Unlock Cost Savings with Power Socket Type C Insights (2025)

Introduction: Navigating the Global Market for power socket type c

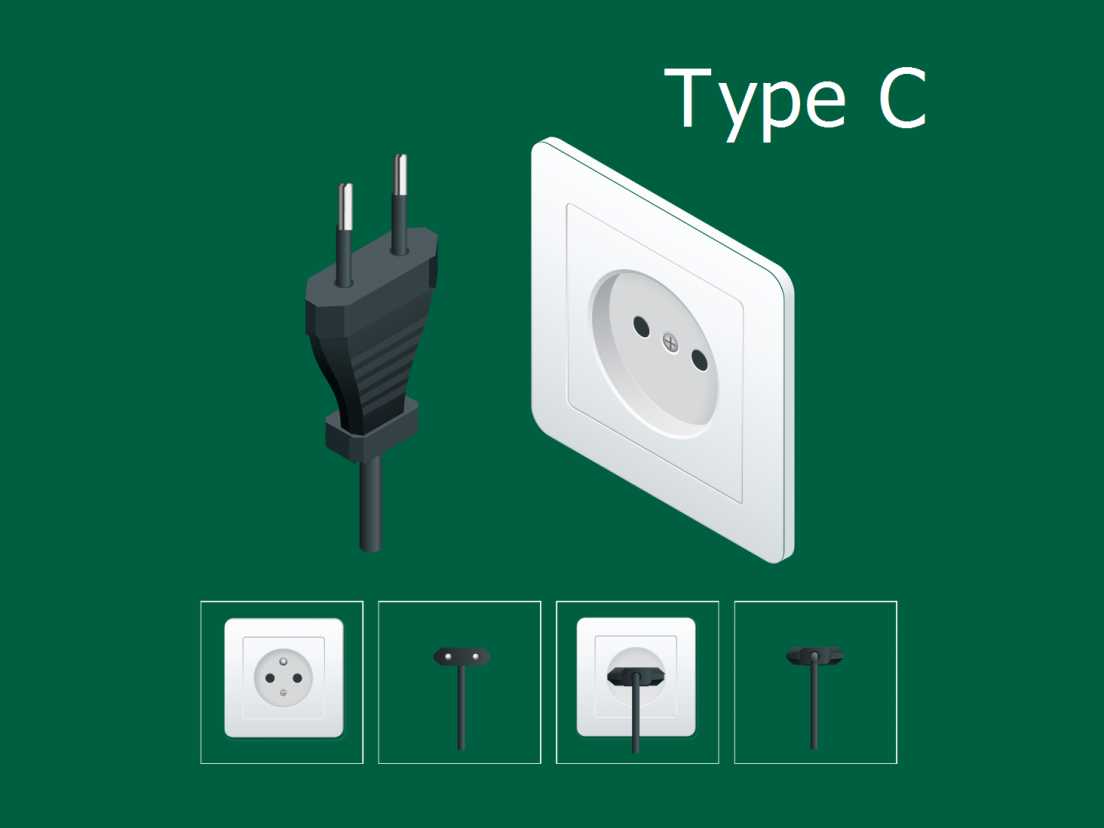

As international B2B buyers navigate the complexities of sourcing power socket Type C, they face the challenge of ensuring compatibility and safety across diverse markets. The Type C plug, known for its two round pins and ungrounded design, is prevalent in numerous regions, particularly throughout Europe and parts of Africa and South America. This guide serves as a comprehensive resource for understanding the intricacies of Type C sockets, including their applications, variations, and the critical considerations when selecting suppliers.

In this guide, you will find detailed insights into the various types of Type C sockets, their specifications, and the markets where they are commonly used. We will explore the implications of sourcing from different regions, the importance of vetting suppliers for quality and reliability, and the cost considerations that can impact your bottom line. This information is crucial for businesses looking to make informed purchasing decisions, especially in areas where electrical standards vary significantly.

For B2B buyers from Africa, South America, the Middle East, and Europe—such as Poland and the UK—this guide aims to empower you with the knowledge needed to navigate the global market effectively. By understanding the nuances of Type C power sockets, you can enhance your procurement strategies and ensure that your operations remain seamless and compliant with local regulations.

Understanding power socket type c Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type C (Europlug) | Two round pins (4-4.8 mm), ungrounded, rated for 2.5A | Low-power appliances (e.g., chargers, lamps) | Pros: Widely compatible; Cons: Limited to low power. |

| Type C (CEE 7/17) | Larger pins (4.8 mm), rated for 10A or 16A, ungrounded | High-power appliances (e.g., hair dryers) | Pros: Suitable for higher loads; Cons: Not compatible with Type N sockets. |

| Type E | Similar to Type C but with an additional grounding pin | Industrial equipment requiring grounding | Pros: Enhanced safety; Cons: Requires compatible sockets. |

| Type F (Schuko) | Grounded, wider pins, compatible with Type C | Heavy machinery, power tools | Pros: High load capacity; Cons: Bulkier design may limit portability. |

| Type N | Hexagonally shaped, used in Brazil and South Africa | Domestic appliances in specific regions | Pros: Unique design prevents incorrect connections; Cons: Limited global compatibility. |

What are the Characteristics of Type C (Europlug)?

The Type C plug, commonly referred to as the Europlug, is characterized by its two round pins measuring 4 to 4.8 mm in diameter. This ungrounded plug is rated for a maximum of 2.5 amperes, making it ideal for low-energy-consuming appliances such as chargers, lamps, and small electronics. Its widespread acceptance across Europe, except in the UK, Ireland, Malta, and Cyprus, makes it an essential consideration for B2B buyers looking to source compatible devices for the European market. When purchasing Type C plugs, businesses should ensure that their products do not exceed the 2.5A rating to avoid safety hazards.

How Does the Type C (CEE 7/17) Differ from the Standard Type C?

The Type C (CEE 7/17) plug is a variation designed for higher power applications, featuring larger pins with a diameter of 4.8 mm and a rating of either 10A or 16A. This plug is suitable for devices that require more power, such as hair dryers and vacuum cleaners. B2B buyers should consider the Type C (CEE 7/17) when sourcing equipment that demands higher energy consumption, particularly in regions where this plug type is prevalent. However, it is crucial to note that this version is incompatible with Type N sockets, which limits its use in certain countries.

In What Situations is Type E Most Suitable?

Type E sockets include an additional grounding pin, providing enhanced safety for industrial applications and high-powered equipment. This plug type is particularly relevant for businesses dealing with machinery and tools that require grounding for safe operation. B2B buyers must ensure that their products are compatible with Type E sockets, especially when entering markets with stringent safety regulations. While Type E plugs enhance safety, they require specific sockets, which may not be universally available.

Why Choose Type F (Schuko) for Heavy Machinery?

Type F plugs, commonly known as Schuko plugs, are grounded and feature wider pins, making them suitable for heavy machinery and power tools. Their design allows for a high load capacity, making them ideal for industrial environments. B2B buyers should consider Type F plugs when sourcing equipment for construction or manufacturing sectors. However, the bulkier design may limit the portability of devices, which could be a drawback for businesses looking for versatile solutions.

What Makes Type N Unique for Specific Markets?

Type N plugs, characterized by their hexagonal shape, are primarily used in Brazil and South Africa. This unique design prevents incorrect connections, enhancing safety in regions where Type N is standard. B2B buyers targeting these markets should ensure compatibility with Type N sockets, especially for domestic appliances. However, the limited global compatibility of Type N plugs means that businesses must be cautious about exporting products that utilize this plug type, as they may not be accepted in other regions.

Key Industrial Applications of power socket type c

| Industry/Sector | Specific Application of power socket type c | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Guest room charging stations | Enhances guest experience by providing convenient charging options for devices. | Ensure compliance with local electrical standards and voltage ratings. |

| Retail | Point of Sale (POS) systems | Facilitates easy setup and operation of electronic payment systems, improving transaction efficiency. | Assess compatibility with existing infrastructure and power needs. |

| Manufacturing | Assembly line equipment | Powers low-energy tools and machines, ensuring smooth production processes. | Source durable and compliant plugs to withstand industrial environments. |

| Education | Classroom technology | Supports projectors, laptops, and other educational tools, enhancing learning experiences. | Consider the safety features and ease of access for students and teachers. |

| Healthcare | Medical devices | Powers essential medical equipment in clinics and hospitals, ensuring reliability and safety. | Focus on sourcing products that meet health and safety regulations. |

How is Power Socket Type C Used in the Hospitality Sector?

In the hospitality industry, power socket type C is commonly used in guest room charging stations. These sockets allow guests to conveniently charge their electronic devices, such as smartphones and laptops, enhancing their overall experience. For international B2B buyers, it is crucial to ensure that the sockets comply with local electrical standards and are rated for the appropriate voltage, particularly in regions like Europe, Africa, and South America, where voltage levels may vary.

What Role Does Power Socket Type C Play in Retail Environments?

In retail settings, power socket type C is often utilized for Point of Sale (POS) systems. These systems require reliable power sources to operate effectively, enabling businesses to process transactions quickly and efficiently. B2B buyers in the retail sector should assess the compatibility of type C sockets with existing electrical infrastructure and ensure they meet the power requirements of modern POS equipment.

How is Power Socket Type C Essential in Manufacturing?

Manufacturing facilities frequently employ power socket type C to power low-energy tools and machinery on assembly lines. This ensures smooth operations and minimizes downtime caused by equipment failures. Buyers in this sector should prioritize sourcing durable and compliant plugs that can withstand the rigors of industrial environments, particularly in regions with varying electrical standards.

A stock image related to power socket type c.

What is the Importance of Power Socket Type C in Educational Settings?

In educational institutions, power socket type C supports various classroom technologies, including projectors and laptops. This enhances the learning experience by ensuring that devices remain powered throughout lessons. International B2B buyers should consider the safety features of these sockets, as well as their accessibility for students and educators, to create an effective learning environment.

How Does Power Socket Type C Benefit the Healthcare Industry?

In healthcare settings, power socket type C is critical for powering essential medical devices, such as monitors and diagnostic equipment. The reliability and safety of these sockets are paramount, as they directly impact patient care. B2B buyers in the healthcare sector must focus on sourcing products that comply with health and safety regulations, ensuring that they are suitable for use in clinical environments across different regions.

3 Common User Pain Points for ‘power socket type c’ & Their Solutions

Scenario 1: Incompatibility with Local Standards

The Problem: Many international B2B buyers face significant challenges when sourcing Type C power sockets due to incompatibility with local electrical standards. For instance, a company sourcing equipment from Europe for use in South Africa may find that while the Type C plug fits the socket, the electrical ratings or grounding requirements differ, potentially leading to equipment malfunction or safety hazards. This issue is particularly prevalent in regions where Type C sockets are being phased out in favor of grounded alternatives, such as Type N.

The Solution: To navigate these compatibility issues, buyers should conduct thorough research on local electrical standards and regulations before making purchases. This includes understanding the specifications of Type C equipment and its compatibility with other socket types in the destination country. It’s advisable to source dual-compatible devices or adapters that can accommodate various plug types while adhering to local safety standards. Furthermore, engage with local suppliers who can provide insights into the best practices for installation and usage, ensuring compliance and reducing the risk of electrical issues.

Scenario 2: Limited Power Capacity

The Problem: Type C sockets are typically rated for a maximum of 2.5 amps, which limits their use with high-energy-consuming appliances. B2B buyers often find themselves in a situation where they need to connect devices that exceed this limit, such as powerful heating equipment or industrial machinery. This not only leads to potential device damage but also poses safety risks, including overheating and fire hazards.

The Solution: Buyers should assess their power requirements and opt for appliances that are compatible with the Type C rating or consider alternatives that offer higher amperage ratings, such as Type E or F plugs. When sourcing equipment, explicitly check the amperage specifications and ensure they align with the capabilities of the Type C socket. In cases where higher energy consumption is unavoidable, investing in appropriate power management solutions, such as circuit breakers or power converters, is crucial. Collaborating with electrical engineers to design a safe and compliant electrical system will also mitigate risks associated with exceeding the socket’s power capacity.

Scenario 3: Transitioning to Modern Standards

The Problem: As safety regulations evolve, many countries are transitioning away from Type C sockets, which are ungrounded and considered outdated. B2B buyers may find themselves with a mix of old and new equipment that requires different socket types, complicating installation and operation in new facilities. This transition can lead to increased costs due to the need for electrical upgrades, as well as operational downtime while changes are implemented.

The Solution: To effectively manage the transition, businesses should conduct an audit of their existing electrical infrastructure to identify which sockets and plugs are currently in use and which need to be upgraded. This will help in planning a phased replacement strategy for older Type C sockets with modern, grounded alternatives. When sourcing new equipment, prioritize manufacturers that comply with contemporary electrical standards to ensure compatibility with the upgraded systems. Additionally, consider engaging a local electrical contractor who is familiar with the latest regulations to assist in the installation process, ensuring that all upgrades are compliant, efficient, and safe. By planning ahead, businesses can minimize disruptions and costs associated with transitioning to modern electrical standards.

Strategic Material Selection Guide for power socket type c

What Are the Common Materials Used in Power Socket Type C?

When selecting materials for power socket Type C, international B2B buyers must consider various factors, including electrical performance, durability, and compliance with regional standards. Below are analyses of four common materials used in the manufacturing of Type C sockets.

Which Plastics Are Suitable for Power Socket Type C?

Polycarbonate (PC) is a widely used plastic in electrical applications due to its excellent thermal resistance and impact strength. It can withstand temperatures up to 130°C and is resistant to many chemicals, making it suitable for various environments.

Pros: Polycarbonate is lightweight, durable, and offers excellent electrical insulation properties. It is also relatively easy to mold, which simplifies manufacturing processes.

Cons: The primary drawback is its cost, which can be higher than other plastics. Additionally, polycarbonate can be prone to scratching, which may affect aesthetics over time.

Impact on Application: Polycarbonate’s high-temperature rating makes it suitable for environments where heat generation is a concern, such as in high-usage commercial settings.

Considerations for International Buyers: Compliance with standards such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) is crucial. Buyers in Europe and the Middle East should ensure that the products meet the relevant safety regulations.

What Metals Are Commonly Used in Power Socket Type C?

Copper is the standard material for electrical contacts in Type C sockets due to its excellent conductivity and reliability. Copper can handle high current loads, making it ideal for sockets designed for various appliances.

Pros: Copper offers low electrical resistance, ensuring efficient energy transfer. It is also widely available and cost-effective.

Cons: Copper is susceptible to corrosion, especially in humid environments, which can lead to performance degradation over time. Protective coatings can mitigate this, but they add to manufacturing complexity.

Impact on Application: Given its conductivity, copper is suitable for applications requiring high power, such as kitchen appliances and power tools.

Considerations for International Buyers: Buyers should consider the local climate when selecting copper components. In regions with high humidity, corrosion-resistant treatments may be necessary to ensure longevity.

How Do Composites Enhance Power Socket Type C Performance?

Thermoplastic Elastomers (TPE) are increasingly used in power socket applications for their flexibility and durability. TPEs can withstand a wide range of temperatures and are resistant to UV light and ozone.

Pros: TPEs provide excellent insulation and mechanical properties, making them suitable for a variety of applications. They are also recyclable, aligning with sustainability goals.

Cons: The cost of TPEs can be higher than traditional plastics, and their manufacturing processes can be more complex, potentially impacting production timelines.

Impact on Application: TPEs are particularly beneficial in applications where flexibility and durability are essential, such as in portable or outdoor power sockets.

Considerations for International Buyers: Compliance with environmental regulations is vital, especially in Europe, where sustainability is a growing concern. Buyers should ensure that TPE materials meet relevant recycling and disposal standards.

What Role Does Steel Play in Power Socket Type C?

Stainless Steel is often used for the structural components of power sockets, especially in commercial settings. It offers excellent strength and resistance to corrosion.

Pros: Stainless steel is durable and can withstand harsh environmental conditions, making it ideal for outdoor or industrial applications.

Cons: The weight of stainless steel can be a disadvantage in portable applications. Additionally, its cost is typically higher than that of plastic or aluminum.

Impact on Application: Stainless steel is suitable for heavy-duty applications where durability is paramount, such as in factories or outdoor installations.

Considerations for International Buyers: Buyers should ensure that the stainless steel used complies with international standards for corrosion resistance, particularly in coastal or humid environments.

Summary Table of Material Selection for Power Socket Type C

| Material | Typical Use Case for power socket type c | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | General residential and commercial use | High impact strength and thermal resistance | Higher cost and prone to scratching | Medium |

| Copper | High-power appliances | Excellent conductivity and low resistance | Susceptible to corrosion | Low |

| Thermoplastic Elastomers (TPE) | Portable and outdoor sockets | Flexibility and durability | Higher cost and complex manufacturing | High |

| Stainless Steel | Industrial and outdoor applications | Exceptional strength and corrosion resistance | Heavier and higher cost | High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for Type C power sockets, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for power socket type c

What Are the Key Stages in the Manufacturing Process of Power Socket Type C?

The manufacturing process of power socket Type C involves several critical stages that ensure the product meets safety and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials used in the production of Type C sockets are high-quality thermoplastics for the casing and copper or brass for the pins. Manufacturers often source materials that comply with international standards to ensure durability and conductivity. This stage includes the inspection of raw materials to verify their quality and suitability for electrical applications.

-

Forming: In this phase, raw materials are shaped into the desired components. For the thermoplastic casing, injection molding is a common technique, where heated plastic is injected into molds to form the socket body. The metal pins are typically stamped or extruded from sheets of copper or brass, ensuring that they meet the precise dimensions and specifications required for compatibility with various sockets.

-

Assembly: Once all components are formed, they are assembled. This involves inserting the metal pins into the molded plastic casing and ensuring secure connections. Automated assembly lines are often used to enhance efficiency and consistency. Quality checks are performed at this stage to ensure that the assembly meets design specifications.

-

Finishing: The final stage includes surface treatment, which may involve applying a protective coating to the pins to prevent oxidation and ensure longevity. Additionally, the assembled sockets are tested for electrical safety, durability, and compliance with international standards before packaging.

How Is Quality Assurance Integrated into the Manufacturing of Power Socket Type C?

Quality assurance (QA) is a vital aspect of the manufacturing process for Type C power sockets. It involves adhering to relevant international standards and implementing rigorous quality control measures throughout production.

-

International Standards: Compliance with standards such as ISO 9001 is crucial for manufacturers targeting international markets. ISO 9001 outlines a framework for quality management systems that enhance customer satisfaction and operational efficiency. For electrical products, certifications like CE mark indicate conformity with European safety standards, which is essential for B2B buyers in Europe.

-

Industry-Specific Certifications: Depending on the target market, manufacturers may also need to comply with additional certifications. For instance, in regions like Africa and South America, adherence to local electrical safety standards may be required. Understanding these nuances can help B2B buyers ensure that the products they source meet local regulations.

-

Quality Control Checkpoints: Quality control is typically divided into several checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify defects early. This may include dimensional checks of molded parts and electrical testing of assembled sockets.

– Final Quality Control (FQC): Comprehensive testing of finished products, which includes electrical safety tests, durability assessments, and compliance checks against relevant standards.

What Testing Methods Are Commonly Used for Power Socket Type C?

Testing is a critical component of quality assurance for power sockets. Various testing methods are employed to verify performance and safety:

-

Electrical Safety Testing: This includes tests for dielectric strength, insulation resistance, and earth continuity. Ensuring that the sockets can handle high voltages without failure is crucial for preventing electrical hazards.

-

Mechanical Testing: This involves assessing the durability of the socket through mechanical stress tests, such as insertion and withdrawal tests. These tests simulate real-world usage conditions to ensure reliability.

-

Thermal Testing: Power sockets must withstand heat generated during operation. Thermal testing evaluates the performance of the socket under elevated temperatures to ensure it does not deform or malfunction.

-

Environmental Testing: This includes exposure to humidity and corrosive environments to ensure that materials used in the sockets can withstand various climatic conditions, particularly relevant for buyers in regions with extreme weather.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This allows buyers to assess the supplier’s commitment to quality firsthand.

-

Requesting Quality Reports: Buyers should request documentation that demonstrates the supplier’s quality control processes, including test reports and certification documents. These reports should detail the results of various testing methods and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform quality checks during and after the manufacturing process, ensuring that the products meet specified requirements before shipment.

-

Monitoring Certifications: Buyers should verify that suppliers maintain current certifications and compliance with applicable standards. Regularly checking for updated certifications can help mitigate risks associated with sourcing products from non-compliant manufacturers.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control?

International buyers should be aware of specific nuances related to quality control when sourcing Type C power sockets:

-

Regulatory Compliance: Different regions have varying regulations regarding electrical products. Buyers must understand local requirements to ensure that the sockets they import comply with safety and performance standards.

-

Cultural and Economic Factors: In regions like Africa and South America, buyers may face challenges related to infrastructure and supply chain logistics. Understanding these factors can help buyers make informed decisions when selecting suppliers.

-

Language Barriers: Effective communication is vital in maintaining quality standards. Buyers should ensure that there is a common language or translation services available to avoid misunderstandings regarding quality expectations.

By focusing on these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing Type C power sockets, ensuring they meet both safety standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power socket type c’

In today’s global market, sourcing power socket type C components requires a clear, strategic approach. This guide aims to provide international B2B buyers, especially from Africa, South America, the Middle East, and Europe, with a practical checklist to facilitate the procurement process efficiently and effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the power socket type C meets your operational needs. Consider the amperage requirements (typically up to 2.5A for standard use) and whether you need the ungrounded version or the higher-rated options (10A or 16A) for more energy-intensive applications. Additionally, specify any compliance with local safety regulations and standards that might affect your procurement.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers with a proven track record in manufacturing power socket type C products. Look for companies that specialize in electrical components and have experience in your specific market regions. Utilize industry directories, trade shows, and online platforms to gather a list of vetted suppliers.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s vital to vet your potential suppliers. Request detailed company profiles, case studies, and references from other businesses in your industry or region. Pay attention to their manufacturing capabilities, quality control processes, and adherence to international standards, such as ISO certifications.

Step 4: Request Samples and Test Product Quality

Once you’ve narrowed down your supplier list, request samples of the power socket type C products for testing. This step allows you to assess the quality, compatibility, and durability of the sockets with your equipment. Ensure the samples comply with the technical specifications you defined earlier, and conduct any necessary stress tests to evaluate their performance.

Step 5: Negotiate Terms and Conditions

Negotiating favorable terms and conditions is essential for securing a beneficial deal. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Make sure to clarify warranty and return policies, as well as any potential penalties for non-compliance with agreed standards.

Step 6: Understand Import Regulations and Compliance

Before finalizing your order, familiarize yourself with the import regulations and compliance standards in your region. This includes understanding any tariffs, taxes, and certifications required for electrical components. Ensuring compliance can save you from unexpected costs and delays in your supply chain.

Step 7: Establish a Long-Term Relationship with Your Supplier

Once you have successfully sourced power socket type C products, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better pricing, improved product offerings, and priority in fulfillment. Consider conducting periodic reviews to assess performance and explore potential for collaboration on future projects.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing power socket type C effectively, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for power socket type c Sourcing

What Are the Key Cost Components in Sourcing Type C Power Sockets?

When sourcing Type C power sockets, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The raw materials for Type C sockets typically consist of high-quality plastic for the casing and copper for the electrical contacts. Prices can fluctuate based on market demand and the sourcing of materials, particularly for copper, which is susceptible to international commodity prices.

-

Labor: Labor costs vary significantly by region. In countries like China and Vietnam, lower labor costs can make manufacturing more economical, while European manufacturers may incur higher labor expenses. It’s essential to consider local wage rates when evaluating suppliers.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which is critical for competitive pricing.

-

Tooling: The initial investment in tooling (molds and dies for production) can be significant, particularly for custom designs. Buyers should assess whether the tooling costs can be amortized over a large production run to reduce the per-unit cost.

-

Quality Control (QC): Ensuring compliance with international standards requires robust QC measures, which can add to the overall cost. Buyers should inquire about the QC processes of potential suppliers to understand how they ensure product reliability and safety.

-

Logistics: Shipping costs can vary based on the distance from the manufacturer, the mode of transport, and the size of the order. Understanding Incoterms is vital as they define who is responsible for shipping costs, insurance, and risk during transit.

-

Margin: Suppliers will typically add a profit margin to the production cost. This can vary based on market conditions, competition, and the supplier’s positioning within the market.

What Influences Pricing for Type C Power Sockets?

Several factors can influence the pricing of Type C power sockets, which are essential for international buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts due to economies of scale. Buyers should negotiate MOQ terms to optimize costs.

-

Specifications and Customization: Custom designs or specific certifications (e.g., CE marking for Europe) can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (like RoHS or UL) can enhance product reliability but may also increase costs. Understanding the importance of these certifications in your target market is crucial.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can significantly impact pricing. Established suppliers may charge more but often provide better reliability and service.

-

Incoterms: The chosen Incoterm can affect total costs. For instance, DDP (Delivered Duty Paid) includes all shipping costs and import duties, providing greater cost predictability.

What Are Effective Buyer Tips for Sourcing Type C Power Sockets?

To maximize value when sourcing Type C power sockets, consider these actionable tips:

-

Negotiate Terms: Engage in negotiations with suppliers to secure favorable pricing, especially if you are placing a large order or have ongoing needs.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes shipping, duties, and potential costs associated with product failures or returns.

-

Understand Pricing Nuances: Be aware that prices can vary based on regional market conditions, exchange rates, and geopolitical factors. This is particularly relevant for buyers in Africa and South America, where market volatility can impact costs.

-

Build Relationships with Suppliers: Establishing long-term relationships with reliable suppliers can lead to better pricing and terms over time.

-

Stay Informed: Regularly monitor changes in material costs, labor rates, and regulatory requirements, as these can influence pricing dynamics.

Disclaimer

A stock image related to power socket type c.

The prices and cost components discussed are indicative and subject to change based on market conditions and supplier negotiations. Always conduct thorough due diligence when sourcing products.

Alternatives Analysis: Comparing power socket type c With Other Solutions

When considering power solutions for various international markets, it is essential to evaluate alternatives to the widely-used Power Socket Type C. Understanding the strengths and weaknesses of different options can help B2B buyers make informed decisions that align with their operational needs.

Comparison Table of Power Socket Type C and Alternatives

| Comparison Aspect | Power Socket Type C | Type E/F Socket | Universal Socket |

|---|---|---|---|

| Performance | Limited to 2.5A; suitable for low-energy devices. | Supports higher current ratings (up to 16A). | Accommodates multiple plug types, including Type C. |

| Cost | Generally low cost; widely available. | Moderate cost; may require specific installation. | Higher cost due to complexity of design. |

| Ease of Implementation | Simple installation; compatible with many devices. | Requires specific compatibility checks; installation may vary by region. | Installation can be complex; requires thorough planning. |

| Maintenance | Minimal; straightforward to replace. | Low; requires occasional checks for wear. | Moderate; more components may lead to higher maintenance needs. |

| Best Use Case | Ideal for low-power appliances in Europe and developing countries. | Best for high-power appliances in residential and commercial settings in Europe. | Suitable for international businesses with diverse plug requirements. |

What Are the Benefits of Using Type E/F Sockets Over Power Socket Type C?

Type E and F sockets are prevalent in many European countries and are designed to handle higher current loads, making them suitable for more energy-intensive devices. The primary advantage of these sockets is their capacity to support appliances that require 10A or 16A, such as hair dryers and kitchen appliances. However, they require careful compatibility checks since not all devices with a Type C plug will work seamlessly with Type E/F sockets, which could lead to potential operational disruptions. Additionally, while the installation costs may be slightly higher, the performance benefits often justify this investment.

How Does a Universal Socket Compare with Power Socket Type C?

Universal sockets are designed to accept multiple types of plugs, including Type C, making them highly versatile. This adaptability is particularly advantageous for international businesses that operate in various regions with different plug standards. However, the complexity of their design can lead to higher installation costs and potential maintenance challenges. While they provide flexibility, B2B buyers must consider whether the additional investment aligns with their operational needs. If their equipment predominantly uses Type C plugs, the universal socket’s benefits may be diminished.

Conclusion: How Should B2B Buyers Choose Between Power Socket Type C and Its Alternatives?

B2B buyers should assess their specific requirements, including the types of devices they plan to power, the frequency of international operations, and regional electrical standards. If the primary need is for low-energy devices and simplicity, Power Socket Type C remains a solid choice. However, for businesses requiring more robust power solutions, Type E/F sockets may offer the necessary performance without significant complexity. Universal sockets provide the greatest flexibility but come with higher costs and potential installation challenges. Ultimately, the decision should be based on a thorough analysis of operational needs, budget constraints, and long-term scalability.

Essential Technical Properties and Trade Terminology for power socket type c

A stock image related to power socket type c.

What Are the Essential Technical Properties of Power Socket Type C?

When engaging with power socket type C, it is crucial for B2B buyers to understand its technical specifications, as these properties directly impact compatibility and safety in various applications.

1. Material Grade

The materials used in the construction of type C sockets and plugs typically include polycarbonate or thermoplastic for the body and copper for the pins. High-grade materials ensure durability and resistance to wear, which is vital for maintaining long-term functionality. Buyers should prioritize suppliers that adhere to international standards for materials to ensure reliability and safety in their products.

2. Current Rating

Type C plugs are primarily rated for a maximum current of 2.5 amperes. This rating is crucial for determining the type of appliances that can be safely connected. B2B buyers must consider the current rating when sourcing plugs to ensure they align with the power requirements of their devices, especially in sectors like hospitality or manufacturing where equipment varies widely.

3. Pin Dimensions and Tolerance

The pins of type C plugs are 4 mm in diameter with a length of 19 mm. They must fit securely into sockets with a tolerance that accommodates slight variations in manufacturing. Ensuring proper tolerances is essential for electrical safety and functionality, reducing the risk of overheating or electrical failure. Buyers should verify that their suppliers maintain strict tolerances in production.

4. Insulation and Safety Features

Type C plugs are ungrounded and lack insulation on the pins, which limits their use to Class II applications. Understanding the implications of this design is critical for buyers sourcing for environments where safety is paramount. It is advisable to ensure that any equipment used with type C plugs incorporates additional safety features, such as circuit breakers or fuses.

5. Voltage Compatibility

Type C plugs are designed for use in voltage ranges of 220-240V at 50Hz. Buyers operating in regions with different voltage standards should ensure compatibility or consider adapters. This knowledge is crucial to prevent damage to appliances and ensure compliance with local regulations.

Which Trade Terminology Should B2B Buyers Understand for Power Socket Type C?

Understanding key industry terms can enhance communication and negotiation with suppliers, ensuring a smoother procurement process.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end product. For buyers, partnering with an OEM for type C sockets can ensure high-quality production and compliance with industry standards. It’s important to assess the OEM’s reputation and capabilities before entering into agreements.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing information for specific products. Crafting a detailed RFQ for type C sockets can help buyers receive accurate quotes and compare offers effectively. It’s a critical step in the sourcing process that can lead to cost savings.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with relevant Incoterms can help B2B buyers avoid misunderstandings and ensure that logistics are handled efficiently.

5. Certification Standards

Certification standards, such as CE or UL, indicate that a product meets certain safety and performance criteria. Buyers should ensure that type C sockets sourced from suppliers are certified, as this affects market acceptance and regulatory compliance.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing power socket type C, ensuring compatibility, safety, and regulatory compliance across their operations.

Navigating Market Dynamics and Sourcing Trends in the power socket type c Sector

What Are the Current Market Dynamics and Key Trends in the Power Socket Type C Sector?

The power socket Type C sector is experiencing significant growth, driven by global electrification efforts, increasing consumer electronics usage, and a shift towards standardization. As the most widely used plug internationally, Type C is prevalent across Europe, parts of Africa, and South America, making it a crucial component for international B2B transactions. Key trends include the rise of smart technology integration, where manufacturers are incorporating IoT capabilities into sockets to enhance user convenience and energy management. Additionally, there’s a growing emphasis on compatibility with emerging plug types, particularly in regions like Africa and South America, where local standards may vary.

For international B2B buyers, understanding regional compliance is essential. Countries in Europe, for example, are increasingly adopting stricter regulations on electrical safety, demanding grounded solutions and energy-efficient designs. Buyers from Africa and South America should be aware of the rapid urbanization and electrification initiatives, as these markets present a significant opportunity for Type C socket suppliers. Furthermore, the shift towards e-commerce platforms for sourcing components is transforming how businesses engage with suppliers, facilitating easier access to global markets.

How Can Sustainability and Ethical Sourcing Impact the Power Socket Type C Market?

Sustainability is becoming a crucial factor in the procurement process for power socket Type C. The environmental impact of manufacturing electrical components, including resource depletion and e-waste, necessitates a focus on ethical sourcing and sustainable practices. For B2B buyers, sourcing from manufacturers that prioritize sustainable materials—such as recycled plastics and eco-friendly manufacturing processes—can enhance their brand reputation and align with corporate social responsibility goals.

Moreover, certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming increasingly important. Buyers should ensure that their suppliers hold these certifications to mitigate legal risks and demonstrate commitment to sustainability. In regions like Europe, where consumers are more environmentally conscious, partnering with suppliers that emphasize sustainability can lead to increased market acceptance and customer loyalty.

What Is the Evolution of Power Socket Type C and Its Relevance for B2B Buyers?

The Type C power socket has evolved significantly since its inception, transitioning from simple ungrounded designs to more sophisticated and versatile applications. Originally designed for low-energy appliances, the Type C plug has adapted to accommodate higher energy demands, particularly in the context of modern consumer electronics. This evolution reflects broader trends in electrical safety and efficiency, which are critical considerations for B2B buyers when selecting components for their products.

Understanding the historical context of Type C can provide valuable insights into its current market position and future potential. As countries modernize their electrical infrastructure, the demand for Type C sockets is likely to increase, making it imperative for B2B buyers to stay informed about technological advancements and regulatory changes. Adapting to these shifts will enable businesses to remain competitive and meet the growing expectations of consumers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of power socket type c

-

How do I ensure compatibility of Type C power sockets with my appliances?

To ensure compatibility, verify the voltage and amperage requirements of your appliances. Type C sockets support devices that consume up to 2.5 amps and operate typically at 220-240V. Check if your appliances have Type C plugs or if they can fit into Type E, F, J, K, or N sockets, as these are compatible with Type C plugs. Always consider the appliance’s power rating to avoid damage and ensure safety. -

What is the best sourcing strategy for Type C power sockets in international markets?

For effective sourcing, start by identifying reliable suppliers through platforms like Alibaba or local trade shows. Assess their certifications, such as CE and ISO, which indicate compliance with international standards. Establish direct communication to discuss your specific needs, including customization options. Additionally, consider engaging a sourcing agent familiar with local regulations and market conditions to streamline the process. -

How can I vet suppliers for Type C power sockets?

Begin by checking the supplier’s reputation through reviews and ratings on B2B platforms. Request references from previous clients and evaluate their experience with similar products. Conduct video calls or site visits to assess their manufacturing capabilities and quality control processes. Verify compliance with safety standards and certifications relevant to your region to ensure product reliability. -

What are the typical payment terms for purchasing Type C power sockets internationally?

Payment terms can vary widely but typically include options such as a 30% deposit upfront with the balance due upon shipment. Some suppliers may offer letters of credit or PayPal for added security. Always negotiate terms that protect your interests, especially for large orders. Be aware of currency fluctuations and consider using a forward contract to mitigate risks. -

What are the minimum order quantities (MOQs) for Type C power sockets?

MOQs for Type C power sockets can vary based on the manufacturer and specific customization needs. Generally, MOQs range from 100 to 1,000 units. If you require a smaller quantity, consider reaching out to suppliers for flexibility or looking for wholesalers. Some suppliers may also offer sample orders to evaluate quality before committing to larger quantities. -

How can I customize Type C power sockets to meet specific requirements?

Customization options often include color, labeling, and branding. Discuss your requirements with the supplier early in the negotiation process. Some manufacturers can also accommodate specific technical modifications, such as different pin configurations or enhanced durability features. Ensure that any customizations comply with international safety standards and regulations to avoid issues during importation. -

What quality assurance processes should I expect when sourcing Type C power sockets?

A reliable supplier should have a robust quality assurance (QA) program, including testing at various stages of production. This may involve inspections for compliance with international standards, such as CE marking. Request documentation of their QA processes, including test reports and certifications. Consider third-party inspections if you’re sourcing from a new supplier to ensure product quality before shipment. -

What logistical considerations should I keep in mind when importing Type C power sockets?

When importing, consider shipping methods (air vs. sea), as they affect delivery time and costs. Understand customs regulations in your country, including tariffs and import duties, to avoid unexpected expenses. Collaborate with a freight forwarder to manage logistics efficiently. Additionally, ensure that your suppliers provide proper documentation to facilitate smooth customs clearance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power socket type c

What Are the Key Takeaways for B2B Buyers of Power Socket Type C?

In summary, the Type C power socket represents a crucial component in the global electrical infrastructure, particularly for international B2B buyers. Its widespread use across Europe, parts of Africa, and South America offers significant opportunities for businesses engaged in importing and exporting electrical goods. Understanding the specifications and limitations of Type C, such as its ungrounded design and current rating, is vital for ensuring compatibility with various devices and appliances.

How Can Strategic Sourcing Enhance Your Business Operations?

Strategic sourcing of Type C sockets and plugs can yield substantial cost savings and operational efficiency. By partnering with reliable manufacturers and suppliers, businesses can ensure compliance with international standards and regulations, thereby minimizing risks associated with electrical safety. Additionally, leveraging local suppliers in markets like Africa or South America can facilitate quicker turnaround times and reduce shipping costs.

What Does the Future Hold for Type C Power Solutions?

Looking ahead, the trend towards grounded solutions in electrical installations may affect the demand for Type C sockets. However, as the Europlug remains integral to many low-energy applications, the need for high-quality Type C products will persist. International B2B buyers should stay informed about evolving market trends and regulatory changes to adapt their sourcing strategies accordingly.

Engage proactively with suppliers and stakeholders to secure advantageous partnerships that will not only meet current needs but also anticipate future demands in the dynamic global marketplace.