are addressed promptly to avoid costly delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Metal Part Manufacturers

In navigating the complex landscape of metal part manufacturing, strategic sourcing emerges as a pivotal element for international B2B buyers. Emphasizing quality, cost efficiency, and timely delivery, organizations can leverage strategic sourcing to mitigate risks and enhance supply chain resilience. By fostering partnerships with reputable manufacturers that offer advanced capabilities such as custom fabrication, CNC machining, and rapid prototyping, businesses can ensure they meet their diverse production needs effectively.

The insights gathered highlight the importance of understanding local market dynamics, especially for buyers from Africa, South America, the Middle East, and Europe. By tapping into global networks and focusing on value-added services, companies can optimize their sourcing strategies and drive innovation in product development.

As the manufacturing sector continues to evolve, embracing digital tools for instant pricing and streamlined communication will be crucial. This forward-thinking approach not only enhances operational efficiency but also positions businesses to capitalize on emerging market opportunities. International buyers are encouraged to take proactive steps in their sourcing strategies, ensuring they align with the best practices of today’s competitive landscape. Explore these opportunities and strengthen your supply chain for a sustainable future.