Understand Dieing or Dying: The Complete Guide for 2025

Introduction: Navigating the Global Market for dieing or dying

In the rapidly evolving global market, understanding the difference between “dieing” and “dying” can be crucial for B2B buyers, particularly when sourcing materials or processes involving die casting or die cutting. The nuances in terminology can lead to misunderstandings that impact procurement decisions, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe. This guide aims to clarify these concepts while providing a comprehensive overview of relevant types, applications, and supplier vetting processes.

Navigating the complexities of sourcing from diverse markets requires a solid understanding of both the technical and commercial aspects of die casting and cutting. International B2B buyers will benefit from insights into cost structures, quality standards, and regional variations in manufacturing practices. This guide will empower you to make informed purchasing decisions by equipping you with the knowledge needed to evaluate suppliers effectively and understand the implications of terminology in your contracts and communications.

By addressing key challenges and providing actionable insights, this resource is designed to enhance your sourcing strategy and optimize your procurement processes. Whether you are looking to establish long-term partnerships or seeking reliable suppliers, understanding the implications of dieing versus dying will play a vital role in your success in the global marketplace.

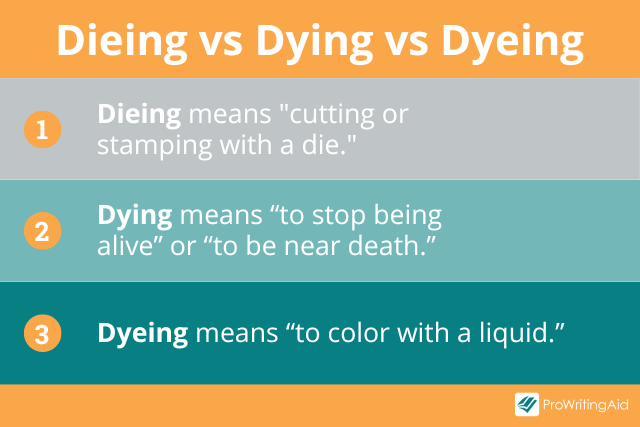

Understanding dieing or dying Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dying (Verb) | Refers to the process of ceasing to exist or function. | Healthcare, Emotional Support Services | Pros: Clear communication; essential in healthcare contexts. Cons: Sensitive topic; requires careful handling. |

| Die Casting | A manufacturing process using a die to shape materials. | Automotive, Electronics, Consumer Goods | Pros: High precision and efficiency; cost-effective for large volumes. Cons: Initial setup costs can be high; limited to certain materials. |

| Die Cutting | A process that uses a die to cut materials into shapes. | Packaging, Textile, Graphic Design | Pros: Versatile across materials; ideal for high-volume production. Cons: Setup can be time-consuming; may require specialized equipment. |

| Dying (Textiles) | The process of coloring fabrics or materials. | Fashion, Home Textiles, Industrial Fabrics | Pros: Enhances product appeal; diverse color options available. Cons: Environmental concerns with certain dyes; quality varies. |

| Dying (Plants) | Refers to the decline of living plants due to various factors. | Agriculture, Landscaping, Horticulture | Pros: Important for understanding plant health; can guide purchasing decisions. Cons: Requires knowledge of plant care; can lead to financial losses if not managed. |

What Are the Key Characteristics of the Dying (Verb) in B2B Contexts?

The term “dying” as a verb is crucial in B2B discussions, particularly within healthcare and emotional support sectors. It denotes the process of ceasing to exist, which can apply to both living organisms and non-functional equipment. In healthcare, clear communication about patient conditions is paramount, necessitating sensitive language when discussing end-of-life scenarios. Buyers in this sector should consider the implications of language and how it impacts patient care and emotional support.

How Does Die Casting Benefit B2B Buyers?

Die casting is a manufacturing technique that allows for the creation of complex shapes with high precision. This method is widely used in industries such as automotive and electronics, where components must meet strict specifications. The efficiency of die casting makes it an attractive option for large production runs, significantly reducing per-unit costs. However, buyers should weigh the initial setup costs and material limitations against the long-term benefits of this process.

What Are the Advantages of Die Cutting for B2B Applications?

Die cutting is a versatile manufacturing process that can create a variety of shapes and sizes from different materials. It is widely used in packaging, textiles, and graphic design, making it essential for businesses looking to produce custom items efficiently. While die cutting offers great flexibility and speed, it requires careful planning and investment in specialized equipment, which can be a barrier for smaller businesses.

Why Is Dying Important in Textiles and Fashion?

In the textile industry, dying refers to the process of coloring fabrics, which is vital for product differentiation and aesthetic appeal. Buyers in the fashion and home textiles sectors must consider the environmental impact of dyes and the quality of the finished product. With a growing demand for sustainable practices, understanding the dying process can influence purchasing decisions and supplier relationships.

How Does Understanding Plant Dying Help Agricultural Buyers?

The concept of dying also applies to plants, where it indicates a decline in health due to various factors such as disease, water stress, or nutrient deficiencies. For buyers in agriculture, landscaping, and horticulture, recognizing the signs of dying plants is essential for making informed purchasing decisions. By understanding plant health, businesses can mitigate potential losses and enhance the sustainability of their operations.

Key Industrial Applications of dieing or dying

| Industry/Sector | Specific Application of dieing or dying | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Die Casting for Engine Components | Enhanced durability and performance | Supplier reliability, material quality, and cost |

| Electronics | Die Cutting for Circuit Boards | Precision and efficiency in production | Technology compatibility, lead times, and certifications |

| Construction and Building | Die Forming for Structural Components | Cost-effective mass production | Material sourcing, custom tooling capabilities |

| Textile and Fashion | Die Cutting for Fabric Patterns | Consistent quality and reduced waste | Supplier experience, machine capabilities, and pricing |

| Packaging | Die Cutting for Custom Packaging Solutions | Improved brand presentation and protection | Flexibility in order sizes, turnaround times, and design support |

How is Die Casting Used in the Automotive Industry?

In the automotive sector, die casting is crucial for manufacturing engine components such as housings and brackets. This process allows for the production of lightweight and durable parts that can withstand high temperatures and pressures. For international buyers, particularly in Africa and South America, sourcing reliable suppliers who offer high-quality aluminum or zinc alloys is essential. Additionally, understanding the production capabilities and certifications of suppliers can mitigate risks related to performance and compliance with local regulations.

What Role Does Die Cutting Play in Electronics?

Die cutting is extensively used in the electronics industry, especially for creating circuit boards and insulation materials. This method ensures high precision, which is vital for the functionality of electronic devices. Buyers from the Middle East and Europe should consider suppliers that utilize advanced die cutting technologies to ensure accuracy and efficiency. Factors such as lead times and the ability to handle custom designs can significantly impact production schedules and costs.

Why is Die Forming Important in Construction?

Die forming is a key application in the construction industry, where it is used to create structural components like beams and panels. This method allows for cost-effective mass production while maintaining structural integrity. For B2B buyers, especially in developing regions, sourcing from manufacturers who can provide tailored solutions and high-quality materials is critical. Understanding the supplier’s capacity for custom tooling and their experience in handling large orders can lead to better project outcomes.

How Does Die Cutting Benefit the Textile Industry?

In the textile and fashion industry, die cutting is used to produce fabric patterns and components with high precision. This process not only enhances the quality of the final products but also reduces fabric waste, making it a sustainable option. Buyers in Europe and Australia should prioritize suppliers with a strong track record in machine capabilities and industry experience. Evaluating the supplier’s ability to meet specific design requirements and manage bulk orders can lead to improved efficiency and cost savings.

What are the Advantages of Die Cutting in Packaging?

Die cutting plays a significant role in the packaging industry, where it is used to create custom packaging solutions that enhance product presentation and protection. This method allows for intricate designs that can elevate brand identity. For international buyers, particularly in South America and Africa, it is important to choose suppliers who can adapt to varying order sizes and provide quick turnaround times. Assessing the design support offered by suppliers can also ensure that packaging meets both aesthetic and functional requirements.

3 Common User Pain Points for ‘dieing or dying’ & Their Solutions

Scenario 1: Miscommunication in Technical Documentation

The Problem: In the manufacturing sector, B2B buyers often rely on precise technical documentation to ensure processes run smoothly. However, the confusion between “dieing” and “dying” can lead to significant miscommunication. For instance, if a supplier uses “dieing” instead of “dying” in a specification document, it may mislead engineers into thinking it refers to a manufacturing process, rather than the intended meaning related to death or cessation of function. This can result in incorrect assumptions, delays in production, and increased costs.

The Solution: To mitigate this issue, B2B buyers should implement a standardized glossary of terms in their technical documentation. This glossary should clearly define terms like “dying” in the context of processes and machinery, while explicitly stating that “dieing” is a misspelling. Buyers can also invest in language editing services that specialize in technical documentation to ensure clarity and prevent ambiguity. Moreover, training sessions for staff on the importance of precise language in documentation can further enhance communication and operational efficiency.

Scenario 2: Impact on Brand Reputation

The Problem: For businesses involved in content marketing, using the correct terminology is crucial for maintaining a professional image. The incorrect usage of “dieing” instead of “dying” can tarnish a company’s reputation and credibility. This is particularly relevant for international B2B buyers who are often scrutinized for their communication standards. A misstep in language can lead potential clients to question the professionalism and attention to detail of a business, potentially costing valuable contracts.

The Solution: To uphold a strong brand reputation, B2B buyers should develop a robust content strategy that includes a review process for all written materials. Employing professional editors or utilizing grammar-checking software can ensure that all content adheres to linguistic standards. Additionally, creating templates for frequently used documents can help maintain consistency in terminology. Regular training on the importance of language accuracy in business communications can empower teams to take pride in their written output and avoid common pitfalls.

Scenario 3: Confusion in E-commerce Transactions

The Problem: In the world of e-commerce, product descriptions and specifications play a pivotal role in influencing purchase decisions. Misusing “dieing” can lead to confusion among potential buyers, especially if they are unfamiliar with the context of the term. For instance, if a product description incorrectly refers to a “dieing” process when discussing a metal component, it may raise doubts about the product’s reliability, leading to decreased sales and customer trust.

The Solution: B2B buyers operating in e-commerce should prioritize accurate product descriptions by employing content specialists who understand the nuances of language. Implementing a quality assurance checklist that includes terminology verification can help avoid such mistakes. Additionally, buyers should encourage customer feedback on product descriptions, allowing them to identify and rectify any confusing language swiftly. Leveraging SEO tools that highlight commonly confused terms can also assist in optimizing product listings while ensuring clarity and correctness in language use.

Alternatives Analysis: Comparing dieing or dying With Other Solutions

Introduction to Alternatives in B2B Solutions

In the realm of B2B operations, selecting the right terminology and processes is crucial for effective communication and execution. The distinction between “dieing” and “dying” highlights the importance of clarity in language. However, when considering practical applications, it’s beneficial to explore alternatives that can serve similar functions. This analysis will compare “dying,” the correct term representing the process of ceasing to exist, with two alternative approaches: life extension technologies and sustainable resource management. These alternatives provide varying methods to address issues related to existence, functionality, and operational sustainability.

Comparison Table

| Comparison Aspect | ‘Dieing Or Dying’ | Life Extension Technologies | Sustainable Resource Management |

|---|---|---|---|

| Performance | Accurate communication essential | Can prolong life and productivity | Enhances resource efficiency |

| Cost | Low (language use) | High (R&D, medical costs) | Moderate (investment in practices) |

| Ease of Implementation | Simple (correct usage) | Complex (requires expertise) | Moderate (requires training) |

| Maintenance | None | Ongoing (medical upkeep) | Regular (monitoring practices) |

| Best Use Case | Clear communication in writing | Healthcare and biotechnology | Environmental sustainability |

Detailed Breakdown of Alternatives

What Are Life Extension Technologies and Their Benefits?

Life extension technologies encompass a range of innovations aimed at prolonging human life and improving quality of life. These technologies include advancements in healthcare such as gene therapy, regenerative medicine, and anti-aging treatments. The primary advantage of these technologies lies in their potential to enhance productivity and longevity. However, they come with significant costs related to research and development, as well as ongoing medical expenses. Furthermore, their implementation often requires specialized knowledge, making them less accessible for average businesses.

How Does Sustainable Resource Management Provide Value?

Sustainable resource management focuses on using resources efficiently to meet current needs while preserving them for future generations. This approach encompasses practices such as recycling, renewable energy sourcing, and waste reduction. The benefits of adopting sustainable practices include improved operational efficiency and reduced costs over time. While the initial investment may be moderate, the long-term savings and positive environmental impact can be significant. Training is necessary to ensure effective implementation, but it is generally easier to adopt than complex life extension technologies.

Conclusion: Choosing the Right Solution for Your Business Needs

For international B2B buyers, the decision between using “dying” or exploring alternatives like life extension technologies and sustainable resource management hinges on specific operational needs and goals. If the priority is clear communication and understanding, ensuring the correct use of terminology is vital. However, for businesses looking to enhance productivity or sustainability, evaluating life extension technologies or sustainable practices may be more beneficial. Each alternative presents unique advantages and challenges, and buyers should carefully consider their resources, expertise, and long-term objectives to determine the best fit for their organizational strategy.

Strategic Material Selection Guide for dieing or dying

When selecting materials for dieing or dying processes in industrial applications, it’s essential to analyze the properties, advantages, and limitations of various materials. This guide focuses on four commonly used materials: aluminum, steel, brass, and plastic. Each material has distinct characteristics that influence its suitability for specific applications, particularly in diverse international markets.

What are the Key Properties of Aluminum in Dieing or Dying Applications?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 600°F (315°C) and can withstand moderate pressure. Aluminum’s malleability allows it to be easily shaped during die casting processes.

Pros & Cons:

– Pros: Lightweight, corrosion-resistant, good thermal conductivity, and cost-effective for high-volume production.

– Cons: Lower strength compared to steel, can be more expensive than some plastics, and may require additional treatments for specific applications.

Impact on Application:

Aluminum is compatible with various media, making it suitable for automotive, aerospace, and consumer goods applications. However, buyers must consider its limitations in high-stress environments.

Considerations for International Buyers:

Aluminum products must comply with standards such as ASTM B221 and EN 573. Buyers in regions like Europe and Australia often prefer aluminum due to its lightweight properties, which enhance fuel efficiency in transportation applications.

How Does Steel Perform in Dieing or Dying Processes?

Steel is a robust material with high tensile strength, making it ideal for applications requiring durability. It can handle high temperatures (up to 1,500°F or 815°C) and pressures, which makes it suitable for heavy machinery and structural components.

Pros & Cons:

– Pros: High strength, excellent wear resistance, and suitable for high-temperature applications.

– Cons: Heavier than aluminum, prone to corrosion without proper treatment, and can be more expensive to manufacture due to machining requirements.

Impact on Application:

Steel’s compatibility with harsh environments makes it ideal for industrial machinery and automotive components. However, its weight can be a disadvantage in applications where reducing mass is critical.

Considerations for International Buyers:

Steel must meet standards such as ASTM A36 and DIN 17100. Buyers in South America and Africa may favor steel for its availability and strength, especially in construction and mining sectors.

What are the Benefits of Using Brass in Dieing or Dying Applications?

Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. It typically operates well at temperatures up to 400°F (204°C) and offers good pressure ratings.

Pros & Cons:

– Pros: Excellent corrosion resistance, good thermal and electrical conductivity, and easy to machine.

– Cons: More expensive than aluminum and steel, and can be less durable under high-stress conditions.

Impact on Application:

Brass is commonly used in plumbing fittings, electrical connectors, and decorative applications. Its compatibility with water and various chemicals makes it a preferred choice in specific industries.

Considerations for International Buyers:

Brass components should comply with standards like ASTM B16 and EN 12164. Buyers in the Middle East may prefer brass for its aesthetic appeal and corrosion resistance in humid environments.

How Do Plastics Fit into Dieing or Dying Processes?

Plastics, particularly thermoplastics like ABS and polycarbonate, are increasingly used in dieing applications due to their lightweight nature and resistance to corrosion. They can withstand temperatures up to 300°F (149°C) and are highly versatile.

Pros & Cons:

– Pros: Lightweight, resistant to corrosion and chemicals, and cost-effective for low-volume production.

– Cons: Lower strength compared to metals, limited temperature resistance, and potential for deformation under stress.

Impact on Application:

Plastics are suitable for consumer goods, packaging, and automotive components where weight reduction is crucial. However, their lower mechanical properties may limit their use in high-stress applications.

Considerations for International Buyers:

Plastics must meet standards such as ASTM D638 and ISO 527. Buyers in Europe and Australia are increasingly adopting plastics for their sustainability benefits and lower environmental impact.

Summary Table of Material Selection for Dieing or Dying

| Material | Typical Use Case for dieing or dying | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive, aerospace components | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Steel | Heavy machinery, structural components | High strength and wear resistance | Heavier and prone to corrosion | Medium |

| Brass | Plumbing fittings, electrical connectors | Excellent corrosion resistance | More expensive and less durable | High |

| Plastics | Consumer goods, packaging | Lightweight and cost-effective | Lower strength and temperature limits | Low |

This comprehensive analysis provides B2B buyers with essential insights into material selection for dieing or dying processes, ensuring they make informed decisions tailored to their specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dieing or dying

What Are the Main Stages in the Manufacturing Process for Die Casting?

Manufacturing processes for die casting involve several critical stages that ensure the production of high-quality components. The process can be broken down into the following main stages:

-

Material Preparation

Material preparation is the first step in die casting, where raw materials—typically metals like aluminum, zinc, or magnesium—are selected based on the product requirements. These materials are then melted in a furnace to reach a molten state. Buyers should ensure that suppliers use high-purity metals, as impurities can significantly affect the final product’s quality. -

Forming

The molten metal is injected into a pre-designed die under high pressure. This die is typically made from high-strength steel to withstand the intense conditions of the casting process. The choice of die design is crucial, as it determines the dimensions and surface finish of the final product. B2B buyers should inquire about the supplier’s die design capabilities, especially for complex geometries. -

Cooling and Solidification

Once the molten metal fills the die, it is allowed to cool and solidify. The cooling time varies depending on the thickness of the casting and the type of metal used. Efficient cooling is essential to ensure dimensional accuracy and to reduce defects. Buyers can ask for cooling rate data as part of the supplier’s process documentation. -

Assembly

After solidification, the casting is ejected from the die. This stage may involve additional operations such as trimming excess material, machining for precision, or surface finishing. Buyers should confirm that their suppliers have the capability for secondary operations, which can significantly impact the overall quality of the final product. -

Finishing

The finishing stage can include processes such as polishing, coating, or anodizing to enhance the appearance and corrosion resistance of the final product. Different finishing techniques may be required based on the application of the components being produced. Buyers should specify their finishing requirements clearly to avoid any discrepancies.

What Key Techniques Are Used in Die Casting Manufacturing?

Different techniques are employed throughout the die casting process to ensure precision and quality:

-

High-Pressure Die Casting: The most common method, where molten metal is injected into a die at high pressure. This technique is ideal for producing intricate shapes with excellent surface finishes.

-

Cold Chamber Die Casting: Suitable for metals with high melting points, this method involves pouring the molten metal into a cold chamber before injecting it into the die. It minimizes contamination from the molten metal.

-

Hot Chamber Die Casting: This method is used primarily for low-melting-point alloys like zinc and lead. The die is kept molten, allowing for quicker cycles but is limited to specific materials.

B2B buyers should assess their requirements carefully to choose the right technique, as each has its advantages and limitations.

How Is Quality Assurance Implemented in Die Casting Processes?

Quality assurance (QA) is integral to the die casting manufacturing process. Here are the key components of QA that B2B buyers should consider:

What International Standards Apply to Die Casting Quality Control?

Adherence to international standards is crucial for ensuring product quality and consistency. Key standards include:

-

ISO 9001: This standard outlines the requirements for a quality management system. Suppliers should be certified to ISO 9001 to demonstrate their commitment to quality.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with EU safety and environmental requirements.

-

API Standards: For suppliers in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial for quality assurance.

Buyers should verify that suppliers possess the necessary certifications relevant to their industry.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints ensure that defects are identified and rectified throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints monitor parameters like temperature, pressure, and dimensional accuracy.

-

Final Quality Control (FQC): After production, the final product undergoes comprehensive testing to ensure it meets all specifications and standards.

B2B buyers should ask suppliers about their quality control processes and the frequency of inspections.

What Common Testing Methods Are Used in Die Casting Quality Assurance?

Several testing methods can be employed to verify the quality of die-cast products:

-

Dimensional Inspection: Using precision measuring tools to verify that the castings meet specified dimensions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are used to detect internal defects without damaging the product.

-

Mechanical Testing: Tests like tensile strength, hardness, and impact resistance are conducted to evaluate the physical properties of the material.

-

Visual Inspection: A thorough visual examination to identify surface defects such as cracks, pits, or incomplete filling.

B2B buyers should request detailed reports on testing results and methodologies from suppliers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that their suppliers maintain rigorous quality control practices, B2B buyers can take the following steps:

-

Conduct Audits: Regular audits of the supplier’s facility can provide insights into their manufacturing processes and quality control measures.

-

Request Documentation: Buyers should ask for quality control documentation, including inspection reports, certifications, and process control charts.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices.

-

Supplier Performance Metrics: Monitoring supplier performance through metrics such as defect rates, delivery timelines, and responsiveness can help identify potential quality issues.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances:

-

Regulatory Compliance: Different regions may have specific regulatory requirements that suppliers must meet. Buyers should ensure that suppliers are aware of and compliant with these regulations.

-

Cultural Differences: Understanding cultural differences can aid in communication and expectations regarding quality. Buyers should foster open communication channels with suppliers to clarify quality standards.

-

Supply Chain Considerations: The complexity of international supply chains can introduce variability in quality. Buyers should consider working with suppliers who have robust quality assurance processes in place.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and ensure that they partner with suppliers who meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dieing or dying’

Introduction

This practical sourcing guide aims to assist international B2B buyers in effectively procuring goods and services related to the concepts of “dieing” and “dying,” particularly in industrial contexts. Understanding the nuances between these terms is essential to avoid confusion and ensure clear communication, especially in procurement processes that involve specialized manufacturing techniques.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. This includes understanding the specific materials, dimensions, and tolerances needed for your project. Having well-defined specifications helps to communicate your needs effectively to potential suppliers, ensuring that you receive accurate quotes and proposals.

- Considerations: Identify whether you require die casting, die cutting, or another related process. Specify the types of materials you intend to use, such as metals or plastics.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in the relevant manufacturing processes. This step is crucial to ensure that you engage with companies that have the right expertise and capabilities to meet your specifications.

- Sources: Utilize industry directories, trade fairs, and online platforms to compile a list of potential suppliers. Pay attention to reviews and ratings from previous customers to gauge reliability.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, it’s essential to assess the capabilities of your shortlisted suppliers. This evaluation should include their production capacity, technology used, and quality control measures.

- Key Metrics: Request information about their machinery, production processes, and certifications. A supplier with advanced technology and robust quality assurance protocols is more likely to deliver high-quality products.

Step 4: Verify Supplier Certifications

Certification verification is a crucial step in the sourcing process. Ensure that your suppliers have the necessary industry certifications, such as ISO or relevant local standards, to affirm their credibility and compliance with safety and quality regulations.

- Documentation: Ask for copies of their certifications and check their validity. This step is particularly important for buyers from Africa and South America, where regulatory compliance may vary significantly.

Step 5: Request Samples

Before finalizing your order, request product samples from potential suppliers. This allows you to assess the quality of their work and determine if it meets your specifications.

- Evaluation Criteria: Examine the samples for durability, finish, and adherence to your technical specifications. This hands-on assessment can prevent costly mistakes later in the procurement process.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, payment terms, and warranties. Clear agreements can prevent misunderstandings and ensure a smooth procurement process.

- Considerations: Be transparent about your budget constraints while also ensuring that you do not compromise on quality. A well-structured contract protects both parties and sets clear expectations.

Step 7: Establish a Communication Plan

Finally, develop a robust communication plan with your chosen supplier to facilitate ongoing collaboration. This includes setting up regular check-ins and updates throughout the production process.

- Communication Tools: Utilize project management tools or dedicated communication platforms to streamline interactions. Clear communication can help address issues promptly and ensure that the project stays on track.

By following these steps, B2B buyers can navigate the complexities of procuring die-related products and services more effectively, ensuring they make informed decisions that meet their operational needs.

Comprehensive Cost and Pricing Analysis for dieing or dying Sourcing

What Are the Key Cost Components in ‘Dieing or Dying’ Sourcing?

When sourcing die-related services or products, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components typically include:

-

Materials: The cost of raw materials varies significantly based on the type of die used—whether for metalworking, plastic molding, or other applications. Sourcing high-quality materials can enhance durability but may increase initial costs.

-

Labor: Labor costs encompass wages for skilled workers who operate machinery and perform quality checks. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing but could also present challenges in terms of skill levels.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility management. Efficient manufacturing processes can reduce overhead costs and improve overall profitability.

-

Tooling: Tooling costs involve the creation of dies, which can be substantial depending on complexity. Custom tooling will typically incur higher costs, so buyers should weigh the benefits of standard versus custom dies.

-

Quality Control (QC): Ensuring product quality is essential, particularly in industries with stringent regulatory requirements. QC processes can increase costs but are vital for reducing defects and ensuring customer satisfaction.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and Incoterms can significantly impact the total logistics cost.

-

Margin: The supplier’s profit margin will vary depending on the market and competition. Understanding how margins are calculated can aid in negotiations.

How Do Pricing Influencers Impact ‘Dieing or Dying’ Costs?

Several factors influence pricing in the dieing or dying industry:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their production schedules.

-

Specifications and Customization: Customized dies or specific material requirements can drive up costs. Buyers should clearly define specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and compliance with industry certifications can increase costs but may also enhance product longevity and performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge premium prices but offer better service and product quality.

-

Incoterms: Understanding the terms of delivery can help buyers manage costs. Different Incoterms (e.g., FOB, CIF) shift responsibilities and costs between buyers and sellers, impacting the overall cost structure.

What Are Some Buyer Tips for Effective Negotiation and Cost Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider these tips to enhance negotiation and cost efficiency:

-

Negotiate Wisely: Leverage volume commitments and long-term relationships to negotiate better pricing and terms. Highlight your reliability as a buyer to foster goodwill.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, operational efficiency, and potential downtime. This comprehensive view can reveal more cost-effective options.

-

Understand Pricing Nuances: Be aware of regional pricing variations and the impact of local economic conditions. Suppliers in emerging markets may offer lower initial costs but may not always deliver the same quality or service.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insights into market pricing and help identify the best value.

Disclaimer on Indicative Prices

Prices in the dieing or dying sector can fluctuate based on market conditions, material availability, and supplier pricing strategies. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain accurate and current pricing information tailored to their specific needs.

Essential Technical Properties and Trade Terminology for dieing or dying

What Are the Key Technical Properties Relevant to Dieing or Dying?

When engaging with dieing or dying processes, particularly in manufacturing and material shaping, it is essential to understand several critical technical specifications. These properties significantly influence the quality, efficiency, and cost-effectiveness of production.

What is Material Grade and Why Is It Important?

Material grade refers to the specific category of material used in the dieing or dying process, such as steel, aluminum, or plastic. Different grades exhibit varying mechanical properties, such as tensile strength, ductility, and corrosion resistance. For B2B buyers, selecting the appropriate material grade is crucial as it directly impacts the durability and functionality of the final product. For instance, high-grade aluminum might be preferred for lightweight applications, whereas stainless steel may be essential for high-stress environments.

How Does Tolerance Affect Production Quality?

Tolerance defines the permissible limits of variation in a manufactured part’s dimensions. In dieing or dying processes, maintaining tight tolerances is critical to ensure that components fit together correctly and function as intended. For international B2B buyers, understanding tolerance specifications can mitigate the risk of production delays and costly rework. Adhering to the specified tolerances can enhance product performance and reliability, which are vital for customer satisfaction.

What Role Does Surface Finish Play in Product Performance?

Surface finish refers to the texture and smoothness of a product’s surface after manufacturing. Different applications may require specific finishes, ranging from rough to polished surfaces. For example, certain components may need a rough finish for better adhesion in coatings, while others may require a smooth finish to reduce friction. Buyers should consider surface finish requirements early in the procurement process, as they can affect both the aesthetic and functional aspects of the final product.

Why Is Understanding Die Life Important in Manufacturing?

Die life refers to the longevity of a die used in the manufacturing process. It can be influenced by factors such as material selection, design, and maintenance practices. A longer die life can lead to reduced production costs and improved efficiency, as it minimizes the frequency of die replacements. For B2B buyers, investing in high-quality dies can lead to significant long-term savings and enhanced production stability.

What Are Common Industry Terms Related to Dieing or Dying?

Navigating the dieing or dying industry involves familiarity with specific jargon and trade terms that are crucial for effective communication and negotiation.

What Does OEM Mean in the Context of Manufacturing?

OEM, or Original Equipment Manufacturer, refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers, as they often dictate the quality and specifications of the products being sourced. Collaborating with reputable OEMs can enhance supply chain reliability and product integrity.

What Is MOQ and Its Significance for B2B Transactions?

MOQ stands for Minimum Order Quantity, which is the smallest amount of a product that a supplier is willing to sell. For international buyers, understanding MOQ is essential for budgeting and inventory management. Suppliers may set MOQs based on production costs, which can affect pricing and overall procurement strategy.

How Does an RFQ Facilitate the Procurement Process?

RFQ, or Request for Quotation, is a document sent to suppliers to request pricing information for specific goods or services. This process allows buyers to compare offers from multiple suppliers and negotiate better terms. For B2B buyers, issuing an RFQ can streamline procurement efforts and lead to cost savings.

What Are Incoterms and Why Are They Important?

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international shipping agreements. They clarify who is responsible for shipping costs, insurance, and risk during transportation. For B2B buyers, understanding Incoterms is crucial for managing logistics and ensuring smooth transactions across borders.

A stock image related to dieing or dying.

A stock image related to dieing or dying.

By familiarizing themselves with these technical properties and industry terminology, international B2B buyers can make informed decisions that enhance their procurement processes in the dieing or dying sectors.

Navigating Market Dynamics and Sourcing Trends in the dieing or dying Sector

What Are the Current Market Dynamics and Key Trends in the Dying Sector?

The global dying sector, which refers to the processes involved in the coloration and finishing of textiles and materials, is witnessing significant transformations driven by technological advancements and shifting consumer demands. Key trends include the increasing adoption of digital dyeing technologies, which enhance efficiency and reduce water usage, appealing to sustainability-conscious buyers. Additionally, automation and AI-driven processes are streamlining operations, leading to cost reductions and faster turnaround times.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should pay attention to these technological shifts. The rise of e-commerce platforms also facilitates easier sourcing from global suppliers, enabling buyers to find specialized providers who meet specific needs. Furthermore, the increasing focus on customization in textile production is fostering a demand for suppliers that can offer tailored dye solutions.

Emerging markets in Africa and South America are capitalizing on local resources and labor, making them competitive players in the dyeing industry. Buyers in these regions should leverage local suppliers who can provide unique dyes derived from natural sources, catering to the growing demand for organic and sustainable options.

How Is Sustainability Shaping B2B Sourcing Trends in the Dying Sector?

Sustainability has become a cornerstone of sourcing strategies in the dying sector, driven by the environmental impact associated with traditional dyeing processes. The industry is notorious for its high water consumption and chemical usage, prompting buyers to seek out suppliers with sustainable practices. Ethical sourcing is not merely a trend; it is an essential consideration for international buyers looking to comply with regulations and meet consumer expectations.

Buyers should prioritize suppliers who are certified in sustainable practices, such as those recognized by Global Organic Textile Standard (GOTS) or OEKO-TEX. These certifications indicate adherence to strict environmental and social criteria, ensuring that the dyes used are non-toxic and produced in an environmentally friendly manner. Additionally, sourcing from suppliers that utilize renewable energy sources and closed-loop systems can significantly reduce the carbon footprint of the dyeing process.

Investing in eco-friendly materials and dyes, such as those derived from natural sources, can enhance a brand’s reputation and appeal to a growing segment of environmentally-conscious consumers. B2B buyers should also consider the lifecycle impacts of dyeing materials, opting for suppliers who engage in responsible waste management and recycling initiatives.

What Is the Brief Evolution and History of the Dying Sector?

A stock image related to dieing or dying.

The dyeing industry has evolved significantly over centuries, transitioning from natural dyes derived from plants and minerals to synthetic options developed in the 19th century. Initially, dyeing was a labor-intensive process, but the industrial revolution introduced mechanization, dramatically increasing production capacity.

In recent decades, the sector has faced scrutiny over environmental impacts, leading to innovations aimed at reducing waste and chemical usage. The shift toward sustainable practices has reshaped the landscape, prompting many companies to invest in greener technologies. As the global market continues to evolve, the focus on ethical sourcing and sustainability is expected to play a critical role in shaping future trends in the dying sector.

For international B2B buyers, understanding this historical context can provide valuable insights into the importance of sustainability and innovation in sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of dieing or dying

1. How do I differentiate between dieing and dying in my business communications?

To maintain clarity in your business communications, it is crucial to use the correct term. “Dying” refers to the process of ceasing to exist, while “dieing” is often a misspelling of “dying.” If you’re discussing industrial processes, use terms like “die casting” or “die cutting” instead of “dieing.” Ensure all written materials are proofread to prevent misunderstandings, especially in contracts or product descriptions, where precise language is essential.

2. What is the best way to source high-quality dies for manufacturing?

When sourcing dies for manufacturing, prioritize suppliers with proven expertise and positive reviews. Research potential vendors through platforms like Alibaba or ThomasNet, and consider attending industry trade shows for direct interactions. Request samples to evaluate quality before placing larger orders. Additionally, inquire about the supplier’s manufacturing processes, certifications, and quality assurance measures to ensure they meet your standards.

3. What are the typical minimum order quantities (MOQs) for dies?

Minimum order quantities for dies can vary significantly based on the supplier and the complexity of the die. Generally, MOQs can range from 10 to several hundred units. It’s advisable to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs, especially for first-time orders or long-term partnerships. Understanding the supplier’s production capabilities will help in planning your orders more effectively.

4. How can I ensure the quality of dies sourced internationally?

To ensure the quality of dies sourced internationally, implement a robust supplier vetting process. Verify supplier certifications, conduct factory audits, and request product samples for inspection. Utilize third-party quality assurance services to inspect goods before shipment. Establish clear quality standards and specifications in your contracts to hold suppliers accountable. Regular communication throughout the production process can also help address any issues proactively.

5. What payment terms should I negotiate with international die suppliers?

When negotiating payment terms with international die suppliers, consider options like letters of credit, which provide security for both parties. Aim for terms that balance risk and cash flow, such as a deposit upon order confirmation and the balance before shipment. Discuss the possibility of payment milestones tied to production stages. Always ensure that payment terms are clearly outlined in your contracts to avoid disputes later.

6. What logistical considerations should I keep in mind when importing dies?

Logistics is critical when importing dies, particularly regarding shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder who understands the regulations of your destination country. Factor in potential delays due to customs inspections or documentation issues. Additionally, consider insurance for high-value items and plan for warehousing if needed. Clear communication with suppliers about shipping schedules can help manage expectations.

7. How can I customize dies to meet my specific manufacturing needs?

Customizing dies involves a collaborative approach with your supplier. Clearly communicate your specifications, including dimensions, materials, and desired features. Request a prototype or CAD drawings to visualize the design before production. Be prepared to provide feedback during the development process to ensure the final product meets your requirements. Establishing a strong partnership with your supplier can facilitate smoother customization.

8. What are the risks of sourcing dies from emerging markets?

Sourcing dies from emerging markets can present risks such as quality inconsistencies, communication barriers, and longer lead times. Conduct thorough research on potential suppliers, focusing on their track record and certifications. It’s also wise to start with smaller orders to assess quality and reliability. Maintain open lines of communication and consider using third-party inspection services to mitigate risks associated with international sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dieing or dying

What Are the Key Insights for B2B Buyers Regarding Dying or Dieing?

In the context of strategic sourcing, understanding the distinction between “dying” and “dieing” is essential for clear communication, especially in international business environments. The correct usage of these terms not only enhances professionalism but also minimizes misunderstandings that can impact negotiations and partnerships. For B2B buyers across Africa, South America, the Middle East, and Europe, it is crucial to utilize precise language that reflects expertise and credibility.

How Can Strategic Sourcing Enhance Your Business Operations?

Effective strategic sourcing can lead to significant cost reductions, improved supplier relationships, and enhanced product quality. By focusing on accurate terminology and understanding industry-specific jargon, businesses can foster better collaboration with suppliers and stakeholders. This is particularly vital in regions with diverse linguistic backgrounds, where clarity can set the foundation for successful international dealings.

What Should International B2B Buyers Do Next?

As you navigate the complexities of global sourcing, prioritize the use of correct terminology and invest in training for your teams. This commitment not only elevates your brand’s image but also positions you for long-term success. Embrace strategic sourcing as a pathway to innovation and efficiency, ensuring your business remains competitive in the evolving market landscape. Engage with reliable partners who value precision in communication and are ready to support your growth objectives.