Unlock CNC Efficiency: The Complete G Code List Guide (2025)

Introduction: Navigating the Global Market for g code list

Navigating the complexities of sourcing a comprehensive G-code list can be a daunting task for international B2B buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe. As industries increasingly adopt CNC technology, understanding the various G-codes and their applications becomes crucial for optimizing manufacturing processes and ensuring product quality. This guide serves as an essential resource, detailing the different types of G-codes, their specific applications, and strategies for vetting suppliers effectively.

In the ever-evolving landscape of global manufacturing, buyers must be equipped with actionable insights to make informed purchasing decisions. This guide covers the scope of G-code applications, from rapid positioning to intricate machining operations, and offers a comprehensive list of common G and M codes that are vital for CNC operations. Additionally, it delves into cost considerations and supplier evaluation criteria, empowering buyers to navigate the market with confidence.

By leveraging the information provided in this guide, international B2B buyers will be better positioned to enhance their operational efficiencies, reduce production costs, and ultimately achieve a competitive edge in their respective industries. Whether you are based in Indonesia, Colombia, or any other global market, understanding G-codes is essential for unlocking the full potential of CNC technology in your manufacturing processes.

Understanding g code list Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard G-Codes | Universal commands across CNC machines | General machining, milling, and turning | Pros: Widely understood; Cons: Limited customization for specific machines. |

| Custom G-Codes | User-defined codes tailored for specific tasks | Specialized applications in manufacturing | Pros: Highly adaptable; Cons: Requires skilled programming knowledge. |

| M-Codes | Control machine functions like spindle and coolant | Used in various CNC operations | Pros: Essential for machine management; Cons: Less standardized across machines. |

| Canned Cycles | Predefined sequences for repetitive tasks | Drilling, tapping, and boring operations | Pros: Increases efficiency; Cons: May not suit all machining scenarios. |

| Modal G-Codes | Codes that remain active until canceled | Continuous operations like milling and turning | Pros: Reduces programming time; Cons: Can lead to errors if not properly managed. |

What Are Standard G-Codes and Their B2B Relevance?

Standard G-Codes form the foundation of CNC programming, providing universal commands applicable across various machines. They are essential for general machining processes such as milling and turning. For B2B buyers, understanding these codes is crucial for ensuring compatibility with existing equipment. However, while they are widely recognized, their lack of customization may limit their effectiveness for specialized tasks, making it important to consider the specific needs of your operations.

How Do Custom G-Codes Enhance CNC Operations?

Custom G-Codes are tailored commands designed to meet specific manufacturing requirements. These codes allow businesses to optimize their CNC programming for unique tasks, enhancing productivity and precision. However, implementing custom codes necessitates skilled programming expertise, which can be a barrier for some organizations. B2B buyers should weigh the benefits of increased efficiency against the potential training costs and the need for specialized knowledge in their workforce.

What Role Do M-Codes Play in CNC Machinery?

M-Codes are integral to controlling various machine functions, such as activating the spindle or coolant systems. They are essential for managing operations and ensuring smooth transitions during machining processes. For B2B buyers, understanding M-Codes is vital for operational efficiency. However, the variability of M-Codes across different machine brands can complicate their use, necessitating thorough research and potential training to ensure proper implementation.

Why Are Canned Cycles Important for Efficiency?

Canned cycles are pre-programmed sequences that simplify repetitive machining tasks, such as drilling and tapping. They enhance operational efficiency by reducing programming time and minimizing errors. For businesses focused on high-volume production, adopting canned cycles can lead to significant time and cost savings. However, these cycles may not be suitable for all machining scenarios, requiring buyers to evaluate their specific applications and workflows carefully.

What Are Modal G-Codes and Their Advantages?

Modal G-Codes remain active until explicitly canceled, allowing for continuous operations without the need for repeated commands. This feature can significantly reduce programming time and streamline workflows in processes like milling and turning. For B2B buyers, the use of modal G-Codes can enhance productivity and consistency in operations. However, proper management is critical, as failure to cancel or modify these codes can lead to machining errors and inefficiencies.

Key Industrial Applications of g code list

| Industry/Sector | Specific Application of g code list | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace Manufacturing | Precision component machining using G-code | High accuracy and repeatability in complex parts | Supplier must provide CNC machines compatible with international standards. |

| Automotive Industry | Automated assembly line operations using G-code | Increased production efficiency and reduced labor costs | Ensure availability of local support and spare parts. |

| Medical Device Manufacturing | Custom implant fabrication through CNC programming | Tailored solutions for patient-specific needs | Look for suppliers with certifications in medical-grade machining. |

| Electronics Manufacturing | PCB milling and drilling using G-code | Enhanced precision in electronic component production | Suppliers should have experience with high-volume production. |

| Tool and Die Making | Tool path optimization for die casting and molding | Reduced cycle times and improved tool life | Evaluate the supplier’s expertise in advanced G-code programming. |

How is G-Code Used in Aerospace Manufacturing?

In the aerospace sector, G-code is utilized for precision machining of components such as turbine blades and fuselage parts. The complexity of these components requires the use of G-code to ensure high accuracy and repeatability. International buyers, particularly from regions like Africa and South America, should focus on suppliers that utilize advanced CNC machines capable of meeting stringent aerospace standards. Additionally, compatibility with international certification processes is crucial for compliance and quality assurance.

What Role Does G-Code Play in Automotive Industry Automation?

Automated assembly lines in the automotive industry leverage G-code for efficient machining and assembly processes. G-code commands control everything from robotic arms to CNC machines, enabling high-speed production with minimal human intervention. For international B2B buyers, sourcing CNC equipment that offers reliable technical support and readily available spare parts is essential to minimize downtime and ensure continuous production.

How is G-Code Applied in Medical Device Manufacturing?

The medical device manufacturing sector employs G-code for the fabrication of custom implants and surgical instruments. The ability to precisely control the machining process allows for the creation of patient-specific solutions, enhancing surgical outcomes. Buyers in this field must prioritize suppliers with the necessary certifications for medical-grade machining, ensuring that the products meet regulatory standards and are safe for use in healthcare settings.

In What Ways is G-Code Used in Electronics Manufacturing?

In electronics manufacturing, G-code is crucial for tasks such as PCB milling and drilling. The precision of G-code programming allows for the accurate placement of components, which is vital in producing reliable electronic devices. International buyers should seek suppliers experienced in high-volume production and capable of delivering consistent quality, as this directly impacts the reliability of electronic products.

How is G-Code Beneficial in Tool and Die Making?

Tool and die making utilizes G-code for optimizing tool paths in die casting and molding processes. The efficient programming of CNC machines reduces cycle times and extends tool life, resulting in significant cost savings. Buyers should assess the supplier’s expertise in advanced G-code programming techniques, as well as their ability to provide tailored solutions for specific tooling requirements, ensuring a competitive edge in the market.

3 Common User Pain Points for ‘g code list’ & Their Solutions

Scenario 1: Difficulty Understanding G-Code Variations Across CNC Machines

The Problem:

International B2B buyers often encounter significant challenges when attempting to utilize a ‘g code list’ across different CNC machines. With various manufacturers adopting their own interpretations of G- and M-codes, buyers may struggle to understand which codes are compatible with their specific equipment. This can lead to programming errors, machine malfunctions, and costly production downtime, especially for companies operating in diverse markets like Africa and South America, where equipment standards may vary significantly.

The Solution:

To address this problem, B2B buyers should invest time in thoroughly understanding the specific G- and M-codes applicable to their CNC machines. This can be achieved by consulting the machine’s user manual and manufacturer resources, which typically provide a comprehensive list of supported codes. Additionally, participating in manufacturer-led training sessions or industry workshops can enhance understanding and provide practical insights. Buyers should also consider creating a standardized reference guide that outlines the core G-codes used across their machinery. This guide can serve as a quick reference for operators, reducing errors and ensuring smoother operations.

Scenario 2: Inadequate Knowledge of G-Code Programming

The Problem:

Many international B2B buyers lack adequate training in G-code programming, leading to inefficient machining processes. This knowledge gap can result in improperly written codes that cause issues such as tool crashes, incorrect feed rates, and suboptimal machining quality. For companies in the Middle East and Europe, where precision and efficiency are paramount, this can mean the difference between meeting client expectations and incurring losses.

The Solution:

B2B buyers should prioritize comprehensive training for their staff on G-code programming. This could involve enrolling in specialized courses that focus on practical applications of G-codes in CNC machining. Online platforms and local technical schools often offer such courses, which can be tailored to the specific equipment used by the business. Additionally, developing a mentorship program where experienced machinists guide less experienced staff can help cultivate a knowledgeable workforce. Buyers should also encourage regular practice and simulation exercises to reinforce learning and build confidence in G-code application.

Scenario 3: Inefficient Code Management and Retrieval

The Problem:

As B2B operations scale, managing and retrieving G-code files can become increasingly cumbersome. Companies may find themselves using outdated or incorrect codes, leading to inefficiencies and errors in production. This issue is particularly pronounced in regions like South America, where rapid growth can outpace the establishment of robust documentation practices.

The Solution:

To overcome this challenge, B2B buyers should implement an organized G-code management system that facilitates easy access to the most current and relevant G-code files. This could involve utilizing software solutions specifically designed for CNC programming and code management, which allow for version control, easy retrieval, and categorization of codes. Additionally, establishing a cloud-based repository can ensure that all team members have access to the latest codes from any location, enhancing collaboration and reducing the risk of using outdated codes. Regular audits and updates of the G-code repository will also ensure that the organization maintains an efficient coding process, minimizing errors and maximizing productivity.

Strategic Material Selection Guide for g code list

What Are the Key Properties of Common Materials Used in G Code Applications?

When selecting materials for CNC machining processes that utilize G codes, it’s essential to consider the properties that directly influence product performance. Here, we analyze four common materials: Aluminum, Steel, Plastic, and Titanium, focusing on their suitability for various applications.

How Does Aluminum Perform in CNC Machining?

Aluminum is a lightweight, versatile material known for its excellent machinability. It typically has a temperature rating of about 600°F (316°C) and offers good corrosion resistance, making it suitable for various environments.

Pros: Aluminum is durable yet lightweight, which reduces shipping costs and is easier to handle during machining. Its relatively low cost and high availability make it a preferred choice for many applications, including automotive and aerospace components.

Cons: While aluminum is strong, it may not withstand high-pressure applications as effectively as other metals. Additionally, it can be more susceptible to wear and tear compared to harder materials.

Impact on Application: Aluminum is compatible with various media, including water and air, but it may not be suitable for harsh chemical environments without proper coatings.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with standards like ASTM B221 for aluminum extrusions and consider local sourcing to reduce costs.

What Are the Benefits and Limitations of Steel?

Steel is renowned for its strength and durability, with temperature ratings that can exceed 2000°F (1093°C) depending on the alloy. It also offers various grades, including stainless steel, which provides excellent corrosion resistance.

Pros: Steel’s high strength-to-weight ratio makes it suitable for heavy-duty applications. It is also widely available and can be manufactured into complex shapes with relative ease.

Cons: The cost of steel can be higher than aluminum, especially for specialty alloys. Additionally, its weight can increase shipping and handling costs.

Impact on Application: Steel is compatible with a wide range of media, including oils and fuels, making it ideal for automotive and industrial applications.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM A36 for carbon steel and ASTM A240 for stainless steel. Understanding local regulations regarding steel sourcing can also be critical.

How Do Plastics Compare in Terms of CNC Machining?

Plastics, such as PVC and Nylon, are increasingly popular in CNC applications due to their lightweight and corrosion-resistant properties. They typically have lower temperature ratings, often around 200°F (93°C) for standard grades.

Pros: Plastics are generally less expensive to machine than metals and can be produced in various colors and finishes. They also provide good insulation properties and are resistant to many chemicals.

Cons: Plastics may not be suitable for high-stress applications due to lower tensile strength. They can also deform under high temperatures, limiting their use in certain environments.

Impact on Application: Plastics are compatible with a variety of media, but their performance can vary significantly based on the specific type of plastic used.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D638 for tensile properties of plastics and consider the environmental impact of plastic sourcing and disposal.

What Makes Titanium a Unique Choice for CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and resistance to corrosion, with temperature ratings that can exceed 1500°F (815°C).

Pros: Titanium is incredibly strong and lightweight, making it ideal for aerospace and medical applications. Its biocompatibility also makes it suitable for implants and surgical instruments.

Cons: The primary drawback of titanium is its high cost and the complexity involved in machining it, which requires specialized tools and techniques.

Impact on Application: Titanium is compatible with various media, including corrosive environments, making it a preferred choice for chemical processing applications.

Considerations for International Buyers: Compliance with standards like ASTM F136 for titanium alloys is crucial. Buyers should also consider the availability of specialized machining services in their region.

Summary Table of Material Selection for G Code Applications

| Material | Typical Use Case for g code list | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and easy to machine | Less suitable for high-pressure applications | Medium |

| Steel | Industrial machinery, automotive parts | High strength and durability | Heavier and potentially more expensive | Medium to High |

| Plastic | Consumer products, housings | Cost-effective and versatile | Lower tensile strength and heat resistance | Low |

| Titanium | Aerospace and medical applications | Exceptional strength and corrosion resistance | High cost and complex machining requirements | High |

This analysis provides a comprehensive overview for international B2B buyers, equipping them with actionable insights for selecting the right materials in their CNC machining processes.

In-depth Look: Manufacturing Processes and Quality Assurance for g code list

What Are the Main Stages of Manufacturing G Code Lists?

When it comes to producing G code lists for CNC machines, understanding the manufacturing process is crucial for B2B buyers. This process can be broadly categorized into four main stages: material preparation, forming, assembly, and finishing.

How Does Material Preparation Impact G Code Production?

Material preparation involves selecting the appropriate materials based on the specific requirements of the CNC machine. This could include metals, plastics, or composites. Key techniques in this stage include cutting, grinding, and treating the materials to ensure they meet the necessary specifications. For B2B buyers, it’s essential to work with suppliers who have a robust material sourcing strategy and can provide certifications for the materials used. This ensures that the G codes generated will function optimally without compromising on quality.

What Forming Techniques Are Used in G Code Manufacturing?

The forming stage focuses on shaping the prepared materials into the desired components. Techniques such as CNC milling, turning, and laser cutting are commonly employed. Each of these methods requires precise G code programming to control the machinery effectively. Buyers should inquire about the machinery and technology used by their suppliers, as well as the skill level of the operators. Understanding these factors can help buyers assess the potential quality of the G code lists produced.

How Is Assembly Conducted in G Code Manufacturing?

Assembly is a critical phase where various components are put together. This stage may involve mechanical fastening, welding, or bonding. The integration of multiple parts often requires additional G codes to ensure that each component is accurately positioned and secured. For B2B buyers, it’s advisable to verify the assembly processes used by suppliers, ensuring they adhere to best practices and standards that minimize errors.

What Finishing Techniques Are Essential for High-Quality G Codes?

Finishing techniques such as sanding, polishing, or coating can significantly enhance the final product’s durability and aesthetic appeal. These processes often require further G code adjustments to ensure that the finishing touches are applied correctly. Buyers should look for suppliers that implement strict quality control measures during the finishing phase, as this can directly influence the performance and longevity of the CNC components.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance is a critical aspect of manufacturing G code lists. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. This standard emphasizes continuous improvement and customer satisfaction, which are essential for international B2B transactions.

How Do Industry-Specific Standards Like CE and API Affect Quality Control?

In addition to general quality standards, industry-specific certifications such as CE marking in Europe and API certification in the oil and gas industry are vital. These certifications indicate that the products meet stringent safety and performance criteria. B2B buyers should prioritize suppliers who are compliant with these standards, as it demonstrates their commitment to quality and safety.

What Are the Key Quality Control Checkpoints in G Code Manufacturing?

Quality control (QC) checkpoints are essential for ensuring that the G code lists produced meet the necessary standards. The main checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Buyers should ask suppliers about their IQC processes to ensure only high-quality materials are used.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is necessary to detect any deviations from standards. This could involve real-time data collection and analysis. Buyers should inquire about the IPQC methods employed by suppliers.

-

Final Quality Control (FQC): This is the final inspection stage where finished products are evaluated against specifications. Buyers can benefit from understanding the FQC processes to ensure they receive products that meet their requirements.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to ensure the integrity of G code lists and the components they control. These methods include:

-

Dimensional Inspection: Using tools like calipers and micrometers to check the dimensions of the components.

-

Functional Testing: Running the CNC machine with the G codes to verify that it operates as intended.

-

Destructive Testing: In some cases, components may undergo destructive testing to assess their limits and failure points.

B2B buyers should request detailed reports on these testing methods to understand the quality assurance measures their suppliers implement.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures.

-

Request Quality Reports: Buyers should ask for documentation that outlines the quality control processes and results from previous batches.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality standards and practices.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in international transactions is vital. Different regions may have varying standards and regulations, which can affect product quality. Buyers should familiarize themselves with local certifications and ensure that their suppliers can navigate these requirements effectively.

Furthermore, cultural differences in business practices can impact quality assurance. Establishing clear communication channels and expectations with suppliers can help mitigate misunderstandings and ensure that quality remains a top priority throughout the manufacturing process.

In conclusion, understanding the manufacturing processes and quality assurance measures for G code lists is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control standards, buyers can make informed decisions that enhance their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘g code list’

In the evolving landscape of CNC machining, having access to a comprehensive G-code list is essential for international B2B buyers. This guide serves as a practical checklist to ensure you procure the right G-code resources effectively, facilitating smoother operations and better machine performance.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before sourcing G-code lists. This includes understanding the specific CNC machines you are using and the types of operations they will perform. Knowing your requirements helps in identifying suppliers that can provide relevant and compatible G-code documentation.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reputable suppliers of G-code lists. Focus on companies with a strong track record in the CNC machining industry and positive feedback from other international buyers. Utilize online platforms, industry forums, and trade shows to gather insights about potential suppliers.

Step 3: Evaluate Supplier Credentials

Before making a commitment, verify the credentials of potential suppliers. Request certifications such as ISO standards relevant to CNC machining and G-code programming. Look for supplier profiles that demonstrate experience in your specific industry or region, as this can significantly influence the quality of the G-code provided.

Step 4: Request Sample G-Code Lists

To assess the quality and applicability of the G-code lists, request sample documents from suppliers. Review these samples for clarity, comprehensiveness, and alignment with your technical specifications. Pay attention to whether the G-codes are tailored for your specific machines and intended operations.

Step 5: Inquire About Customization Options

Explore whether suppliers offer customization options for their G-code lists. Customization can be vital if your business has unique operational needs or if you require specific G-code commands not commonly included in standard lists. Ensure that the supplier can accommodate modifications without compromising the integrity of the G-code.

Step 6: Understand Technical Support and Training

Consider the level of technical support and training provided by the supplier. Access to training resources or customer support can be invaluable, especially for teams unfamiliar with G-code programming. Ensure that the supplier offers adequate resources to help your staff effectively utilize the G-code.

Step 7: Review Pricing and Terms of Service

Finally, carefully review the pricing structure and terms of service from potential suppliers. Ensure that the cost aligns with your budget while considering the value provided, such as quality, support, and updates to the G-code list. Clear terms regarding licensing, updates, and support can prevent future complications.

By following this checklist, B2B buyers from Africa, South America, the Middle East, and Europe can confidently procure G-code lists that enhance their CNC machining operations, ensuring efficiency and precision in their production processes.

Comprehensive Cost and Pricing Analysis for g code list Sourcing

What Are the Key Cost Components in G-Code List Sourcing?

When sourcing G-code lists for CNC machining, understanding the cost components is essential for effective budgeting and financial planning. The main cost components include:

-

Materials: The quality and type of materials used for the CNC machines directly affect pricing. High-quality materials may incur higher upfront costs but can lead to better machine performance and longevity.

-

Labor: Skilled labor is required for programming and operating CNC machines. Labor costs vary significantly based on geographic location, skill level, and market demand.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and maintenance of equipment, which can vary widely between different regions, especially for international buyers.

-

Tooling: Specialized tooling may be necessary for certain G-code applications. The investment in tooling can be significant, so buyers should consider how tooling costs factor into their total budget.

-

Quality Control (QC): Implementing effective QC processes to ensure that G-code outputs meet specifications is crucial. This can involve additional costs, but it ultimately safeguards against costly errors in production.

-

Logistics: Shipping and handling costs can impact overall pricing, particularly for international transactions. Understanding the logistics involved can help buyers avoid unexpected fees.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This can vary based on market competition and the supplier’s pricing strategy.

How Do Price Influencers Affect G-Code List Sourcing?

Several key factors influence the pricing of G-code lists, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Pricing often improves with higher order volumes. Buyers should negotiate MOQ terms to benefit from bulk pricing.

-

Specifications and Customization: Custom G-code lists tailored to specific applications may incur additional costs. Buyers should clearly communicate their needs to avoid unforeseen expenses.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., ISO standards) can increase costs. However, investing in quality often leads to better performance and reduced downtime.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge higher prices but offer better service and product quality.

-

Incoterms: Understanding the terms of shipping and delivery can affect the overall cost. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid surprises.

What Are Effective Buyer Tips for Cost-Efficiency in G-Code Sourcing?

International B2B buyers should adopt several strategies to enhance cost-efficiency when sourcing G-code lists:

-

Negotiation Strategies: Always negotiate terms with suppliers. Highlighting potential long-term partnerships can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront cost. Factors like maintenance, downtime, and resale value should be included in the financial analysis.

-

Understanding Pricing Nuances: Be aware that pricing may vary significantly based on region, exchange rates, and local economic conditions. Researching these factors can provide leverage in negotiations.

-

Leverage Technology: Utilizing software tools for G-code generation can reduce the need for external sourcing and lower costs associated with programming.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming market trends that could affect costs.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on specific circumstances, regional factors, and supplier agreements. Buyers are encouraged to conduct thorough market research and engage in direct negotiations to secure the best pricing for their unique sourcing needs.

Alternatives Analysis: Comparing g code list With Other Solutions

Introduction to Alternatives in CNC Programming

When it comes to CNC programming, the ‘G Code List’ is a widely recognized standard for controlling machine tools. However, it is essential for B2B buyers to explore viable alternatives that might better suit specific operational needs or budget constraints. This section compares the G Code List with two alternative solutions: Parametric Programming and Conversational Programming. Each method offers unique advantages and potential drawbacks, which can significantly influence decision-making for international buyers.

Comparison Table of CNC Programming Solutions

| Comparison Aspect | G Code List | Parametric Programming | Conversational Programming |

|---|---|---|---|

| Performance | High precision, widely supported | Highly efficient for complex tasks | User-friendly, good for simple tasks |

| Cost | Generally low (software availability) | Moderate (depends on software) | Low to moderate (varies by tool) |

| Ease of Implementation | Steeper learning curve | Requires programming knowledge | Intuitive, less training needed |

| Maintenance | Standardized maintenance protocols | Maintenance varies by platform | Low maintenance, user-driven updates |

| Best Use Case | Complex machining operations | Custom parts with variable dimensions | Quick setups and simple operations |

Detailed Breakdown of Alternatives

What are the Advantages of Parametric Programming?

Parametric Programming allows for the creation of complex shapes and patterns through parameters that can be easily modified. This approach is particularly beneficial for manufacturers producing custom parts that require precise dimensional adjustments. The main advantage is its efficiency in modifying designs without the need to rewrite entire programs. However, it requires users to have a solid understanding of programming concepts, which may necessitate additional training and lead to higher initial costs, depending on the software chosen.

How Does Conversational Programming Simplify CNC Operations?

Conversational Programming offers a more intuitive interface for CNC operations, allowing operators to input commands through simple dialogue boxes rather than traditional code. This method is particularly advantageous for businesses that require quick setups or have staff with limited programming experience. The ease of use can significantly reduce the learning curve and training costs. However, it may not provide the same level of precision or flexibility for complex machining tasks compared to the G Code List or Parametric Programming, making it less suitable for intricate designs.

Conclusion: How Can B2B Buyers Choose the Right CNC Programming Solution?

When selecting a CNC programming solution, international B2B buyers should consider their specific operational needs, staff expertise, and budget constraints. The G Code List remains a robust choice for those dealing with complex machining operations, while Parametric Programming is ideal for businesses focused on customization. Conversely, Conversational Programming is an excellent option for companies seeking ease of use and quick turnaround times on simpler projects. By assessing these factors, buyers can make an informed decision that aligns with their production goals and operational capabilities.

Essential Technical Properties and Trade Terminology for g code list

What Are the Critical Technical Properties of G-Code?

When dealing with G-code, especially in an international B2B context, understanding its technical properties is essential for effective communication and operational efficiency. Below are key specifications that buyers should consider:

1. Precision and Tolerance

Precision in G-code programming refers to the exactness of tool movements and operations. Tolerance is the allowable deviation from a specified dimension. In B2B transactions, especially in manufacturing, maintaining strict tolerances is crucial for producing parts that fit together correctly. Buyers must ensure that their G-code adheres to the required precision standards to avoid costly reworks or product failures.

2. Feed Rate

Feed rate is the speed at which the tool moves through the material, typically measured in units per minute (IPM or IPM). Selecting the appropriate feed rate is vital for optimizing machining efficiency and tool life. Buyers should evaluate the capabilities of their CNC machines and the materials they are working with to determine the ideal feed rates for different operations.

3. Material Compatibility

Understanding the compatibility of G-code with various materials is critical for international buyers. Different materials (metals, plastics, composites) may require specific G-code commands to achieve optimal cutting results. Buyers should communicate with suppliers to ensure that their G-code is suitable for the materials they intend to process.

4. Measurement System

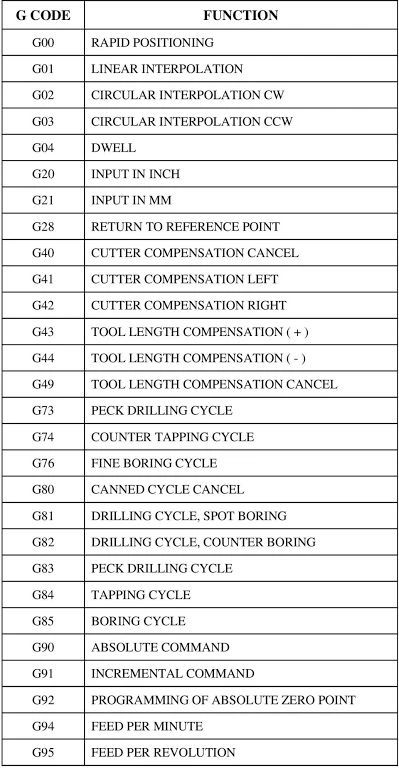

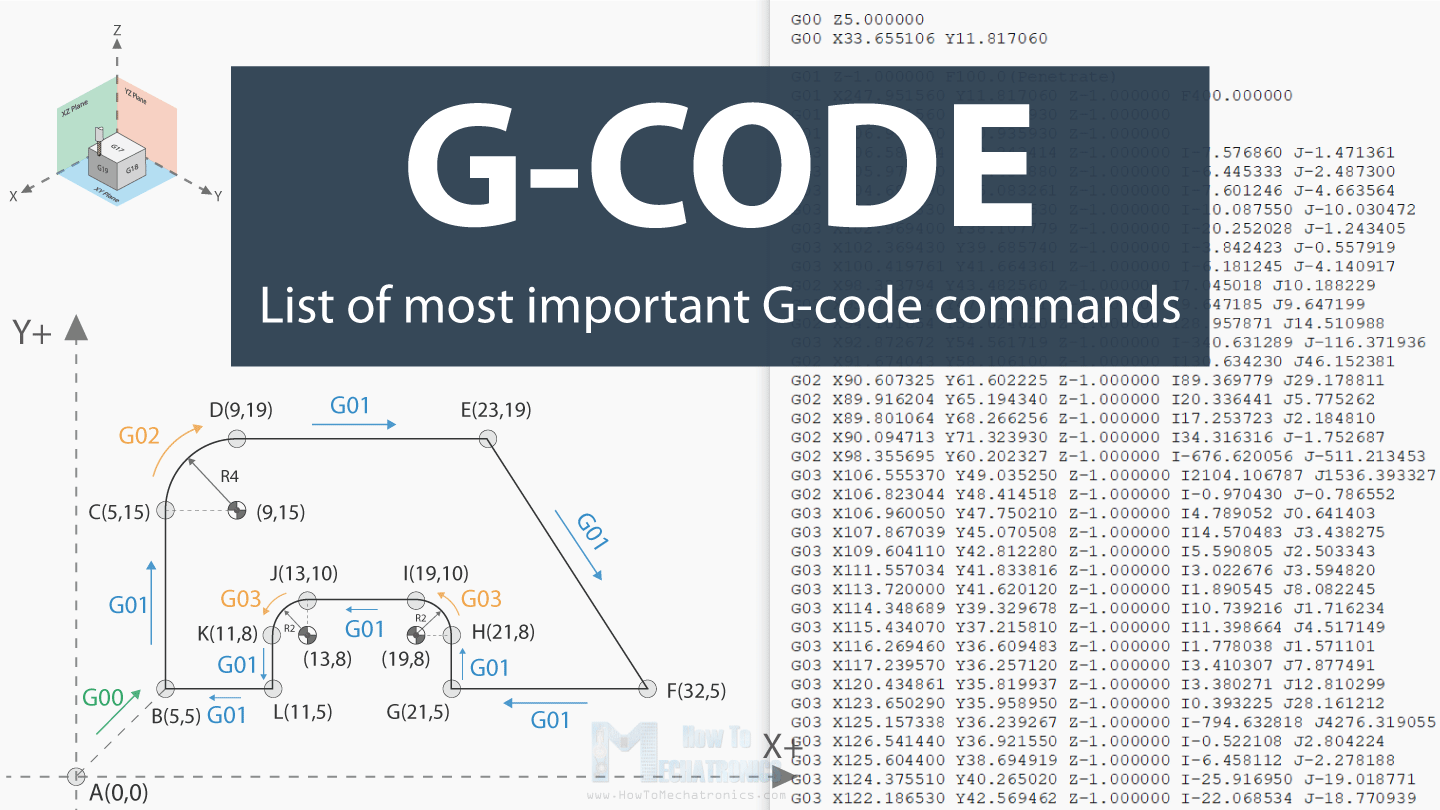

G-code operates in both metric and imperial units, as indicated by G20 (inches) and G21 (millimeters). This flexibility is essential for international transactions, as different regions may prefer one measurement system over the other. Buyers should clarify which system their CNC machines utilize to avoid miscommunication and errors in machining.

5. Canned Cycles

Canned cycles are predefined sequences of G-code that simplify complex machining tasks, such as drilling and tapping. Understanding the available canned cycles (like G81 for drilling) can significantly reduce programming time and improve workflow efficiency. Buyers should familiarize themselves with the canned cycles supported by their machines to leverage this feature effectively.

What Are Common Trade Terms Related to G-Code?

In the context of G-code and CNC machining, several industry terms are frequently used. Understanding these terms is crucial for international B2B buyers to navigate contracts and negotiations effectively.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are sold under another company’s brand. In the CNC industry, understanding OEM relationships can help buyers identify reliable suppliers of machinery and components that are compliant with specific G-code standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory planning. Buyers should negotiate MOQs with suppliers to ensure they can meet production demands without excessive surplus.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for a particular product or service. In the CNC machining sector, submitting an RFQ can help buyers obtain competitive pricing and ensure that suppliers understand their specific G-code requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is vital for B2B transactions involving G-code applications, as they dictate who is responsible for shipping, insurance, and tariffs, thus affecting overall costs.

5. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

CAD refers to software used for designing parts, while CAM is used for manufacturing those parts. Integrating G-code with CAD/CAM systems can streamline the transition from design to production. Buyers should consider suppliers that offer compatible CAD/CAM solutions to enhance their operational efficiency.

By grasping these essential technical properties and trade terms related to G-code, international B2B buyers can make informed decisions, optimize their machining processes, and foster successful supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the g code list Sector

What Are the Current Market Dynamics and Key Trends in the G Code List Sector?

The global landscape for G-code and CNC technology is rapidly evolving, driven by the increasing demand for automation and precision manufacturing across various industries. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are experiencing a shift towards advanced CNC machining capabilities that enhance production efficiency and reduce operational costs. Key trends include the integration of AI and machine learning into CNC programming, which allows for adaptive machining processes that can optimize tool paths and reduce waste.

Moreover, the rise of Industry 4.0 is leading to an increased focus on smart manufacturing technologies that utilize real-time data analytics. This enables manufacturers to make informed decisions about production schedules and inventory management. As international buyers seek suppliers who can provide not just products but comprehensive solutions, there is a growing emphasis on supplier partnerships that facilitate technology transfer and training.

A stock image related to g code list.

In addition, the COVID-19 pandemic has highlighted the need for supply chain resilience, prompting buyers to reconsider sourcing strategies. Diversifying supplier networks and investing in local production capabilities are becoming essential strategies for mitigating risks associated with global supply chains. This dynamic environment presents significant opportunities for B2B buyers to leverage innovative technologies and practices in their sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the G Code List Sector?

Sustainability is increasingly becoming a focal point in B2B procurement, particularly for sectors reliant on technology such as CNC machining. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting buyers to seek out suppliers who prioritize sustainable practices. This includes using energy-efficient machines and adopting processes that minimize material waste.

A stock image related to g code list.

A stock image related to g code list.

Ethical sourcing is also gaining traction, with a growing emphasis on ensuring that supply chains are transparent and socially responsible. Buyers are looking for certifications that indicate a commitment to sustainability, such as ISO 14001 for environmental management or adherence to the UN Global Compact principles. Incorporating ‘green’ materials and technologies into the manufacturing process not only enhances brand reputation but also meets the increasing consumer demand for sustainable products.

For B2B buyers in Africa, South America, the Middle East, and Europe, aligning with suppliers who share these values can lead to stronger partnerships and improved market positioning. By investing in sustainable and ethical sourcing practices, companies can enhance their competitiveness and appeal to a broader customer base.

What is the Brief Evolution and History of G Code in the B2B Context?

The evolution of G-code dates back to the 1950s when it was first developed to control CNC machines. Originally designed to streamline the machining process, G-code has become the standard programming language for CNC machinery globally. Over the years, enhancements in technology have led to the development of more sophisticated G-code variations, enabling complex machining operations with precision and efficiency.

As industries have evolved, so too has G-code, adapting to the needs of modern manufacturing environments. The introduction of more advanced features, such as parametric programming and the integration of CAD/CAM systems, has further transformed how B2B buyers and manufacturers approach CNC operations. This historical context is crucial for buyers looking to understand the capabilities and limitations of G-code, as it continues to shape the future of manufacturing and sourcing strategies in a rapidly changing global market.

Frequently Asked Questions (FAQs) for B2B Buyers of g code list

-

How do I solve issues with G-code compatibility across different CNC machines?

To address G-code compatibility issues, it’s essential to first confirm the specific G-code standards used by the CNC machines in your operation. Different manufacturers may implement variations of G-codes, so obtaining a comprehensive list that includes any custom codes is vital. Engage with your CNC machine suppliers to acquire the right G-code list and consider standardizing your equipment to minimize discrepancies. Additionally, running compatibility tests with a sample G-code program can help identify potential issues before full-scale implementation. -

What is the best resource for a complete G-code list for CNC programming?

The most reliable resource for a complete G-code list typically includes manufacturer documentation and industry-standard references. Websites dedicated to CNC programming, like GCodeTutor, often provide downloadable G-code lists and tutorials. For international B2B buyers, consulting with your CNC machine supplier can yield manufacturer-specific G-code lists that are crucial for your operations. Online forums and communities can also be valuable for sharing insights and tips on G-code programming. -

How can I vet suppliers for G-code lists and CNC programming services?

Vetting suppliers for G-code lists and CNC programming services should involve assessing their industry experience, customer reviews, and technical expertise. Request case studies or references from similar businesses in your region. Additionally, evaluate their communication skills and responsiveness, as these are critical for ongoing support. Consider conducting an initial trial order or project to gauge their capability and reliability before committing to larger contracts. -

What are the typical minimum order quantities (MOQs) for G-code software or lists?

Minimum order quantities (MOQs) for G-code software or lists can vary significantly among suppliers. Many software providers offer subscriptions or licenses with no minimum purchase requirements, while others may have MOQs for bulk orders of customized G-code lists. It’s advisable to inquire directly with suppliers about their MOQs, especially if you are considering a tailored solution for specific CNC machines or applications. -

What payment terms should I expect when sourcing G-code lists internationally?

Payment terms for sourcing G-code lists internationally can differ based on the supplier’s policies and the buyer’s relationship with them. Common terms include upfront payments, net 30, or 50% upfront with the balance upon delivery. For first-time orders, consider negotiating secure payment methods like escrow services or letters of credit to mitigate risk. Always clarify terms in writing to avoid misunderstandings later on. -

How do I ensure quality assurance (QA) for G-code lists before implementation?

To ensure quality assurance for G-code lists, conduct thorough reviews and tests before implementation. Validate the G-code by running it in a controlled environment with a CNC machine to monitor for errors. Collaborate with your supplier to understand their QA processes, including testing protocols and documentation. Regular updates and maintenance of the G-code lists are also essential to adapt to any changes in machine specifications or software updates. -

What logistics considerations should I keep in mind when sourcing G-code lists internationally?

When sourcing G-code lists internationally, logistics considerations include shipping times, customs clearance, and potential tariffs. Ensure that your suppliers can provide digital files to avoid delays associated with physical shipping. Additionally, clarify the formats available for the G-code lists (e.g., .txt, .nc) and ensure compatibility with your CNC systems. A reliable logistics partner can facilitate smooth communication and tracking throughout the shipping process. -

How can I customize G-code lists for my specific CNC machinery?

Customizing G-code lists for specific CNC machinery involves understanding the unique capabilities and requirements of your machines. Work closely with your CNC supplier to identify the necessary modifications to standard G-codes. Many suppliers offer customization services to tailor G-code lists based on your machining needs. Additionally, using simulation software can help visualize and test custom G-codes before actual implementation, ensuring optimal performance and accuracy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for g code list

How Can Strategic Sourcing Enhance Your G-Code Operations?

In today’s competitive landscape, strategic sourcing of G-code lists is essential for optimizing CNC machining processes. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must prioritize sourcing comprehensive G-code resources that align with their specific machining needs. By understanding the various G- and M-codes, businesses can enhance operational efficiency, reduce errors, and ultimately improve product quality.

Investing in high-quality, accurate G-code documentation facilitates smoother operations and minimizes costly downtimes. Moreover, aligning with suppliers who provide robust technical support and training can further empower your workforce, ensuring that your teams are well-equipped to leverage these codes effectively.

As we look to the future, the demand for precision machining will only grow. Buyers should actively seek partnerships that not only offer G-code lists but also provide insights into emerging technologies and trends. Embrace this opportunity to enhance your CNC capabilities, drive innovation, and foster growth in your markets. Take the next step—evaluate your sourcing strategies today and position your business for success in the evolving manufacturing landscape.