Unlock Cost Savings: The Ultimate Guide to Aluminum Profiles (2025)

Introduction: Navigating the Global Market for aluminum profiles

In today’s competitive global market, sourcing aluminum profiles efficiently can be a significant challenge for international B2B buyers. With diverse applications ranging from construction to manufacturing, selecting the right aluminum profiles involves navigating complex supplier networks and understanding varying quality standards. This guide aims to simplify that process by providing a comprehensive overview of aluminum profiles, including types, applications, and key considerations for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe—particularly the UK and Italy—will find actionable insights that empower them to make informed purchasing decisions. The guide addresses common questions such as how to evaluate suppliers, the cost factors to consider, and the implications of different profile specifications. By the end of this guide, you will be equipped with the knowledge to effectively source aluminum profiles that meet your specific business needs while optimizing both quality and cost.

Understanding the global landscape of aluminum profiles is essential for maximizing operational efficiency and ensuring the success of your projects. With the right information and strategies at your disposal, you can confidently navigate the complexities of this market and secure the best possible deals for your organization.

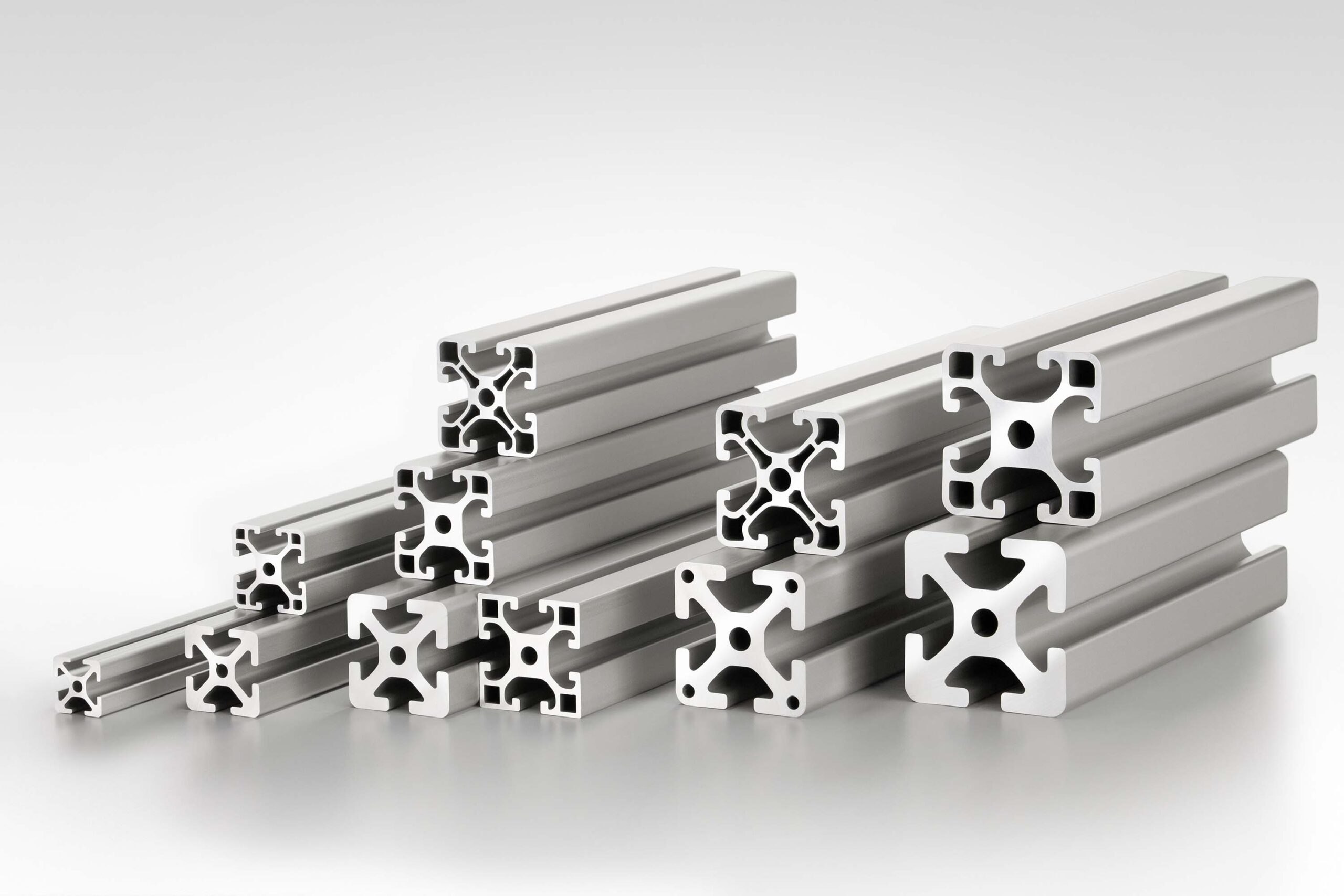

Understanding aluminum profiles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-Slot Profiles | Features multiple slots for easy assembly and customization | Industrial framing, workstations, and automation systems | Pros: Versatile, easy to assemble, and adjustable. Cons: Can be more expensive than traditional profiles. |

| Structural Profiles | Heavy-duty profiles designed for load-bearing applications | Construction, transport, and heavy machinery | Pros: High strength and durability. Cons: Limited design flexibility compared to lighter profiles. |

| Decorative Profiles | Aesthetic designs used for visual appeal | Architectural elements and furniture design | Pros: Enhances visual appeal, customizable finishes. Cons: May not be suitable for structural applications. |

| Angle Profiles | L-shaped profiles used for reinforcement and framing | Construction, shelving, and brackets | Pros: Simple design, cost-effective. Cons: Limited applications compared to other profile types. |

| Round & Square Tubes | Hollow profiles available in various diameters | Structural supports and piping systems | Pros: Lightweight yet strong, versatile. Cons: May require additional fittings for connections. |

What are T-Slot Profiles and Their Applications?

T-Slot profiles are characterized by their multiple slots along the length, allowing for easy assembly and customization. They are widely used in industrial framing, workstations, and automation systems. Buyers should consider the versatility and adjustability these profiles offer, which can lead to significant time savings during assembly. However, they may come at a higher cost compared to traditional profiles, making it essential to assess the long-term value against initial expenses.

How Do Structural Profiles Differ from Other Types?

Structural profiles are designed for heavy-duty applications, providing high strength and durability for load-bearing structures. Commonly used in construction, transport, and heavy machinery, these profiles are ideal for projects requiring robust support. Buyers should prioritize structural integrity and material quality when selecting these profiles. While they excel in strength, their limited design flexibility can be a drawback in applications requiring aesthetic considerations.

Why Choose Decorative Profiles for Aesthetic Applications?

Decorative profiles are specifically designed to enhance visual appeal in architectural elements and furniture design. These profiles come in various shapes and finishes, allowing for extensive customization. B2B buyers should consider the aesthetic impact and branding opportunities these profiles provide. However, it’s important to note that decorative profiles may not be suitable for structural applications, which necessitates careful consideration of their intended use.

What are the Advantages of Angle Profiles?

Angle profiles, with their L-shaped design, are primarily used for reinforcement and framing in construction and shelving applications. They are simple, cost-effective, and provide reliable support. Buyers should evaluate the profile’s strength-to-weight ratio and its ease of installation. While angle profiles are versatile, their limited applications compared to other profile types may restrict their use in more complex structures.

How Do Round and Square Tubes Serve B2B Needs?

Round and square tubes are hollow aluminum profiles that offer a balance of lightweight construction and strength. They are commonly utilized as structural supports and in piping systems. B2B buyers should appreciate the versatility these profiles provide, as they can be used in a wide range of applications. However, the requirement for additional fittings to connect these tubes may add to the overall project costs, necessitating careful planning in procurement.

Key Industrial Applications of aluminum profiles

| Industry/Sector | Specific Application of Aluminum Profiles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Machine Frames | Lightweight yet strong structures that enhance mobility and safety in production environments. | Ensure profiles meet specific load-bearing requirements and consider local availability to reduce lead times. |

| Construction | Modular Building Systems | Quick assembly and disassembly, reducing construction time and costs. | Look for corrosion-resistant finishes to withstand varying climates, especially in humid regions. |

| Automotive | Assembly Line Fixtures | Improved efficiency in assembly processes through tailored solutions that optimize workflow. | Consider profiles that can accommodate automation technology and ensure compatibility with existing systems. |

| Renewable Energy | Solar Panel Mounting Structures | Durable and lightweight options that withstand environmental stresses while ensuring optimal panel orientation. | Assess the strength and thermal properties of profiles to ensure they meet specific regional weather conditions. |

| Electronics | Enclosures for Electronics | Enhanced protection for sensitive components, improving lifespan and reliability of products. | Focus on profiles that allow for effective thermal management and ease of access for maintenance. |

How Are Aluminum Profiles Used in Manufacturing?

In the manufacturing sector, aluminum profiles are extensively used to create custom machine frames. These frames serve as the backbone of production equipment, providing stability and support while being lightweight enough to facilitate mobility. By integrating aluminum profiles, manufacturers can solve common problems such as equipment wear and tear due to heavy materials. International buyers should consider the specific load-bearing requirements of their operations and the availability of profiles in their region to minimize lead times and costs.

What Role Do Aluminum Profiles Play in Construction?

In construction, aluminum profiles are integral to modular building systems, allowing for rapid assembly and disassembly. This flexibility not only accelerates project timelines but also reduces labor costs, making it an attractive option for developers. The profiles can be designed to withstand various environmental factors, which is crucial for projects in diverse climates, particularly in Africa and the Middle East. Buyers should prioritize corrosion-resistant finishes to ensure longevity in their specific environmental conditions.

How Are Aluminum Profiles Applied in the Automotive Industry?

Aluminum profiles are vital in the automotive industry, particularly for creating assembly line fixtures. These profiles enhance workflow efficiency by offering tailored solutions that accommodate various assembly processes. By using lightweight materials, automotive manufacturers can also reduce overall vehicle weight, leading to improved fuel efficiency. Buyers should ensure that the profiles can integrate with existing automation technology and meet industry standards for safety and performance.

What Benefits Do Aluminum Profiles Provide in Renewable Energy?

In the renewable energy sector, aluminum profiles are used for solar panel mounting structures. Their lightweight nature and strength enable the construction of durable mounts that can withstand harsh weather conditions while optimizing panel orientation for maximum energy absorption. International buyers should assess the thermal and mechanical properties of aluminum profiles to ensure they are suitable for the specific weather conditions prevalent in their regions, particularly for projects in Europe and South America.

How Are Aluminum Profiles Utilized in Electronics?

Aluminum profiles are commonly used in the electronics industry to create enclosures for sensitive components. These profiles provide essential protection against environmental factors while allowing for effective thermal management, which is crucial for maintaining the reliability of electronic devices. For international buyers, it is important to consider profiles that facilitate easy access for maintenance and are compatible with the specific cooling requirements of their products.

3 Common User Pain Points for ‘aluminum profiles’ & Their Solutions

Scenario 1: Sourcing the Right Aluminum Profiles for Unique Applications

The Problem: B2B buyers often struggle to find aluminum profiles that meet their specific application requirements. For instance, a company in South America might need profiles that not only fit precise dimensions but also comply with local safety standards and environmental regulations. The challenge is compounded by the variety of profiles available, which can lead to confusion and potential delays in project timelines. Furthermore, many suppliers may not provide clear specifications or detailed technical information, making it hard for buyers to determine the best fit for their needs.

The Solution: To effectively source the right aluminum profiles, buyers should begin by clearly defining their project requirements, including dimensions, load-bearing capacity, and any specific regulatory compliance needs. Engaging with suppliers who offer customizable solutions can significantly enhance this process. For instance, platforms like Misumi provide extensive catalogs with options for custom dimensions and finishes, ensuring that buyers can find exactly what they need. Additionally, requesting technical data sheets and engaging in direct communication with suppliers can clarify any ambiguities regarding the profiles’ specifications. By investing time upfront in understanding the product range and utilizing supplier expertise, buyers can streamline their procurement process and avoid costly mistakes.

Scenario 2: Managing Cost Efficiency in Aluminum Profile Purchases

The Problem: Many businesses face the challenge of managing costs while sourcing aluminum profiles. For example, a manufacturer in Europe may find that prices vary significantly between suppliers, leading to confusion and potential overspending. Moreover, hidden costs such as shipping fees, tariffs, and minimum order quantities can further complicate budgeting. This is particularly critical for businesses operating on thin margins, where every dollar counts.

The Solution: To enhance cost efficiency, buyers should adopt a comprehensive procurement strategy that includes evaluating total landed costs, not just the initial purchase price. This involves calculating all associated costs, including shipping, customs duties, and any potential tariffs, especially when sourcing from international suppliers in Africa or the Middle East. Utilizing platforms that offer transparent pricing and bulk purchasing discounts can also help reduce expenses. Buyers should consider establishing long-term relationships with suppliers who can provide consistent quality at competitive prices, as negotiating volume discounts can lead to substantial savings. Additionally, leveraging local suppliers can minimize shipping costs and lead times, further enhancing overall budget management.

Scenario 3: Ensuring Quality and Consistency in Aluminum Profiles

The Problem: Quality control is a significant concern for B2B buyers, particularly when sourcing aluminum profiles for critical applications such as structural frameworks or custom machinery. A business in Africa might receive profiles that vary in thickness or finish, leading to compatibility issues during assembly and ultimately affecting the integrity of the final product. This inconsistency can result in increased waste, project delays, and reputational damage.

The Solution: To ensure quality and consistency, buyers should prioritize suppliers with robust quality assurance processes and certifications. Requesting samples before making a bulk order can be a critical step to verify that the profiles meet the required specifications. Furthermore, establishing clear quality standards in the procurement agreement can help mitigate risks. Implementing a system for regular quality audits and supplier evaluations can also foster continuous improvement. For those involved in complex projects, utilizing advanced software for 3D modeling and simulation can help assess how different profiles will perform under various conditions, ultimately leading to more informed purchasing decisions. By prioritizing quality from the outset, buyers can enhance their project outcomes and maintain strong supplier relationships.

Strategic Material Selection Guide for aluminum profiles

When selecting aluminum profiles for various applications, understanding the properties and implications of different materials is crucial for international B2B buyers. Here, we analyze four common materials used for aluminum profiles, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of 6061 Aluminum Alloy Profiles?

6061 aluminum alloy is one of the most versatile and widely used materials for aluminum profiles. It offers excellent corrosion resistance, good weldability, and medium-to-high strength. With a temperature rating of up to 150°C (302°F), it is suitable for various applications, including structural components and frames.

Pros: 6061 aluminum is durable and easy to machine, making it ideal for custom applications. Its relatively low cost and availability in different shapes and sizes make it a popular choice.

Cons: While it has good corrosion resistance, it may not be suitable for highly corrosive environments without additional protective coatings. Its strength is lower compared to other alloys like 7075.

Impact on Application: 6061 is compatible with a wide range of media, making it suitable for both indoor and outdoor applications.

Considerations for International Buyers: Compliance with standards such as ASTM B221 and EN 573 is essential. Buyers should also consider local availability and shipping costs, especially in regions like Africa and South America.

How Does 7075 Aluminum Alloy Compare for High-Strength Applications?

7075 aluminum alloy is known for its exceptional strength-to-weight ratio, making it ideal for high-performance applications such as aerospace and military components. It has a higher temperature rating, up to 120°C (248°F), and offers good fatigue resistance.

Pros: The high strength of 7075 allows for thinner profiles, reducing overall weight without sacrificing performance. It is also highly resistant to stress corrosion cracking.

Cons: The alloy is more expensive and less readily available than 6061. Additionally, it is more challenging to weld and machine, which can increase manufacturing complexity.

Impact on Application: 7075 is suitable for applications requiring high strength and durability, but it may not be the best choice for environments with high corrosion potential.

Considerations for International Buyers: Buyers should ensure compliance with military and aerospace standards like MIL-A-8625 and ASTM B211. Understanding local regulations and certifications is crucial, especially in the Middle East and Europe.

What Are the Advantages of 5083 Aluminum Alloy for Marine Applications?

5083 aluminum alloy is particularly known for its exceptional performance in marine environments. It offers excellent corrosion resistance, especially against seawater, and maintains strength at elevated temperatures.

Pros: 5083 is highly durable and can withstand harsh conditions, making it ideal for shipbuilding and offshore structures. Its weldability is also a significant advantage.

Cons: The cost of 5083 is generally higher than that of 6061 and 7075, which may deter budget-conscious buyers. Additionally, its machining properties are less favorable, often requiring specialized tools.

Impact on Application: 5083 is specifically designed for marine applications, ensuring long-lasting performance in saltwater environments.

Considerations for International Buyers: Compliance with marine standards such as ASTM B928 and ISO 21457 is vital. Buyers should also consider local sourcing options to reduce shipping costs, particularly in coastal regions of Africa and South America.

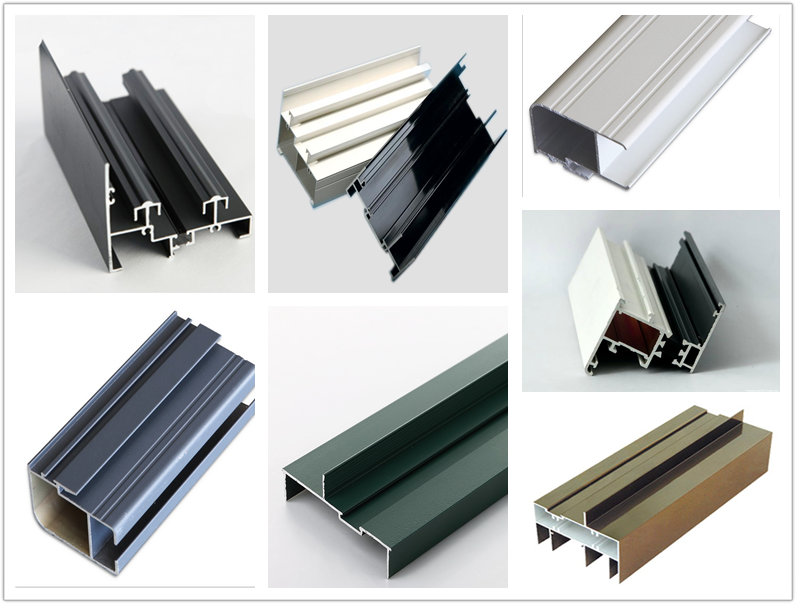

Why Choose 6063 Aluminum Alloy for Architectural Applications?

6063 aluminum alloy is favored for architectural applications due to its excellent extrudability and surface finish. It is often used in window frames, doors, and architectural facades.

A stock image related to aluminum profiles.

Pros: 6063 offers good corrosion resistance and is easy to anodize, providing aesthetic finishes. It is also relatively lightweight, which is beneficial for large structures.

Cons: While it has good mechanical properties, it is not as strong as 6061 or 7075, which may limit its use in structural applications.

Impact on Application: 6063 is ideal for applications requiring intricate designs and high-quality finishes, making it popular in the construction industry.

Considerations for International Buyers: Compliance with architectural standards such as EN 12020 is essential. Buyers should also consider the aesthetic preferences of local markets, particularly in Europe and the Middle East.

Summary Table of Material Selection for Aluminum Profiles

| Material | Typical Use Case for aluminum profiles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 | Structural components, frames | Versatile, good weldability | Lower strength compared to 7075 | Medium |

| 7075 | Aerospace, military components | Exceptional strength | Higher cost, difficult to machine | High |

| 5083 | Marine applications | Excellent corrosion resistance | Higher cost, specialized machining | High |

| 6063 | Architectural applications | Great extrudability, aesthetic finishes | Lower strength than other alloys | Medium |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum profiles

What Are the Main Stages of Manufacturing Aluminum Profiles?

Manufacturing aluminum profiles involves several key stages that ensure the final product meets the desired specifications and quality standards. Understanding these processes is crucial for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Material Preparation: How Is Raw Aluminum Processed?

The manufacturing process begins with material preparation, where aluminum ingots or billets are selected based on the intended application. These materials are typically made from high-grade aluminum alloy, ensuring optimal strength and durability. The preparation involves several steps:

- Melting: The aluminum is melted in a furnace at high temperatures, typically around 660°C (1220°F).

- Alloying: Specific alloying elements, such as silicon or magnesium, may be added to enhance properties like corrosion resistance and strength.

- Casting: The molten aluminum is cast into billets, which are then cooled and solidified for further processing.

This stage is critical as the quality of the raw material directly influences the final product’s performance.

Forming: What Techniques Are Used to Shape Aluminum Profiles?

Once the aluminum billets are prepared, the next step is forming, where the material is shaped into profiles. This can be achieved through various techniques, including:

- Extrusion: The most common method, where heated aluminum is forced through a die to create the desired shape. This process allows for the production of complex profiles with precise dimensions.

- Rolling: In some cases, aluminum sheets may be rolled to create flat profiles, which can later be cut to size.

- Forging: This method involves shaping the aluminum using compressive forces, often used for high-strength applications.

These techniques enable manufacturers to create a wide range of profiles, from simple bars to intricate designs used in construction and automotive applications.

Assembly: How Are Aluminum Profiles Joined Together?

In the assembly phase, aluminum profiles may be joined together using various methods depending on the application. Common techniques include:

- Welding: Different welding methods, such as TIG or MIG, are used to join aluminum components securely.

- Mechanical Fastening: Bolts, screws, or rivets may be used for assembly, allowing for easy disassembly and repair.

- Adhesives: Specialized adhesives can bond aluminum profiles without the need for mechanical fasteners, offering a clean aesthetic.

The choice of assembly method impacts the structural integrity and appearance of the final product, which is particularly important for B2B buyers in industries like construction and manufacturing.

Finishing: What Treatments Are Applied to Enhance Aluminum Profiles?

Finishing processes are crucial for improving the aesthetic and functional properties of aluminum profiles. Common finishing treatments include:

- Anodizing: This electrochemical process enhances corrosion resistance and allows for dyeing, adding color to the profiles.

- Powder Coating: A dry powder is applied and then cured, providing a durable and attractive finish.

- Polishing: This technique enhances the surface finish, making it smooth and reflective.

These finishing processes not only improve the appearance of the profiles but also enhance their durability and lifespan, making them suitable for various applications.

How Is Quality Assurance Implemented in Aluminum Profile Manufacturing?

Quality assurance (QA) is critical in ensuring that aluminum profiles meet international standards and customer expectations. B2B buyers must understand the QA processes to ensure they are sourcing high-quality products.

What International Standards Are Relevant for Aluminum Profiles?

Several international standards govern the quality of aluminum profiles, with ISO 9001 being one of the most recognized. This standard focuses on quality management systems, ensuring that manufacturers have processes in place to consistently produce high-quality products. Other relevant standards include:

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: For aluminum profiles used in the oil and gas industry, adherence to American Petroleum Institute standards is crucial.

Understanding these standards helps buyers assess the credibility and reliability of their suppliers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that products meet specified standards. Key QC checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects early.

- Final Quality Control (FQC): A thorough inspection of finished products to ensure they meet quality standards before shipping.

These checkpoints help prevent defects and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used for Aluminum Profiles?

To verify the quality of aluminum profiles, various testing methods are employed:

- Mechanical Testing: Evaluates properties such as tensile strength, yield strength, and elongation.

- Dimensional Inspection: Ensures that profiles meet specified dimensions using tools like calipers and gauges.

- Surface Testing: Checks for surface defects, including scratches, corrosion, and finish quality.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure they are receiving products that meet their quality requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure the reliability of their products. Here are actionable steps buyers can take:

- Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and quality assurance measures.

- Request Quality Reports: Buyers should ask for documentation that outlines quality control procedures and testing results.

- Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices.

By implementing these strategies, B2B buyers can mitigate risks and ensure they are sourcing high-quality aluminum profiles that meet their needs.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of quality control can be challenging for B2B buyers, especially those sourcing from different regions. Key considerations include:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help buyers communicate effectively with suppliers.

- Regulatory Compliance: Buyers must ensure that suppliers comply with both local and international regulations, which may vary significantly.

- Supply Chain Transparency: Building relationships with suppliers that offer transparency in their processes can enhance trust and reliability.

By being aware of these nuances, international B2B buyers can make informed decisions and foster successful partnerships in the aluminum profile industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum profiles’

This guide serves as a practical checklist for international B2B buyers looking to procure aluminum profiles. It outlines essential steps to ensure a smooth sourcing process, from defining specifications to selecting the right supplier. Follow these steps to enhance your purchasing decisions and secure high-quality aluminum profiles that meet your needs.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s critical to have a clear understanding of your technical requirements for aluminum profiles. This includes dimensions, weight capacity, surface finish, and specific design features needed for your applications.

- Considerations:

- Determine whether you need metric or fractional profiles.

- Specify any industry standards that must be met, such as ISO or ASTM certifications.

Step 2: Research Potential Suppliers

Invest time in researching suppliers that specialize in aluminum profiles. Look for companies with a solid reputation and experience in your industry. This helps ensure that you are dealing with a reliable source.

- Key Actions:

- Utilize online directories and industry-specific platforms to find suppliers.

- Read customer reviews and testimonials to gauge supplier reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold the necessary certifications and comply with international quality standards. This is crucial for ensuring that the aluminum profiles you purchase meet safety and quality benchmarks.

- What to Check:

- Look for certifications such as ISO 9001 or specific industry-related standards.

- Confirm compliance with local regulations in your region, especially for imports.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the aluminum profiles you intend to purchase. This allows you to assess the quality, finish, and suitability of the products for your specific application.

- Why It Matters:

- Evaluating samples helps you avoid costly mistakes associated with poor quality or incorrect specifications.

- It also provides an opportunity to check the supplier’s response time and customer service.

Step 5: Negotiate Terms and Pricing

Once you’ve narrowed down your supplier options, engage in negotiations to establish favorable terms and pricing. Clear communication about your budget and expectations can lead to better deals.

- Important Factors:

- Discuss bulk order discounts, payment terms, and shipping costs.

- Ensure that all agreements are documented to avoid misunderstandings later.

Step 6: Review Logistics and Delivery Options

Understanding the logistics involved in your order is essential for timely delivery. Confirm shipping methods, lead times, and any potential customs or import duties that may apply.

- Considerations:

- Choose a supplier that offers reliable shipping options tailored to your location.

- Discuss tracking options and delivery schedules to ensure transparency throughout the process.

Step 7: Establish a Long-term Relationship

After successful procurement, consider establishing a long-term relationship with your chosen supplier. This can lead to better service, preferential pricing, and quicker turnaround times for future orders.

- Benefits:

- A strong partnership can provide you with insights into new products and innovations in aluminum profiles.

- Ongoing collaboration can streamline your supply chain and enhance overall efficiency.

By following this comprehensive checklist, B2B buyers can streamline their procurement process for aluminum profiles, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for aluminum profiles Sourcing

What Are the Key Cost Components in Sourcing Aluminum Profiles?

When sourcing aluminum profiles, understanding the cost structure is vital for international B2B buyers. The main cost components include:

-

Materials: The primary cost driver, aluminum prices fluctuate based on market demand and supplier conditions. Buyers should track aluminum market trends to anticipate price changes.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as those in parts of Africa and South America, the overall manufacturing cost can be reduced. However, the expertise and skill level of labor can impact the quality of the profiles produced.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom profiles often require specific tooling, which can be a significant upfront investment. Buyers should inquire about tooling costs and consider them in their total cost analysis.

-

Quality Control (QC): Ensuring that aluminum profiles meet international standards involves QC measures that can add to overall costs. Buyers should seek suppliers with robust QC processes to ensure product reliability.

-

Logistics: Transportation costs can vary widely depending on the distance from the manufacturer to the buyer’s location. Understanding local logistics options and costs is essential, especially for buyers in remote regions.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can help buyers negotiate better deals.

How Do Price Influencers Affect Aluminum Profiles Costs?

Several factors can influence the pricing of aluminum profiles, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

-

Specifications and Customization: Customized profiles generally incur higher costs due to the need for specialized tooling and production processes. Buyers should balance their need for customization with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can increase costs but also enhance product durability and compliance with local regulations. Buyers should assess the importance of certifications for their applications.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Buyers should research potential suppliers thoroughly to find those that offer the best value for their needs.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can significantly impact total costs. Understanding Incoterms is crucial for calculating landed costs and negotiating better terms with suppliers.

What Are the Best Negotiation Strategies for International Buyers?

International B2B buyers should adopt strategic approaches to enhance cost-efficiency when sourcing aluminum profiles:

-

Understand Total Cost of Ownership (TCO): TCO encompasses all costs associated with a product throughout its lifecycle, including purchase price, maintenance, and disposal. Buyers should evaluate suppliers based on TCO rather than just upfront costs.

-

Leverage Volume Discounts: When possible, consolidate orders to achieve higher volumes and negotiate better pricing. Establishing a long-term relationship with suppliers can also lead to more favorable terms.

-

Be Transparent About Requirements: Clearly communicate specifications, quality standards, and delivery timelines. This transparency can help suppliers provide more accurate quotes and reduce misunderstandings.

-

Conduct Market Research: Stay informed about market trends, competitor pricing, and supplier performance. This knowledge empowers buyers to negotiate effectively and make informed decisions.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers may reduce logistics costs and lead times. Evaluating local options can also support regional economies.

Conclusion: Pricing Nuances for International B2B Buyers

Navigating the complexities of sourcing aluminum profiles requires a comprehensive understanding of cost structures and pricing influencers. International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be equipped with actionable insights to enhance their sourcing strategies. By focusing on cost components, leveraging negotiation strategies, and considering total cost of ownership, buyers can secure favorable pricing while ensuring quality and reliability in their aluminum profile purchases.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions and supplier negotiations. Always conduct thorough research and obtain quotes from multiple suppliers before making purchasing decisions.

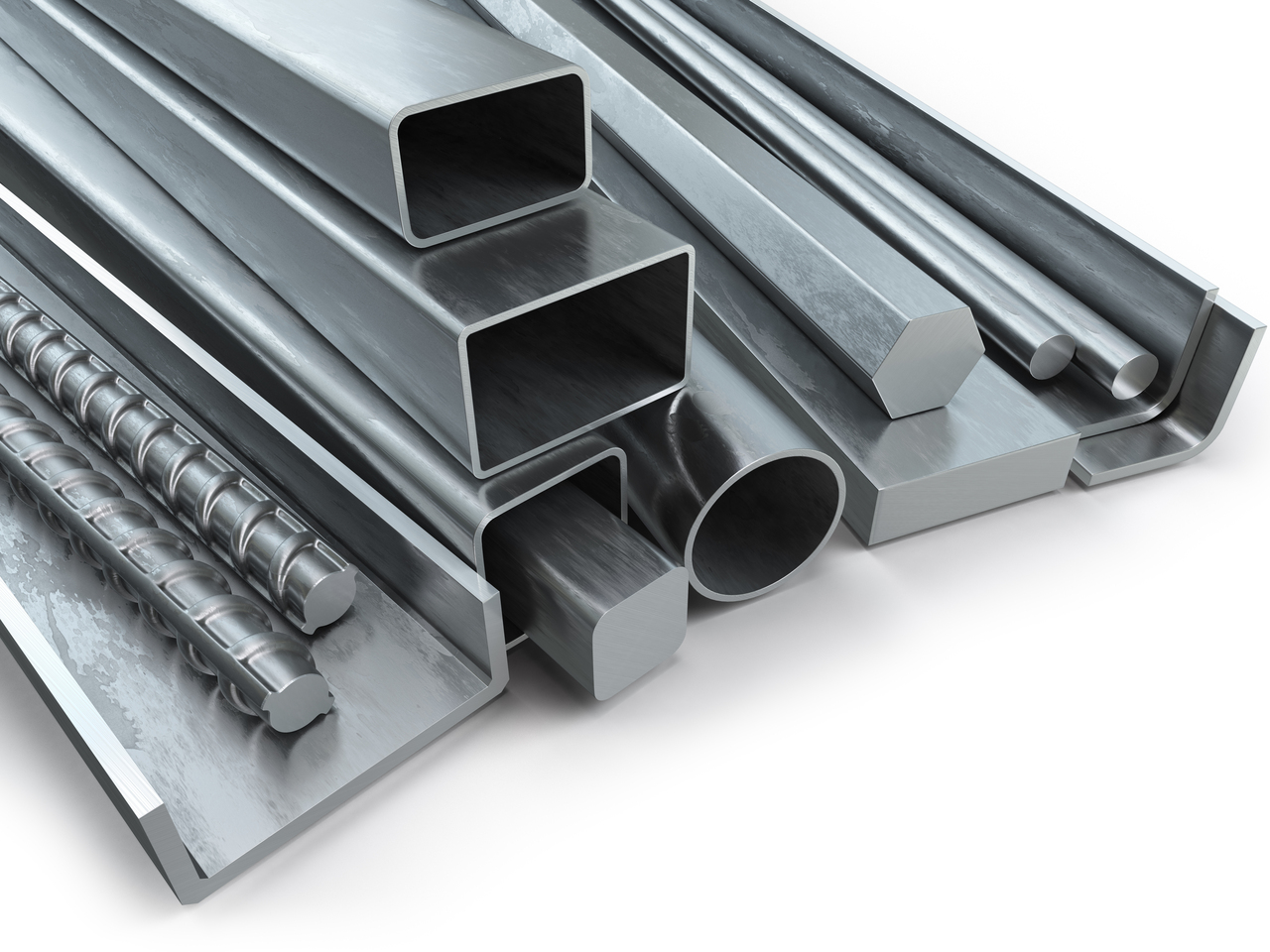

Alternatives Analysis: Comparing aluminum profiles With Other Solutions

A stock image related to aluminum profiles.

When evaluating solutions for structural frameworks, aluminum profiles often stand out due to their versatility and strength. However, it’s essential for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to consider viable alternatives that may better suit their unique project requirements. This section will compare aluminum profiles against two alternative solutions: steel framing and plastic composites.

| Comparison Aspect | Aluminum Profiles | Steel Framing | Plastic Composites |

|---|---|---|---|

| Performance | High strength-to-weight ratio; resistant to corrosion. | Excellent load-bearing capabilities; prone to rust if not treated. | Lightweight; can be engineered for specific performance characteristics. |

| Cost | Moderate initial investment; cost-effective in long-term applications. | Generally lower upfront cost; higher long-term maintenance costs. | Higher initial costs; potential savings on maintenance. |

| Ease of Implementation | Simple to assemble with standard tools; modular design allows for customization. | Requires specialized tools and skills for installation; less flexible. | Generally easy to work with; requires careful handling due to material properties. |

| Maintenance | Low maintenance; does not require painting or rust treatment. | Requires regular maintenance and rust prevention treatments. | Minimal maintenance; may require UV protection depending on application. |

| Best Use Case | Ideal for modular systems, robotics, and automation setups. | Suitable for heavy-duty applications like commercial buildings and infrastructure. | Best for lightweight applications, consumer products, and specialized environments. |

What Are the Advantages and Disadvantages of Steel Framing Compared to Aluminum Profiles?

Steel framing is a traditional alternative that has been used extensively in construction and manufacturing. Its primary advantage lies in its exceptional load-bearing capabilities, making it suitable for large structures like buildings and bridges. However, while the initial cost can be lower than aluminum profiles, ongoing maintenance can be a significant drawback due to rust and corrosion, particularly in humid environments. Additionally, steel framing requires specialized tools and skills for installation, which may increase labor costs and time.

How Do Plastic Composites Stack Up Against Aluminum Profiles?

Plastic composites are increasingly popular in various applications due to their lightweight nature and resistance to corrosion. They can be engineered for specific performance characteristics, which makes them versatile for different projects. However, they typically come with a higher initial cost compared to aluminum profiles and may require careful handling during installation. While they demand less maintenance, certain plastic composites may need UV protection depending on their exposure to sunlight, adding to the overall cost.

How Should B2B Buyers Decide Between Aluminum Profiles and Alternatives?

Choosing the right solution depends on several factors, including project requirements, budget constraints, and long-term performance expectations. B2B buyers should assess the specific application needs—whether they prioritize lightweight structures, load-bearing capabilities, or corrosion resistance. Additionally, understanding the total cost of ownership, including maintenance and installation complexities, can help buyers make informed decisions. Ultimately, evaluating the nuances of each alternative will empower buyers to select the solution that best aligns with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for aluminum profiles

What Are the Key Technical Properties of Aluminum Profiles?

When purchasing aluminum profiles, understanding their technical properties is crucial for ensuring that the materials meet your specific needs. Here are some essential specifications to consider:

-

Material Grade

– The material grade of aluminum profiles typically follows the 1000 to 7000 series, with each series representing different alloying elements and properties. For instance, the 6000 series is popular for its good corrosion resistance and medium strength, making it suitable for structural applications. Selecting the appropriate grade affects not only performance but also costs, so understanding the specific requirements of your project is vital. -

Tolerance

– Tolerance refers to the allowable variation in dimensions of the aluminum profiles. Tight tolerances are critical in applications requiring precise fitting, such as in machinery or structural frames. Inaccuracies in dimensions can lead to assembly issues, impacting overall project timelines and costs. Therefore, always specify your tolerance needs when sourcing profiles. -

Surface Finish

– The surface finish of aluminum profiles can vary widely, from smooth to anodized or powder-coated. The choice of finish affects not only the aesthetic appeal but also the durability and resistance to corrosion and wear. For B2B buyers, understanding the environmental conditions and application requirements can help determine the best surface treatment. -

Weight

– The weight of aluminum profiles is a significant factor for transportation and installation. Lightweight profiles can reduce shipping costs and make handling easier on-site. However, the weight must be balanced with the strength requirements of the application. Buyers should consider both aspects when selecting profiles. -

Load Capacity

– Load capacity is a measure of how much weight an aluminum profile can support without deformation or failure. This property is essential for structural applications, where safety and stability are paramount. Understanding the load specifications helps in designing efficient and safe structures.

What Are Common Trade Terms Used in Aluminum Profile Transactions?

Familiarity with trade terminology is essential for effective communication in the aluminum profile market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum profiles, it refers to companies that manufacture profiles specifically for integration into larger systems or products. Understanding OEM relationships can help buyers ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it can impact inventory management and cash flow. Knowing the MOQ helps in making informed purchasing decisions, especially for smaller businesses or projects. -

RFQ (Request for Quotation)

– An RFQ is a formal request sent to suppliers to receive pricing and terms for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process by comparing multiple suppliers’ quotes, leading to better cost management and supplier selection. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for buyers to ensure they are aware of shipping responsibilities, insurance, and risk transfer. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. In the aluminum profile industry, lead times can vary based on factors such as production schedules and shipping logistics. Buyers should factor lead times into project planning to avoid delays.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions regarding aluminum profiles, ensuring they meet both operational and strategic objectives in their projects.

Navigating Market Dynamics and Sourcing Trends in the aluminum profiles Sector

What Are the Key Market Dynamics in the Aluminum Profiles Sector?

The aluminum profiles market is currently experiencing robust growth, driven by several global factors. The rising demand for lightweight materials in construction, automotive, and manufacturing sectors has made aluminum a favored choice due to its strength-to-weight ratio. Additionally, the shift towards sustainable construction practices and energy-efficient materials is pushing B2B buyers to seek out aluminum profiles as a viable alternative to traditional materials. In emerging markets like Africa and South America, infrastructure development is accelerating, creating substantial opportunities for aluminum suppliers.

Technology is reshaping sourcing trends in the aluminum profiles sector. The rise of e-commerce platforms has streamlined procurement processes, allowing international buyers to source products more efficiently. Digital tools, including AI and machine learning, are enhancing supply chain transparency and improving inventory management, enabling businesses to adapt quickly to market fluctuations. Furthermore, the use of Industry 4.0 technologies in manufacturing processes is increasing, facilitating customized solutions and reducing lead times. International B2B buyers should consider these trends when evaluating suppliers to ensure they remain competitive in a fast-evolving marketplace.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy?

A stock image related to aluminum profiles.

Sustainability is becoming a critical focus for international B2B buyers in the aluminum profiles sector. The environmental impact of production processes, including carbon emissions and energy consumption, has led to increased scrutiny of sourcing practices. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable operations and ethical sourcing. This includes ensuring that raw materials are sourced from responsible suppliers and that production processes minimize waste and energy use.

Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming essential benchmarks for buyers looking to validate their suppliers’ sustainability claims. Additionally, the use of recycled aluminum in profiles is gaining traction, aligning with the growing demand for “green” materials. By prioritizing sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable future, which is increasingly important to consumers and stakeholders alike.

What Is the Historical Context of Aluminum Profiles in B2B Markets?

The use of aluminum profiles dates back to the early 20th century when aluminum was first recognized for its lightweight and corrosion-resistant properties. Initially, the material was primarily used in aviation and military applications. However, as industries evolved, aluminum profiles began to find their place in construction, automotive, and consumer goods.

By the late 20th century, advancements in extrusion technology enabled the production of a wider range of aluminum profiles, enhancing their versatility and applications. Today, aluminum profiles are integral to modern manufacturing, providing solutions for everything from structural frameworks to specialized components. Understanding this evolution is crucial for B2B buyers, as it highlights the material’s adaptability and ongoing relevance in various industries.

In summary, international B2B buyers must navigate the dynamic aluminum profiles market by staying informed about current trends, prioritizing sustainability, and understanding the historical context of the material to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum profiles

-

How do I choose the right aluminum profile for my project?

Choosing the right aluminum profile involves assessing your specific project requirements, such as load capacity, dimensions, and environmental conditions. Consider the type of application—whether it’s structural, aesthetic, or functional. Reviewing product specifications, such as weight and surface finish, is crucial. Additionally, consult with suppliers about their range of profiles, including T-slotted and custom options, to find a solution that best fits your needs. -

What are the benefits of using aluminum profiles in B2B applications?

Aluminum profiles offer numerous advantages for B2B applications, including lightweight properties, corrosion resistance, and ease of fabrication. Their versatility allows for a wide range of uses, from structural frames to intricate designs. Moreover, aluminum’s recyclability makes it an environmentally friendly choice, which can enhance your corporate sustainability profile. This combination of benefits can lead to reduced overall costs and improved project timelines. -

What is the typical lead time for ordering aluminum profiles internationally?

Lead times for international orders of aluminum profiles can vary significantly based on factors like the supplier’s location, production capacity, and shipping methods. Generally, you can expect lead times ranging from 2 to 6 weeks. To minimize delays, it’s advisable to communicate clearly with your supplier about your timeline and any specific requirements, such as customizations or bulk orders. -

How can I vet suppliers of aluminum profiles effectively?

Vetting suppliers involves researching their reputation, quality standards, and customer service. Start by checking certifications (like ISO) and customer reviews. Request samples to assess quality firsthand and inquire about their production processes and materials used. Establishing direct communication can also help gauge their responsiveness and willingness to meet your specific needs, ensuring a reliable partnership. -

What is the minimum order quantity (MOQ) for aluminum profiles?

Minimum order quantities for aluminum profiles can vary based on the supplier and the specific product. Many suppliers may set MOQs ranging from 100 to 1,000 units, while others may offer more flexible options for smaller businesses. It’s essential to discuss your requirements with potential suppliers to determine if they can accommodate your order size, especially if you need custom profiles. -

What payment terms should I expect when sourcing aluminum profiles?

Payment terms for sourcing aluminum profiles often include options like upfront payments, deposits, or payment upon delivery. Common practices in B2B transactions may require a 30% deposit with the balance due upon shipment. Always clarify payment terms with your supplier upfront and consider using secure payment methods to protect your investment, especially for large orders. -

How do I ensure quality assurance when purchasing aluminum profiles?

To ensure quality assurance, request detailed specifications and certifications from your supplier, including material test reports and compliance with industry standards. Implementing a quality control process, such as inspecting samples before bulk orders, can help mitigate risks. Additionally, consider establishing a clear agreement outlining quality expectations and recourse options in case of defects or discrepancies. -

What logistics considerations should I keep in mind for international shipping of aluminum profiles?

When planning logistics for shipping aluminum profiles internationally, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who can navigate international shipping complexities. Additionally, ensure that your supplier packages the profiles adequately to prevent damage during transit. Discuss delivery timelines and tracking options to stay informed throughout the shipping process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum profiles

In summary, strategic sourcing of aluminum profiles is critical for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the diverse specifications—such as T-slotted profiles, metric and fractional dimensions, and surface finishes—enables buyers to make informed decisions that align with their project requirements. Leveraging suppliers who offer a wide range of options ensures adaptability and cost-effectiveness in sourcing, as aluminum profiles serve as foundational components across numerous industries.

What is the future outlook for sourcing aluminum profiles globally? The increasing demand for sustainable and lightweight materials positions aluminum profiles as a key player in innovation and efficiency. Buyers are encouraged to engage with suppliers who prioritize sustainability and offer comprehensive support, from design to delivery. By fostering strong supplier relationships and keeping abreast of market trends, businesses can optimize their sourcing strategies and enhance their competitive edge.

As you navigate the evolving landscape of aluminum profiles, consider the opportunities for collaboration and innovation that lie ahead. Start refining your sourcing strategy today to secure the best materials for your projects and contribute to a sustainable future.