Unlock Cost Savings: The Ultimate Guide to Ceramic Magnets (2025)

Introduction: Navigating the Global Market for ceramic magnets

In the quest for reliable and cost-effective solutions, international B2B buyers face the challenge of sourcing ceramic magnets that meet their specific industrial needs. These versatile ferrite magnets, composed predominantly of iron oxide and strontium carbonate, are essential in various applications, from automotive to consumer electronics. However, navigating the vast array of types, sizes, and strengths can be overwhelming. This guide aims to demystify the global market for ceramic magnets, providing insights into different magnet types—including block, disc, and ring magnets—as well as their applications in diverse industries.

Understanding the nuances of ceramic magnet properties, such as temperature resistance and pull strength, is crucial for making informed purchasing decisions. Additionally, this guide will cover essential topics like supplier vetting, pricing strategies, and logistical considerations tailored for international buyers, particularly those from Africa, South America, the Middle East, and Europe, including countries like Egypt and the UAE. By empowering buyers with detailed knowledge and actionable insights, this comprehensive resource will streamline the procurement process, ensuring that your organization selects the right ceramic magnets to enhance operational efficiency and product performance.

As you delve into this guide, you will gain the confidence needed to navigate the complexities of the ceramic magnet market, ultimately leading to better sourcing decisions that align with your business goals.

Understanding ceramic magnets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ceramic Block Magnet | Rectangular shape, high pull strength, versatile | Industrial assembly, signage, crafts | Pros: Cost-effective, easy to handle. Cons: Limited magnetic strength compared to neodymium. |

| Ceramic Disc Magnet | Circular shape, available in various sizes and thicknesses | Electronics, refrigerator magnets, crafts | Pros: Wide range of applications, economical. Cons: Lower pull strength than other magnet types. |

| Ceramic Ring Magnet | Hollow center, ideal for rotational applications | Motor applications, sensors | Pros: Good for specific design needs, stable performance. Cons: More complex design may increase cost. |

| Ceramic Pot Magnet | Encased in a steel shell, enhanced clamping force | Lifting and holding applications | Pros: High pull strength, protects magnet. Cons: Heavier, may require more handling care. |

| Ceramic Countersunk Magnet | Designed with a hole for easy mounting | Construction, equipment mounting | Pros: Simple installation, versatile. Cons: Requires precise drilling for mounting. |

What Are the Characteristics of Ceramic Block Magnets?

Ceramic block magnets are one of the most commonly used types in B2B applications. They feature a rectangular shape, allowing for efficient use of space in assemblies. Known for their high pull strength relative to their size, these magnets are ideal for industrial settings, signage, and craft projects. When purchasing, buyers should consider the specific dimensions and pull strength needed for their applications, as well as the cost-effectiveness of bulk purchasing options.

How Do Ceramic Disc Magnets Differ from Other Types?

Ceramic disc magnets are characterized by their circular shape and are available in a variety of sizes and thicknesses. They are widely used in electronics, refrigerator magnets, and craft applications due to their versatility. B2B buyers should focus on the specific diameter and thickness required for their projects, as well as the strength of the magnet, which can vary significantly. Their economical price point makes them an attractive option for large-scale applications.

Why Are Ceramic Ring Magnets Suitable for Rotational Applications?

Ceramic ring magnets have a hollow center, making them particularly suitable for applications requiring rotation, such as motors and sensors. Their unique shape allows for efficient use in specialized assemblies. Buyers should evaluate the inner and outer diameters, as well as the thickness, to ensure compatibility with their equipment. While they may come at a higher price due to their design, the stability and performance they offer can justify the investment.

What Are the Advantages of Using Ceramic Pot Magnets?

Ceramic pot magnets are encased in a steel shell, which significantly enhances their clamping force. This design makes them ideal for lifting and holding applications in various industries. When considering ceramic pot magnets, buyers should focus on the weight they need to lift and the specific dimensions required for their applications. While they tend to be heavier than other types, their protective casing adds durability and longevity to the product.

How Do Ceramic Countersunk Magnets Facilitate Installation?

Ceramic countersunk magnets feature a hole that allows for easy mounting, making them a popular choice for construction and equipment mounting applications. Their design simplifies installation, enabling quick and efficient setup in various projects. Buyers should ensure that the size and depth of the countersunk hole match their mounting requirements. While they provide versatility, precise drilling is necessary for effective installation, which can be a consideration for project planning.

Key Industrial Applications of ceramic magnets

| Industry/Sector | Specific Application of Ceramic Magnets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Magnetic sensors for vehicle systems | Enhances precision in vehicle operations and safety | Ensure compatibility with temperature and environmental conditions. |

| Electronics | Loudspeakers and audio equipment | Provides high-quality sound performance | Look for magnets with specific pull strength and size requirements. |

| Manufacturing | Magnetic conveyor systems | Improves efficiency in material handling and production flow | Assess the magnet’s strength and durability for heavy loads. |

| Home Appliances | Refrigerator door seals and closures | Increases energy efficiency and appliance longevity | Verify the resistance to corrosion and temperature variations. |

| Renewable Energy | Wind turbine generators | Enhances energy conversion efficiency | Focus on sourcing magnets that can withstand harsh outdoor conditions. |

How Are Ceramic Magnets Used in the Automotive Industry?

In the automotive sector, ceramic magnets are utilized in magnetic sensors that monitor various vehicle systems, including anti-lock braking systems (ABS) and traction control. These magnets enhance the precision of these systems, ensuring that they operate effectively under different driving conditions. For international buyers, especially in regions like Africa and the Middle East, sourcing ceramic magnets that can withstand high temperatures and vibrations is crucial for maintaining vehicle safety and performance.

What Role Do Ceramic Magnets Play in Electronics?

Ceramic magnets are integral to the production of loudspeakers and audio equipment, where they are used to create the magnetic field necessary for sound reproduction. Their cost-effectiveness and ability to maintain performance over time make them a preferred choice for manufacturers. Buyers from Europe and South America should consider the specific pull strength and dimensions required for their audio applications to ensure optimal sound quality.

How Are Ceramic Magnets Applied in Manufacturing?

In manufacturing, ceramic magnets are employed in magnetic conveyor systems that transport materials efficiently. These systems rely on the magnets’ ability to hold and move ferrous materials without interruption. For businesses sourcing in regions like South America or Africa, it is essential to assess the magnets’ strength and durability, especially when handling heavy loads, to avoid operational disruptions.

What Are the Benefits of Ceramic Magnets in Home Appliances?

Ceramic magnets are commonly used in refrigerator door seals and closures, providing a tight seal that enhances energy efficiency by preventing cold air from escaping. This application not only prolongs the lifespan of the appliance but also reduces energy costs for consumers. Buyers in the Middle East and Europe should focus on magnets that resist corrosion and can perform well in varying temperature conditions to ensure long-lasting appliance performance.

How Do Ceramic Magnets Contribute to Renewable Energy Solutions?

In the renewable energy sector, ceramic magnets are crucial components in wind turbine generators, where they help convert mechanical energy into electrical energy. Their ability to function efficiently in outdoor environments makes them ideal for this application. International buyers should prioritize sourcing magnets that can endure harsh weather conditions and provide consistent performance to maximize energy conversion efficiency.

3 Common User Pain Points for ‘ceramic magnets’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Size and Type of Ceramic Magnet

The Problem: B2B buyers often face confusion when selecting the appropriate size and type of ceramic magnet for their specific applications. With various shapes—block, disc, and ring—and a wide range of pull strengths, it’s easy to misjudge the requirements. This confusion can lead to costly errors, including purchasing magnets that are either too weak to hold essential components or too strong, resulting in safety hazards during handling or installation.

The Solution: To avoid this issue, start by clearly defining the application requirements. Conduct a thorough analysis of the load the magnet needs to carry, the environmental conditions (such as temperature and exposure to moisture), and the available space. Utilize online calculators and guides from reputable suppliers that help determine the necessary pull strength based on your application. Collaborate with a knowledgeable supplier or magnet expert who can provide recommendations tailored to your specific needs. Additionally, consider requesting samples before making a bulk purchase, allowing you to test the magnets in real-world scenarios.

Scenario 2: Concerns Over Durability and Environmental Resistance

The Problem: International buyers, particularly in regions with extreme weather conditions such as the Middle East or South America, frequently express concerns about the durability and environmental resistance of ceramic magnets. These magnets, while generally rust-resistant, can degrade if exposed to extreme humidity, corrosive substances, or high temperatures over time. This situation can result in unexpected failures and increased operational costs for businesses relying on these materials.

The Solution: To mitigate these concerns, prioritize sourcing ceramic magnets specifically designed for high-performance applications. Look for magnets that have been tested for temperature tolerance and environmental resistance. Suppliers often provide detailed specifications, so be sure to request data sheets that include information about maximum operating temperatures and moisture resistance. For added protection, consider applying a protective coating or using encasing materials that can shield the magnets from harsh environments. Furthermore, regular maintenance checks can help identify any potential degradation early, allowing for timely replacements.

Scenario 3: Challenges in Finding Cost-Effective Bulk Purchases

The Problem: Many B2B buyers struggle with finding a reliable supplier that offers competitive pricing on bulk orders of ceramic magnets. The imbalance in supply and demand in regions such as Africa can lead to inflated prices, making it difficult for businesses to maintain profitability while ensuring they have the necessary materials for production.

The Solution: To address this issue, conduct a market analysis to identify multiple suppliers and compare their pricing structures. Use online platforms that specialize in magnets to find competitive quotes. Consider forming alliances with other businesses in your industry to place a joint bulk order, which can lead to significant discounts. Additionally, negotiate long-term contracts with suppliers to secure better pricing and consistency in supply. Investigate alternative logistics solutions that can reduce shipping costs, especially for international orders, to further enhance cost-effectiveness. Establishing a reliable relationship with a supplier can also yield favorable terms in the long run, ensuring you get the best value for your purchases.

Strategic Material Selection Guide for ceramic magnets

What Are the Key Materials Used in Ceramic Magnets?

Ceramic magnets, also known as ferrite magnets, are composed of various materials that significantly influence their performance and application suitability. Understanding these materials is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in ceramic magnets.

Which Materials Are Commonly Used in Ceramic Magnets?

1. Barium Ferrite (BaFe12O19)

Key Properties:

Barium ferrite is known for its excellent magnetic properties and high resistance to demagnetization. It can operate effectively at temperatures up to 250°C, making it suitable for high-temperature applications.

Pros & Cons:

The durability of barium ferrite is a significant advantage, as it is resistant to corrosion and does not require protective coatings. However, the manufacturing process can be complex and costly, which may impact pricing for bulk orders.

Impact on Application:

Barium ferrite is commonly used in applications requiring strong magnetic fields, such as loudspeakers and magnetic sensors. Its high temperature tolerance makes it ideal for automotive and industrial applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN, especially when sourcing from different regions. The availability of barium ferrite may vary, so understanding local supply chains is essential.

2. Strontium Ferrite (SrFe12O19)

Key Properties:

Strontium ferrite offers similar magnetic performance to barium ferrite but is often more cost-effective. It operates efficiently at temperatures up to 180°C.

Pros & Cons:

This material is less expensive to produce, making it a popular choice for budget-conscious projects. However, it may not perform as well in high-temperature applications compared to barium ferrite.

Impact on Application:

Strontium ferrite is widely used in consumer products like refrigerator magnets and toys. Its lower cost makes it suitable for mass production.

Considerations for International Buyers:

Buyers from regions like the Middle East and Africa should consider local sourcing options to reduce shipping costs and ensure timely delivery. Understanding regional preferences for material strength and durability can also guide purchasing decisions.

3. Ceramic Composite Materials

Key Properties:

Ceramic composites combine ferrite with other materials to enhance specific properties, such as thermal stability and magnetic strength. These materials can withstand high temperatures and are often tailored for specific applications.

Pros & Cons:

The primary advantage of ceramic composites is their customization potential, allowing for specific performance enhancements. However, the complexity of manufacturing can lead to higher costs and longer lead times.

Impact on Application:

These materials are ideal for specialized applications in aerospace and defense, where performance under extreme conditions is critical.

Considerations for International Buyers:

Buyers should be aware of the certifications required for specialized materials, particularly in regions with stringent safety regulations. Establishing clear communication with suppliers about application requirements is vital.

4. Plastic-Bonded Ferrite Magnets

Key Properties:

These magnets combine ferrite with a plastic binder, resulting in a lightweight and flexible product. They can operate at temperatures up to 120°C.

Pros & Cons:

Plastic-bonded ferrite magnets are less brittle than traditional ceramic magnets, making them easier to handle and install. However, their magnetic strength is generally lower, which may limit their use in high-performance applications.

Impact on Application:

They are commonly used in applications where lightweight and flexibility are essential, such as in automotive interiors and consumer electronics.

Considerations for International Buyers:

Buyers should consider the environmental impact of plastic materials and ensure compliance with regulations regarding plastic use in their respective markets.

Summary Table of Material Selection for Ceramic Magnets

| Material | Typical Use Case for Ceramic Magnets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Barium Ferrite | Loudspeakers, magnetic sensors | High resistance to demagnetization | Complex and costly manufacturing | Medium |

| Strontium Ferrite | Refrigerator magnets, toys | Cost-effective for mass production | Lower performance at high temperatures | Low |

| Ceramic Composite Materials | Aerospace, defense applications | Customizable for specific needs | Higher costs and longer lead times | High |

| Plastic-Bonded Ferrite Magnets | Automotive interiors, consumer electronics | Lightweight and flexible | Lower magnetic strength | Medium |

This analysis of ceramic magnet materials provides international B2B buyers with actionable insights to make informed decisions based on performance, cost, and application suitability. Understanding these factors can significantly enhance procurement strategies and product development initiatives.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic magnets

Ceramic magnets, also known as ferrite magnets, are widely used in various applications due to their cost-effectiveness and robust performance characteristics. Understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. This section will provide an in-depth overview of typical manufacturing stages, key quality control practices, and how buyers can ensure the reliability of their suppliers.

What Are the Main Stages of Manufacturing Ceramic Magnets?

How Is Material Prepared for Ceramic Magnet Production?

The manufacturing process begins with the preparation of raw materials, primarily iron oxide and strontium or barium carbonate. These materials are carefully measured and mixed in precise ratios to ensure consistent magnetic properties. The mixture is then subjected to high-energy milling to achieve a fine powder, which enhances the homogeneity and reactivity of the materials.

What Techniques Are Used in Forming Ceramic Magnets?

Once the materials are prepared, the next stage involves forming the magnets. This is typically done through a process called pressing, where the powdered mixture is compacted into molds under high pressure. The pressing can be performed either cold or hot, depending on the desired properties of the final product. Hot pressing allows for better alignment of magnetic domains, resulting in stronger magnets. After pressing, the formed shapes are sintered in a furnace at high temperatures, which causes the particles to bond together and develop their magnetic properties.

How Is Assembly and Finishing Done in Ceramic Magnet Production?

After sintering, the magnets undergo a cooling phase before they are machined to achieve the required dimensions and surface finishes. This may include grinding and polishing to meet specific tolerances. In some cases, magnets are coated with protective layers to enhance their durability, especially in applications exposed to harsh environments. The final assembly might involve incorporating these magnets into larger systems or products, depending on customer specifications.

What Quality Assurance Standards Are Applicable for Ceramic Magnets?

Which International Standards Should Buyers Be Aware Of?

Quality assurance in ceramic magnet production is critical for ensuring product reliability and safety. International standards like ISO 9001 set the framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Additionally, industry-specific standards such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for certain industrial applications are essential for compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to identify and address issues early. These checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications before production begins.

-

In-Process Quality Control (IPQC): This step includes monitoring the manufacturing process at various stages, such as during pressing and sintering, to detect deviations from quality standards.

-

Final Quality Control (FQC): Once the magnets are finished, they undergo a final inspection to verify their dimensions, magnetic strength, and surface quality.

What Common Testing Methods Are Used for Quality Assurance?

How Are Ceramic Magnets Tested for Performance and Compliance?

Testing methods for ceramic magnets include:

-

Magnetic Testing: This measures the magnetic strength and coercivity of the magnets, ensuring they meet the required specifications for their intended applications.

-

Dimensional Measurement: Using precision instruments, manufacturers verify that the dimensions of the magnets conform to customer requirements.

-

Environmental Testing: This may include exposure to extreme temperatures and humidity to assess the magnets’ performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Buyers Take to Ensure Supplier Compliance?

B2B buyers should adopt a proactive approach to verify the quality control measures of their suppliers. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits of suppliers can help buyers assess compliance with international standards and internal quality processes. Buyers can evaluate the supplier’s facilities, equipment, and quality management systems.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality assurance processes, including results from testing and inspection. This transparency can build trust and ensure accountability.

-

Utilize Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the quality of ceramic magnets before shipment. This is particularly important for buyers in regions with varying standards of quality assurance.

What Are the Quality Control Nuances for International Buyers?

How Do Regional Standards Affect Quality Assurance for Ceramic Magnets?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding regional standards is vital. Different regions may have specific requirements for product certification, labeling, and safety. Buyers should familiarize themselves with local regulations and ensure their suppliers are compliant with these standards to avoid potential legal issues and product recalls.

How Can Buyers Navigate Import Regulations and Certifications?

When sourcing ceramic magnets, buyers must also consider import regulations that may affect the shipment of goods across borders. It is advisable to work with suppliers who can provide necessary documentation and certifications that validate the quality and safety of the products. This includes understanding tariffs, trade agreements, and any special documentation required for customs clearance.

Conclusion

In summary, the manufacturing processes and quality assurance practices for ceramic magnets are integral to ensuring that these products meet the high standards required for diverse applications. By understanding the stages of production, relevant international standards, and effective quality control measures, B2B buyers can make informed decisions when sourcing ceramic magnets. This knowledge not only aids in selecting reliable suppliers but also ensures that the products will perform effectively in their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic magnets’

In today’s global market, sourcing ceramic magnets can be a strategic advantage for your business. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is critical before initiating the sourcing process. Clearly define the dimensions, pull strength, and intended application of the ceramic magnets. Consider whether you need block, disc, or ring shapes, as different designs offer various functionalities.

- Key Considerations:

- Application type (e.g., automotive, consumer goods)

- Environmental conditions (e.g., temperature resistance)

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for manufacturers that specialize in ceramic magnets and have a solid reputation within the industry. Utilize platforms like trade shows, online directories, and industry publications to compile a list of candidates.

- What to Look For:

- Years of experience and expertise in magnet production

- Customer reviews and testimonials

Step 3: Evaluate Supplier Certifications

Before finalizing any deals, verify that suppliers possess the necessary certifications. Relevant certifications ensure that the products meet international quality standards and regulations, which is crucial for maintaining your company’s reputation.

- Important Certifications:

- ISO 9001 for quality management systems

- Compliance with RoHS or REACH standards for environmental safety

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the ceramic magnets. Testing these samples allows you to assess their performance against your specifications, ensuring they meet your quality expectations before placing a bulk order.

- Testing Criteria:

- Pull strength and durability

- Resistance to environmental factors (e.g., moisture, temperature)

Step 5: Negotiate Terms and Conditions

Engaging in negotiations with your chosen suppliers is essential to secure favorable terms. Discuss pricing, payment terms, delivery schedules, and return policies to ensure that both parties have clear expectations.

- Negotiation Tips:

- Aim for bulk discounts based on order volume

- Clarify lead times and shipping arrangements

Step 6: Establish a Quality Assurance Process

Post-purchase, implement a quality assurance process to monitor the performance of the ceramic magnets. This will help identify any issues early on and maintain the integrity of your supply chain.

- Quality Control Measures:

- Regular audits of supplier performance

- Continuous feedback loops with your production team

Step 7: Build Long-Term Supplier Relationships

Developing strong relationships with your suppliers can lead to better pricing, improved service, and access to new products. Regular communication and collaboration can foster trust and ensure that your sourcing needs are met efficiently.

- Relationship Building Strategies:

- Schedule regular check-ins to discuss performance

- Explore opportunities for joint product development

By following this checklist, B2B buyers can streamline their sourcing of ceramic magnets, ensuring they secure the best products for their applications while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for ceramic magnets Sourcing

What Are the Key Cost Components for Sourcing Ceramic Magnets?

When sourcing ceramic magnets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: Ceramic magnets are primarily made from iron oxide and strontium or barium carbonate. The prices of these raw materials can fluctuate based on market demand and availability, impacting overall magnet costs.

-

Labor: Labor costs vary significantly depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can sometimes affect quality.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Initial tooling costs for custom shapes or sizes can be significant, especially for low-volume orders. Considerations for tooling are essential when planning for customization.

-

Quality Control (QC): Ensuring product quality is vital, particularly for industrial applications. Companies may need to invest in rigorous testing and certification processes, which can add to costs.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, are particularly relevant for international buyers. Geographic location can significantly influence these expenses.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the margin expectations of suppliers is crucial for effective negotiation.

How Do Price Influencers Impact Ceramic Magnet Costs?

Several factors influence the pricing of ceramic magnets, which international buyers should be aware of:

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger orders due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Customized designs or specifications can lead to higher costs. Buyers should assess the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials or certifications (e.g., ISO standards) can result in increased costs but may enhance performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium but often provide better service and quality assurance.

-

Incoterms: Understanding the shipping terms (like FOB, CIF, etc.) can help buyers clarify cost responsibilities and avoid unexpected expenses.

What Are the Best Practices for Negotiating Ceramic Magnet Prices?

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving favorable pricing:

-

Leverage Volume Discounts: When placing large orders, buyers should clearly communicate their volume expectations to negotiate better terms.

-

Discuss Total Cost of Ownership (TCO): Emphasize the importance of TCO rather than just upfront costs. Include factors like durability and maintenance that could lead to savings over time.

-

Be Informed About Market Prices: Conduct market research to understand the standard pricing for ceramic magnets. This knowledge empowers buyers to negotiate more effectively.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms, as suppliers are often willing to reward loyal customers with discounts.

-

Explore Multiple Suppliers: Obtaining quotes from several suppliers can provide leverage in negotiations and ensure competitive pricing.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers must be mindful of specific pricing nuances when sourcing ceramic magnets:

-

Currency Fluctuations: Changes in exchange rates can affect the final cost. Buyers should consider locking in prices or using currency hedging strategies.

-

Import Duties and Taxes: Understand the applicable tariffs and taxes for importing ceramic magnets into your country to avoid budget overruns.

-

Shipping Times and Costs: Longer shipping routes may incur higher costs and delay delivery. Buyers should factor in these logistics when making purchasing decisions.

Disclaimer on Indicative Prices

The prices for ceramic magnets can vary widely based on specifications, volume, and supplier. The figures provided in this analysis are indicative and may not reflect current market conditions. Buyers are encouraged to request quotes and conduct due diligence to obtain accurate pricing tailored to their specific needs.

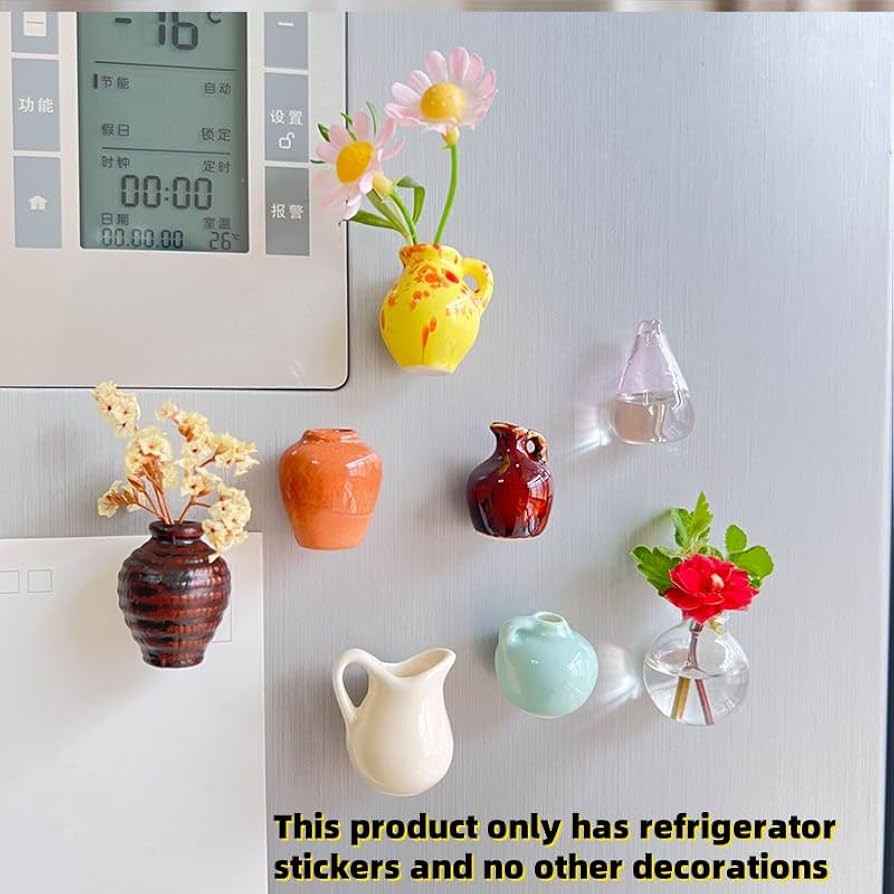

A stock image related to ceramic magnets.

Alternatives Analysis: Comparing ceramic magnets With Other Solutions

In the realm of industrial applications, selecting the right type of magnet can significantly impact performance, efficiency, and cost-effectiveness. While ceramic magnets (also known as ferrite magnets) are a popular choice due to their affordability and reliability, there are viable alternatives that may better suit specific needs. This section will compare ceramic magnets with neodymium magnets and alnico magnets, highlighting their distinct characteristics and applications.

Comparison Table: Ceramic Magnets vs. Alternatives

| Comparison Aspect | Ceramic Magnets | Neodymium Magnets | Alnico Magnets |

|---|---|---|---|

| Performance | Moderate strength; good thermal stability | High strength; can be hazardous | Moderate strength; good temperature stability |

| Cost | Low cost; economical for bulk use | Higher cost; premium pricing | Moderate cost; dependent on alloy composition |

| Ease of Implementation | Simple to install; widely available | Requires careful handling; more complex installation | Easy to install; relatively stable |

| Maintenance | Low maintenance; rust-resistant | Moderate; may require protective coatings | Low; generally stable and durable |

| Best Use Case | General applications; toys; refrigeration | High-performance applications; motors; electronics | High-temperature applications; sensors; automotive |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Neodymium Magnets?

Neodymium magnets are known for their exceptional strength, making them ideal for applications where space is limited but high magnetic force is required. They are commonly used in electric motors, generators, and magnetic assemblies. However, their high cost can be a drawback, particularly for companies operating on tight budgets. Additionally, neodymium magnets can be brittle and may require careful handling to avoid chipping or cracking. They also tend to demagnetize at elevated temperatures, which can limit their application in certain environments.

What Makes Alnico Magnets a Viable Option?

Alnico magnets, composed primarily of aluminum, nickel, and cobalt, offer good thermal stability and are capable of operating in high-temperature environments. They are often used in applications such as electric guitar pickups and various sensing devices. While they provide moderate magnetic strength, their cost can vary significantly based on the specific alloy used. Alnico magnets are generally more robust than neodymium magnets, making them suitable for applications where durability is crucial. However, their performance pales in comparison to the sheer strength offered by neodymium magnets, which could be a limiting factor in competitive applications.

How Should B2B Buyers Choose the Right Solution?

When evaluating which magnet to choose, B2B buyers should consider several factors, including the specific application, required strength, budget constraints, and environmental conditions. Ceramic magnets are often the best choice for general applications due to their cost-effectiveness and sufficient performance. In contrast, neodymium magnets are ideal for high-performance needs, while alnico magnets serve well in high-temperature environments. Ultimately, the right choice will depend on balancing these factors to meet the unique requirements of your business while ensuring optimal performance and cost efficiency.

Essential Technical Properties and Trade Terminology for ceramic magnets

What Are the Key Technical Properties of Ceramic Magnets?

When sourcing ceramic magnets for various applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

Ceramic magnets, also known as ferrite magnets, are primarily composed of barium or strontium ferrite. The material grade impacts the magnet’s performance, with higher grades typically providing better magnetic strength and thermal stability. For B2B buyers, selecting the appropriate material grade ensures that the magnets will meet specific application requirements, such as temperature resistance and durability. -

Magnetic Pull Strength

This metric indicates how much weight a magnet can hold. Pull strength is critical in applications where the magnet’s holding force must counteract external forces, such as in conveyor systems or manufacturing processes. Understanding the pull strength is vital for buyers to ensure that the selected magnets can safely and effectively perform their intended functions. -

Temperature Resistance

Ceramic magnets can operate in temperatures up to 180 degrees Celsius. Knowing the temperature resistance is essential for buyers in industries that involve high-temperature environments, such as automotive or aerospace. Choosing magnets with adequate thermal resistance prevents demagnetization and ensures long-term reliability. -

Tolerance

Tolerance refers to the allowable deviation from specified dimensions. It is vital for ensuring that the magnets fit properly within their intended applications. B2B buyers should pay attention to tolerance levels to avoid compatibility issues, especially when integrating magnets into precision-engineered products. -

Coating and Corrosion Resistance

While ceramic magnets are inherently resistant to rust, additional coatings can enhance their durability in specific environments. Buyers should consider the corrosion resistance of magnets if they will be exposed to moisture or harsh chemicals, ensuring longevity and reducing replacement costs.

What Are Common Trade Terms Used in the Ceramic Magnet Industry?

Familiarity with industry terminology is essential for B2B buyers to navigate procurement processes effectively. Here are some common trade terms related to ceramic magnets:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships is crucial for buyers looking to source custom ceramic magnets for specific applications, as it can influence product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For international buyers, especially those in Africa and South America, being aware of MOQ helps in budgeting and ensures that the order size aligns with operational needs without incurring excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should prepare detailed RFQs when sourcing ceramic magnets to receive accurate and competitive quotes, helping to streamline the procurement process. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms helps buyers from the Middle East and Europe to clarify shipping costs, risk, and insurance responsibilities, facilitating smoother transactions. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the products. For B2B buyers, particularly those involved in time-sensitive projects, understanding lead times is critical for effective supply chain management and planning. -

Custom Solutions

This term pertains to magnets designed specifically to meet unique customer specifications. Buyers should inquire about custom solutions if standard products do not meet their application requirements, ensuring that they receive the best possible fit for their needs.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational goals and industry standards.

Navigating Market Dynamics and Sourcing Trends in the ceramic magnets Sector

What Are the Key Market Dynamics and Trends Influencing Ceramic Magnets?

The ceramic magnets market is experiencing dynamic growth driven by several global factors. The increasing demand for energy-efficient solutions in various industries, including automotive, electronics, and renewable energy, plays a significant role. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Egypt and the UAE) seek reliable and cost-effective magnetic solutions, ceramic magnets are emerging as a preferred choice due to their affordability and versatile applications.

Current sourcing trends indicate a shift towards digital platforms and e-commerce solutions for procurement. B2B buyers are leveraging online marketplaces to streamline their purchasing processes, access a broader range of suppliers, and compare products effectively. Additionally, the rise of Industry 4.0 has led to increased automation in manufacturing, enhancing the production capabilities of ceramic magnets. This trend is particularly relevant for buyers looking to integrate advanced technologies in their operations, ensuring higher efficiency and reduced costs.

A stock image related to ceramic magnets.

Emerging markets in Africa and South America are witnessing a surge in industrialization, which is further propelling the demand for ceramic magnets. As these regions invest in infrastructure and technology, the need for reliable magnetic solutions will only continue to grow. Furthermore, the global emphasis on sustainability is prompting manufacturers to innovate and produce eco-friendly ceramic magnets, which align with the evolving preferences of international buyers.

How Important is Sustainability and Ethical Sourcing for Ceramic Magnets?

The environmental impact of manufacturing processes has become a critical concern for B2B buyers, making sustainability a key factor in sourcing decisions. Ceramic magnets, made primarily from iron oxide and strontium or barium carbonate, have a lower environmental footprint compared to other magnet types, such as neodymium magnets. As such, they are increasingly favored for applications where sustainability is a priority.

Ethical sourcing of materials is also gaining traction among international buyers. Companies are increasingly scrutinizing their supply chains to ensure responsible sourcing practices that minimize environmental degradation and promote fair labor practices. Certifications such as ISO 14001 for environmental management and adherence to the REACH regulation in Europe can provide assurance to buyers regarding the sustainability of ceramic magnets.

Moreover, the adoption of ‘green’ materials and processes in the production of ceramic magnets is becoming more prevalent. Manufacturers are exploring innovative ways to reduce waste and energy consumption during production, which not only contributes to environmental sustainability but also enhances the overall appeal of their products to conscientious buyers. This shift aligns with the growing demand for sustainable products, particularly in markets like Europe and the UAE, where regulatory frameworks and consumer preferences increasingly favor eco-friendly solutions.

What is the Historical Context of Ceramic Magnets in B2B Markets?

A stock image related to ceramic magnets.

Ceramic magnets, also known as ferrite magnets, have a rich history that dates back to the early 20th century. Initially developed in the 1950s, these magnets quickly gained popularity due to their cost-effectiveness and robust performance in a variety of applications. As industries began to recognize the benefits of ceramic magnets, their use expanded significantly, particularly in consumer electronics and automotive components.

Over the decades, advancements in manufacturing techniques have further improved the quality and reliability of ceramic magnets. The introduction of sintering processes and enhanced material formulations has led to stronger and more durable products, making them a staple in the B2B market. Today, ceramic magnets are widely used across numerous sectors, from industrial machinery to household appliances, solidifying their position as a critical component in modern manufacturing and technology.

In conclusion, understanding the market dynamics, embracing sustainability, and recognizing the historical significance of ceramic magnets will empower international B2B buyers to make informed sourcing decisions that align with their operational and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic magnets

-

How do I choose the right ceramic magnet for my application?

Choosing the right ceramic magnet involves understanding your specific application needs. Consider factors like size, shape, and pull strength. For instance, if your application requires a large surface area, a ceramic block magnet may be ideal. Assess the environmental conditions—ceramic magnets perform well in high-temperature settings, making them suitable for industrial applications. Always consult with suppliers to determine the best type based on your technical specifications and operational requirements. -

What is the strength of ceramic magnets compared to other types?

Ceramic magnets, also known as ferrite magnets, are generally weaker than neodymium magnets but offer a cost-effective solution for many applications. They are suitable for situations requiring moderate strength without the risk of injury associated with stronger magnets. For instance, while a ceramic magnet of size 75mm x 50mm x 20mm provides adequate pull for conveyor systems, it remains manageable for handling. Evaluate your requirements carefully, balancing strength, safety, and cost. -

What are the common applications for ceramic magnets in industry?

Ceramic magnets are widely used in various industries due to their versatility and cost-effectiveness. Common applications include magnetic separators, motors, loudspeakers, and refrigerator magnets. They are particularly valued in high-temperature environments due to their resistance to demagnetization. Additionally, they find use in consumer products and industrial machinery, making them a staple in sectors such as automotive, electronics, and manufacturing. -

What should I consider when vetting suppliers of ceramic magnets?

When vetting suppliers, consider their reputation, experience in the industry, and the range of products offered. Verify their certifications and compliance with international quality standards, especially if sourcing from different continents like Africa or South America. Request samples to assess product quality and inquire about their manufacturing processes. Additionally, evaluate their customer service and support capabilities to ensure they can meet your needs effectively. -

What are the typical minimum order quantities (MOQs) for ceramic magnets?

Minimum order quantities for ceramic magnets can vary significantly by supplier and product type. Generally, MOQs can range from as few as 100 pieces for smaller items to several thousand for larger, custom magnets. For international buyers, negotiating MOQs can be beneficial, especially for bulk orders. Always discuss your needs with potential suppliers to find a mutually agreeable quantity that accommodates your inventory management. -

Can I customize ceramic magnets for specific applications?

Yes, many suppliers offer customization options for ceramic magnets. This may include alterations in size, shape, coating, or even magnetic strength to suit particular applications. Communicate your specifications clearly to the supplier and inquire about their design capabilities. Keep in mind that customized orders may have higher MOQs and longer lead times, so plan your procurement strategy accordingly to avoid delays in production. -

What payment terms are typical for international B2B transactions involving ceramic magnets?

Payment terms can vary widely among suppliers but typically include options like bank transfers, letters of credit, or payment upon delivery. For larger orders, some suppliers may offer installment payments. It’s crucial to negotiate favorable terms that align with your cash flow needs while ensuring security in the transaction. Always review the supplier’s payment policies and any potential additional costs, such as tariffs or customs fees. -

How do logistics and shipping impact the sourcing of ceramic magnets?

Logistics and shipping are critical factors in the sourcing process, particularly for international transactions. Evaluate shipping methods (air vs. sea) based on cost, speed, and reliability. Ensure the supplier can provide clear information on lead times, shipping costs, and tracking options. Additionally, consider local regulations and customs duties that may affect delivery times and overall costs. Collaborating with a logistics partner familiar with international trade can streamline the process and mitigate risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic magnets

In today’s competitive landscape, international B2B buyers must prioritize strategic sourcing of ceramic magnets to maximize operational efficiency and cost-effectiveness. As highlighted, ceramic magnets, or ferrite magnets, are an economical choice due to their composition of abundant materials like iron oxide and strontium carbonate. They provide a robust solution for various applications, offering excellent resistance to high temperatures and corrosion, making them suitable for diverse industries.

How Can Strategic Sourcing Enhance Your Supply Chain?

By establishing strong relationships with reliable suppliers, businesses can secure better pricing, ensure consistent quality, and reduce lead times. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage local and international suppliers to capitalize on the unique advantages of ceramic magnets in their specific markets.

What Does the Future Hold for Ceramic Magnets in Global Markets?

As industries increasingly adopt sustainable practices, the demand for efficient and cost-effective materials will only grow. Buyers are encouraged to explore innovative applications of ceramic magnets and stay informed on advancements in magnet technology. Engaging with suppliers who prioritize eco-friendly production methods can further enhance your brand’s sustainability credentials.

In conclusion, investing in strategic sourcing of ceramic magnets today will position your business for long-term success. Connect with trusted suppliers to unlock the full potential of ceramic magnets in your operations.