Top 8 Wire Harness Manufacturers List and Guide: How To Solve Sce…

Introduction: Navigating the Global Market for Wire Harness Manufacturers

In today’s global economy, sourcing reliable wire harness manufacturers poses a significant challenge for international B2B buyers. The complexities of navigating diverse markets, varying standards, and the demand for customized solutions can often lead to uncertainty in procurement processes. This guide addresses these challenges head-on, offering a comprehensive resource for understanding the various types of wire harnesses, their applications across industries, and strategies for effective supplier vetting.

From agriculture to aerospace, wire harnesses serve as critical components in a multitude of applications, ensuring the seamless operation of electronic systems. B2B buyers from regions such as Africa, South America, the Middle East, and Europe will find valuable insights into the manufacturing capabilities of different suppliers, helping them assess quality, cost, and compliance with international standards.

By delving into this guide, buyers will be empowered to make informed purchasing decisions that align with their specific needs. We will explore key factors such as pricing structures, quality control certifications, and the importance of communication throughout the manufacturing process. Ultimately, this resource aims to facilitate successful partnerships with wire harness manufacturers, ensuring that businesses can efficiently power their innovations while minimizing risks associated with global sourcing.

Top 10 Wire Harness Manufacturers Manufacturers & Suppliers List

1. Omega Leads – Custom Wire Harness Solutions

Domain: omegaleads.com

Registered: 1999 (26 years)

Introduction: Custom wire harness manufacturer with over 55 years of experience. Provides turnkey solutions for various industries including aerospace, military, automotive, electronic, medical, lighting, and solar. Custom wire harnesses and assemblies are built to exact design specifications using high-quality materials. Capabilities include unlimited wire selection, gauge, insulation style, and color, as well…

2. Electri-Cord – Custom Wiring Harnesses

Domain: ecmfg.com

Registered: 2018 (7 years)

Introduction: Custom wiring harnesses are assemblies of wires designed for easier installation and maintenance, providing protection from environmental conditions. Electri-Cord manufactures a wide variety of wiring harnesses, from single conductor jumpers to peg board assemblies with hundreds of breakouts. They specialize in custom applications ranging from light-duty lead wire to heavy-duty cable assemblies an…

3. Elite Harness – Electrical Wire Harnesses & Custom Cables

Domain: elite-harness.com

Registered: 2023 (2 years)

Introduction: Elite Harness is a leading manufacturer of electrical wire harnesses and custom cables with over 150 years of combined manufacturing experience. They utilize advanced equipment to ensure efficiency, precision, and cost-effectiveness. The company serves various industries including aerospace and defense, heavy industry, transportation, agricultural equipment, high-voltage, and solar. Elite Harness …

4. Wiringo – Custom Wire Harness Solutions

Domain: wiringo.com

Registered: 2018 (7 years)

Introduction: Wiringo: Founded in 2014, headquartered in China with strong US operations in automotive, aerospace, medical device, telecommunication, and industrial sectors. Offers custom wire harness design, rapid prototyping, electrical testing, and quick turnaround. Products include engine harnesses, dashboard/cabin harnesses, battery wiring harnesses, body and lighting harnesses, and HVAC wiring harnesses. …

5. Custom Wire Industries – Custom Wire Harnesses

Domain: customwireind.com

Registered: 2000 (25 years)

Introduction: Custom Wire Industries is a leading wire harness manufacturer with over 40 years of experience, specializing in custom wire harnesses and cable assemblies. They produce a variety of wire harnesses for different applications, including automotive, medical, military, telecommunications, aerospace, instrumentation, industrial, construction, gaming, agriculture, software, energy, and dental industries…

6. Senra Systems – High-Quality Wire Harness Manufacturing

Domain: senrasystems.us

Registered: 2023 (2 years)

Introduction: Senra Systems specializes in high-quality wire harness manufacturing, utilizing advanced automation and smart manufacturing systems to produce wire harnesses at 4x the speed of traditional vendors. Their process includes precision-engineered automation, design support for production-ready designs, and capabilities in complex cable assemblies, automated label printing, and heat-shrink tubing. They …

7. Star Engineering – Custom Wire Harness Solutions

Domain: starengineeringinc.com

Registered: 2008 (17 years)

Introduction: Star Engineering, Inc. is a leading custom wire harness assembly and cable harness manufacturer in the USA, with nearly 40 years of experience. They provide tailored wire harness solutions for various industries, including automotive, medical, telecommunications, consumer electronics, aerospace and defense, industrial machinery, energy, and transportation. Their services include in-house manufactu…

8. Komax Group – Zeta 620 & 630

Domain: komaxgroup.com

Registered: 2004 (21 years)

Introduction: The Komax harness manufacturing systems automate the processing of complex wire harnesses, including cutting, crimping, housing insertion, and routing. Key products include: Zeta 620 (assembly machine for control cabinet construction), Zeta 630 (increases productivity with two process modules), Zeta 640/650 (processes up to 36 wires without changeover), Omega 740/750 (produces wire harnesses with …

Understanding Wire Harness Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Wire Harness | Tailored to specific requirements; can include various connectors and materials | Aerospace, Automotive, Medical, Military | Pros: High customization, meets unique specifications. Cons: Potentially longer lead times. |

| Standard Wire Harness | Pre-defined designs with limited customization options | Consumer Electronics, Appliances | Pros: Quick turnaround, generally lower costs. Cons: May not meet all specific application needs. |

| Heavy-Duty Wire Harness | Built for extreme conditions; robust materials and connectors | Industrial Equipment, Transportation | Pros: High durability, reliable performance. Cons: Heavier and may be more expensive to manufacture. |

| High-Voltage Wire Harness | Designed to handle high voltage applications with specialized insulation | Renewable Energy, High-Power Electronics | Pros: Enhanced safety for high voltage applications. Cons: Requires specialized manufacturing processes. |

| Multi-Conductor Harness | Contains multiple wires bundled together for streamlined installation | Telecommunications, Networking | Pros: Space-saving, organized wiring solution. Cons: Complexity in design can lead to higher costs. |

What Are the Characteristics of Custom Wire Harness Manufacturers?

Custom wire harness manufacturers focus on creating unique wiring solutions tailored to the specific needs of their clients. These manufacturers can adapt to various specifications, including wire gauge, insulation type, and connector styles. This flexibility makes them ideal for industries like aerospace, automotive, and military applications where precise requirements are crucial. When purchasing, B2B buyers should consider the manufacturer’s experience with similar projects, lead times, and the ability to provide prototypes for testing.

How Do Standard Wire Harnesses Differ from Custom Options?

Standard wire harnesses are pre-defined designs that offer limited customization. These harnesses are often used in consumer electronics and appliances, where quick production and cost-effectiveness are prioritized. B2B buyers can benefit from lower costs and faster turnaround times, but they may need to compromise on specific requirements. It is essential for buyers to evaluate whether the standard options can meet their application needs or if customization is necessary.

What Makes Heavy-Duty Wire Harnesses Suitable for Industrial Use?

Heavy-duty wire harnesses are engineered to withstand extreme conditions, making them suitable for industrial applications and transportation. They utilize robust materials and connectors designed to endure harsh environments. Buyers should consider the specific conditions their wire harnesses will face, such as temperature fluctuations and mechanical stress, when selecting heavy-duty options. While these harnesses provide reliability and longevity, they may come at a higher price point.

Why Are High-Voltage Wire Harnesses Critical in Certain Industries?

High-voltage wire harnesses are specifically designed to handle applications involving significant electrical loads, such as renewable energy systems and high-power electronics. These harnesses feature specialized insulation materials that enhance safety. B2B buyers must assess the safety standards and certifications of potential manufacturers, as well as their experience in producing high-voltage solutions. While these harnesses ensure safety and performance, they may require more intricate manufacturing processes.

What Advantages Do Multi-Conductor Harnesses Offer in Telecommunications?

Multi-conductor harnesses bundle multiple wires together, which simplifies installation and organization, making them particularly advantageous in telecommunications and networking applications. These harnesses help reduce installation time and improve space efficiency. However, their complexity can lead to increased manufacturing costs. Buyers should weigh the benefits of streamlined wiring against the potential for higher expenses and ensure that the manufacturer can meet their specific design requirements.

Key Industrial Applications of Wire Harness Manufacturers

| Industry/Sector | Specific Application of Wire Harness Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom wire harnesses for avionics systems | Enhanced reliability and performance in critical systems | Certification standards (AS9100), weight considerations, and testing protocols |

| Automotive | Wiring harnesses for electric vehicles | Improved efficiency and safety in vehicle performance | Compliance with automotive standards, thermal management, and connector compatibility |

| Medical Devices | Wire harness assemblies for diagnostic equipment | Precision and reliability in life-saving devices | Biocompatibility, sterilization requirements, and traceability of components |

| Renewable Energy | Wire harnesses for solar panel installations | Increased efficiency and durability in harsh environments | UV resistance, environmental certifications, and scalability for large projects |

| Military & Defense | Heavy-duty wire harnesses for tactical equipment | Durability and functionality under extreme conditions | Compliance with military specifications, ruggedization, and electromagnetic interference (EMI) shielding |

How Are Wire Harness Manufacturers Used in Aerospace Applications?

In the aerospace sector, wire harness manufacturers provide custom harnesses for avionics systems, ensuring reliable connections in critical flight operations. These assemblies are designed to withstand extreme temperatures and vibrations, solving issues related to system failures. Buyers must consider stringent certification standards like AS9100 and ensure that the harnesses are lightweight yet durable, which is crucial for aircraft performance.

What Role Do Wire Harness Manufacturers Play in the Automotive Industry?

Wire harnesses are essential in automotive applications, especially for electric vehicles (EVs). They facilitate efficient power distribution and data communication between various components. By utilizing custom wire harnesses, manufacturers can enhance vehicle safety and performance while addressing challenges related to thermal management and connector compatibility. International buyers should prioritize suppliers who comply with automotive industry standards and possess the capability to adapt to evolving technologies.

How Are Wire Harnesses Utilized in Medical Devices?

In the medical device industry, wire harness assemblies are crucial for diagnostic and therapeutic equipment. They ensure precision and reliability, which are vital for life-saving applications. Manufacturers must focus on biocompatibility and sterilization requirements, as well as provide traceability for all components used. For international buyers, understanding regional regulations and certifications is essential to ensure compliance and safety in medical applications.

What Are the Benefits of Wire Harnesses in Renewable Energy?

Wire harnesses play a significant role in renewable energy sectors, particularly in solar panel installations. They help improve efficiency by providing durable connections that withstand harsh environmental conditions. Buyers should look for harnesses with UV resistance and other environmental certifications to ensure longevity and performance. Additionally, sourcing from manufacturers capable of scaling production for larger projects can enhance project viability.

How Do Wire Harness Manufacturers Support Military and Defense Applications?

In military and defense applications, heavy-duty wire harnesses are designed to endure extreme conditions, providing reliable connections for tactical equipment. These harnesses must meet specific military specifications and often require ruggedization and EMI shielding to protect against interference. Buyers in this sector should prioritize manufacturers with proven experience in defense applications and the ability to comply with stringent quality standards to ensure operational readiness.

3 Common User Pain Points for ‘Wire Harness Manufacturers’ & Their Solutions

Scenario 1: Struggling with Customization Needs for Unique Applications

The Problem: Many B2B buyers find themselves in a bind when their projects require highly specialized wire harnesses that standard manufacturers cannot accommodate. This is particularly common in industries like aerospace and medical devices, where specifications can be intricate and demanding. Buyers often encounter issues with manufacturers who lack the flexibility to provide custom solutions, leading to delays in production and increased costs. The inability to source harnesses that meet unique operational requirements can hinder project timelines and affect overall product quality.

The Solution: To navigate this challenge, B2B buyers should thoroughly evaluate potential wire harness manufacturers based on their customization capabilities. Start by requesting detailed information about the manufacturer’s previous projects and their experience in producing specialized wire harnesses. Engage in discussions about your specific needs, including materials, dimensions, and any necessary certifications (e.g., IPC/WHMA-A-620 standards). Additionally, consider manufacturers that offer engineering support to help refine your designs. By establishing a strong partnership and open communication, you can ensure that the manufacturer understands your requirements and can deliver a product that meets your standards.

Scenario 2: Quality Assurance Concerns in Wire Harness Production

The Problem: Quality assurance is a significant concern for B2B buyers, especially when dealing with complex wire harnesses that are crucial for device performance and safety. Buyers often face the risk of receiving subpar products that do not meet industry standards, leading to costly recalls and reputational damage. This issue can be exacerbated when sourcing from manufacturers with inadequate testing protocols or quality control measures, particularly in regions where industry regulations may differ.

The Solution: To mitigate quality assurance issues, buyers should prioritize manufacturers with robust quality control processes and certifications. Request documentation that outlines their testing procedures, such as electrical testing and compliance with international quality standards. Establishing a thorough vetting process before placing large orders can be beneficial. Consider starting with smaller pilot runs to assess product quality and performance. Furthermore, maintain ongoing communication with the manufacturer throughout the production process to address any concerns proactively. This approach not only enhances product reliability but also builds a foundation of trust between both parties.

Scenario 3: Navigating Supply Chain Disruptions and Lead Times

The Problem: Supply chain disruptions and extended lead times have become increasingly common in the wire harness manufacturing industry. B2B buyers often find themselves facing unexpected delays that can stall production schedules and impact delivery commitments. These disruptions can arise from various factors, including shortages of raw materials, logistical challenges, or geopolitical issues that affect manufacturing capabilities.

The Solution: To effectively navigate supply chain challenges, B2B buyers should develop a proactive sourcing strategy that includes multiple manufacturers and alternative suppliers. Diversifying your supplier base can provide additional flexibility and reduce dependency on a single source. It is also advisable to engage in thorough discussions with manufacturers about their supply chain resilience and inventory management practices. Implementing Just-In-Time (JIT) inventory systems can help manage stock levels while ensuring timely deliveries. Establishing clear lead time expectations and maintaining a buffer stock for critical components can also help mitigate the impact of unforeseen delays, ensuring that production processes remain on track.

Strategic Material Selection Guide for Wire Harness Manufacturers

What Are the Key Properties of Common Materials Used in Wire Harness Manufacturing?

Wire harness manufacturers often select materials based on their specific performance requirements, environmental conditions, and application needs. Here, we analyze four common materials: PVC, Polyurethane, Teflon, and Silicone, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does PVC Perform in Wire Harness Applications?

Polyvinyl Chloride (PVC) is a widely used insulation material in wire harnesses due to its excellent electrical insulating properties and cost-effectiveness. It typically has a temperature rating of up to 105°C and offers moderate resistance to chemicals and moisture.

Pros: PVC is durable, lightweight, and relatively inexpensive, making it suitable for a variety of applications, including automotive and consumer electronics. Its ease of manufacturing allows for efficient production processes.

Cons: However, PVC can become brittle over time, especially when exposed to extreme temperatures or UV light. Its chemical resistance is limited compared to other materials, which may restrict its use in harsh environments.

Impact on Application: PVC is compatible with most common media but may not perform well in applications involving aggressive chemicals.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding PVC use, especially in regions with stringent environmental standards. Familiarity with ASTM standards can aid in quality assurance.

What Are the Advantages of Using Polyurethane in Wire Harnesses?

Polyurethane (PU) is another popular choice, known for its flexibility and resilience. It can withstand temperatures ranging from -40°C to 90°C and offers excellent abrasion resistance.

Pros: PU is highly durable and can maintain its integrity in challenging environments, making it ideal for applications in automotive and aerospace industries. Its flexibility allows for easier installation and routing.

Cons: The primary drawback is its higher cost compared to PVC. Additionally, PU can be more complex to manufacture, requiring specialized processes.

Impact on Application: PU is suitable for applications exposed to mechanical stress and harsh conditions, such as outdoor equipment and machinery.

Considerations for International Buyers: Buyers should check for compliance with international standards like DIN and JIS, especially in regions like Europe and Asia, where quality certifications are critical.

Why Choose Teflon for High-Performance Wire Harnesses?

Teflon (PTFE) is renowned for its exceptional thermal stability and chemical resistance, with a temperature rating of up to 260°C. It is often used in high-performance applications, including aerospace and military.

Pros: Teflon’s non-stick properties and resistance to corrosive substances make it ideal for applications where exposure to harsh chemicals is expected. Its longevity and reliability are significant advantages.

Cons: The main limitation is its high cost and the complexity of manufacturing, which can lead to longer lead times.

Impact on Application: Teflon is particularly effective in applications involving aggressive media, ensuring long-term performance without degradation.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for Teflon products, particularly in regulated industries like aerospace and defense.

How Does Silicone Compare in Wire Harness Manufacturing?

Silicone is another versatile material used in wire harnesses, particularly in applications requiring high flexibility and temperature resistance. It can operate effectively in temperatures ranging from -60°C to 200°C.

Pros: Silicone is highly resistant to extreme temperatures and offers excellent flexibility, making it suitable for dynamic applications. Its durability under harsh conditions is a significant advantage.

Cons: However, silicone is generally more expensive than PVC and PU, which may be a consideration for budget-conscious buyers. Its manufacturing processes can also be more complex.

Impact on Application: Silicone’s properties make it ideal for applications in medical devices, automotive, and aerospace, where reliability is paramount.

Considerations for International Buyers: Buyers should ensure compliance with relevant international standards, especially in the medical and automotive sectors, where safety and quality are critical.

Summary Table of Material Selection for Wire Harness Manufacturers

| Material | Typical Use Case for Wire Harness Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Automotive, consumer electronics | Cost-effective and lightweight | Brittle over time, limited chemical resistance | Low |

| Polyurethane | Automotive, aerospace | Highly durable and flexible | Higher cost, complex manufacturing | Medium |

| Teflon | Aerospace, military applications | Exceptional thermal and chemical resistance | High cost, longer lead times | High |

| Silicone | Medical devices, automotive, aerospace | High flexibility and temperature resistance | More expensive, complex manufacturing | High |

This guide provides a comprehensive overview of material selection considerations for wire harness manufacturers, enabling international buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for Wire Harness Manufacturers

What Are the Main Stages of the Manufacturing Process for Wire Harnesses?

The manufacturing process for wire harnesses involves several critical stages that ensure the final product meets the exact specifications and quality standards required by various industries. Understanding these stages can help B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, make informed decisions when selecting a supplier.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in wire harness manufacturing is material preparation, which involves selecting high-quality materials tailored to the specific application. This includes various types of wires, connectors, and insulation materials. Manufacturers typically source materials based on industry standards and customer specifications, ensuring compatibility and performance.

Once the materials are sourced, they undergo processing, which includes cutting wires to the required lengths, stripping insulation, and preparing connectors. Advanced machinery is often employed to ensure precision and reduce human error. For instance, automated cutting and stripping machines can enhance efficiency while maintaining consistent quality.

What Techniques Are Used in the Forming Stage of Wire Harness Manufacturing?

The forming stage is where the raw materials are shaped and configured into the desired wire harness design. This process includes bending, crimping, and attaching connectors and terminals. Manufacturers utilize specialized equipment such as crimping machines and bending tools to ensure the correct formation of each component.

Precision is paramount in this stage, as improper forming can lead to connection failures or performance issues. Manufacturers often implement automated systems that allow for high-speed production while maintaining strict tolerances, reducing the risk of defects.

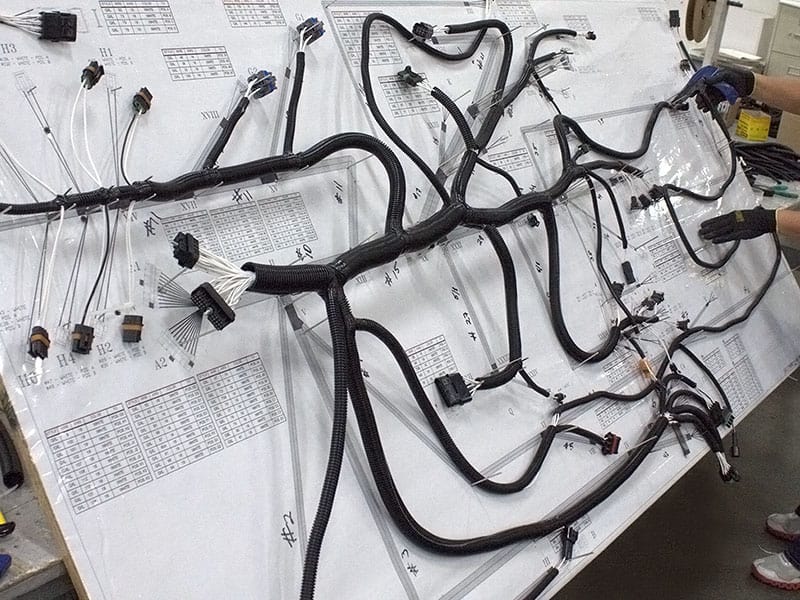

How Is the Assembly Process Executed in Wire Harness Manufacturing?

Following the forming stage, the assembly process brings together all components into a cohesive unit. This typically involves integrating multiple wires and connectors according to the design specifications. Skilled technicians or automated systems meticulously assemble the harness, ensuring that each connection is secure and in the correct configuration.

During assembly, manufacturers often employ techniques such as wire identification marking, which helps streamline installation and maintenance processes. This is particularly beneficial for B2B buyers, as it enhances the usability of the harness in complex applications.

What Are the Key Finishing Steps in Wire Harness Manufacturing?

The finishing stage involves several important steps, including final inspections, labeling, and packaging. After assembly, the wire harness undergoes electrical testing to confirm functionality and safety. Common tests include continuity tests, insulation resistance tests, and functional tests, which verify that the harness meets the required specifications.

Once testing is complete, manufacturers label the harness with relevant information such as part numbers, manufacturing dates, and compliance certifications. Finally, the harness is packaged appropriately to prevent damage during transportation, ensuring that it arrives at the buyer’s facility in optimal condition.

What Quality Assurance Standards Should B2B Buyers Look For in Wire Harness Manufacturers?

Quality assurance (QA) is a critical aspect of wire harness manufacturing, ensuring that products meet both industry and customer standards. B2B buyers should look for manufacturers that adhere to international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO standards indicates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications such as CE marking for European markets or API standards for the oil and gas sector can further assure buyers of product quality. It’s essential for buyers from diverse regions to understand these certifications, as they can vary based on local regulations and industry requirements.

What Are the Common Quality Control Checkpoints in Wire Harness Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and rectify issues before they escalate. Key checkpoints include:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps detect any deviations from quality standards early on.

- Final Quality Control (FQC): Before products are shipped, final inspections and testing are conducted to verify that each harness meets all requirements.

Implementing these checkpoints allows manufacturers to maintain high standards and reduce the risk of defective products reaching customers.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of potential suppliers. One effective method is to conduct audits, which involve on-site visits to assess manufacturing practices, equipment, and quality management systems. This provides buyers with firsthand insight into the supplier’s operations and commitment to quality.

Additionally, requesting quality assurance reports and certifications can help buyers evaluate a supplier’s compliance with relevant standards. Engaging third-party inspection services is another option, providing an unbiased assessment of the supplier’s quality control processes and product integrity.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific nuances when it comes to quality control. Different regions may have varying regulations and standards that impact product compliance. For instance, buyers in Europe may need to ensure products meet CE marking requirements, while those in the Middle East might consider local certifications.

Furthermore, language barriers and cultural differences can affect communication about quality expectations. Therefore, it is advisable for buyers to establish clear channels of communication with suppliers, ensuring that all quality standards are understood and adhered to throughout the manufacturing process.

By comprehensively understanding the manufacturing processes and quality assurance measures in wire harness production, B2B buyers can make informed choices that enhance their supply chain efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Wire Harness Manufacturers’

Introduction

Navigating the procurement process for wire harness manufacturing can be complex, especially for international B2B buyers. This guide provides a practical checklist to help you make informed decisions when sourcing wire harness manufacturers. By following these steps, you can ensure that you partner with a reliable manufacturer that meets your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Consider factors such as the type of wire harness required, dimensions, materials, and environmental conditions it must withstand. This clarity will help you communicate effectively with potential manufacturers and ensure they can meet your requirements.

- Key Details: Include wire gauge, connector types, and insulation material.

- Outcome: A well-defined specification reduces the risk of miscommunication and errors during production.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential wire harness manufacturers. Utilize online directories, industry associations, and trade shows to compile a list of candidates. Pay close attention to their industry experience and specialization, as different manufacturers may excel in various sectors such as automotive, aerospace, or medical applications.

- Key Details: Look for customer reviews and testimonials.

- Outcome: A diverse supplier list allows for comparison and better negotiation opportunities.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Ensure that they have a history of delivering quality products on time and can handle your specific requirements.

- Key Details: Ask for certifications such as ISO 9001 or IPC/WHMA-A-620.

- Outcome: This step minimizes the risk of partnering with unreliable manufacturers.

Step 4: Verify Manufacturing Capabilities

Assess the manufacturing capabilities of shortlisted suppliers. Inquire about their production processes, equipment, and technology used. Understanding their capabilities will help you gauge whether they can meet your volume requirements and deliver products that meet your quality standards.

- Key Details: Check for state-of-the-art equipment and quality control measures.

- Outcome: A manufacturer with robust capabilities is more likely to meet your expectations consistently.

Step 5: Request Samples and Prototypes

Before finalizing a supplier, request samples or prototypes of their wire harnesses. This allows you to evaluate the quality and functionality of their products firsthand. Assess aspects such as wire quality, connector integrity, and overall assembly craftsmanship.

- Key Details: Pay attention to the accuracy of the samples against your specifications.

- Outcome: Testing samples helps ensure that the final product will meet your needs.

Step 6: Discuss Pricing and Terms

Engage in discussions about pricing, payment terms, and delivery schedules with your shortlisted suppliers. Ensure that you understand the total cost of ownership, including shipping and any potential tariffs, especially if you are sourcing internationally.

- Key Details: Compare quotes while considering quality and service, not just price.

- Outcome: Clear financial agreements prevent misunderstandings later in the procurement process.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the procurement process and beyond. Set expectations for regular updates and establish points of contact on both sides. This ensures that any issues can be addressed promptly, fostering a collaborative relationship.

- Key Details: Agree on preferred communication channels and response times.

- Outcome: Strong communication reduces the likelihood of delays and misunderstandings.

By following this checklist, you can navigate the complex landscape of wire harness manufacturing with confidence, ensuring that you select a partner that aligns with your business goals and quality standards.

Comprehensive Cost and Pricing Analysis for Wire Harness Manufacturers Sourcing

What Are the Key Cost Components in Wire Harness Manufacturing?

Understanding the cost structure of wire harness manufacturing is crucial for B2B buyers seeking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The choice of wire, connectors, and insulation materials significantly impacts the overall cost. High-quality materials such as those from reputable manufacturers (e.g., Molex, JST) can elevate costs but often lead to improved durability and performance.

-

Labor: Labor costs are influenced by the complexity of the wire harness designs. Skilled labor is essential for custom assemblies, which can drive up costs. Regions with lower labor costs might offer attractive pricing, but quality assurance remains paramount.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, ultimately benefiting buyers.

-

Tooling: Initial tooling costs can be significant for custom wire harnesses. However, once established, the cost can be amortized over larger production runs, making it more cost-effective.

-

Quality Control (QC): Ensuring that products meet industry standards incurs additional costs. Rigorous QC processes are essential, especially for applications in sensitive industries such as aerospace and medical.

-

Logistics: Shipping costs depend on the destination, volume, and weight of the wire harnesses. International buyers should consider Incoterms that define shipping responsibilities and costs clearly.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition, market demand, and the perceived value of their offerings.

What Influences Pricing in Wire Harness Manufacturing?

Several factors can influence the pricing of wire harnesses, particularly for international B2B buyers:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to align with their needs without incurring excess inventory costs.

-

Specifications and Customization: Highly customized wire harnesses can be more expensive due to the additional engineering and labor involved. Standardized designs may offer cost advantages.

-

Material Selection: The choice of materials directly correlates with the price. Buyers should balance cost with performance, especially for applications that require high reliability.

-

Quality and Certifications: Products that meet industry certifications (e.g., ISO, IPC standards) might carry a premium but provide assurance of quality and reliability, which is critical in high-stakes industries.

-

Supplier Factors: Supplier reputation, experience, and location can influence pricing. Established suppliers with a track record of quality may command higher prices, justified by their reliability and service.

-

Incoterms: Understanding the implications of Incoterms can affect total costs. Different terms outline responsibilities for shipping, insurance, and tariffs, impacting overall pricing.

What Tips Can Help Buyers Optimize Costs in Wire Harness Sourcing?

B2B buyers can employ several strategies to enhance cost efficiency when sourcing wire harnesses:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a long-term relationship can lead to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, durability, and performance. Cheaper options may lead to higher operational costs.

-

Research and Compare: Gather quotes from multiple suppliers to understand market pricing and identify the best value. Consider both domestic and international suppliers, keeping in mind quality and service levels.

-

Plan for Demand: Accurate forecasting can help optimize order quantities, reducing excess inventory while ensuring timely delivery of necessary components.

-

Leverage Local Suppliers: For buyers in regions like Africa and South America, sourcing from local manufacturers can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

Conclusion

When sourcing wire harnesses, understanding the intricate cost structure and pricing influencers is essential for making informed purchasing decisions. By employing strategic negotiation tactics and considering the total cost of ownership, international B2B buyers can effectively optimize their sourcing processes, ensuring they receive high-quality products at competitive prices. As always, it’s advisable to request indicative pricing and remain adaptable to market changes.

Alternatives Analysis: Comparing Wire Harness Manufacturers With Other Solutions

Introduction: Understanding Alternatives in Wire Harness Solutions

In the complex landscape of electronic assembly, selecting the right solution for wiring harnesses is crucial for ensuring efficiency and reliability. While traditional wire harness manufacturers provide tailored assemblies for various applications, businesses may also consider alternative solutions. This analysis compares wire harness manufacturing with two viable alternatives: Flexible Printed Circuit Boards (FPCBs) and Connectorized Wiring Systems. Understanding these options allows B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Wire Harness Manufacturers | Flexible Printed Circuit Boards (FPCBs) | Connectorized Wiring Systems |

|---|---|---|---|

| Performance | High durability and customizability | Lightweight, compact, and flexible | Modularity and ease of replacement |

| Cost | Higher initial investment | Generally lower manufacturing costs | Moderate cost, depending on connectors |

| Ease of Implementation | Requires specific design and assembly skills | Quick assembly and integration | Simple installation and scalability |

| Maintenance | Moderate; depends on the environment | Low maintenance due to fewer parts | Easy to replace parts as needed |

| Best Use Case | Complex applications requiring customization | Consumer electronics, compact devices | Systems requiring frequent upgrades |

Detailed Breakdown of Alternatives

Flexible Printed Circuit Boards (FPCBs)

FPCBs are an innovative alternative to traditional wire harnesses, offering significant advantages in terms of space and weight reduction. These boards are designed to be flexible, allowing them to fit into compact spaces where traditional wiring may not be feasible. The primary benefits of FPCBs include lower manufacturing costs and quicker assembly times, making them ideal for consumer electronics and devices where space is at a premium. However, their design limits them to applications where flexibility is more beneficial than robustness, which may not suit all industries, particularly those requiring high durability or environmental resilience.

Connectorized Wiring Systems

Connectorized wiring systems offer a modular approach to wiring, allowing for easy assembly and maintenance. These systems use connectors to join wires, enabling quick changes and upgrades without needing complete rewiring. This is particularly beneficial in applications where components are frequently updated or replaced, such as in automotive or industrial machinery. While these systems are generally more cost-effective than custom wire harnesses, they may not provide the same level of durability and protection against environmental factors, making them less suitable for harsh conditions.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a solution for wiring needs, B2B buyers should consider several factors, including the specific application, environmental conditions, and long-term maintenance requirements. Wire harness manufacturers excel in delivering custom solutions for complex applications, while alternatives like FPCBs and connectorized systems provide flexibility and modularity. Ultimately, the choice will depend on balancing performance, cost, and implementation ease to align with the operational goals of the business. Assessing the unique demands of each project will ensure that the chosen solution not only meets immediate requirements but also supports future scalability and efficiency.

Essential Technical Properties and Trade Terminology for Wire Harness Manufacturers

What Are the Key Technical Properties Relevant to Wire Harness Manufacturing?

When evaluating wire harnesses, understanding their technical specifications is critical for ensuring compatibility and performance in various applications. Here are some essential properties that B2B buyers should consider:

-

Material Grade

The choice of materials, such as copper or aluminum for conductors and various types of plastics or thermoplastics for insulation, significantly affects performance. Copper is typically preferred for its superior conductivity, while thermoplastics offer flexibility and durability. Selecting the right material grade ensures that the wire harness can withstand environmental conditions and operational demands specific to each industry, from automotive to medical devices. -

Gauge (AWG)

The American Wire Gauge (AWG) system measures wire diameter. A lower AWG number indicates a thicker wire, which can carry more current. Understanding gauge is vital for determining the appropriate wire for an application, ensuring that it can handle the required electrical load without overheating or failure. For instance, automotive applications may require thicker wires for high-load components, while delicate electronics can utilize finer gauge wires. -

Tolerance

Tolerance refers to the permissible variation in the dimensions of the wire harness components, such as length and diameter. High tolerance standards ensure that the harness fits perfectly within the intended assembly, reducing the risk of malfunctions or installation issues. In industries like aerospace and military, stringent tolerance levels are crucial for safety and reliability. -

Operating Temperature Range

Wire harnesses must be rated for specific temperature ranges to ensure safe operation under varying environmental conditions. For example, harnesses used in automotive engines need to withstand high temperatures, while those in medical devices may require lower thresholds. Understanding the operating temperature range helps in selecting wire harnesses that maintain functionality and safety across different applications. -

Shielding and Insulation Types

Shielding protects wires from electromagnetic interference (EMI), which is vital in high-frequency applications like telecommunications. Insulation types, such as PVC, silicone, or Teflon, provide varying levels of protection against heat, moisture, and chemicals. Identifying the correct shielding and insulation types ensures that the wire harness performs reliably in its intended environment.

What Are Common Trade Terms Used in the Wire Harness Industry?

Familiarity with industry jargon can facilitate smoother communication and negotiations between manufacturers and buyers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM produces components or products that are used in another company’s end product. For wire harness manufacturers, being an OEM means providing custom solutions that integrate seamlessly with the client’s machinery or systems. This term is crucial for establishing trust and credibility in the supply chain. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs helps buyers determine the feasibility of ordering custom wire harnesses, especially for specialized applications. It can also impact cost per unit, as lower quantities often lead to higher prices. -

RFQ (Request for Quote)

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products or services. In wire harness manufacturing, a well-structured RFQ should include detailed specifications, expected quantities, and delivery timelines. This process ensures that buyers receive competitive pricing and accurate proposals. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers manage logistics effectively and avoid potential disputes related to delivery obligations and costs. -

Turnkey Solutions

This term refers to a complete service where the manufacturer handles everything from design to delivery of the final product. For wire harness manufacturers, offering turnkey solutions can simplify the purchasing process for buyers, allowing them to focus on other aspects of their operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and industry standards, fostering successful partnerships with wire harness manufacturers.

Navigating Market Dynamics and Sourcing Trends in the Wire Harness Manufacturers Sector

What Are the Key Market Dynamics and Trends Affecting Wire Harness Manufacturing?

The wire harness manufacturing sector is experiencing significant transformations driven by various global factors. The increasing demand for electrical vehicles (EVs), coupled with advancements in automation and IoT technology, is propelling the market forward. As industries such as automotive, aerospace, and renewable energy expand, the need for custom wire harness solutions becomes paramount. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must stay attuned to these trends to enhance their procurement strategies.

Emerging technologies, such as Industry 4.0, are revolutionizing manufacturing processes. Automation, data analytics, and real-time monitoring are enabling manufacturers to optimize production efficiency and reduce lead times. Additionally, the rise of e-commerce platforms has simplified the sourcing process, allowing buyers to access a wider range of manufacturers and products globally. For businesses in emerging markets, leveraging these technologies can significantly enhance supply chain management and product quality.

Moreover, geopolitical factors and trade policies are influencing sourcing decisions. Buyers need to consider tariffs, trade agreements, and local manufacturing capabilities when selecting suppliers. As companies increasingly prioritize resilience in their supply chains, diversifying sourcing options and establishing strong relationships with manufacturers across different regions can mitigate risks associated with market volatility.

How Are Sustainability and Ethical Sourcing Shaping Wire Harness Manufacturing?

Sustainability and ethical sourcing have become critical considerations in the wire harness manufacturing sector. The environmental impact of production processes and materials is under scrutiny, compelling manufacturers to adopt greener practices. For international B2B buyers, understanding the sustainability policies of potential suppliers is essential. Manufacturers are increasingly utilizing eco-friendly materials, such as recyclable plastics and lead-free solder, which not only minimize environmental footprints but also appeal to consumers who prioritize sustainability.

Ethical supply chains are becoming a non-negotiable aspect of procurement strategies. Buyers are urged to inquire about the sourcing of raw materials and the labor practices of manufacturers. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety serve as indicators of a manufacturer’s commitment to ethical practices. By partnering with certified suppliers, businesses can enhance their brand reputation and meet regulatory requirements while contributing to a more sustainable industry.

What Is the Historical Context of Wire Harness Manufacturing and Its Evolution?

The wire harness manufacturing sector has evolved significantly over the past few decades. Initially, wire harnesses were basic assemblies used predominantly in the automotive industry. However, with technological advancements and the proliferation of electronics across various sectors, the complexity and functionality of wire harnesses have expanded dramatically.

In the early days, manufacturers relied heavily on manual processes, which limited production scale and efficiency. The introduction of automated machinery and advanced engineering techniques has transformed the landscape, allowing for the production of highly specialized wire harnesses tailored to specific applications. Today, wire harnesses are integral components in diverse fields, including aerospace, medical devices, and renewable energy systems, reflecting their critical role in modern technology and innovation.

Understanding this historical context helps B2B buyers appreciate the advancements in manufacturing capabilities and the importance of selecting suppliers who are not only experienced but also equipped to meet the demands of contemporary markets. As the industry continues to evolve, staying informed about these dynamics will be crucial for successful sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of Wire Harness Manufacturers

-

1. How do I choose the right wire harness manufacturer for my project?

Choosing the right wire harness manufacturer involves evaluating several key factors. Look for manufacturers with industry-specific experience relevant to your needs, such as automotive, aerospace, or medical applications. Assess their manufacturing capabilities, including custom designs and quality control processes. Check for certifications like ISO compliance, which indicate adherence to international quality standards. Additionally, consider their communication and support throughout the project, as strong collaboration is essential for successful outcomes. Request samples and references to further gauge their reliability and product quality. -

2. What customization options should I consider when sourcing wire harnesses?

Customization is crucial for ensuring that wire harnesses meet your specific application requirements. Consider options like wire gauge, insulation type, connector types, and the number of breakouts. You may also want to explore additional features such as wire identification labels, EMI shielding, and environmental protection measures. Discuss your unique specifications with potential manufacturers to understand their capabilities and how they can accommodate your needs. Prototyping services can also be beneficial to test designs before full production. -

3. What are the typical minimum order quantities (MOQs) for wire harness manufacturers?

Minimum order quantities (MOQs) can vary significantly between manufacturers and depend on factors such as the complexity of the wire harness and the materials used. Generally, MOQs can range from as low as 50 units for simple designs to several hundred for more complex assemblies. When negotiating with manufacturers, inquire about their flexibility with MOQs, especially if you’re a smaller business or are testing a new product. Some manufacturers may offer lower MOQs for initial orders or prototype runs. -

4. What payment terms should I expect when working with wire harness manufacturers?

Payment terms can vary among manufacturers but typically include options such as upfront deposits, progress payments, or payment upon delivery. It’s common to pay a deposit of 30-50% of the total cost before production begins, with the balance due upon completion. Discuss payment terms early in the negotiation process to ensure clarity and avoid misunderstandings. Additionally, explore options for credit terms or financing if you expect to place larger orders in the future. -

5. How do I ensure quality assurance in my wire harness order?

To ensure quality assurance, request detailed information about the manufacturer’s quality control processes. Look for certifications such as ISO 9001 or IPC/WHMA-A-620, which indicate adherence to high-quality standards. Ask about their testing procedures, including electrical testing and visual inspections, to verify that products meet your specifications. Additionally, consider implementing a first-article inspection (FAI) process, where the initial production unit is reviewed for compliance before full-scale manufacturing begins. -

6. What logistics considerations should I keep in mind when sourcing wire harnesses internationally?

When sourcing wire harnesses internationally, logistics play a crucial role in timely delivery and cost management. Consider shipping methods, customs duties, and import regulations specific to your country. It’s important to work with manufacturers who have experience in international shipping and can provide reliable timelines. Additionally, factor in lead times for production and shipping when planning your inventory. Establish clear communication regarding tracking shipments and handling potential delays. -

7. How can I assess the reliability of a wire harness manufacturer before placing an order?

To assess a manufacturer’s reliability, start by reviewing their reputation in the industry. Look for customer testimonials, case studies, and online reviews. Conduct due diligence by checking their certifications and quality management systems. It can also be beneficial to request references from previous clients to gain insights into their experiences. Additionally, consider visiting the manufacturing facility if possible, to observe their operations and quality control practices firsthand. -

8. What industries can benefit from custom wire harness manufacturing?

Custom wire harness manufacturing can benefit a wide range of industries, including automotive, aerospace, military, medical devices, renewable energy, and telecommunications. Each industry has unique requirements that can be met through tailored wire harness solutions. For example, automotive applications may require harnesses designed for high-temperature resistance, while medical devices may focus on biocompatibility and precision. By collaborating with a manufacturer who understands your industry’s specific needs, you can ensure optimal performance and reliability in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Wire Harness Manufacturers

In navigating the complexities of sourcing wire harnesses, international B2B buyers must prioritize strategic partnerships that align with their unique industry requirements. Customization, quality assurance, and adherence to international standards are paramount. As highlighted, manufacturers like Electri-Cord, Omega Leads, and Elite Harness excel in providing tailored solutions across diverse sectors, from aerospace to medical devices. This versatility not only enhances operational efficiency but also mitigates risks associated with supply chain disruptions.

Moreover, leveraging advanced manufacturing technologies and robust quality control measures ensures that buyers receive products that meet or exceed their expectations. Engaging with manufacturers who offer comprehensive support—from design consultation to post-production assistance—can significantly streamline procurement processes and enhance overall value.

Looking ahead, as global markets continue to evolve, embracing strategic sourcing practices will be crucial for businesses aiming to maintain a competitive edge. Buyers from Africa, South America, the Middle East, and Europe are encouraged to explore partnerships that foster innovation and reliability in wire harness manufacturing. By doing so, they can secure sustainable supply chains that are responsive to market demands, ultimately driving growth and success in their respective industries.