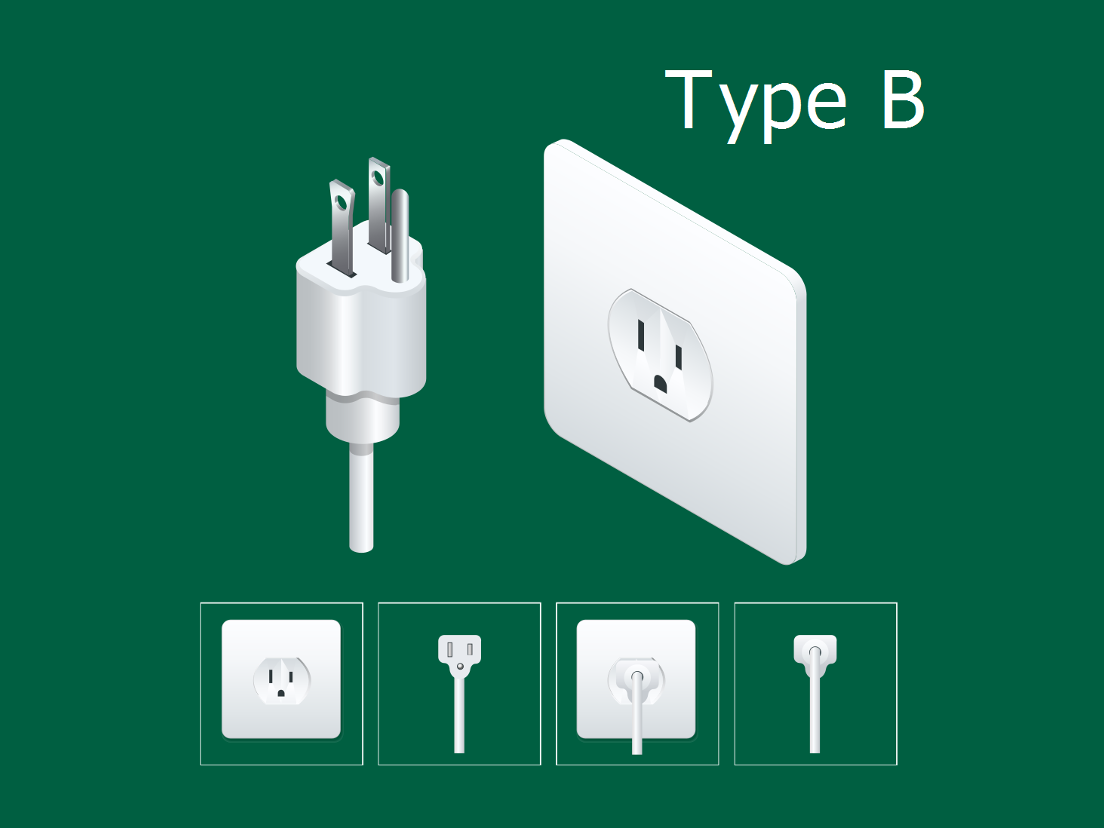

Ultimate Guide to Sourcing Type B Electrical Plug (2025)

Introduction: Navigating the Global Market for type b electrical plug

In an increasingly interconnected world, sourcing the right electrical components, such as the Type B electrical plug, can pose significant challenges for international B2B buyers. Understanding the nuances of this plug—commonly used in North America and parts of Central and South America—while navigating varying voltage and frequency standards across regions like Africa, Europe, and the Middle East is essential for ensuring operational efficiency and safety. This guide provides a comprehensive overview of the Type B electrical plug, including its specifications, applications, and compliance requirements, thereby enabling businesses to make informed purchasing decisions.

What Are the Key Considerations When Sourcing Type B Electrical Plugs?

This guide delves into essential topics such as the different types of plugs, their applications across various industries, and the importance of vetting suppliers for quality assurance. Additionally, it covers cost considerations and logistical aspects that can affect procurement decisions. By addressing these critical areas, the guide empowers B2B buyers from regions like Africa, South America, the Middle East, and Europe—such as the UK and Argentina—to streamline their sourcing processes and mitigate risks associated with electrical compatibility.

How Can Understanding the Global Market Improve Your Purchasing Strategy?

With insights tailored to international markets, this resource equips buyers with the knowledge needed to navigate the complexities of sourcing Type B plugs effectively. By leveraging this information, businesses can enhance their operational reliability and foster sustainable partnerships in the global marketplace.

Understanding type b electrical plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15 | Two flat parallel pins and one round grounding pin; rated for 15A | Electronics, Appliances | Pros: Widely used, easy compatibility; Cons: Grounding issues in some regions. |

| NEMA 5-20 | Similar to NEMA 5-15 but with a T-shaped pin; rated for 20A | High-power devices, Industrial | Pros: Higher current capacity; Cons: Less common, may require special sockets. |

| NEMA L5-15 | Locking mechanism for secure connection; rated for 15A | Critical applications, Medical | Pros: Reduces accidental disconnection; Cons: More expensive, specific socket needed. |

| NEMA 6-15 | Designed for 240V applications; two flat pins and a round pin | Heavy machinery, Industrial tools | Pros: Suitable for higher voltage; Cons: Not compatible with standard 120V outlets. |

| Type B (Japanese) | Similar to NEMA 5-15 but with minor variations in dimensions | Consumer electronics, Appliances | Pros: Compatibility with Japanese devices; Cons: May require adapters in other regions. |

What are the Characteristics of the NEMA 5-15 Plug?

The NEMA 5-15 is the most common type B plug, characterized by two flat parallel blades and a round grounding pin. It is rated for 15 amps and is predominantly used in North America, making it an ideal choice for electronics and appliances. B2B buyers should consider its compatibility with a wide range of devices, but be cautious of grounding issues in regions where this plug is not standard.

How Does the NEMA 5-20 Plug Differ from the NEMA 5-15?

The NEMA 5-20 plug features a T-shaped pin that allows it to fit into both 15A and 20A sockets. This plug is rated for 20 amps, making it suitable for high-power devices such as industrial equipment. Buyers should note that while it offers a higher current capacity, it is less common and may necessitate specific sockets, which could complicate integration in existing setups.

What Advantages Does the NEMA L5-15 Offer?

The NEMA L5-15 plug is designed with a locking mechanism to ensure a secure connection, making it ideal for critical applications like medical equipment. Rated for 15 amps, it prevents accidental disconnections, a significant benefit in environments where power stability is crucial. However, this type comes at a higher cost and requires specific sockets, which may limit its usability in some contexts.

Why Choose the NEMA 6-15 Plug for Heavy Machinery?

The NEMA 6-15 plug is tailored for 240V applications, featuring two flat pins and a round grounding pin. It is typically used in heavy machinery and industrial tools. B2B buyers should consider this option when dealing with high-voltage equipment, but must also account for its incompatibility with standard 120V outlets, potentially requiring additional infrastructure.

What Should Buyers Know About the Type B Plug Variations in Japan?

The Japanese version of the Type B plug closely resembles the NEMA 5-15 but has slight variations in dimensions. This type is commonly found in consumer electronics and appliances in Japan. International buyers should be aware of these differences, as they may need adapters when integrating Japanese devices into their operations, especially if they are located in regions with different plug standards.

Key Industrial Applications of type b electrical plug

| Industry/Sector | Specific Application of type b electrical plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures reliable operation of heavy machinery, enhancing productivity. | Verify compatibility with local voltage and amperage standards. |

| Hospitality | Charging stations for electronic devices | Increases customer satisfaction and convenience through accessible power sources. | Consider plug durability and safety standards for public use. |

| Healthcare | Medical equipment connectivity | Critical for patient safety and operational efficiency in medical environments. | Ensure compliance with healthcare regulations and safety certifications. |

| Construction | Temporary power supply for tools and equipment | Facilitates efficient work processes and reduces downtime on job sites. | Assess weather resistance and robustness for outdoor applications. |

| Retail | Point of Sale (POS) systems | Enhances transaction efficiency, leading to improved customer service. | Evaluate the reliability of power supply in high-traffic areas. |

What Are the Key Industrial Applications of Type B Electrical Plug?

The manufacturing sector utilizes the type B electrical plug to power various machinery and equipment. This plug’s grounding feature ensures safety and reliability, minimizing the risk of electrical faults that could lead to production downtime. International B2B buyers should confirm that the plugs meet local voltage and amperage requirements, as discrepancies can affect machinery performance.

In the hospitality industry, type B plugs are often found in charging stations for electronic devices in hotels and restaurants. This application enhances customer experience by providing convenient access to power, encouraging longer stays and repeat business. Buyers should consider the durability of these plugs, particularly in high-traffic areas, to ensure they withstand frequent use.

The healthcare sector relies on type B plugs to connect vital medical equipment. The grounding pin is essential for patient safety, preventing electrical shocks during operation. B2B buyers in this field must ensure that all electrical components comply with stringent healthcare regulations and safety standards, as any failure could have serious repercussions.

In construction, type B plugs are commonly used for temporary power supply to tools and equipment on job sites. This application is crucial for maintaining workflow and reducing project delays. Buyers should evaluate the plugs for weather resistance and robustness, as they often operate in harsh outdoor conditions where reliability is paramount.

Finally, in the retail sector, type B plugs are integral to Point of Sale (POS) systems, ensuring that transactions are processed quickly and efficiently. This application directly impacts customer satisfaction and overall business performance. Retailers should assess the reliability of these power sources, especially in high-traffic environments where consistent uptime is critical for operations.

3 Common User Pain Points for ‘type b electrical plug’ & Their Solutions

Scenario 1: Compatibility Issues with Local Socket Standards

The Problem:

International B2B buyers frequently encounter compatibility issues when trying to use Type B electrical plugs in regions where different socket standards are prevalent. For example, a company in South America might import machinery from the United States that uses Type B plugs, but their local infrastructure predominantly features Type C or Type I sockets. This misalignment can lead to operational delays, increased costs due to the need for additional adapters, and potential safety hazards if inappropriate modifications are made.

The Solution:

To mitigate compatibility issues, it’s essential to conduct thorough research on the electrical standards of the target market before purchasing equipment. Buyers should look for suppliers that offer products with interchangeable plug options or integrated adapters. Additionally, consider sourcing Type B plugs that are designed with a universal compatibility feature, allowing for easy adaptation to various socket types. Establishing a relationship with a local electrical contractor can also provide valuable insights on regional standards and help facilitate a smoother integration of imported equipment into local systems.

Scenario 2: Safety Concerns Regarding Grounding

The Problem:

Another significant pain point for B2B buyers involves the safety concerns related to grounding when using Type B plugs. In areas where grounding is inconsistent or improperly implemented, there is a heightened risk of electrical shock or equipment damage. This situation is particularly concerning in regions like parts of Africa and the Middle East, where infrastructure may not always meet international safety standards.

The Solution:

To address these safety concerns, buyers should prioritize sourcing Type B plugs with verified safety certifications and those that comply with international electrical standards. It is also beneficial to conduct a comprehensive assessment of the existing electrical infrastructure before installation. Collaborating with local electricians to implement proper grounding techniques can significantly enhance safety. Additionally, consider investing in surge protectors or circuit breakers that are compatible with Type B plugs to further mitigate risks associated with electrical surges.

Scenario 3: Limited Availability of Type B Plugs and Accessories

The Problem:

Many B2B buyers face the challenge of limited availability of Type B plugs and associated accessories, such as power strips and extension cords, in their local markets. This scarcity can lead to project delays and increased procurement costs as businesses may need to order these items from overseas suppliers, incurring higher shipping fees and longer lead times.

The Solution:

To overcome the issue of limited availability, buyers should establish partnerships with reliable manufacturers or distributors that specialize in electrical components. By negotiating bulk purchasing agreements, businesses can ensure a steady supply of Type B plugs and accessories at competitive prices. Additionally, consider exploring local trade shows or industry expos that showcase electrical products; this can provide opportunities to connect with suppliers who may not have a strong online presence. Lastly, maintaining an inventory of essential components can help mitigate the impact of supply chain disruptions, ensuring that operations remain uninterrupted.

Strategic Material Selection Guide for type b electrical plug

What Are the Key Materials Used in Type B Electrical Plugs?

When selecting materials for Type B electrical plugs, it is crucial to consider their performance characteristics, manufacturing complexities, and compliance with international standards. The most common materials used in the production of these plugs include thermoplastics, thermosetting plastics, copper, and brass. Each material has its unique properties and applications, making them suitable for different environments and requirements.

How Do Thermoplastics Perform in Type B Electrical Plugs?

Key Properties: Thermoplastics such as Polyvinyl Chloride (PVC) and Nylon are widely used in electrical plugs due to their excellent electrical insulation properties and resistance to heat. They typically have temperature ratings ranging from -40°C to 85°C, making them suitable for various climates.

Pros & Cons: The primary advantage of thermoplastics is their durability and impact resistance, which helps protect the internal components of the plug. However, they can be less resistant to certain chemicals and UV exposure, which may limit their use in outdoor applications. Manufacturing complexity is moderate, as thermoplastics can be molded easily.

Impact on Application: Thermoplastics are ideal for indoor applications where exposure to harsh chemicals is minimal. They are commonly used in consumer electronics and appliances.

Considerations for International Buyers: Buyers should ensure that the thermoplastics used comply with relevant standards such as ASTM D256 for impact resistance and UL 94 for flammability. This is particularly important in regions with strict safety regulations, such as Europe.

What Role Do Metals Like Copper and Brass Play in Type B Electrical Plugs?

Key Properties: Copper is known for its excellent electrical conductivity, while brass, an alloy of copper and zinc, offers good corrosion resistance and strength. Copper typically has a conductivity rating of 58 MS/m, making it ideal for electrical applications.

Pros & Cons: The key advantage of copper is its superior conductivity, which ensures efficient power transfer. Brass, while slightly less conductive, provides enhanced durability and resistance to wear. However, both materials can be susceptible to corrosion if not properly treated, which may affect long-term performance. The manufacturing process for metal components is generally more complex and costly compared to plastics.

Impact on Application: These metals are essential for the pins and connectors in Type B plugs, ensuring reliable electrical connections. They are suitable for environments where high conductivity is paramount, such as industrial applications.

Considerations for International Buyers: Buyers should verify that the metals used meet compliance standards such as ASTM B16 for copper and ASTM B453 for brass. This is particularly relevant for buyers in regions like Africa and South America, where environmental conditions can accelerate corrosion.

How Do Thermosetting Plastics Compare for Type B Electrical Plugs?

Key Properties: Thermosetting plastics, such as Bakelite, are known for their high thermal stability and electrical insulation properties. They can withstand temperatures up to 150°C without deforming.

Pros & Cons: The main advantage of thermosetting plastics is their excellent heat resistance and durability, making them suitable for high-temperature applications. However, they are more brittle than thermoplastics, which can lead to cracking under stress. The manufacturing process is more complex, as these materials cannot be remolded once set.

Impact on Application: Thermosetting plastics are often used in applications where heat generation is a concern, such as power tools and heavy-duty appliances.

Considerations for International Buyers: Compliance with standards like UL 746C for thermal properties is essential for buyers, especially in regions like the Middle East, where high temperatures are common.

Summary of Material Selection for Type B Electrical Plugs

| Material | Typical Use Case for Type B Electrical Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Indoor consumer electronics | Durable and impact-resistant | Limited chemical resistance | Medium |

| Copper | Electrical connections | Excellent electrical conductivity | Susceptible to corrosion | High |

| Brass | Pins and connectors | Corrosion-resistant and durable | Lower conductivity than copper | Medium |

| Thermosetting Plastics | High-temperature appliances | High thermal stability | Brittle and complex manufacturing | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in Type B electrical plugs, facilitating informed purchasing decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for type b electrical plug

What Are the Main Stages of Manufacturing Type B Electrical Plugs?

Manufacturing type B electrical plugs involves several critical stages, each designed to ensure efficiency, safety, and compliance with international standards. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: What Materials Are Used?

The production of type B electrical plugs begins with the selection of high-quality materials. Common materials include:

- Copper: Used for the prongs due to its excellent conductivity.

- Thermoplastics: Employed for the outer casing to provide insulation and durability.

- Nickel or Tin Plating: Often applied to copper to prevent corrosion and enhance conductivity.

The preparation phase involves sourcing these materials from reliable suppliers, ensuring they meet specific quality standards. For international buyers, verifying the material certifications from suppliers can prevent issues related to substandard components.

How Are Type B Electrical Plugs Formed?

The forming stage involves several techniques that shape the materials into the desired plug configuration. Key processes include:

- Injection Molding: This is primarily used for creating the plastic casing of the plug. The thermoplastic material is heated until it becomes liquid and then injected into molds that shape the outer casing.

- Stamping: Copper sheets are stamped into the required shapes for the prongs. This method allows for high-volume production while maintaining precision.

- Machining: Some components may require further machining to meet exact specifications, particularly for the grounding pin.

Using advanced technologies, such as computer numerical control (CNC) machines, ensures that each component meets the stringent dimensional tolerances required for safe electrical connections.

What Does the Assembly Process Entail?

Once the individual components are prepared, the assembly process begins. This stage typically includes:

- Inserting the Prongs: The copper prongs are inserted into the molded plastic casing. Care is taken to ensure that the grounding pin is positioned correctly and that all connections are secure.

- Soldering Connections: If applicable, soldering techniques are used to ensure solid electrical connections between components. This step is crucial for the plug’s functionality and safety.

- Final Assembly: The outer casing is closed, and any additional features, such as strain reliefs or locking mechanisms, are incorporated.

Effective assembly practices are vital for the overall quality of the type B plug. B2B buyers should inquire about the assembly techniques used by suppliers to ensure adherence to best practices.

What Finishing Techniques Are Used for Type B Plugs?

The finishing stage involves applying surface treatments and quality checks to ensure the plugs meet aesthetic and functional requirements. Techniques include:

- Surface Coating: To enhance durability and resistance to wear, plugs may undergo surface treatments such as electroplating or powder coating.

- Polishing: This step improves the appearance of the plug and can also enhance electrical contact surfaces.

Finishing processes should comply with relevant international standards, ensuring that the final product is both safe and reliable.

How Is Quality Assurance Implemented in Type B Plug Manufacturing?

Quality assurance (QA) is critical in the manufacturing of type B electrical plugs, ensuring that products meet safety and performance standards. Here’s how quality assurance is typically structured.

What International Standards Apply to Type B Electrical Plugs?

For type B plugs, several international standards are relevant, including:

- ISO 9001: A quality management standard that ensures consistent quality in manufacturing processes.

- IEC 60884-1: This standard specifies the requirements for plugs and socket-outlets for household and similar purposes.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

B2B buyers should verify that their suppliers adhere to these standards, as compliance is often a prerequisite for market entry in many regions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring occurs during production to identify any deviations from quality standards immediately.

- Final Quality Control (FQC): The finished products undergo comprehensive testing to ensure they meet all specifications before shipment.

These checkpoints help catch defects early, minimizing the risk of delivering substandard products to customers.

How Are Type B Plugs Tested for Safety and Performance?

Testing methods for type B plugs may include:

- Electrical Testing: This involves checking for proper grounding and insulation resistance to prevent electrical hazards.

- Mechanical Testing: Tests are conducted to ensure the plug can withstand physical stresses, such as pull tests and insertion tests.

- Environmental Testing: Products are subjected to various environmental conditions (e.g., temperature, humidity) to assess performance under different scenarios.

For B2B buyers, requesting test reports from suppliers can provide assurance of product safety and reliability.

How Can International B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain rigorous quality control standards, international buyers should consider the following approaches:

- Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality assurance measures.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes and results of testing.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s operations and product quality.

What Are the QC and Certification Nuances for Different Regions?

B2B buyers from Africa, South America, the Middle East, and Europe may face unique challenges regarding quality control and certification.

- Africa: Regulatory frameworks can vary significantly, so it’s vital to understand local compliance requirements.

- South America: Import regulations may necessitate additional certifications, which should be verified with suppliers.

- Middle East: Some countries require specific local certifications that might not be recognized elsewhere.

- Europe: CE marking is crucial for market entry; buyers should ensure suppliers are familiar with EU regulations.

Understanding these regional nuances can significantly influence procurement strategies and partnership choices.

Conclusion

The manufacturing processes and quality assurance protocols for type B electrical plugs are complex but essential for ensuring product reliability and safety. B2B buyers should focus on understanding these processes, verifying supplier compliance with international standards, and implementing robust quality control measures. By doing so, they can mitigate risks and enhance their supply chain efficiency, ultimately leading to safer and more reliable electrical solutions for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type b electrical plug’

In the global market, sourcing Type B electrical plugs effectively requires a methodical approach. This checklist is designed for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. It will guide you through the essential steps to ensure a successful procurement process.

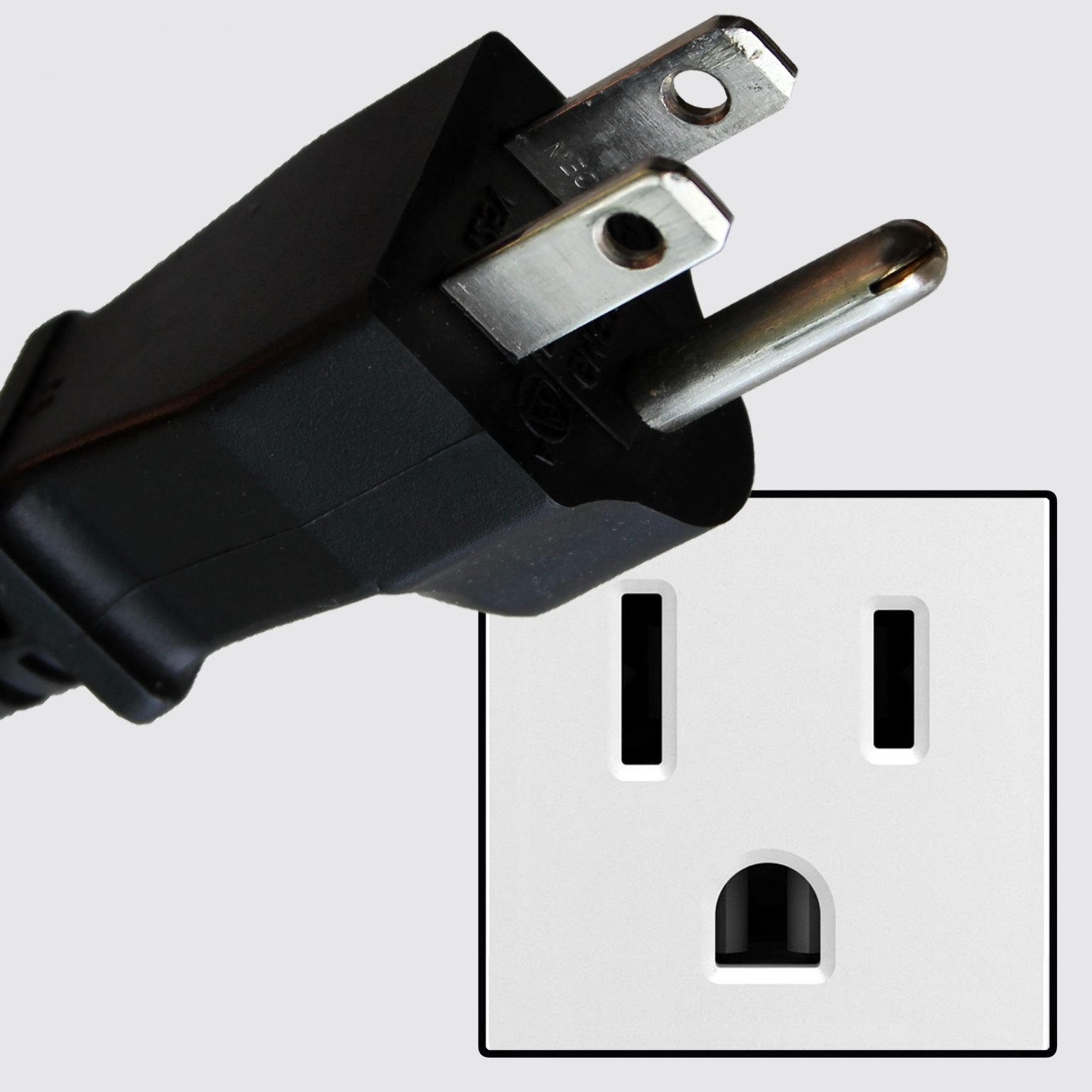

A stock image related to type b electrical plug.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the Type B electrical plug. This includes voltage ratings, amperage (typically 15A for Type B), and safety certifications. Having precise specifications helps in filtering suppliers who can meet your needs and ensures compatibility with your electrical systems.

- Voltage and Frequency: Ensure the plugs are rated for 120V, 60Hz, as commonly used in North America.

- Safety Standards: Look for compliance with local and international safety standards, such as UL, CE, or IEC certifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in Type B electrical plugs. Utilize online directories, industry forums, and trade shows to create a list of reputable manufacturers.

- Supplier Reputation: Look for suppliers with a strong track record and positive reviews from previous customers.

- Product Range: Ensure they offer a variety of products that meet your specifications, including variations in design and features.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that your selected suppliers hold relevant certifications. This step is crucial for ensuring product quality and compliance with safety regulations.

- Documentation Review: Request copies of certifications and quality assurance documentation.

- Factory Audits: Consider arranging for factory audits to assess manufacturing processes and quality control measures.

Step 4: Request Samples

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality and functionality of the Type B plugs firsthand.

- Performance Testing: Check for durability, electrical performance, and safety features.

- Compatibility Checks: Ensure the plugs work seamlessly with your existing electrical systems and equipment.

Step 5: Assess Pricing and Payment Terms

Compare pricing across different suppliers but don’t solely focus on the lowest price. Evaluate the total cost of ownership, including shipping, tariffs, and potential duties.

- Transparent Pricing: Ensure pricing is clear, with no hidden fees.

- Flexible Payment Terms: Look for suppliers offering favorable payment terms, such as net 30 or net 60, which can improve cash flow.

Step 6: Check Shipping and Delivery Options

Understand the shipping options and delivery timelines offered by your supplier. Efficient logistics are critical to ensuring your supply chain remains uninterrupted.

- Lead Times: Confirm the lead times for production and shipping.

- Shipping Methods: Evaluate available shipping methods and their costs, as well as options for tracking shipments.

Step 7: Establish Communication Channels

Strong communication is key to a successful supplier relationship. Ensure you have clear lines of communication established for ongoing discussions and updates.

- Dedicated Contacts: Identify a primary point of contact within the supplier’s organization.

- Regular Updates: Set expectations for regular updates on order status, potential delays, or issues.

By following these steps, B2B buyers can effectively source Type B electrical plugs that meet their needs, ensuring quality and compliance while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for type b electrical plug Sourcing

What Are the Key Cost Components in Sourcing Type B Electrical Plugs?

When sourcing Type B electrical plugs, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The materials used in manufacturing Type B plugs primarily include high-quality plastics for the housing and copper for the prongs. The choice of materials significantly affects the durability and safety of the plugs, as well as the overall cost.

-

Labor: Labor costs vary by region. In countries with lower wage standards, labor can be a significant cost saver. However, investing in skilled labor ensures better quality and adherence to safety standards.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and factory management costs. A well-optimized manufacturing process can reduce overheads and improve profitability.

-

Tooling: Initial costs for molds and manufacturing tools can be substantial but are amortized over production runs. Custom designs may require additional tooling, increasing the upfront investment.

-

Quality Control (QC): Rigorous testing and quality assurance processes are essential to ensure compliance with international safety standards. Effective QC can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping costs depend on the mode of transport, distance, and volume of orders. Understanding the logistics landscape can help buyers optimize their supply chain and reduce costs.

-

Margin: Suppliers typically include a profit margin on their prices. This margin can vary significantly based on competition, market demand, and the supplier’s reputation.

How Do Price Influencers Impact Type B Electrical Plug Sourcing?

Several factors influence the pricing of Type B electrical plugs, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Negotiating favorable MOQs can result in significant savings.

-

Specifications and Customization: Customized plugs that meet specific regulatory requirements or branding needs usually come at a premium. Buyers should weigh the benefits of customization against the additional costs.

-

Materials: The quality and type of materials directly affect the price. High-grade materials may incur higher upfront costs but can lead to better longevity and performance.

-

Quality Certifications: Compliance with international safety standards (e.g., UL, CE) can add to the costs but is critical for market acceptance, especially in regions with stringent regulations.

-

Supplier Factors: Reputation, reliability, and manufacturing capabilities of suppliers can influence pricing. Establishing long-term relationships with trusted suppliers may yield better pricing and terms.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining cost responsibilities in shipping. The chosen Incoterm can affect the total landed cost significantly.

What Tips Can Help International B2B Buyers Negotiate Better Pricing?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are vital:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider shipping, duties, and potential maintenance costs to evaluate the true expense of sourcing.

-

Leverage Competitive Quotes: Obtaining multiple quotes from different suppliers can enhance negotiation power. Use this information to push for better pricing or terms.

-

Build Relationships: Establishing strong relationships with suppliers can lead to preferential pricing, better service, and improved communication.

-

Be Aware of Pricing Nuances: Currency fluctuations, geopolitical factors, and local economic conditions can influence pricing. Staying informed about these factors helps in making better purchasing decisions.

-

Negotiate Payment Terms: Favorable payment terms can ease cash flow. Discuss options such as staggered payments or extended payment periods to manage costs effectively.

Disclaimer

Prices for Type B electrical plugs can vary widely based on the factors discussed. Buyers are encouraged to conduct thorough market research and consult with suppliers to obtain the most accurate and relevant pricing information tailored to their specific needs.

Alternatives Analysis: Comparing type b electrical plug With Other Solutions

Introduction to Alternative Solutions for Electrical Connectivity

In the realm of electrical connectivity, the Type B electrical plug (NEMA 5-15) is widely recognized for its reliability and grounding capabilities. However, as international B2B buyers evaluate options for their specific needs, it’s essential to consider alternative solutions. These alternatives may offer unique benefits in terms of performance, cost, or ease of implementation, particularly in diverse regions such as Africa, South America, the Middle East, and Europe.

Comparison Table of Electrical Plug Solutions

| Comparison Aspect | Type B Electrical Plug | Type C Electrical Plug (Europlug) | Type G Electrical Plug (British) |

|---|---|---|---|

| Performance | Rated for 15A, grounded | Rated for 2.5A, ungrounded | Rated for 13A, grounded |

| Cost | Moderate | Low | Moderate |

| Ease of Implementation | Widely available in North America | Common in Europe, easy to find | Standard in UK, may require adapters in other regions |

| Maintenance | Low | Low | Moderate (fuse replacement needed) |

| Best Use Case | North America, grounded applications | General household use in Europe | UK and countries using British standard |

Detailed Breakdown of Alternatives

Type C Electrical Plug (Europlug)

The Type C plug is primarily used in Europe and is designed for devices that require lower power, typically up to 2.5A. Its compact design allows for easy insertion into various sockets, making it a versatile option for travelers and businesses operating in Europe. The main advantage is its widespread availability and low cost, but it lacks grounding, which can pose safety risks for higher power devices. Companies looking for a cost-effective solution for low-power devices in European markets may find the Type C plug suitable, but they should ensure that devices are compatible with ungrounded connections.

Type G Electrical Plug (British)

The Type G plug is commonly used in the UK and several other countries. It is rated for 13A and features a built-in fuse for added safety. While the Type G plug offers superior safety features compared to Type C, it is bulkier and may not be as easily integrated into devices designed for other plug types. For businesses operating in the UK or dealing with British products, the Type G plug is a secure choice. However, international buyers should consider the additional costs associated with sourcing adapters or converting devices to accommodate this plug type.

Conclusion: Choosing the Right Electrical Plug Solution

When selecting the right electrical plug solution, B2B buyers must consider their specific operational needs, regional standards, and device compatibility. The Type B electrical plug is an excellent choice for applications in North America where grounding is crucial. However, for operations in Europe or the UK, exploring alternatives like the Type C or Type G plugs may provide enhanced flexibility or safety, depending on the situation. Ultimately, the decision should align with the intended use case, safety requirements, and budget constraints to ensure seamless electrical connectivity across different markets.

Essential Technical Properties and Trade Terminology for type b electrical plug

What Are the Essential Technical Properties of a Type B Electrical Plug?

When considering the procurement of Type B electrical plugs, understanding their technical specifications is crucial for ensuring compatibility and safety in diverse markets. Here are the key properties that B2B buyers should prioritize:

1. Material Composition

The Type B plug is typically constructed from high-grade thermoplastic materials, such as polycarbonate or nylon. These materials provide excellent durability, resistance to heat, and electrical insulation. For international buyers, ensuring the plugs meet local regulations regarding material safety is vital to avoid compliance issues.

2. Current Rating

Type B plugs are rated for a maximum current of 15 amps. This specification is essential for determining the plug’s capability to handle electrical loads safely. Buyers must consider the appliances and devices that will utilize these plugs to ensure they do not exceed this current rating, which could lead to overheating or electrical fires.

3. Voltage Compatibility

The standard voltage for Type B plugs is 120V, primarily used in North America and parts of Central America. However, some regions, such as the Caribbean and parts of South America, may also use Type B plugs at different voltages (e.g., 230V). Understanding the voltage requirements of target markets helps buyers avoid costly product returns and enhances customer satisfaction.

4. Pin Dimensions and Configuration

Type B plugs feature two flat parallel pins and a round earth pin. The flat pins measure approximately 15.9 to 18.3 mm in length and are spaced 12.7 mm apart, while the earth pin is longer (4.8 mm in diameter). This configuration ensures that the device is grounded before electrical contact is made, enhancing user safety. Buyers should verify these dimensions against local standards to ensure compatibility with sockets.

5. Safety Certifications

Compliance with international safety standards, such as UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission), is critical. These certifications ensure that the plugs have undergone rigorous testing for safety and reliability. Buyers must request certification documentation to confirm compliance, especially when sourcing from overseas manufacturers.

What Trade Terminology Should B2B Buyers Know?

Familiarity with industry terminology can significantly streamline the procurement process for Type B electrical plugs. Here are some key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s end product. In the context of electrical plugs, identifying OEM suppliers can provide assurance of quality and reliability, as these manufacturers often adhere to strict industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and cash flow. Negotiating favorable MOQ terms can lead to cost savings and better supply chain management.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. When sourcing Type B plugs, issuing an RFQ allows buyers to compare prices, terms, and product specifications from various manufacturers, aiding in informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and liability during transit.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are delivered. Understanding lead times for Type B plugs is critical for supply chain planning and ensuring timely product availability in target markets.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed purchasing decisions that align with their operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the type b electrical plug Sector

What Are the Current Market Dynamics for Type B Electrical Plugs?

The type B electrical plug market is experiencing notable growth driven by several global factors. The increase in international trade and cross-border travel has spurred demand for electrical devices compatible with multiple plug types, including type B. Countries in Africa, South America, and the Middle East are increasingly adopting electrical appliances from North America, where type B is standard. This trend is amplified by the growing influence of technology and e-commerce platforms, allowing B2B buyers to source products from international manufacturers more easily.

A stock image related to type b electrical plug.

Emerging sourcing trends highlight a shift towards customization and localization. International buyers are looking for suppliers who can provide tailored solutions that meet specific regional standards and preferences. Furthermore, the rise of e-mobility and renewable energy applications is pushing manufacturers to innovate and improve the design and functionality of electrical plugs, including enhanced safety features and energy efficiency. This transformation presents opportunities for B2B buyers to engage with manufacturers offering advanced type B plugs that comply with international safety standards.

How Is Sustainability Shaping the Sourcing of Type B Electrical Plugs?

Sustainability has become a critical consideration in the sourcing of type B electrical plugs. The environmental impact of electrical components, from production to disposal, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing practices. This includes transparency in the supply chain, responsible material sourcing, and adherence to environmental regulations.

Buyers should seek out manufacturers that utilize ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) compliance, ensuring that products are made without harmful substances and are recyclable. Additionally, the use of sustainable materials, such as recycled plastics and metals, is gaining traction. By choosing suppliers who prioritize sustainability, B2B buyers can not only minimize their environmental footprint but also enhance their corporate social responsibility profile, aligning with the values of their customers and stakeholders.

What Is the Historical Context of the Type B Electrical Plug?

The type B electrical plug, standardized as NEMA 5-15, has its roots in the early 20th century, specifically developed in 1904 by Harvey Hubbell II. Initially designed for use in North America, the plug features two flat parallel pins and a round earth pin, emphasizing safety through grounding. Over the decades, as global trade expanded, the type B plug became a common standard in many regions, particularly in North and Central America.

Despite its widespread adoption, the type B plug has faced challenges in other regions, particularly in parts of South America and the Middle East, where grounded outlets are still relatively rare. This historical context is essential for B2B buyers as it underscores the importance of understanding regional electrical standards and market demands when sourcing type B plugs for international applications. Recognizing the evolution of this plug type can guide buyers in making informed decisions that align with both safety standards and local market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of type b electrical plug

-

How do I identify the right type B electrical plug for my needs?

To choose the appropriate type B electrical plug, consider the voltage and frequency requirements of your electrical devices. Type B plugs are commonly used in North America and are rated for 120V at 60Hz. Ensure that the plug specifications match your equipment, especially if you’re importing products from regions like Africa or South America where voltage standards may differ. Additionally, verify the plug’s compatibility with the sockets in your target market to avoid electrical hazards. -

What are the safety standards for type B electrical plugs?

Type B plugs must comply with international safety standards, such as IEC 60884-1 and NEMA standards in the U.S. Look for certifications from recognized bodies like UL or CE, which indicate that the plugs have been tested for safety and performance. When sourcing from suppliers, request documentation proving compliance with these standards to ensure the plugs meet safety requirements in your region. -

What customization options are available for type B electrical plugs?

Many manufacturers offer customization options for type B electrical plugs, including variations in colors, materials, and branding. You may also request modifications such as longer or shorter prongs, different wire gauges, or specific insulation types. When discussing customization, clarify your requirements with suppliers and inquire about the minimum order quantities (MOQ) and any additional costs involved. -

How can I vet suppliers for type B electrical plugs?

Vetting suppliers involves several steps: check their credentials, read customer reviews, and request product samples. Look for manufacturers with ISO certification or those that have been in the industry for several years. Additionally, consider visiting their facilities if possible or engaging third-party auditing services to verify their production capabilities and quality control processes. -

What are common payment terms in international B2B transactions for electrical plugs?

Payment terms can vary widely depending on the supplier and the transaction size. Common practices include paying a deposit upfront (usually 30%) with the balance due before shipment. Some suppliers may offer payment through letters of credit for larger orders. Always clarify payment methods and terms in advance to avoid misunderstandings and ensure that they align with your financial processes.

A stock image related to type b electrical plug.

-

What logistics considerations should I keep in mind when importing type B electrical plugs?

When importing type B electrical plugs, consider shipping methods, customs regulations, and import duties specific to your country. Choose a reliable freight forwarder experienced in handling electrical goods. Ensure all documentation, including invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

How do I ensure quality assurance (QA) for type B electrical plugs?

To maintain quality assurance, establish a QA process that includes regular inspections during production and before shipment. Request samples from your supplier for testing and consider using third-party quality control services. Additionally, set clear specifications and expectations regarding performance, safety standards, and packaging to ensure that the products delivered meet your requirements. -

What are the implications of electrical plug variations across regions?

Variations in electrical plugs, including type B, can lead to compatibility issues when devices are used in different regions. For international buyers, it’s crucial to understand the local standards and regulations regarding electrical plugs. Ensure that any devices imported or sold in regions like Europe or the Middle East comply with local plug types and voltage requirements to avoid electrical hazards and maintain customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type b electrical plug

In today’s interconnected marketplace, understanding the nuances of the Type B electrical plug is vital for international B2B buyers. This plug, commonly utilized in North and Central America, is designed for devices requiring grounded connections, ensuring safety and reliability. The ongoing demand for Type B plugs, particularly in regions like Africa, South America, and the Middle East, presents lucrative opportunities for suppliers who can meet compliance standards and offer high-quality products.

What Key Factors Should International Buyers Consider for Type B Plugs?

Strategic sourcing is essential in navigating the complexities of global supply chains. Buyers must consider the voltage and frequency compatibility in their target markets, as variations can significantly impact product performance. Establishing relationships with trusted manufacturers who adhere to international safety standards will mitigate risks associated with product quality and compliance.

How Can Buyers Leverage Market Trends?

As the demand for Type B plugs grows, particularly with the increasing globalization of technology, buyers should stay informed about market trends and emerging technologies. Engaging with suppliers who offer innovative solutions, such as eco-friendly materials or advanced safety features, can enhance their competitive edge.

As we look ahead, the future of Type B electrical plugs is promising. By prioritizing strategic sourcing and building strong supplier partnerships, international B2B buyers can capitalize on new opportunities and ensure their products meet the evolving needs of the global market.