Unlock Cost Savings: The Ultimate Die Stamping Guide (2025)

Introduction: Navigating the Global Market for die stamping

In today’s fast-paced global market, effectively sourcing die stamping solutions can pose significant challenges for international B2B buyers. The die stamping process, which involves shaping metal sheets into precise forms, is a critical component across various industries, from automotive to electronics. However, navigating the complexities of this manufacturing method, understanding the diverse types of dies, and assessing supplier capabilities can overwhelm even the most seasoned procurement professionals.

This comprehensive guide aims to demystify die stamping by exploring essential aspects such as the various types of dies, their applications, and the intricacies of the stamping process. We will also delve into the critical factors for vetting suppliers, understanding cost structures, and identifying quality assurance measures that ensure optimal outcomes. By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe with actionable insights, this guide empowers informed purchasing decisions.

Whether you are seeking to enhance production efficiency, reduce costs, or improve product quality, understanding the nuances of die stamping is paramount. This resource will serve as your roadmap to successfully navigate the global die stamping market, ensuring you connect with the right suppliers and achieve your manufacturing goals.

Understanding die stamping Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Progressive Die Stamping | Utilizes a series of stations to perform multiple operations in one cycle. | Automotive parts, electronics, appliances | Pros: High efficiency, reduced cycle time. Cons: Higher initial setup costs. |

| Transfer Die Stamping | Moves parts between stations using a mechanical transfer system. | Complex shapes in automotive and aerospace | Pros: Greater flexibility for complex designs. Cons: More intricate machinery required. |

| Compound Die Stamping | Combines cutting and forming in a single operation. | Metal brackets, fasteners, and connectors | Pros: Simplifies manufacturing, reduces material waste. Cons: Limited to simpler shapes. |

| Blanking Die Stamping | Cuts out shapes from metal sheets, leaving a slug or blank. | Fabrication of parts for various industries | Pros: Versatile for large volumes, cost-effective. Cons: Waste management required for slugs. |

| Piercing Die Stamping | Creates holes in metal sheets or parts, with the slug discarded. | Electronics, automotive, and appliances | Pros: Efficient for creating multiple holes. Cons: May require additional finishing for sharp edges. |

What Are the Characteristics of Progressive Die Stamping?

Progressive die stamping is characterized by its ability to perform multiple operations in a single pass through a series of stations. This method is particularly well-suited for high-volume production of parts such as automotive components and electronic housings. For B2B buyers, the key purchasing considerations include the complexity of the part design and the expected production volume, as the initial investment can be significant but pays off with efficiency in mass production.

How Does Transfer Die Stamping Differ from Other Methods?

Transfer die stamping utilizes a mechanical transfer system to move parts between different stations, allowing for more complex shapes and designs. This method is ideal for industries such as automotive and aerospace, where precision and flexibility are paramount. Buyers should consider the additional machinery and setup required, which can lead to higher upfront costs but offers the advantage of versatile manufacturing capabilities.

What Are the Advantages of Compound Die Stamping?

Compound die stamping combines both cutting and forming operations in a single die, making it an efficient choice for producing items like metal brackets and fasteners. This method simplifies the manufacturing process by reducing the number of operations and minimizing material waste. B2B buyers should evaluate the complexity of their desired shapes, as compound dies are best for simpler designs but can streamline production significantly.

Why Choose Blanking Die Stamping for Your Business Needs?

Blanking die stamping focuses on cutting out specific shapes from metal sheets, creating blanks for further processing. This method is widely used across various industries, including appliance and automotive manufacturing. Buyers benefit from the cost-effectiveness and versatility of blanking, particularly for high-volume runs. However, attention must be paid to waste management, as the leftover slugs can accumulate and require disposal.

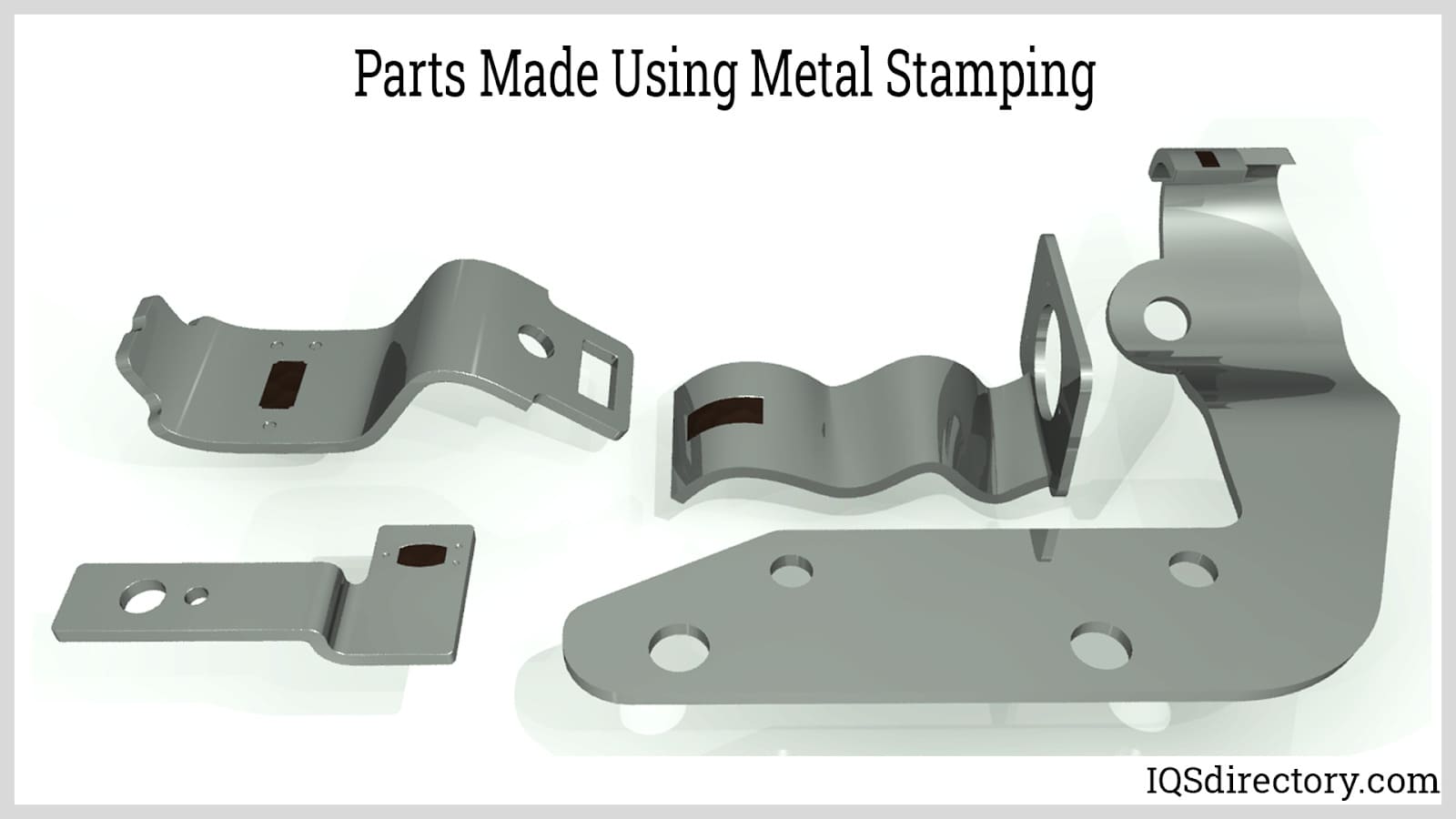

A stock image related to die stamping.

What Is the Role of Piercing Die Stamping in Manufacturing?

Piercing die stamping is specifically designed to create holes in metal sheets, with the resulting slug typically discarded. This method is commonly applied in sectors such as electronics and automotive manufacturing. B2B buyers should consider the efficiency of piercing for producing multiple holes in a single operation, although they may need to invest in additional finishing processes to ensure the edges of the holes are safe and smooth.

Key Industrial Applications of die stamping

| Industry/Sector | Specific Application of die stamping | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of metal brackets and fasteners | Enhances structural integrity and assembly efficiency | Supplier reliability, tooling capabilities, lead times |

| Aerospace | Manufacturing of precision parts and fittings | Ensures compliance with stringent safety standards | Certifications (e.g., AS9100), material quality, precision |

| Electronics | Creation of metal eyelets and washers | Improves product durability and performance | Customization options, production volume, cost-effectiveness |

| Construction & HVAC | Fabrication of metal shims and brackets | Provides support and stability in installations | Material specifications, local sourcing, delivery timelines |

| Consumer Goods | Stamping of decorative components | Enhances product appeal and differentiation | Design flexibility, finishing options, scalability |

How is Die Stamping Used in the Automotive Industry?

In the automotive sector, die stamping is crucial for producing metal brackets and fasteners that provide structural integrity to vehicles. These components are critical for assembling parts such as chassis and body panels, ensuring safety and durability. B2B buyers should prioritize suppliers with robust tooling capabilities and proven reliability, as delays in the supply chain can significantly impact production timelines. It’s essential to evaluate lead times and the supplier’s ability to meet high-volume demands, especially for automotive manufacturers operating in competitive markets.

What Role Does Die Stamping Play in Aerospace Manufacturing?

Die stamping in aerospace involves the manufacturing of precision parts and fittings that must adhere to strict safety and quality standards. Components produced through this process often include brackets, housing, and other intricate parts that are vital for aircraft performance and safety. International buyers from regions like Europe and the Middle East should focus on suppliers with relevant certifications, such as AS9100, which indicates compliance with aerospace industry standards. Material quality and precision are paramount, given the critical nature of aerospace applications.

How is Die Stamping Applied in Electronics Production?

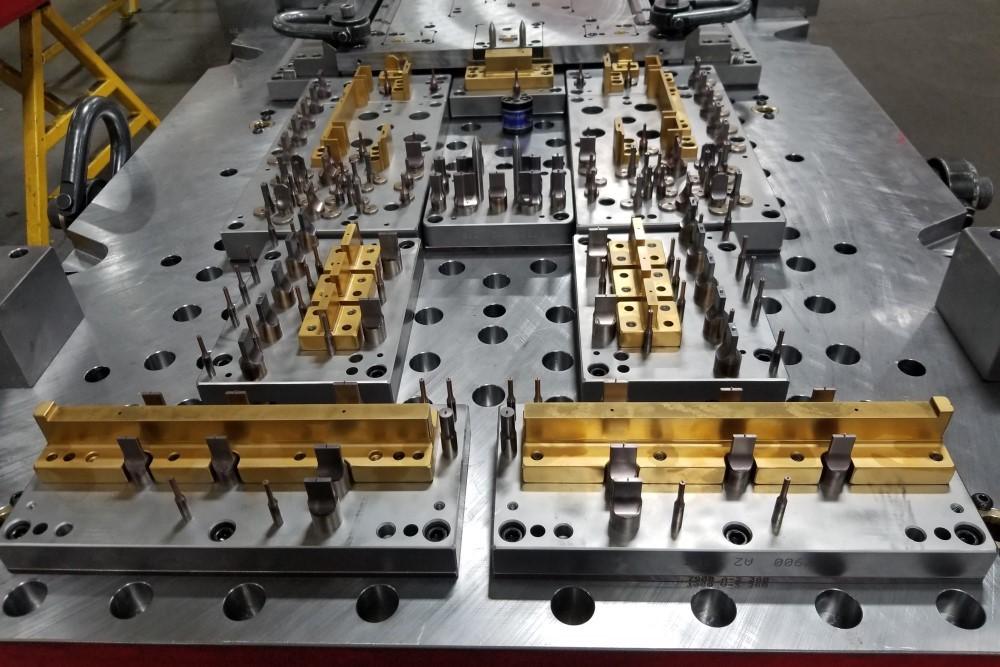

A stock image related to die stamping.

In the electronics industry, die stamping is employed to create components like metal eyelets and washers, which are essential for enhancing the durability and functionality of electronic devices. These components help in securing connections and providing insulation, thereby improving overall device performance. B2B buyers should seek suppliers that offer customization options to cater to specific electronic designs and requirements. Additionally, understanding production volumes and the cost-effectiveness of sourcing these components is critical for maintaining competitive pricing in the electronics market.

What are the Benefits of Die Stamping in Construction and HVAC?

Die stamping is extensively used in the construction and HVAC industries for fabricating metal shims and brackets. These components are essential for providing support and stability in various installations, from windows to HVAC systems. Buyers in these sectors should consider local sourcing options to reduce transportation costs and lead times. Furthermore, understanding material specifications is crucial, as different applications may require specific metal types or thicknesses to ensure durability and performance under varying environmental conditions.

How Does Die Stamping Enhance Consumer Goods?

In the consumer goods sector, die stamping is used to produce decorative components that enhance product appeal. This can include intricate designs for appliances, furniture, and packaging. For B2B buyers, sourcing partners that offer design flexibility and various finishing options is vital to achieving the desired aesthetic while maintaining cost efficiency. Scalability is also an important factor, as demand can fluctuate based on market trends, necessitating suppliers that can adapt to changing volumes without compromising quality.

3 Common User Pain Points for ‘die stamping’ & Their Solutions

Scenario 1: High Production Costs and Inefficiencies in Die Stamping

The Problem:

For many B2B buyers, particularly in emerging markets across Africa and South America, the initial investment in die stamping machinery can be daunting. With tight budgets, companies often face the challenge of balancing quality production and cost efficiency. Inefficiencies in the stamping process can lead to excessive scrap material, prolonged lead times, and ultimately, reduced profit margins. Buyers often find themselves trapped between sourcing high-quality dies that promise precision and managing operational costs effectively.

The Solution:

To combat high production costs, B2B buyers should focus on investing in advanced die stamping technologies that optimize material usage. Sourcing dies that utilize progressive stamping techniques can significantly reduce waste by allowing multiple operations to occur in one cycle. Additionally, conducting a thorough cost-benefit analysis of the die’s lifespan versus its initial cost can help buyers make informed decisions. Engaging with reputable suppliers who provide comprehensive maintenance packages can also ensure that equipment remains in peak condition, minimizing downtime and further controlling costs.

Moreover, integrating lean manufacturing principles into the die stamping process can streamline operations. This includes training staff on best practices for machine operation and maintenance, thus maximizing the use of machinery and reducing the likelihood of errors that lead to waste.

Scenario 2: Quality Control Issues in Stamped Parts

The Problem:

B2B buyers often encounter quality control issues when sourcing stamped parts, particularly when dealing with multiple suppliers across different regions like the Middle East and Europe. Variability in die design, material quality, and manufacturing processes can lead to inconsistent part dimensions, surface finishes, and mechanical properties. This inconsistency not only affects the final product’s performance but also strains supplier relationships and leads to costly rework or returns.

The Solution:

To mitigate quality control issues, buyers should prioritize suppliers that adhere to strict quality management systems, such as ISO 9001 certification. Establishing clear specifications for each stamped part, including tolerances and material requirements, can help ensure that suppliers understand the buyer’s quality expectations. Additionally, implementing a robust supplier evaluation and selection process can further reduce the risk of quality issues.

Conducting regular audits and performance reviews of suppliers will provide insights into their manufacturing processes and help buyers identify potential risks early. Utilizing technologies such as automated inspection systems can also enhance quality assurance by providing real-time feedback on part conformity, thus enabling immediate corrective actions.

Scenario 3: Difficulty in Sourcing Specialized Dies for Unique Applications

The Problem:

In diverse markets like Europe and Africa, buyers often face challenges when it comes to sourcing specialized dies for unique applications, such as those required for automotive or aerospace components. The complexity of designing and manufacturing custom dies can lead to long lead times and increased costs, causing delays in production schedules and impacting the overall supply chain.

The Solution:

To address the difficulty in sourcing specialized dies, buyers should consider forming partnerships with die manufacturers who specialize in custom solutions. Engaging with suppliers that offer design assistance can streamline the process, as they can provide insights into material selection, die design, and production techniques that align with the buyer’s specific needs.

Furthermore, investing in rapid prototyping technologies can significantly reduce lead times for custom dies. By utilizing 3D printing for initial die prototypes, buyers can test designs and make necessary adjustments before committing to full-scale production. This approach not only speeds up the development process but also helps minimize the risk of costly errors. Building strong communication channels with suppliers will also ensure that any changes in requirements or unforeseen challenges are addressed promptly, fostering a collaborative approach to problem-solving.

Strategic Material Selection Guide for die stamping

What Are the Key Properties of Common Materials Used in Die Stamping?

When selecting materials for die stamping, international B2B buyers must consider several factors, including mechanical properties, cost-effectiveness, and suitability for specific applications. Below is an analysis of four common materials used in die stamping: carbon steel, stainless steel, aluminum, and brass.

How Does Carbon Steel Perform in Die Stamping Applications?

Key Properties: Carbon steel is known for its high strength and hardness, making it suitable for heavy-duty applications. It typically has excellent wear resistance and can withstand high pressure and temperature, which is essential during the stamping process.

Pros & Cons: The advantages of carbon steel include its durability and relatively low cost compared to other materials. However, it is prone to corrosion if not properly treated, which could limit its application in humid or corrosive environments. Additionally, the manufacturing complexity can increase if heat treatment is required to enhance its properties.

Impact on Application: Carbon steel is compatible with various media, making it versatile for different industries. However, its susceptibility to rust may necessitate protective coatings, especially in regions with high humidity, such as parts of Africa and South America.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM A36 or DIN 10130. Understanding the local climate and potential corrosive factors is crucial for selecting the right grade of carbon steel.

What Are the Advantages of Using Stainless Steel in Die Stamping?

Key Properties: Stainless steel is renowned for its corrosion resistance, high strength, and ability to maintain structural integrity at elevated temperatures. It is often used in applications where hygiene is critical, such as in the food and medical industries.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and staining. However, it is generally more expensive than carbon steel and can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is ideal for applications requiring high cleanliness and corrosion resistance. Its compatibility with various media makes it suitable for diverse industries, including automotive and aerospace.

Considerations for International Buyers: Compliance with standards such as ASTM A240 or DIN 1.4301 is essential. Buyers should also consider the availability of stainless steel grades in their region, as sourcing may vary significantly between Africa, Europe, and South America.

Why Choose Aluminum for Die Stamping?

Key Properties: Aluminum is lightweight and possesses good corrosion resistance, making it an excellent choice for applications where weight savings are crucial. It has a lower melting point than steel, which can simplify the stamping process.

Pros & Cons: The advantages of aluminum include its lightweight nature and ease of fabrication. However, it is less durable than steel, which may limit its use in heavy-duty applications. Additionally, the cost of aluminum can be higher than carbon steel.

Impact on Application: Aluminum’s compatibility with various environmental conditions makes it suitable for automotive and aerospace applications. Its lightweight property is particularly beneficial in industries focused on fuel efficiency.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B209 and JIS H4000. The availability of aluminum may vary, and understanding local market conditions is vital for procurement.

What Role Does Brass Play in Die Stamping?

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It also has good thermal and electrical conductivity, making it suitable for specific applications.

Pros & Cons: The primary advantage of brass is its ability to resist corrosion and its aesthetic appeal, which is often favored in decorative applications. However, brass can be more expensive than steel and may not be suitable for high-stress applications.

Impact on Application: Brass is commonly used in electrical components and fittings due to its conductivity. Its resistance to corrosion makes it suitable for marine applications, particularly in regions with high humidity.

Considerations for International Buyers: Compliance with standards such as ASTM B36 and DIN 17660 is crucial. Buyers should also consider the cost implications of brass in comparison to other materials when budgeting for projects.

Summary Table of Material Selection for Die Stamping

| Material | Typical Use Case for die stamping | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive parts, heavy machinery | High strength and durability | Prone to corrosion | Low |

| Stainless Steel | Food processing, medical equipment | Corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace, automotive lightweight components | Lightweight and easy to fabricate | Less durable than steel | Medium |

| Brass | Electrical components, decorative fittings | Excellent machinability and corrosion resistance | Higher cost and limited stress applications | High |

In conclusion, selecting the appropriate material for die stamping involves a careful assessment of the specific requirements of the application, cost considerations, and compliance with relevant standards. Each material presents its own set of advantages and limitations, making it essential for international B2B buyers to align their choices with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for die stamping

What Are the Main Stages of Die Stamping Manufacturing Processes?

The die stamping manufacturing process involves several critical stages that ensure precision and quality in producing metal parts. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

1. Material Preparation

Material preparation is the first step in the die stamping process, focusing on selecting the right type and thickness of metal sheets. Common materials include steel, aluminum, and brass, which are chosen based on the final product’s requirements. The metal sheets are typically cut to the desired dimensions and cleaned to remove any contaminants. This step may involve processes such as shearing and deburring to ensure that the material is free of sharp edges and defects.

2. Forming

The forming stage is where the actual die stamping occurs. Specialized dies, made from hardened steel or carbide, are used to cut and shape the metal sheets. The operation can include various techniques such as blanking, piercing, and notching. The choice of technique depends on the design specifications of the part being produced. Die stamping is a cold-forming process, meaning it does not involve heat, which helps maintain the integrity of the material. During this phase, it’s essential to control parameters such as stamping speed and pressure to ensure consistent quality.

3. Assembly

Post-stamping, parts may require assembly, especially in complex products that consist of multiple components. This stage can involve welding, riveting, or the use of fasteners. For B2B buyers, understanding the assembly techniques used by suppliers can provide insights into the strength and durability of the final product.

4. Finishing

The finishing stage includes surface treatments such as painting, plating, or coating to enhance the product’s appearance and resistance to corrosion. This step is crucial for products that will face harsh environmental conditions. Buyers should inquire about the finishing techniques used by suppliers to ensure they meet industry standards and specific project requirements.

How Is Quality Assurance Implemented in Die Stamping?

Quality assurance (QA) in die stamping is vital for ensuring that the final products meet both international and industry-specific standards. For B2B buyers, understanding the QA process can help in selecting reliable suppliers.

Relevant International Standards and Certifications

International standards such as ISO 9001 are essential for ensuring quality management systems are in place. Additionally, industry-specific certifications such as CE marking for products sold in Europe and API standards for oil and gas components are critical indicators of compliance. B2B buyers should prioritize suppliers with these certifications, as they demonstrate a commitment to quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the die stamping process, typically categorized into three main areas:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production. Buyers should ensure that suppliers conduct thorough material inspections to confirm they meet specifications.

-

In-Process Quality Control (IPQC): During the stamping process, continuous monitoring is essential to identify defects early. This can include checks on die alignment, stamping pressure, and part dimensions.

-

Final Quality Control (FQC): After production, the finished parts undergo rigorous testing to ensure they meet the required standards. This may involve dimensional checks, functional testing, and visual inspections.

What Testing Methods Are Common in Die Stamping Quality Control?

Several testing methods are employed to verify the quality of stamped parts. Common techniques include:

-

Dimensional Inspection: Utilizing calipers and micrometers to ensure that parts meet specified dimensions.

-

Tensile Testing: Assessing the strength and ductility of the metal to ensure it can withstand operational stresses.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle inspection can identify internal defects without damaging the parts.

-

Visual Inspection: A thorough examination for surface defects or irregularities.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some actionable steps:

-

Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards. Buyers should request audit reports and certifications to confirm compliance.

-

Request Quality Assurance Documentation: Suppliers should provide documentation detailing their QC processes, including inspection and testing protocols.

-

Engage Third-Party Inspectors: For critical components, employing third-party inspection services can provide an unbiased assessment of the supplier’s quality control.

What Are the Quality Control Nuances for International Buyers?

When sourcing from suppliers in Africa, South America, the Middle East, and Europe, B2B buyers should be aware of specific nuances:

-

Cultural Differences: Understand that quality perceptions may vary by region. Building strong relationships with suppliers can foster better communication regarding quality expectations.

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Ensure that suppliers are compliant with local regulations and international standards to avoid issues in the supply chain.

-

Supply Chain Transparency: Seek suppliers that provide visibility into their sourcing and production processes, which can help mitigate risks related to quality and compliance.

Conclusion

In summary, understanding the die stamping manufacturing process and the associated quality assurance practices is essential for B2B buyers. By focusing on the main stages of production, recognizing the importance of quality control, and verifying suppliers’ processes, international buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘die stamping’

The purpose of this practical sourcing guide is to equip international B2B buyers with a step-by-step checklist for procuring die stamping services. This guide is particularly relevant for businesses in Africa, South America, the Middle East, and Europe looking to optimize their sourcing process and ensure quality in their die stamping projects.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for your die stamping project. This includes details such as material types, thickness, dimensions, and tolerances. Defining these parameters upfront will help you communicate effectively with potential suppliers and ensure they can meet your requirements.

- Material Considerations: Specify the types of metals you need (e.g., stainless steel, aluminum) and any special properties (e.g., corrosion resistance).

- Tolerances: Clearly state the acceptable tolerances for your stamped parts, as these can significantly impact the performance and fit of the final product.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in die stamping. Look for companies that have a strong reputation in the industry and relevant experience with projects similar to yours.

- Industry Associations: Check memberships in relevant industry associations or certifications that indicate a commitment to quality.

- Geographic Considerations: Consider suppliers in regions that offer competitive pricing and logistics advantages, especially if you’re sourcing from Africa, South America, or the Middle East.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. This step is critical to ensure you partner with reliable and capable manufacturers.

- Company Profiles: Request detailed profiles of the suppliers, including their manufacturing capabilities, technology used, and previous projects.

- References: Ask for references or case studies from clients in similar industries to assess their performance and reliability.

Step 4: Verify Supplier Certifications

Check for relevant industry certifications and standards. Compliance with international quality standards (like ISO 9001) is essential for ensuring that your products meet the necessary quality benchmarks.

- Quality Management Systems: Ensure the supplier has robust quality management practices in place to minimize defects and ensure consistency.

- Environmental Standards: Consider suppliers who comply with environmental regulations and sustainability practices, which are increasingly important for global sourcing.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the stamped parts. This will allow you to evaluate the quality and precision of their work.

- Testing for Fit and Functionality: Ensure the samples meet your specifications for fit and functionality.

- Feedback Loop: Use this opportunity to provide feedback and make any necessary adjustments before full-scale production begins.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish clear terms and conditions. This includes pricing, lead times, payment terms, and quality assurance processes.

- Pricing Transparency: Ensure that the pricing structure is clear and includes all potential costs.

- Delivery Timelines: Establish realistic delivery timelines based on your project needs and the supplier’s capabilities.

Step 7: Establish a Communication Plan

Set up a clear communication plan for ongoing collaboration. Effective communication is vital for addressing any issues that may arise during the production process.

- Regular Updates: Agree on regular check-ins to discuss progress, challenges, and any adjustments needed.

- Point of Contact: Designate a primary point of contact on both sides to streamline communication and decision-making.

By following this comprehensive checklist, international B2B buyers can enhance their die stamping procurement process, ensuring they partner with the right suppliers who can deliver high-quality, cost-effective solutions tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for die stamping Sourcing

What Are the Key Cost Components in Die Stamping Sourcing?

When sourcing die stamping services, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of metal significantly affects the overall price. Common metals like aluminum, stainless steel, and carbon steel vary in cost based on market demand and availability. Additionally, sourcing materials locally can mitigate import tariffs and reduce lead times.

-

Labor: Labor costs can differ greatly depending on the region. In countries with higher wages, such as Germany or Australia, labor can make up a larger percentage of the total cost. Conversely, sourcing from regions with lower labor costs, such as parts of Africa or South America, may offer savings but could also impact quality.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Buyers should inquire about how these costs are calculated and whether they are fixed or variable.

-

Tooling: Tooling is a significant upfront cost in die stamping. Custom tooling can be expensive, but it is essential for achieving precise specifications. Understanding the tooling lifespan and potential amortization over production runs can help buyers evaluate long-term costs.

-

Quality Control (QC): Robust QC processes ensure product reliability and compliance with specifications, which can add to the cost. Buyers should assess the QC measures in place and consider how these processes align with their quality requirements.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, can significantly impact total costs, especially for international buyers. Choosing the right Incoterms can help clarify responsibilities and minimize unexpected expenses.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the market norms for margins in the specific regions of interest can aid buyers in evaluating pricing fairness.

How Do Price Influencers Affect Die Stamping Costs?

Several factors can influence the pricing structure for die stamping services:

-

Volume and Minimum Order Quantities (MOQ): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Custom designs or specialized materials can increase costs. Buyers should weigh the necessity of custom features against potential price increases.

-

Quality and Certifications: Products that meet specific industry standards (ISO, AS9100, etc.) may come at a premium. Buyers must consider whether these certifications are essential for their application.

-

Supplier Factors: The supplier’s reputation, experience, and location can all influence pricing. Established suppliers with a strong track record may charge more but could offer better reliability and service.

-

Incoterms: The chosen Incoterms dictate the division of costs and responsibilities between buyer and seller. Understanding these terms can help buyers negotiate better shipping and logistics arrangements.

What Are the Best Negotiation Tips for International B2B Buyers?

-

Research and Compare: Gather quotes from multiple suppliers to understand the market rate for die stamping services. This information will empower you during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial price, consider all associated costs, including logistics, customs, and potential downtime. A lower upfront cost may lead to higher long-term expenses.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and more favorable terms in future negotiations.

-

Leverage Volume: If possible, negotiate based on projected future orders. Suppliers may be more inclined to offer discounts for long-term commitments.

-

Be Clear About Expectations: Clearly communicate your specifications, quality requirements, and timelines to avoid misunderstandings that could lead to increased costs later.

Conclusion: Understanding Pricing Nuances for International Buyers

Navigating the complexities of die stamping sourcing requires a solid grasp of cost components and influencing factors. For international buyers from Africa, South America, the Middle East, and Europe, being informed about local market conditions, material availability, and supplier dynamics is essential. Always approach negotiations with a comprehensive understanding of both the upfront and long-term costs involved to secure the best deal.

- Disclaimer: Prices mentioned in this analysis are indicative and can vary based on specific project requirements, market conditions, and supplier negotiations.*

Alternatives Analysis: Comparing die stamping With Other Solutions

When exploring manufacturing solutions, B2B buyers often find themselves weighing the benefits of die stamping against other viable methods. Understanding the strengths and weaknesses of each approach can significantly impact production efficiency, cost-effectiveness, and overall operational success. In this section, we will compare die stamping with two alternative methods: laser cutting and metal fabrication.

Comparison Table of Die Stamping and Alternatives

| Comparison Aspect | Die Stamping | Laser Cutting | Metal Fabrication |

|---|---|---|---|

| Performance | High speed, precision, and repeatability | Excellent precision, suitable for complex shapes | Versatile; allows for various processes including cutting and bending |

| Cost | High initial die cost, but low per-part cost for large runs | Lower initial investment but higher cost per part for larger volumes | Moderate initial investment; costs vary depending on processes used |

| Ease of Implementation | Requires specialized tooling and setup | Easier setup; can handle various materials without extensive tooling | Flexible; can be adapted for different materials and designs |

| Maintenance | High maintenance for dies; regular checks needed | Low maintenance; mainly involves equipment upkeep | Varies by process; general maintenance is required |

| Best Use Case | Ideal for high-volume production of uniform parts | Best for low to medium volume with complex designs | Suitable for custom parts and lower volume production |

What Are the Advantages and Disadvantages of Laser Cutting as an Alternative?

Laser Cutting is a popular alternative to die stamping, especially for intricate designs. It uses a focused laser beam to cut through materials, offering exceptional precision. One of the main advantages of laser cutting is its flexibility; it can handle a variety of materials such as metals, plastics, and wood, making it suitable for diverse applications. However, the cost per part can become prohibitive for large-scale production, and while it excels in precision, it may not achieve the same speed as die stamping in high-volume scenarios.

How Does Metal Fabrication Compare to Die Stamping?

Metal Fabrication encompasses a range of processes including cutting, bending, and assembling metal components. This method is highly versatile, allowing manufacturers to create custom parts tailored to specific needs. Metal fabrication can be more adaptable than die stamping, particularly for smaller runs or unique designs. However, it may not achieve the same efficiency for mass production as die stamping, and the costs can vary widely depending on the processes involved and the complexity of the part being fabricated.

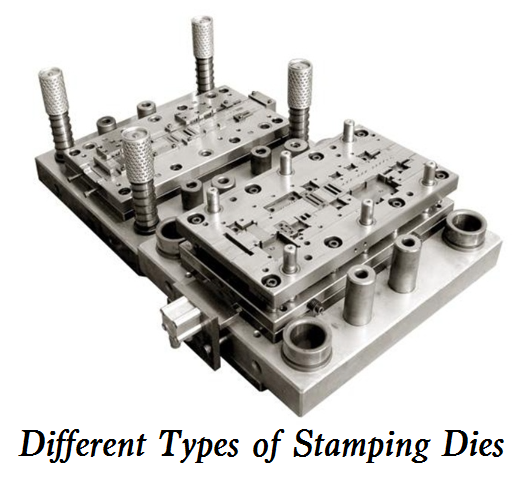

A stock image related to die stamping.

Conclusion: How Should B2B Buyers Choose the Right Manufacturing Solution?

For international B2B buyers, selecting the right manufacturing method depends on several factors including production volume, part complexity, and budget constraints. Die stamping is often the preferred choice for high-volume production of uniform parts due to its efficiency and low per-part cost. However, if flexibility and customization are paramount, or if the production volume is lower, alternatives like laser cutting or metal fabrication may be more appropriate. By carefully assessing specific needs and evaluating these alternatives, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for die stamping

What Are the Key Technical Properties of Die Stamping?

Understanding the technical specifications of die stamping is crucial for international B2B buyers, especially when sourcing components across different regions. Here are some essential properties to consider:

1. Material Grade

The material grade of the metal being stamped is a primary factor in determining the performance and durability of the final product. Common materials include stainless steel, aluminum, and carbon steel, each offering different mechanical properties. Selecting the right material grade ensures that the stamped parts meet the required strength and corrosion resistance for their intended application.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In die stamping, tight tolerances are often required to ensure that parts fit together correctly in assemblies. Understanding tolerance specifications helps buyers avoid costly rework and ensures that parts meet the necessary quality standards, which is particularly important in industries like automotive and aerospace.

3. Cutting Clearance

Cutting clearance is the gap between the cutting edges of the die and the material being stamped. It is typically expressed as a percentage of the material thickness. The correct cutting clearance is vital for achieving clean cuts and minimizing wear on the die. Buyers should be aware that improper clearance can lead to defects in the finished product, such as burrs or rough edges.

4. Die Life

Die life refers to the number of cycles a die can perform before it requires maintenance or replacement. A longer die life reduces downtime and increases production efficiency, making it a key consideration for B2B buyers. Understanding die life can help in assessing the total cost of ownership for stamped components, allowing for better budget planning.

5. Surface Finish

The surface finish of stamped parts affects their aesthetic appeal and functionality. Different applications may require specific finishes, such as smooth, textured, or coated surfaces. Buyers need to specify surface finish requirements to ensure compatibility with their product designs and performance expectations.

What Are Common Trade Terms in Die Stamping?

Familiarizing yourself with industry terminology is essential for effective communication and negotiation in die stamping. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs in the supply chain is crucial for buyers looking to source components that meet specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategies and manage inventory effectively. It is particularly important for international buyers who may face higher shipping costs for small orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. Buyers should provide detailed specifications in their RFQs to receive accurate quotes, which aids in budget planning and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers negotiate contracts and understand their obligations in cross-border transactions.

5. Lead Time

Lead time is the time it takes from placing an order to receiving the finished product. Understanding lead times is critical for buyers to align their production schedules and manage supply chain disruptions effectively.

By grasping these essential technical properties and industry terminology, B2B buyers can make informed decisions when sourcing die-stamped components, ensuring they meet their quality, cost, and delivery requirements.

Navigating Market Dynamics and Sourcing Trends in the die stamping Sector

What Are the Current Market Dynamics and Key Trends in the Die Stamping Sector?

The global die stamping market is witnessing significant transformation driven by technological advancements, increasing automation, and rising demand for precision-engineered components. Key markets in Africa, South America, the Middle East, and Europe are experiencing a surge in manufacturing activities, particularly in the automotive, aerospace, and electronics sectors. As these regions strive for industrial growth, international B2B buyers are focusing on sourcing high-quality stamped parts that meet stringent specifications.

Emerging trends such as the adoption of Industry 4.0 technologies—including IoT, AI, and machine learning—are revolutionizing the die stamping process. These technologies enhance operational efficiency, reduce downtime, and improve product quality, making them attractive to buyers seeking competitive advantages. Furthermore, as companies adopt just-in-time (JIT) manufacturing, the demand for reliable suppliers capable of rapid prototyping and small-batch production is on the rise.

Another notable trend is the increasing use of advanced materials, such as high-strength steel and lightweight composites, which require specialized die stamping techniques. Buyers must be aware of suppliers who have invested in these technologies to ensure they receive components that align with current material trends. Additionally, geopolitical factors and supply chain disruptions are pushing international buyers to diversify their supplier base, focusing on local sourcing options to mitigate risks.

How Important Is Sustainability and Ethical Sourcing in Die Stamping?

In today’s market, sustainability and ethical sourcing are not just buzzwords; they are essential considerations for B2B buyers in the die stamping sector. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly held accountable for their carbon footprint. Buyers are encouraged to seek suppliers who employ eco-friendly practices, such as reducing waste and utilizing energy-efficient machinery.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should prioritize partnerships with suppliers who adhere to fair labor practices and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) signal a supplier’s dedication to sustainability.

The use of green materials in die stamping processes—such as recycled metals and biodegradable lubricants—can significantly reduce environmental impact. By choosing suppliers that focus on sustainable practices, international B2B buyers can enhance their brand reputation, appeal to environmentally conscious customers, and potentially benefit from tax incentives or regulatory advantages.

How Has Die Stamping Evolved Over Time?

The evolution of die stamping can be traced back to the industrial revolution when it was primarily utilized for manufacturing simple metal components. Initially, the process relied heavily on manual labor and rudimentary tooling. Over the decades, significant advancements in technology and materials have transformed die stamping into a highly automated and precise manufacturing method.

Today, stamping dies are engineered with advanced materials such as carbide and tool steel, allowing for more complex geometries and higher production rates. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) has further refined the design and production processes, enabling manufacturers to achieve tighter tolerances and enhanced quality control.

As the market continues to evolve, the focus on efficiency, sustainability, and ethical practices remains paramount. This progression not only meets the demands of modern manufacturing but also positions the die stamping sector as a key player in the global supply chain, offering numerous opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of die stamping

-

How do I choose the right die stamping supplier for my business?

Selecting the right die stamping supplier involves evaluating several factors. Start by researching their experience and expertise in your specific industry. Check customer testimonials and case studies to assess their reliability. It’s also important to inquire about their certifications and quality control processes. A good supplier should offer customization options that align with your needs and have the capacity to meet your volume requirements. Finally, ensure they have a solid logistics framework to deliver on time, especially for international shipping. -

What is the best way to ensure quality in die stamping production?

To ensure quality in die stamping production, implement a robust quality assurance (QA) process. This includes defining clear specifications for the parts you need and ensuring your supplier adheres to them. Regular inspections and testing during the production process can help catch defects early. Additionally, consider suppliers who are ISO-certified or have other relevant quality certifications. Establishing a feedback loop with your supplier can also enhance quality, allowing for continuous improvement based on your observations. -

What are the common minimum order quantities (MOQs) for die stamping products?

Minimum order quantities (MOQs) for die stamping products can vary widely based on the supplier and the complexity of the parts. Generally, MOQs can range from a few hundred to several thousand units. Suppliers often set MOQs to ensure that production costs are justified. For international buyers, it is crucial to discuss MOQs upfront and explore options for smaller orders, especially if you are testing a new product or entering a new market. -

How can I customize die stamping parts for my specific application?

Customization in die stamping begins with clear communication of your requirements to the supplier. Discuss the specific dimensions, materials, and finishes you need. Many suppliers offer design assistance and can help optimize your part for manufacturability. Providing 3D models or prototypes can facilitate better understanding and execution of your design. Always verify that the supplier has the necessary capabilities to handle your customization requests effectively. -

What payment terms should I expect when sourcing die stamping services?

Payment terms for die stamping services can vary, but common practices include a deposit upfront (typically 30-50%) with the balance due upon completion or delivery. Some suppliers may offer net 30 or net 60 terms, especially for established relationships. Be sure to clarify terms before finalizing the agreement, as international transactions may also involve currency exchange and additional fees. Ensure you have a clear understanding of all costs involved to avoid surprises. -

What logistics considerations should I keep in mind when sourcing die stamping internationally?

When sourcing die stamping internationally, logistics play a crucial role in the overall success of your procurement. Evaluate the supplier’s shipping capabilities, including their experience with customs and international regulations. Discuss lead times for production and shipping, as these can significantly impact your supply chain. Additionally, consider incoterms (International Commercial Terms) to clarify responsibilities for shipping costs, insurance, and delivery locations. Building a good relationship with your logistics provider can also help streamline the process. -

How do I handle communication barriers when sourcing die stamping services from different countries?

Handling communication barriers in international die stamping sourcing involves establishing clear and consistent channels of communication. Utilize tools like video calls, emails, and project management software to facilitate discussions. If language differences exist, consider hiring a translator or using translation software to ensure accurate understanding. Providing visual aids, such as drawings or prototypes, can also bridge gaps. Regular updates and feedback can help maintain alignment and address any issues promptly. -

What are the key factors influencing the cost of die stamping services?

The cost of die stamping services is influenced by several factors, including material selection, complexity of the design, and production volume. Materials like stainless steel or aluminum can vary significantly in price, affecting overall costs. The complexity of the die and required tooling also plays a role; intricate designs may require more expensive and time-consuming processes. Additionally, economies of scale can lead to lower per-unit costs with higher production volumes. Always request detailed quotes to understand the breakdown of costs involved.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for die stamping

What Are the Key Takeaways for International B2B Buyers in Die Stamping?

In conclusion, strategic sourcing in die stamping is essential for international B2B buyers aiming to enhance their supply chain efficiency and cost-effectiveness. By understanding the complexities of die stamping processes, such as cutting, forming, and the various types of dies, businesses can identify the right manufacturing partners who align with their production needs. Factors such as material selection, production volume, and technological capabilities should be prioritized when evaluating potential suppliers, particularly for companies operating in diverse regions like Africa, South America, the Middle East, and Europe.

How Can Strategic Sourcing Shape Future Operations?

As the demand for precision-engineered components continues to rise, investing in strategic sourcing will not only ensure competitive pricing but also foster innovation and quality in product offerings. Buyers are encouraged to leverage the growing capabilities of local manufacturers while considering global suppliers who can provide advanced technologies and expertise.

What Should International Buyers Do Next?

Looking ahead, B2B buyers should actively seek partnerships that facilitate flexibility and scalability in their operations. Engaging with suppliers who demonstrate a commitment to sustainability and technological advancement can lead to long-term benefits. By prioritizing strategic sourcing in die stamping, businesses can position themselves for success in an increasingly competitive market. Start exploring potential partnerships today to unlock new opportunities and drive your business forward.