Unlock Cost Savings: The Complete Alumina Ceramic Guide (2025)

Introduction: Navigating the Global Market for alumina ceramic

Navigating the global market for alumina ceramic can be daunting for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality suppliers but also in understanding the diverse applications and material grades of alumina ceramics. With its exceptional properties—such as high hardness, corrosion resistance, and thermal stability—alumina ceramic is an essential material across various industries, including aerospace, electronics, and manufacturing.

This comprehensive guide addresses key aspects of the alumina ceramic market, including the different types and grades available, their specific applications, and critical considerations for supplier vetting. It will also delve into cost factors, ensuring that you can make informed purchasing decisions tailored to your unique operational needs. By equipping yourself with this knowledge, you’ll be better positioned to navigate the complexities of sourcing alumina ceramic products effectively and efficiently.

Whether you are looking to procure high-purity grades for electronic components or durable materials for wear-resistant applications, this guide empowers you to choose the right products and suppliers. As you explore the intricacies of alumina ceramics, you will gain valuable insights that can enhance your procurement strategy and ultimately contribute to the success of your business in a competitive global marketplace.

Understanding alumina ceramic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CeramAlox 96 | 96% purity, cost-effective, versatile machining | Electronic components, high-temperature insulators | Pros: Good balance of cost and performance. Cons: Lower purity may limit use in critical applications. |

| CeramAlox 99.7 | 99.7% purity, superior mechanical properties | High-performance electrical insulators, wear components | Pros: Excellent durability and thermal stability. Cons: Higher cost compared to CeramAlox 96. |

| CeramAlox 99.95 Ultra Pure | 99.95% purity, exceptional electrical resistivity | High-voltage insulators, precision components | Pros: Outstanding performance in demanding environments. Cons: Premium price point may deter some buyers. |

| Alumina Foam | Lightweight, porous structure, thermal insulation | Filtration, thermal barriers, lightweight applications | Pros: Reduces weight without compromising strength. Cons: Less suitable for applications requiring solid structure. |

| Zirconia Toughened Alumina (ZTA) | Enhanced toughness, combines alumina with zirconia | Aerospace, automotive, and high-stress components | Pros: Increased toughness and wear resistance. Cons: More complex manufacturing process increases costs. |

What are the Characteristics of CeramAlox 96?

CeramAlox 96 is a widely used alumina ceramic with a purity of 96%. It strikes a balance between performance and cost, making it suitable for various industrial applications, including electronic components and high-temperature insulators. Its ability to be machined in the green state allows for diverse shapes, which is a significant advantage for manufacturers looking for customization. Buyers should consider its suitability for less critical applications where cost efficiency is paramount, but be aware that its lower purity may limit its use in highly specialized environments.

How Does CeramAlox 99.7 Stand Out?

With a purity of 99.7%, CeramAlox 99.7 offers superior mechanical and electrical properties, making it ideal for high-performance applications. This type is commonly used in high-voltage insulators and wear components, where durability is essential. The ability to machine this material before sintering ensures high precision in component fabrication. Buyers in sectors requiring robust performance in aggressive environments should consider this grade, though they should also factor in the higher cost compared to lower-purity options.

Why Choose CeramAlox 99.95 Ultra Pure?

CeramAlox 99.95 Ultra Pure is the highest purity option available, featuring exceptional mechanical stability and electrical resistivity. This makes it particularly suitable for high-voltage applications and precision components in demanding environments. Its excellent thermal stability and corrosion resistance make it a preferred choice in critical applications. However, buyers must consider the premium pricing associated with this grade, which may not be justifiable for all projects, particularly those with less stringent performance requirements.

What are the Benefits of Alumina Foam?

Alumina Foam is characterized by its lightweight and porous structure, which provides excellent thermal insulation and filtration capabilities. This type is particularly useful in applications where weight reduction is essential, such as aerospace and automotive industries. While it offers significant advantages in terms of thermal performance, buyers should note that its porous nature may not be suitable for applications requiring solid structural integrity. Understanding the specific application requirements will help buyers determine if this material meets their needs.

How Does Zirconia Toughened Alumina (ZTA) Enhance Performance?

Zirconia Toughened Alumina (ZTA) combines the strength of alumina with the toughness of zirconia, resulting in a material that excels in high-stress applications. This variation is commonly used in aerospace and automotive sectors where enhanced toughness and wear resistance are critical. While ZTA offers significant advantages, the complexity of its manufacturing process can lead to higher costs. Buyers should weigh the benefits of increased durability against the investment required, especially for applications with stringent performance demands.

Key Industrial Applications of alumina ceramic

| Industry/Sector | Specific Application of alumina ceramic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal insulators for engines | High-temperature resistance ensures safety and efficiency | Verify high purity grades and thermal stability for aerospace standards |

| Electronics | Substrates for electronic components | Excellent dielectric properties improve device performance | Source materials with consistent purity and electrical characteristics |

| Automotive | Wear-resistant components in engines | Enhanced durability reduces maintenance costs | Ensure compliance with automotive industry specifications |

| Medical | Bio-inert implants and surgical tools | Corrosion resistance ensures patient safety | Focus on high purity and biocompatibility for medical applications |

| Semiconductor Manufacturing | Components for high-temperature processing | Increased yield and efficiency in semiconductor production | Look for suppliers with a proven track record in semiconductor-grade materials |

How is Alumina Ceramic Used in Aerospace Applications?

In the aerospace industry, alumina ceramics are primarily utilized for thermal insulators in engines and other high-temperature environments. These materials can withstand extreme heat, ensuring safety and efficiency during flight operations. B2B buyers in this sector should prioritize sourcing high-purity grades of alumina with proven thermal stability to meet stringent aerospace standards and regulations.

What Role Does Alumina Ceramic Play in Electronics Manufacturing?

Alumina ceramics serve as substrates for electronic components due to their excellent dielectric properties and thermal conductivity. This application enhances the performance and reliability of electronic devices, crucial for industries that demand high precision. Buyers should consider the consistency of purity and electrical characteristics when sourcing these materials to ensure optimal performance in electronic applications.

How is Alumina Ceramic Applied in the Automotive Sector?

In the automotive industry, alumina ceramics are employed in wear-resistant components, such as engine parts and braking systems. The high hardness and durability of alumina significantly reduce maintenance costs and improve the longevity of automotive components. Buyers should ensure that their suppliers can meet automotive specifications and provide materials that can withstand the rigors of automotive applications.

Why is Alumina Ceramic Important in Medical Applications?

Alumina ceramics are increasingly used in the medical field for bio-inert implants and surgical tools. Their corrosion resistance and mechanical strength make them suitable for long-term implantation in the human body. B2B buyers in this sector must focus on high-purity alumina to guarantee biocompatibility and safety in medical applications, as well as compliance with health regulations.

How Does Alumina Ceramic Benefit Semiconductor Manufacturing?

In semiconductor manufacturing, alumina ceramics are crucial for components used in high-temperature processing. Their ability to withstand extreme conditions contributes to increased yield and efficiency in production. Buyers should look for suppliers that specialize in semiconductor-grade materials, ensuring that the alumina meets the specific requirements for temperature resistance and purity essential for this advanced manufacturing sector.

3 Common User Pain Points for ‘alumina ceramic’ & Their Solutions

Scenario 1: Navigating Quality Variations in Alumina Ceramics

The Problem: B2B buyers often face challenges in sourcing alumina ceramics that meet specific performance standards. Variations in purity levels—ranging from 96% to ultra-pure grades of 99.95%—can significantly impact the material’s mechanical and electrical properties. For instance, a manufacturer in the semiconductor industry may require 99.7% purity alumina for high-voltage insulators. If they inadvertently procure a lower-grade product, the insulators may fail under stress, leading to production downtimes and financial losses. The lack of standardized quality assurance across suppliers adds to the frustration, making it hard to ascertain which products are truly reliable.

The Solution: To effectively navigate these quality variations, buyers should establish clear specifications based on the intended application of alumina ceramics. When sourcing, engage with suppliers who provide detailed datasheets and transparency about their manufacturing processes. It’s beneficial to request samples for testing under operational conditions before placing large orders. Additionally, consider partnering with suppliers that offer certification of material properties, which can serve as a quality guarantee. This proactive approach not only mitigates risks but also fosters long-term relationships with trusted suppliers, ensuring consistent performance in critical applications.

Scenario 2: Managing High-Cost Implications of Alumina Ceramics

The Problem: Cost is a significant factor for B2B buyers, especially in regions like Africa and South America, where budget constraints can be tight. Alumina ceramics, particularly high-purity grades, can come with steep price tags. For instance, a manufacturer might find that opting for ultra-pure alumina increases their initial investment substantially. However, the long-term benefits such as durability and performance in high-stress environments may justify the cost. The challenge lies in justifying these expenditures to stakeholders while ensuring the chosen materials will deliver the expected ROI.

The Solution: Buyers should conduct a thorough cost-benefit analysis that considers both the upfront costs and the lifecycle expenses of alumina ceramics. Collaborate with suppliers to explore bulk purchasing options or negotiate pricing based on long-term contracts. Additionally, consider the total cost of ownership by evaluating the expected lifespan of the materials against potential downtime costs associated with cheaper alternatives. Implementing this analytical approach allows buyers to present a compelling case to stakeholders, demonstrating that investing in high-quality alumina ceramics can lead to cost savings over time due to reduced maintenance and replacement needs.

Scenario 3: Addressing Performance Limitations in Extreme Conditions

The Problem: In sectors such as aerospace and manufacturing, alumina ceramics must perform reliably under extreme conditions, including high temperatures and corrosive environments. A B2B buyer may encounter scenarios where standard alumina products fail to meet performance expectations, leading to costly operational failures. For example, if an alumina component used in a high-temperature furnace lacks adequate thermal shock resistance, it could crack or shatter, jeopardizing safety and productivity.

The Solution: To address these performance limitations, buyers should prioritize understanding the specific environmental conditions their alumina ceramics will face. Engage with suppliers who can provide tailored solutions based on detailed operational parameters. This may include selecting higher-grade alumina that offers enhanced thermal conductivity and shock resistance, such as the 99.95% purity variant. Additionally, consider implementing a testing phase where the chosen materials are subjected to simulated operational conditions before full-scale deployment. This not only helps in validating the product’s performance but also ensures that the materials will withstand the rigorous demands of their intended applications.

Strategic Material Selection Guide for alumina ceramic

What Are the Key Properties of Common Alumina Ceramic Materials?

Alumina ceramics, particularly in industrial applications, are categorized based on their purity levels and specific properties. The most common grades include CeramAlox 96, CeramAlox 99.7, and CeramAlox 99.95 Ultra Pure. Each of these materials offers unique characteristics that can significantly impact their suitability for various applications.

How Does CeramAlox 96 Perform in Industrial Applications?

Key Properties: CeramAlox 96 features a purity level of 96% and exhibits excellent mechanical strength, high hardness, and good thermal conductivity. It can withstand temperatures up to 1,600°C and is resistant to wear and abrasion.

Pros & Cons: This material provides a balanced cost-to-quality ratio, making it a popular choice for applications where budget constraints are significant. However, its lower purity compared to higher grades may limit its performance in extremely corrosive environments.

Impact on Application: CeramAlox 96 is well-suited for electronic components, high-temperature electrical insulators, and mechanical seals. Its compatibility with various media makes it versatile, though it may not be ideal for highly aggressive chemical environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local manufacturing capabilities and compliance with international standards such as ASTM or DIN. Availability of this material can vary, so sourcing from reputable suppliers is essential.

What Advantages Does CeramAlox 99.7 Offer?

Key Properties: With a purity of 99.7%, CeramAlox 99.7 provides superior mechanical and electrical properties. It can handle high temperatures and has excellent resistance to chemical corrosion.

Pros & Cons: This material is well-regarded for its durability and performance in aggressive environments, making it suitable for high-stress applications. However, its higher cost may be a limiting factor for projects with tight budgets.

Impact on Application: CeramAlox 99.7 is ideal for high-voltage insulators and precision components in semiconductor processing. Its high purity ensures that it performs well in challenging environments, providing reliability and longevity.

Considerations for International Buyers: Compliance with local regulations is crucial, especially in the Middle East, where material standards can be stringent. Buyers should also assess the supply chain reliability to avoid delays in production.

Why Choose CeramAlox 99.95 Ultra Pure?

Key Properties: CeramAlox 99.95 Ultra Pure is distinguished by its exceptional purity, which enhances its mechanical strength and thermal stability. It can withstand extreme temperatures and offers excellent dielectric properties.

Pros & Cons: The main advantage of this grade is its performance in high-stress applications, particularly in the aerospace and medical fields. However, the cost is significantly higher, which may not be justifiable for all applications.

Impact on Application: This material is particularly effective in applications requiring high wear resistance and chemical inertness, such as precision shafts and high-voltage insulators.

Considerations for International Buyers: In Europe, where environmental regulations are stringent, buyers must ensure that their suppliers adhere to compliance standards. Additionally, the higher price point may necessitate careful budgeting and cost analysis.

Summary of Material Selection for Alumina Ceramics

| Material | Typical Use Case for alumina ceramic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| CeramAlox 96 | Electronic components, high-temperature insulators | Balanced cost-to-quality ratio | Lower performance in aggressive environments | Medium |

| CeramAlox 99.7 | High-voltage insulators, semiconductor processing | Superior mechanical and electrical properties | Higher cost may limit usage | High |

| CeramAlox 99.95 Ultra Pure | Aerospace components, medical applications | Exceptional purity and performance | Significantly higher cost | High |

This guide provides a comprehensive overview of the strategic selection of alumina ceramic materials, focusing on properties, advantages, limitations, and considerations for international B2B buyers. Understanding these factors will aid in making informed procurement decisions tailored to specific industrial needs.

In-depth Look: Manufacturing Processes and Quality Assurance for alumina ceramic

What Are the Key Manufacturing Processes for Alumina Ceramic?

The manufacturing of alumina ceramics involves several critical stages that ensure the material meets the desired specifications for various applications. Understanding these processes is crucial for B2B buyers looking to source high-quality alumina ceramics.

How Is Material Prepared for Alumina Ceramic Production?

The first step in the manufacturing process is material preparation. Alumina ceramics are primarily derived from bauxite, which undergoes refining to produce alumina (Al₂O₃). This stage may include:

- Crushing and Grinding: Bauxite is crushed and ground to increase the surface area, enhancing the efficiency of subsequent processing steps.

- Calcination: The ground alumina is then subjected to high temperatures to remove moisture and impurities, resulting in a fine powder suitable for ceramic production.

What Forming Techniques Are Used in Alumina Ceramic Manufacturing?

Once the material is prepared, it moves to the forming stage, where various techniques are employed to shape the alumina into the desired form. Common forming methods include:

- Injection Molding: A process that involves mixing the alumina powder with a binder and injecting it into a mold. This method is ideal for complex shapes and large production runs.

- Die Pressing: In this technique, the alumina powder is compacted into a die under high pressure. This method is suitable for producing dense, uniform components.

- Isostatic Pressing: This involves applying pressure uniformly from all directions, resulting in components with excellent density and mechanical properties.

- Slip Casting: A technique where a slurry of alumina is poured into a porous mold, allowing water to be absorbed, leaving a solid ceramic shape.

- Extrusion: The alumina is forced through a die to create long shapes, which are then cut to size.

What Are the Finishing Processes for Alumina Ceramics?

After forming, the components undergo finishing processes to achieve the required dimensions and surface quality. Key finishing techniques include:

- Sintering: This heat treatment process involves heating the formed alumina components to a temperature below their melting point, causing particles to bond and densify. Sintering is critical for enhancing the mechanical properties of the ceramic.

- Machining: For precise dimensions, alumina ceramics can be diamond ground or machined post-sintering. This ensures tight tolerances and smooth surfaces.

- Polishing: A final step that enhances the aesthetic appearance and surface finish of the alumina components.

What Quality Control Measures Are Essential in Alumina Ceramic Production?

Quality assurance is vital in ensuring that alumina ceramics meet international standards and customer specifications. B2B buyers must be aware of the quality control processes involved in alumina ceramic manufacturing.

Which International Standards Should B2B Buyers Look For?

Several international standards govern the quality of alumina ceramics, including:

- ISO 9001: This standard ensures that the manufacturing processes are consistent and meet customer requirements. It is essential for suppliers to be certified to this standard.

- CE Marking: Particularly important for products sold in the European market, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Certification: For applications in the oil and gas industry, API certification ensures that materials meet specific performance criteria.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in alumina ceramic manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, various parameters such as temperature, pressure, and dimensional accuracy are monitored to ensure product consistency.

- Final Quality Control (FQC): After the manufacturing process, finished products undergo rigorous testing to verify that they meet the required specifications.

Which Testing Methods Are Commonly Used for Alumina Ceramics?

Various testing methods are employed to assess the quality and performance of alumina ceramics, including:

- Mechanical Testing: This includes hardness tests, compressive strength tests, and flexural strength tests to evaluate the material’s durability.

- Thermal Testing: High-temperature tests assess thermal stability and conductivity, crucial for applications in extreme conditions.

- Electrical Testing: Dielectric strength tests determine the electrical insulation properties of the ceramics.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can adopt several verification strategies:

What Auditing Practices Should Be Followed?

Conducting supplier audits is an effective way to assess manufacturing capabilities and quality assurance practices. Buyers should consider:

- On-site Audits: Visiting the manufacturing facility allows buyers to inspect production processes, equipment, and quality control measures firsthand.

- Documentation Review: Requesting documentation such as quality assurance reports, inspection records, and compliance certificates can provide insight into the supplier’s practices.

How Can Buyers Leverage Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These services can conduct:

- Random Sampling: Inspecting randomly selected batches of products to ensure they meet the specified standards.

- Performance Testing: Conducting tests on products to validate their performance characteristics as per the specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding the cultural context can influence communication and negotiation with suppliers, impacting quality expectations.

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers must ensure that suppliers comply with local and international standards relevant to their market.

- Logistics and Supply Chain Considerations: Timely delivery of quality products is crucial. Buyers should evaluate the supplier’s logistics capabilities and their impact on quality assurance.

By understanding the manufacturing processes and quality assurance measures associated with alumina ceramics, international B2B buyers can make informed decisions, ensuring they source high-quality materials tailored to their specific industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alumina ceramic’

This sourcing guide provides a structured approach for international B2B buyers seeking to procure alumina ceramics. With its diverse applications across various industries, understanding the sourcing process is essential to ensure quality and compatibility with specific business needs.

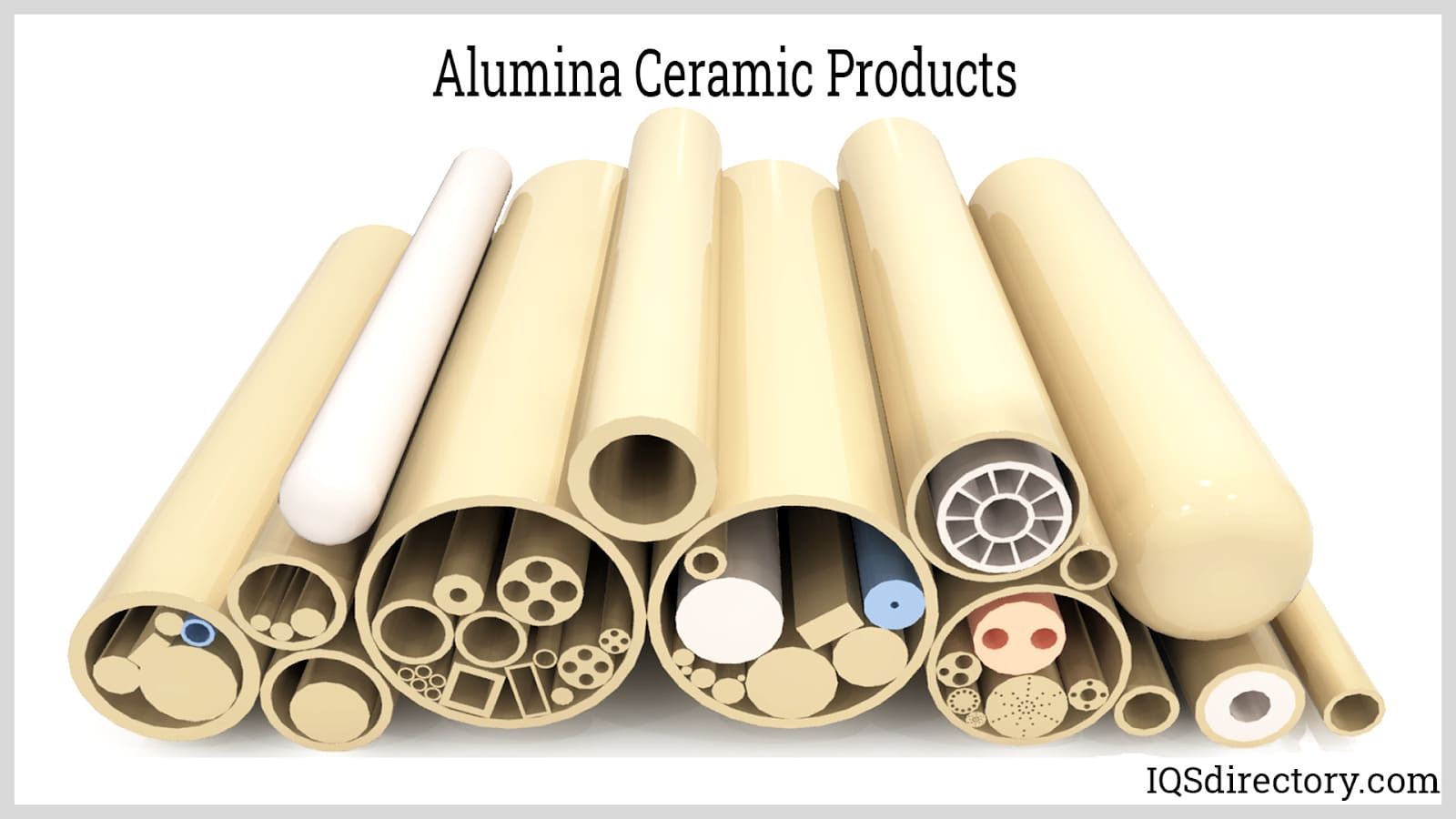

A stock image related to alumina ceramic.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to outline your specific requirements for alumina ceramics. This includes defining the purity level (e.g., 96%, 99.7%, or 99.95%), mechanical properties (such as compressive and flexural strength), and intended application (e.g., electrical insulation, wear resistance). Clearly defined specifications help streamline the procurement process by enabling you to communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of alumina ceramics. Look for companies with a strong track record in the industry, positive customer reviews, and relevant certifications (e.g., ISO 9001). Utilize online directories, industry forums, and trade shows to gather a comprehensive list of potential suppliers who can meet your technical specifications.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is a critical step in ensuring product quality and compliance with international standards. Check for certifications such as ISO, ASTM, or other relevant industry-specific standards that apply to alumina ceramics. These certifications indicate that the supplier adheres to rigorous quality management practices and can provide consistent product performance.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the alumina ceramic products you are considering. Testing these samples in your specific application allows you to evaluate their performance under actual working conditions. Pay attention to factors like wear resistance, thermal conductivity, and electrical insulation properties to ensure they meet your requirements.

Step 5: Inquire About Customization Options

Many suppliers offer customization services for alumina ceramics to better suit your application. Inquire about the possibility of tailoring the size, shape, and grade of the ceramic material. Understanding the supplier’s capabilities in customization can enhance your procurement process and ensure that you receive products that fit your specific needs.

Step 6: Discuss Pricing and Payment Terms

Once you have shortlisted potential suppliers, initiate discussions about pricing and payment terms. Request detailed quotations that include unit prices, bulk order discounts, and shipping costs. Additionally, clarify payment terms to avoid misunderstandings later in the procurement process. This step is vital for budgeting and financial planning.

Step 7: Establish a Communication Plan

Effective communication with your chosen supplier is key to a successful procurement process. Establish a clear communication plan that outlines points of contact, preferred methods of communication, and timelines for updates. Regular communication helps in addressing any issues that may arise during production or shipping, ensuring that you receive your alumina ceramics on time and as specified.

By following this checklist, B2B buyers can effectively navigate the sourcing process for alumina ceramics, ensuring quality products that meet their specific industrial applications.

Comprehensive Cost and Pricing Analysis for alumina ceramic Sourcing

What Are the Key Cost Components in Alumina Ceramic Sourcing?

When sourcing alumina ceramics, understanding the cost structure is essential for making informed purchasing decisions. The primary components of cost include:

- Materials: The base material, aluminum oxide (Al2O3), varies in price based on purity levels and market demand. Higher purity grades, such as CeramAlox 99.95, typically come with a premium.

- Labor: Labor costs can fluctuate depending on the complexity of production processes and the geographic location of the manufacturing facility. Skilled labor in regions with advanced manufacturing capabilities may demand higher wages.

- Manufacturing Overhead: This encompasses utilities, maintenance, and facility costs, which are often allocated per unit produced. Efficient production methods can help minimize this overhead.

- Tooling: The cost of molds and specialized machinery is significant, especially for custom or complex shapes. These expenses can be amortized over larger production runs.

- Quality Control (QC): Rigorous testing and certification processes to ensure product integrity add to overall costs. Depending on the intended application, certifications may be required, which can influence pricing.

- Logistics: Shipping costs can vary widely based on distance, volume, and shipping terms (Incoterms). Import duties and taxes also play a crucial role in final pricing.

- Margin: Suppliers typically add a profit margin that varies by market, competition, and product exclusivity.

How Do Price Influencers Affect Alumina Ceramic Sourcing?

Several factors can significantly influence the pricing of alumina ceramics:

- Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower unit prices due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

- Specifications and Customization: Custom specifications can lead to higher costs, particularly if specialized tooling or processes are required. Standardized products generally offer better pricing.

- Materials Quality and Certifications: Higher quality materials and compliance with international standards can drive up costs but may be necessary for specific applications. Buyers should balance quality with budget constraints.

- Supplier Factors: Supplier reputation, reliability, and production capacity can impact pricing. Established suppliers may command higher prices due to perceived quality and service levels.

- Incoterms: The agreed terms of shipment (e.g., FOB, CIF) can affect the overall cost. Understanding these terms helps buyers manage their total landed costs effectively.

What Are Some Buyer Tips for Cost-Efficiency in Alumina Ceramic Sourcing?

International B2B buyers should consider the following tips to enhance cost-efficiency when sourcing alumina ceramics:

- Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially for larger orders. Discuss potential discounts for bulk purchases or long-term contracts.

- Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the TCO, which includes shipping, handling, and future maintenance costs. A lower initial price may lead to higher operational costs.

- Understand Pricing Nuances: Be aware of regional pricing differences, especially if sourcing from markets with varying labor and material costs. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America.

- Quality vs. Cost: While it may be tempting to opt for the lowest price, ensure that quality standards are met. Compromising on quality can lead to higher costs in the long run due to failures or replacements.

- Stay Informed: Regularly review market trends and pricing fluctuations for alumina ceramics. Being informed can help buyers make timely decisions and capitalize on favorable pricing opportunities.

Disclaimer Regarding Indicative Prices

Prices for alumina ceramics can vary significantly based on the factors outlined above. The information provided serves as a general guide, and actual prices should be confirmed with suppliers to reflect current market conditions and specific buyer requirements.

Alternatives Analysis: Comparing alumina ceramic With Other Solutions

A stock image related to alumina ceramic.

When considering materials for industrial applications, B2B buyers often seek alternatives to alumina ceramics that can meet specific performance requirements and cost constraints. Understanding these alternatives allows buyers to make informed decisions based on their unique operational needs.

Comparison Table of Alumina Ceramic and Alternatives

| Comparison Aspect | Alumina Ceramic | Boron Nitride | Silicon Carbide |

|---|---|---|---|

| Performance | High hardness, excellent thermal stability, good electrical insulation | High thermal conductivity, good chemical resistance | Extremely hard, excellent wear resistance, high thermal conductivity |

| Cost | Moderate cost; good cost-to-performance ratio | Higher cost; premium material | Higher initial investment; cost-effective over time due to durability |

| Ease of Implementation | Easy to machine; various shaping methods available | Requires specialized machining techniques | Difficult to machine; requires advanced equipment |

| Maintenance | Low maintenance; durable under harsh conditions | Low maintenance; stable in extreme conditions | Moderate maintenance; may require periodic inspection |

| Best Use Case | High-temperature insulators, wear components | Semiconductor applications, high-temperature environments | Abrasive environments, cutting tools |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Boron Nitride as an Alternative?

Boron nitride is renowned for its exceptional thermal conductivity and chemical stability. It excels in high-temperature applications and is often used in semiconductor manufacturing due to its electrical insulation properties. However, it comes with a higher price point compared to alumina ceramics, which may deter budget-conscious buyers. Additionally, the specialized machining requirements can lead to increased production times and costs.

How Does Silicon Carbide Compare to Alumina Ceramic?

Silicon carbide stands out for its remarkable hardness and superior wear resistance, making it an ideal choice for applications in abrasive environments. Its thermal conductivity is also noteworthy, enabling efficient heat dissipation. However, the higher initial cost and the complexity of machining silicon carbide may pose challenges for some manufacturers. While it offers long-term durability and cost savings through reduced maintenance, the upfront investment can be a barrier for smaller enterprises.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the best material for their specific applications, B2B buyers should weigh the performance characteristics, cost implications, and maintenance requirements of each option. For applications demanding high thermal stability and electrical insulation at a moderate cost, alumina ceramics remain a solid choice. However, if the application involves extreme conditions where wear resistance is paramount, silicon carbide may justify its higher cost. Alternatively, for high-temperature semiconductor applications, boron nitride could provide the necessary performance despite its premium pricing. Ultimately, understanding the specific operational demands and budget constraints will guide buyers toward the most suitable material for their needs.

Essential Technical Properties and Trade Terminology for alumina ceramic

Alumina ceramic is a vital material in various industrial applications, recognized for its unique properties and versatility. Understanding its technical specifications and trade terminology is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of Alumina Ceramic?

1. Material Grades: Why Do They Matter?

Alumina ceramics come in various grades, primarily categorized by their purity levels: CeramAlox 96 (96% purity), CeramAlox 99.7 (99.7% purity), and CeramAlox 99.95 Ultra Pure (99.95% purity). Higher purity grades offer enhanced mechanical and electrical properties, making them suitable for high-performance applications. For B2B buyers, selecting the appropriate grade can significantly influence the performance and longevity of their products.

2. Compressive Strength: What Does It Indicate?

Compressive strength is a measure of a material’s ability to withstand axial loads without failing. For alumina ceramics, this property varies with grade, ranging from 2000 MPa for CeramAlox 96 to 3500 MPa for the Ultra Pure variant. This strength is critical for applications involving heavy machinery or high-pressure environments. Buyers should prioritize compressive strength to ensure the durability of components in demanding conditions.

3. Thermal Conductivity: How Does It Affect Performance?

Alumina ceramics exhibit high thermal conductivity, which allows for efficient heat dissipation in applications such as insulators and substrates. This property is particularly important in electronics and aerospace industries, where overheating can lead to failure. Understanding thermal conductivity helps B2B buyers assess how well alumina ceramics will perform in their specific applications.

4. Dielectric Strength: What Is Its Importance in Electrical Applications?

Dielectric strength refers to a material’s ability to resist electrical breakdown. High-purity alumina ceramics possess excellent dielectric properties, making them suitable for high-voltage applications. For buyers in the electronics sector, selecting materials with adequate dielectric strength is essential to ensure safety and reliability in electrical components.

5. Hardness: Why Is It a Critical Specification?

Alumina is known for its exceptional hardness, measured in GPa. For instance, the hardness of CeramAlox 99.95 is approximately 18 GPa. This property is crucial for applications requiring wear resistance, such as in grinding tools and bearings. Buyers should evaluate hardness to ensure that the alumina ceramic can withstand abrasive conditions without degrading.

What Are Common Trade Terms Related to Alumina Ceramics?

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of alumina ceramics, understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing machinery.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for alumina ceramics is essential for budgeting and inventory management, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document that solicits price proposals from suppliers. When purchasing alumina ceramics, an RFQ can help buyers obtain competitive pricing and understand the cost implications of different grades and specifications.

4. Incoterms (International Commercial Terms): Why Are They Important?

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk management, and logistics when importing alumina ceramics from global suppliers.

5. Sintering: What Is Its Role in Manufacturing?

Sintering is a process that involves compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. This term is essential for buyers to understand as it directly affects the mechanical properties and performance of alumina ceramics.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right alumina ceramic products for their industrial applications.

Navigating Market Dynamics and Sourcing Trends in the alumina ceramic Sector

What Are the Key Market Trends in the Alumina Ceramic Sector?

The alumina ceramic market is currently experiencing significant growth driven by several global factors. Increased demand for high-performance materials in industries such as electronics, aerospace, and automotive is a primary driver. As these sectors evolve, they require advanced materials that can withstand harsh environments, leading to a surge in demand for alumina ceramics due to their superior mechanical and thermal properties.

Emerging B2B technology trends, such as the adoption of automation in manufacturing processes, are also reshaping the sourcing landscape. Automated production techniques enhance efficiency and precision, allowing suppliers to offer customized solutions that cater to specific industry needs. Additionally, the rise of Industry 4.0 is pushing manufacturers towards more integrated supply chains, where real-time data analytics inform inventory management and production schedules, thus improving overall operational efficiency for international buyers.

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. The demand for alumina ceramics is often influenced by regional economic conditions, regulatory frameworks, and technological advancements. Buyers should be aware of the growing trend toward localized sourcing to mitigate risks associated with global supply chain disruptions.

How Is Sustainability Shaping the Sourcing of Alumina Ceramics?

Sustainability has become a critical consideration for international B2B buyers, particularly in the alumina ceramic sector. The environmental impact of sourcing materials, including energy consumption and waste production, is under scrutiny. This has led to an increased focus on sustainable sourcing practices that prioritize the use of recycled materials and environmentally friendly production methods.

A stock image related to alumina ceramic.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 (Environmental Management) or specific ‘green’ certifications for alumina products. These certifications assure buyers that the materials are sourced responsibly and that the manufacturing processes minimize environmental harm.

Furthermore, the shift towards ‘green’ alumina materials is evident in the rise of companies investing in cleaner production technologies. Buyers should look for suppliers who employ innovative methods to reduce their carbon footprint, such as using renewable energy sources or implementing waste-reduction initiatives. This trend not only aligns with global sustainability goals but also resonates with consumers and businesses that prioritize environmentally friendly practices.

What Is the Historical Context of Alumina Ceramics for B2B Buyers?

Alumina ceramics have a rich history that has shaped their current applications and market dynamics. Initially developed in the early 20th century, alumina ceramics emerged from the need for materials that could withstand extreme conditions in industrial settings. Their unique combination of high hardness, thermal stability, and corrosion resistance made them ideal for various applications, from electrical insulators to wear-resistant components.

Over the decades, advancements in processing techniques, such as sintering and hot pressing, have enhanced the material properties of alumina ceramics, leading to the development of high-purity grades. This evolution has opened new markets and applications, allowing businesses to leverage alumina ceramics for increasingly demanding environments. As a result, understanding this historical context can help B2B buyers appreciate the material’s capabilities and the ongoing innovations driving its use in contemporary manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of alumina ceramic

-

How do I choose the right alumina ceramic grade for my application?

Selecting the appropriate alumina ceramic grade depends on your specific application requirements. The three main grades—CeramAlox 96, 99.7, and 99.95 Ultra Pure—vary in purity and performance. For general applications with a balance of cost and quality, CeramAlox 96 is ideal. For high-performance needs in aggressive environments, CeramAlox 99.7 offers superior mechanical properties. If your application involves extreme conditions, such as high temperatures or corrosive environments, consider the 99.95 Ultra Pure grade for its exceptional stability and strength. -

What are the key properties of alumina ceramics that make them suitable for industrial use?

Alumina ceramics are favored for their high hardness, wear resistance, thermal stability, and excellent electrical insulation properties. They also exhibit low density and resistance to strong acids and alkalis at elevated temperatures. These characteristics make alumina ceramics suitable for applications in electronics, high-temperature insulators, and wear components. Understanding these properties helps in identifying the right applications for your specific needs. -

What is the minimum order quantity (MOQ) for alumina ceramic products?

MOQs for alumina ceramics can vary significantly by supplier and product type. Typically, manufacturers may set an MOQ ranging from 100 to 1,000 units. It’s essential to communicate your needs directly with suppliers to negotiate terms that suit your purchasing strategy. Some suppliers might offer flexibility, especially for first-time orders or custom products, so don’t hesitate to inquire about options for lower MOQs. -

How can I ensure quality when sourcing alumina ceramics internationally?

To ensure quality when sourcing alumina ceramics, consider several steps: conduct thorough supplier vetting by checking their certifications, client testimonials, and production capabilities. Request product samples to assess quality firsthand. Establish clear quality assurance protocols, such as specifying testing methods for mechanical properties and thermal stability. Additionally, consider engaging third-party inspection services to verify compliance with international standards before finalizing your order. -

What payment terms should I expect when buying alumina ceramics?

Payment terms can vary widely among suppliers, but common practices include upfront deposits (20-50%) with the balance due upon shipment. Some suppliers may offer net payment terms (e.g., Net 30 or Net 60) for established customers. Be sure to clarify payment options and negotiate terms that align with your cash flow needs. Utilizing secure payment methods, such as letters of credit, can also protect your investment in international transactions. -

What shipping options are available for alumina ceramic products?

Shipping options for alumina ceramics typically include air freight and sea freight, depending on urgency and cost considerations. Air freight is faster but more expensive, suitable for smaller orders or urgent deliveries. Sea freight, while slower, is more cost-effective for larger shipments. Ensure to discuss logistics with your supplier, including packaging requirements to prevent damage during transport and customs documentation to facilitate smooth clearance. -

Can I customize alumina ceramic products to fit my specific requirements?

Yes, many manufacturers offer customization options for alumina ceramic products. You can specify dimensions, shapes, and performance characteristics tailored to your application needs. It’s important to communicate your requirements clearly during the initial discussions. Be aware that customized orders may have longer lead times and potentially higher costs, so factor these elements into your planning process. -

What are the typical applications for alumina ceramics in different industries?

Alumina ceramics are used across various industries, including electronics (for insulators and substrates), automotive (for wear-resistant components), aerospace (for thermal protection), and medical (for implants due to their bio-inertness). In semiconductor processing, they serve as critical components due to their high thermal conductivity and electrical resistivity. Understanding the specific applications relevant to your industry can help you identify potential uses for alumina ceramics in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for alumina ceramic

What Are the Key Takeaways for B2B Buyers of Alumina Ceramics?

In conclusion, strategic sourcing of alumina ceramics offers international B2B buyers a unique opportunity to leverage the material’s exceptional properties such as high hardness, thermal stability, and corrosion resistance. Understanding the various grades—CeramAlox 96, 99.7, and 99.95—allows buyers to make informed decisions based on specific applications ranging from wear components to high-temperature insulators.

How Can Strategic Sourcing Enhance Competitive Advantage?

Establishing strong supplier relationships and exploring diverse sourcing options across regions—particularly in Africa, South America, the Middle East, and Europe—can significantly enhance operational efficiency and cost-effectiveness. By aligning with manufacturers who prioritize quality and innovation, businesses can ensure that they not only meet but exceed industry standards.

What’s Next for International B2B Buyers?

As the demand for alumina ceramics continues to rise, staying ahead of market trends and technology advancements is crucial. Buyers are encouraged to engage with suppliers, attend industry events, and participate in forums to stay updated on best practices. This proactive approach will position your business favorably in a competitive landscape. Embrace the potential of alumina ceramics and make strategic sourcing a cornerstone of your procurement strategy.