Unlock Efficiency: The Complete Guide to 55 Gal Drum Dimensions (2025)

Introduction: Navigating the Global Market for 55 gal drum dimensions

Navigating the complexities of sourcing 55-gallon drum dimensions can be a daunting challenge for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Understanding the precise measurements, material types, and applications of these essential containers is critical for ensuring compliance, optimizing logistics, and ultimately reducing costs. This comprehensive guide will delve into the various types of 55-gallon drums—ranging from steel and plastic to fiber—and their specific dimensions and features, such as open-head and closed-head configurations.

Throughout this guide, we will equip you with actionable insights on how to evaluate suppliers, consider cost implications, and assess the suitability of drum types for your specific needs. By addressing common questions and challenges related to 55-gallon drum dimensions, this resource empowers B2B buyers to make informed purchasing decisions. Whether you’re in the chemical, pharmaceutical, or food industry, understanding the nuances of drum dimensions can enhance your supply chain efficiency and product safety.

With the right knowledge, you can confidently navigate the global market for 55-gallon drums, ensuring your operations are both compliant and cost-effective. Let’s explore the key considerations that will aid you in selecting the right drum for your business needs.

Understanding 55 gal drum dimensions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Drum | Durable, standard height (33-36.75 inches), 22.38-24.5 inches in diameter, closed-head or open-head options. | Chemicals, oils, food products, hazardous materials. | Pros: High durability, reusable, excellent for hazardous materials. Cons: Heavier, may require special handling equipment. |

| Plastic Drum | Lightweight, typically made from HDPE, standard height (34-36 inches), 22-24 inches in diameter. | Chemicals, food products, pharmaceuticals. | Pros: Corrosion-resistant, less weight, often UV resistant. Cons: Limited use for hazardous materials compared to steel. |

| Fiber Drum | Made from layered kraft paper, often customizable height, typically lighter than metal drums. | Powders, dry goods, non-hazardous materials. | Pros: Lightweight, customizable, eco-friendly. Cons: Less durable, not suitable for liquids. |

| UN-Rated Drum | Complies with UN standards for hazardous materials, available in steel or plastic. | Transporting dangerous goods, chemicals. | Pros: Meets international safety standards, reliable for hazardous materials. Cons: May be more expensive due to certification. |

| Open-Head Drum | Removable lid secured with a locking ring, larger opening for easy access. | Semi-solids, thick liquids, adhesives. | Pros: Easy access for filling and dispensing. Cons: Not suitable for volatile or hazardous liquids due to exposure. |

What Are the Key Characteristics of Steel Drums?

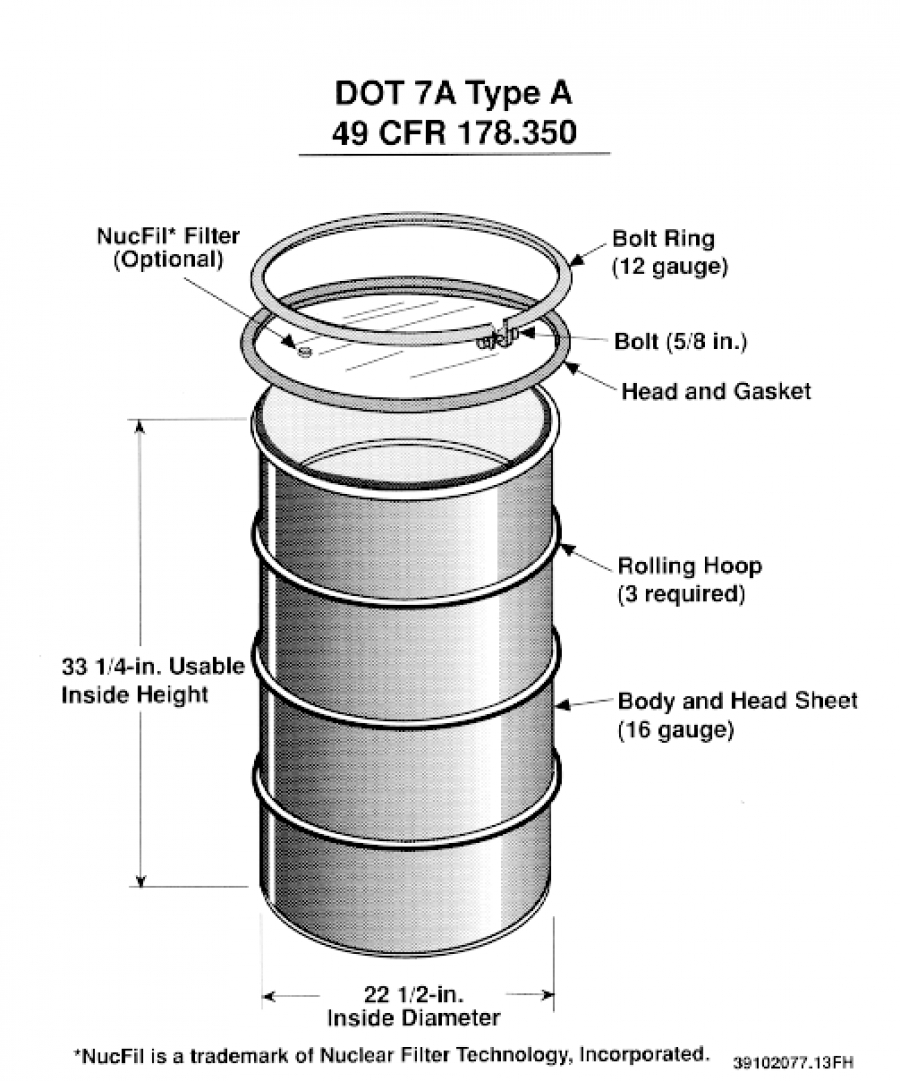

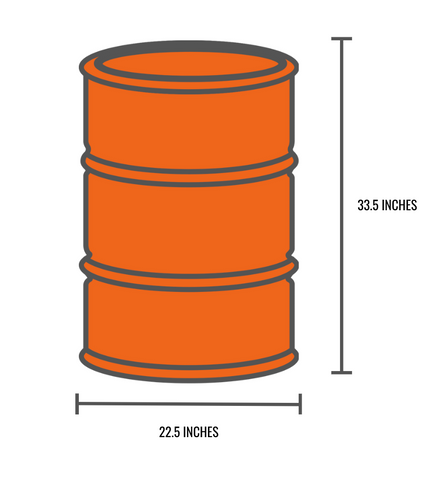

Steel drums are the most widely used type for bulk storage and transportation. Their standard height ranges from 33 to 36.75 inches, with a diameter of approximately 22.38 to 24.5 inches. They can come in both open-head and closed-head variations. Steel drums are ideal for handling hazardous materials and chemicals due to their durability and resistance to punctures. When purchasing, buyers should consider the weight and potential need for handling equipment, as filled steel drums can be quite heavy.

How Do Plastic Drums Differ from Steel Drums?

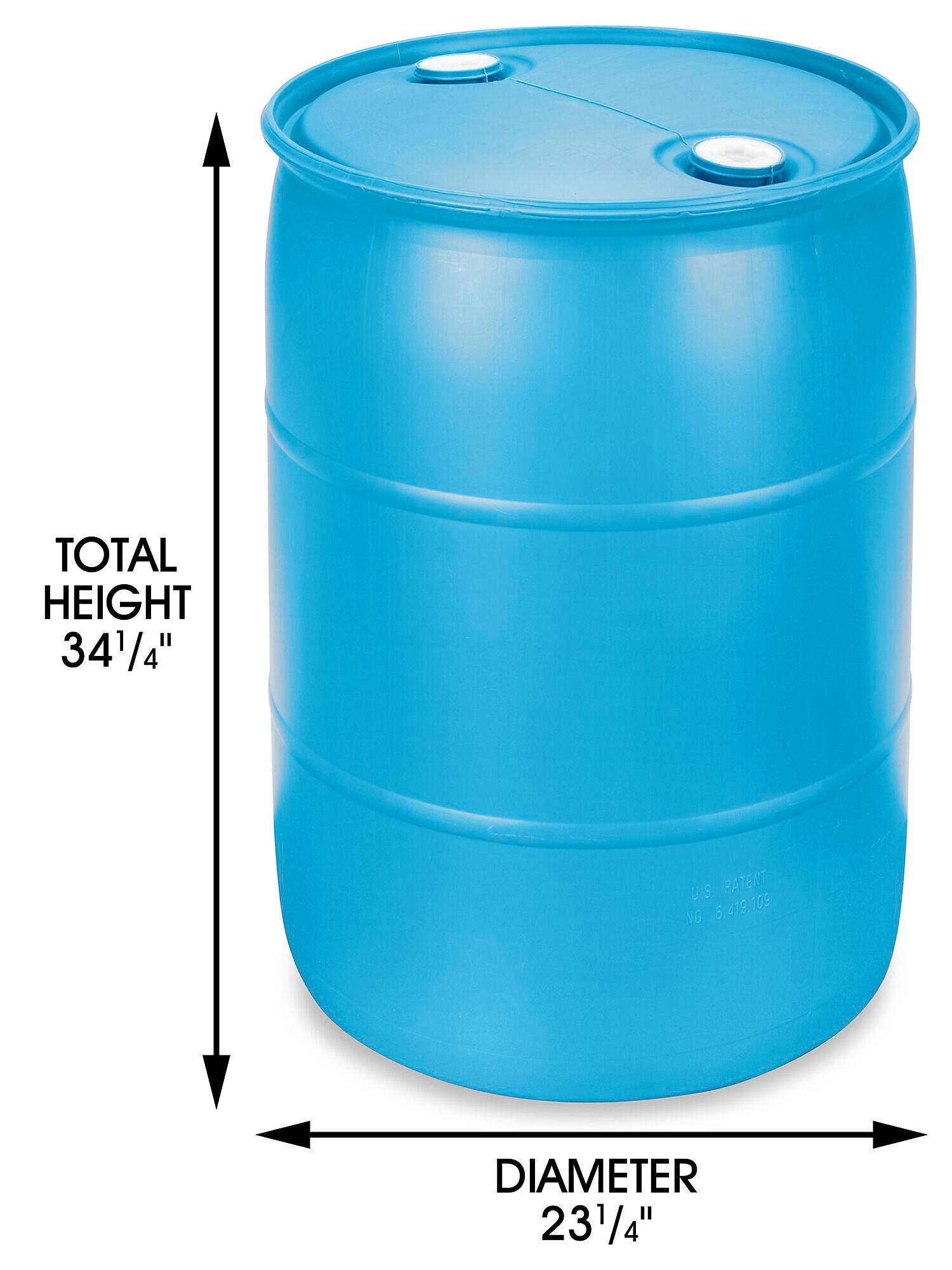

Plastic drums, often constructed from high-density polyethylene (HDPE), are lightweight and typically measure between 34 to 36 inches in height and 22 to 24 inches in diameter. They are particularly suitable for transporting chemicals, food products, and pharmaceuticals. While they are resistant to corrosion and can be UV resistant, buyers should be cautious about using them for hazardous materials, as they may not provide the same level of safety as steel drums.

A stock image related to 55 gal drum dimensions.

What Makes Fiber Drums a Viable Option?

Fiber drums are made from layered kraft paper and are often customizable in height, making them a flexible choice for various applications. They are lightweight and ideal for storing powders and dry goods. However, their durability is less than that of steel or plastic drums, limiting their use for liquids. B2B buyers should consider the environmental benefits of fiber drums, but also recognize that they are not suitable for hazardous materials.

Why Choose a UN-Rated Drum for Hazardous Materials?

UN-rated drums meet strict international standards for the transport of hazardous materials. Available in both steel and plastic, these drums are designed to safely contain dangerous goods, making them essential for compliance with safety regulations. While they offer peace of mind and reliability, buyers should be prepared for potentially higher costs due to the certification requirements.

What Are the Benefits of Open-Head Drums?

Open-head drums feature a removable lid, providing easy access to the contents. They are well-suited for semi-solids and thick liquids, making them ideal for products like adhesives or thick paints. However, their design may expose contents to the environment, which could be a concern for volatile or hazardous materials. When purchasing, businesses should evaluate the type of product being stored and the need for easy access versus containment.

Key Industrial Applications of 55 gal drum dimensions

| Industry/Sector | Specific Application of 55 gal drum dimensions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Manufacturing | Storage and transport of bulk chemicals | Ensures safe handling and compliance with regulations | Material compatibility, UN rating, and local regulations |

| Food and Beverage | Packaging for liquid food products | Maintains product integrity and extends shelf life | Food-grade certification, ease of cleaning, and sealing |

| Pharmaceuticals | Transport of active pharmaceutical ingredients (APIs) | Preserves purity and prevents contamination | Quality certifications, material type, and volume capacity |

| Agriculture | Storage of fertilizers and pesticides | Efficient use of space and ease of transport | Compatibility with chemicals, weight capacity, and durability |

| Oil and Gas | Transport of crude oil and refined products | Facilitates bulk transport and reduces shipping costs | Compliance with hazardous materials regulations and durability |

How Are 55 Gallon Drum Dimensions Used in Chemical Manufacturing?

In the chemical manufacturing industry, 55-gallon drums are essential for the storage and transportation of bulk chemicals. Their dimensions allow for easy handling and compliance with safety regulations. Buyers need to ensure that the drums are compatible with the specific chemicals being stored, and they should seek UN-rated containers to guarantee safety during transport. Additionally, understanding local regulations regarding hazardous materials is crucial for international buyers, especially in regions like Africa and the Middle East.

What Are the Benefits of Using 55 Gallon Drums in Food and Beverage Packaging?

In the food and beverage sector, 55-gallon drums are commonly used for packaging liquid products such as oils, sauces, and beverages. These drums help maintain product integrity and extend shelf life due to their durable construction and sealing capabilities. When sourcing these drums, businesses must prioritize food-grade certifications and ensure they are easy to clean. This is particularly important for buyers in Europe, where stringent food safety regulations apply.

How Do Pharmaceuticals Utilize 55 Gallon Drums for Transport?

Pharmaceutical companies use 55-gallon drums to transport active pharmaceutical ingredients (APIs) and other sensitive materials. The precise dimensions of these drums ensure that they can be securely stored and transported without compromising the purity of the contents. Buyers in this sector must consider quality certifications and the type of material used in the drum to prevent contamination. This is especially vital for international buyers in regions with varying regulatory standards, such as South America and Europe.

What Role Do 55 Gallon Drums Play in Agriculture?

In agriculture, 55-gallon drums are utilized for the storage of fertilizers and pesticides. Their dimensions allow for efficient use of space and ease of transport, making them ideal for large-scale agricultural operations. Buyers should ensure that the drums are compatible with the chemicals being stored and are durable enough to withstand outdoor conditions. This is particularly relevant for buyers in Africa and South America, where agricultural practices can vary significantly.

How Are 55 Gallon Drums Essential in the Oil and Gas Industry?

The oil and gas industry relies heavily on 55-gallon drums for the transport of crude oil and refined products. Their size and strength facilitate bulk transport, which can significantly reduce shipping costs. When sourcing these drums, companies must ensure compliance with hazardous materials regulations and select drums that can withstand the rigors of transport. This is particularly important for international buyers in the Middle East, where oil transportation is a critical aspect of the economy.

3 Common User Pain Points for ’55 gal drum dimensions’ & Their Solutions

Scenario 1: Misalignment of Drum Dimensions with Storage Facilities

The Problem:

B2B buyers often face challenges when the dimensions of 55-gallon drums do not align with their storage facilities. For instance, a buyer in South Africa may purchase a batch of steel drums that are taller than anticipated, leading to difficulty in stacking or storing them within existing warehouse constraints. This misalignment can lead to inefficient use of space, increased costs, and logistical headaches as the buyer has to either redesign their storage layout or incur additional expenses to modify their facilities.

The Solution:

To prevent this issue, it is crucial for buyers to thoroughly assess their storage capabilities before placing an order. They should measure their existing storage areas and consider the drum dimensions, which typically range from 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter. When ordering, buyers should specify the required dimensions and confirm them with suppliers. Additionally, investing in adjustable shelving or modular storage solutions can provide flexibility to accommodate variations in drum size, allowing for efficient use of space and easy access to products.

Scenario 2: Incompatibility of Drum Type with Product Specifications

The Problem:

Another common pain point for B2B buyers revolves around selecting the wrong type of drum for their specific product needs. For instance, a chemical manufacturer in Europe might purchase open-head drums, only to find that their viscous substances are better suited for closed-head drums. This incompatibility can lead to product spoilage, compliance issues, and financial losses due to the inability to transport or store materials securely.

The Solution:

To address this challenge, buyers must invest time in understanding the specific requirements of their products and the types of drums available. They should consider factors such as viscosity, chemical compatibility, and whether the product is a solid, liquid, or semi-solid. Consulting with suppliers to obtain detailed information about drum materials and configurations is essential. Moreover, implementing a checklist that includes product characteristics and drum specifications can help streamline the selection process, ensuring that the right type of drum is ordered every time.

Scenario 3: Confusion Over Drum Weight and Shipping Logistics

The Problem:

B2B buyers frequently encounter difficulties related to the weight of filled 55-gallon drums and the implications this has for shipping logistics. For example, a buyer in South America might underestimate the total weight of a shipment, which includes the drum and its contents, leading to higher shipping costs or restrictions on transportation methods. This confusion can result in delays, unexpected expenses, and even compliance issues if weight limits are exceeded.

The Solution:

To mitigate this risk, buyers should calculate the total weight of filled drums accurately before finalizing orders. A filled 55-gallon drum typically weighs around 500 pounds, depending on the product. Buyers should request detailed specifications from suppliers regarding the weight of both empty and filled drums, and consider using logistics software that factors in drum weight and volume for shipping calculations. Furthermore, establishing a relationship with a reliable logistics provider can help navigate shipping complexities, ensuring that the buyer is informed about weight limits and potential costs associated with their shipments.

Strategic Material Selection Guide for 55 gal drum dimensions

What Are the Key Properties of Steel 55-Gallon Drums?

Steel drums, particularly those made from carbon steel, are renowned for their strength and durability. They typically have a temperature rating that can withstand a wide range of conditions, making them suitable for both high and low-temperature applications. Steel also offers excellent corrosion resistance when properly coated, which is crucial for transporting chemicals and other corrosive materials.

Pros and Cons of Steel Drums

The primary advantage of steel drums is their robustness, which allows them to be reused multiple times without significant wear. They are also compliant with international standards such as UN ratings for hazardous materials, making them a safe choice for shipping dangerous goods. However, they can be heavier and more expensive than other materials, which may affect shipping costs. Additionally, if not properly coated, they can rust when exposed to moisture.

Impact on Application

Steel drums are ideal for storing and transporting liquids and solids, particularly hazardous materials like chemicals and oils. Their durability ensures that they can handle rough handling during transport, making them suitable for international shipping.

How Do Plastic 55-Gallon Drums Compare?

Plastic drums, often made from high-density polyethylene (HDPE), are lightweight and resistant to corrosion. They typically have a temperature rating that is lower than steel, but they perform well in many chemical applications due to their resistance to a wide range of substances.

Pros and Cons of Plastic Drums

The main advantage of plastic drums is their cost-effectiveness and lightweight nature, which reduces shipping costs. They are also resistant to UV light and can be molded in various colors for identification purposes. However, they may not be suitable for high-pressure applications, and their mechanical strength is generally lower than that of steel drums. Additionally, they may not be as widely accepted for hazardous materials in certain regions.

Impact on Application

Plastic drums are commonly used for storing non-hazardous liquids, chemicals, and food products. Their compatibility with various substances makes them a versatile option for many industries, particularly in regions where weight is a significant concern.

What Are the Benefits of Fiber Drums?

Fiber drums, constructed from layers of kraft paper and adhesive, offer a lightweight alternative for dry goods. They are typically used for transporting powders and semi-solids and can be customized in height and diameter.

Pros and Cons of Fiber Drums

One of the key advantages of fiber drums is their lightweight design, which makes them easy to handle and reduces shipping costs. They are also recyclable, aligning with sustainable practices. However, they are not suitable for liquids, particularly those that are corrosive or require a sealed environment. Their durability is also less than that of steel and plastic drums, making them less ideal for rough handling.

Impact on Application

Fiber drums are best suited for dry products like grains, powders, and other non-liquid materials. Their design allows for easy stacking and storage, making them a practical choice for warehouses and distribution centers.

What Should International B2B Buyers Consider?

When selecting a 55-gallon drum, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe must consider compliance with local and international standards, such as ASTM, DIN, and JIS. Understanding the specific requirements for hazardous materials is crucial, as regulations can vary significantly across regions. Additionally, preferences for materials may differ, with some regions favoring plastic for its lightweight nature, while others may prioritize the durability of steel.

| Material | Typical Use Case for 55 gal drum dimensions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Transporting hazardous liquids and chemicals | High durability and strength | Heavier and potentially more expensive | High |

| Plastic | Storing non-hazardous liquids and chemicals | Lightweight and cost-effective | Limited pressure handling capability | Medium |

| Fiber | Transporting dry goods and powders | Lightweight and recyclable | Not suitable for liquids | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the various types of 55-gallon drums available, helping them make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 55 gal drum dimensions

What Are the Key Stages in the Manufacturing Process of 55-Gallon Drums?

The manufacturing of 55-gallon drums involves several critical stages, ensuring that the final product meets both functional and regulatory standards. Understanding these stages is essential for B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

Material Preparation: What Materials Are Used for 55-Gallon Drums?

The primary materials used in manufacturing 55-gallon drums include steel, plastic, and fiber.

- Steel Drums: Typically made from low-carbon or stainless steel, these drums offer high durability and strength. The sheets are cut to specific dimensions before being processed.

- Plastic Drums: Made from high-density polyethylene (HDPE) or other polymers, these drums are ideal for chemical storage and provide resistance to corrosion.

- Fiber Drums: Constructed from multi-layer kraft paper, these drums are lightweight and suitable for dry goods.

Material selection depends on the intended use of the drum, ensuring compatibility with the contents while maintaining integrity.

How Are 55-Gallon Drums Formed and Assembled?

The forming and assembly of 55-gallon drums involve several precise techniques to ensure quality and consistency:

-

Forming: For steel drums, the material is rolled into a cylindrical shape and welded. Plastic drums undergo blow molding, where molten plastic is expanded into a mold. Fiber drums are formed by rolling layers of paper into a cylinder.

-

Assembly:

– Open-Head Drums: Feature a removable lid secured with a locking ring. They are better suited for thicker substances.

– Closed-Head Drums: Have a permanently attached top with specific openings for filling and dispensing.

After forming, the drums undergo a process where the bottom and top are mechanically seamed to ensure structural integrity.

What Finishing Techniques Are Used for 55-Gallon Drums?

Finishing techniques significantly impact the drum’s usability and longevity.

- Coating: Steel drums may be coated with paint or a protective layer to prevent rust and corrosion. The interior may also be lined with a protective coating depending on the contents.

- Labeling and Marking: Drums are often labeled with essential information regarding contents, handling instructions, and compliance marks.

These finishing touches not only enhance durability but also ensure compliance with international shipping regulations.

What Quality Assurance Standards Are Relevant for 55-Gallon Drums?

Quality assurance is critical in the manufacturing process of 55-gallon drums, particularly for international B2B buyers who require consistent quality across various suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

Several international standards govern the manufacturing and quality assurance processes for 55-gallon drums:

- ISO 9001: This standard focuses on quality management systems and is vital for manufacturers aiming to ensure consistent quality and customer satisfaction.

- UN Standards: Drums intended for hazardous materials must meet specific UN performance standards for dangerous goods, ensuring safety during transport.

- CE Marking: In Europe, products must meet certain safety, health, and environmental protection standards to be sold within the European Economic Area.

Understanding these standards helps B2B buyers evaluate potential suppliers and ensure compliance with regulatory requirements.

What Are the Key Quality Control Checkpoints in Drum Manufacturing?

Quality control (QC) checkpoints are crucial for maintaining the integrity and safety of the manufacturing process.

What Are the Main QC Checkpoints in Drum Production?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before production begins. It ensures that only high-quality materials are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC measures are taken to monitor production processes. This includes checking dimensions, weld integrity, and coating application.

-

Final Quality Control (FQC): Once the drums are completed, FQC involves comprehensive testing, including pressure testing for leaks, visual inspections, and weight verification.

These checkpoints are designed to catch any discrepancies early in the process, minimizing the risk of defects in the final product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing 55-gallon drums, B2B buyers should proactively verify the quality control practices of potential suppliers to ensure product reliability.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting regular audits of suppliers can help assess their quality management systems. This includes reviewing their manufacturing processes, QC checkpoints, and compliance with international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for documented quality reports, including IQC, IPQC, and FQC results. This transparency can build trust and ensure accountability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s processes and products. This is particularly important for buyers in regions where regulatory compliance is critical.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control that could affect their sourcing decisions.

What Are the Key Considerations for International Sourcing?

-

Cultural and Regulatory Differences: Understanding the local manufacturing practices and regulations in the supplier’s country can influence quality assurance. Buyers should familiarize themselves with the local standards that may differ from their own.

-

Logistical Challenges: International shipping adds complexity to quality assurance. Buyers should consider the potential for damage during transport and ensure that the drums are packaged appropriately.

-

Language Barriers: Communication is key in quality assurance. Buyers should ensure that they can clearly convey their requirements and understand the supplier’s capabilities.

By taking these factors into account, international B2B buyers can make informed decisions when sourcing 55-gallon drums, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’55 gal drum dimensions’

When sourcing 55-gallon drums, understanding their dimensions and specifications is crucial for ensuring compatibility with your products and operational requirements. This guide outlines a systematic approach for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to effectively procure the right drums.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the 55-gallon drums you need. This includes specifying the type of material (steel, plastic, or fiber), whether you require an open-head or closed-head configuration, and any specific size constraints based on your storage and shipping capabilities. Knowing these details upfront will streamline your sourcing process and help avoid compatibility issues later.

Step 2: Research Industry Standards and Regulations

Understand the relevant industry standards and regulations that apply to the transportation and storage of your products. This is especially important if you deal with hazardous materials, as UN-rated drums must meet specific performance standards. Familiarize yourself with the regulations in your target markets, as compliance can vary significantly between regions, impacting both safety and legal responsibilities.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product specifications, and references from other businesses in your industry. Focus on suppliers who have experience in your geographical area, as they will be more familiar with local regulations and logistical challenges.

Step 4: Request Samples for Quality Assessment

Once you’ve narrowed down your options, request samples of the 55-gallon drums to assess their quality firsthand. Examine the construction, dimensions, and any additional features such as linings or coatings that may be relevant to your specific needs. This step is vital to ensure that the drums meet your quality standards and are suitable for your intended application.

Step 5: Confirm Shipping and Handling Capabilities

Before finalizing your order, confirm the supplier’s shipping capabilities and policies. Understand how many drums can fit on a standard pallet, and whether the supplier can accommodate your preferred shipping method. Additionally, clarify the costs associated with shipping and handling, as these can significantly impact your total procurement budget.

Step 6: Negotiate Terms and Conditions

Engage in discussions regarding pricing, payment terms, and delivery schedules. Ensure that the terms are favorable and reflect the market conditions. Be clear about your expectations regarding lead times and any penalties for delays, as timely delivery is crucial for maintaining your operations.

Step 7: Establish a Long-term Relationship

Consider establishing a long-term partnership with a reliable supplier. A strong relationship can lead to better pricing, priority service, and access to new products or technologies as they become available. Regularly communicate your needs and feedback to foster a mutually beneficial relationship that can adapt to changing market demands.

By following this checklist, international B2B buyers can ensure they select the right 55-gallon drums for their specific needs, ultimately leading to improved operational efficiency and product safety.

Comprehensive Cost and Pricing Analysis for 55 gal drum dimensions Sourcing

What Are the Key Cost Components in Sourcing 55-Gallon Drums?

When sourcing 55-gallon drums, international B2B buyers must consider several key cost components that contribute to the overall price. These include:

-

Materials: The choice of material—steel, plastic, or fiber—significantly impacts cost. Steel drums tend to be the most expensive due to their durability and strength, while plastic drums are generally more affordable but may not offer the same level of protection for sensitive contents.

-

Labor: Labor costs can vary widely depending on the region of manufacturing. Countries with lower labor costs may offer more competitive pricing, but this could come at the expense of quality or compliance with international standards.

-

Manufacturing Overhead: This encompasses all costs related to the production process, including utilities, maintenance, and facility costs. Efficient manufacturing practices can reduce overhead, leading to lower prices for buyers.

-

Tooling: Custom designs or specifications require specialized tooling, which can add to the initial cost. Buyers should assess whether their needs justify these expenses.

-

Quality Control (QC): Ensuring that drums meet safety and quality standards is critical, especially for hazardous materials. Rigorous QC processes can increase costs but are essential for compliance and safety.

-

Logistics: Shipping costs can vary based on distance, transportation method, and regional tariffs. For international buyers, understanding Incoterms is crucial to avoid unexpected expenses.

-

Margin: Suppliers often include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Impact 55-Gallon Drum Costs?

Several factors influence the pricing of 55-gallon drums, particularly for international buyers:

-

Volume/MOQ: Buying in bulk can lead to significant discounts. Understanding the minimum order quantity (MOQ) set by suppliers can help buyers negotiate better pricing.

-

Specifications and Customization: Custom features such as specific sizes, colors, or linings can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-quality materials or specific certifications (e.g., UN-rated for hazardous materials) can lead to higher prices. It’s important for buyers to balance cost with the necessary quality standards.

-

Supplier Factors: Established suppliers with a proven track record may charge more but offer better reliability and service. Evaluating potential suppliers based on their reputation and experience can yield long-term benefits.

-

Incoterms: Understanding the implications of different Incoterms can affect total costs, including who is responsible for shipping, insurance, and duties. This knowledge can prevent misunderstandings and additional charges.

What Are the Best Tips for International B2B Buyers in Sourcing 55-Gallon Drums?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, here are actionable tips for sourcing 55-gallon drums effectively:

-

Negotiate Wisely: Leverage your purchasing power, especially if you are ordering in bulk. Suppliers are often willing to offer discounts for larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including shipping, handling, and potential disposal fees. A lower initial price may not always be the most cost-effective choice.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, sourcing from suppliers in Europe may be more expensive than from South America due to labor and material costs.

-

Request Samples: Before committing to large orders, request samples to assess quality. This helps ensure that the drums meet your specifications and reduces the risk of costly returns.

-

Stay Informed About Market Trends: Understanding market fluctuations in material costs, labor rates, and logistics can help you time your purchases effectively.

Disclaimer on Indicative Prices

Prices for 55-gallon drums can vary significantly based on the factors discussed above. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they receive a fair and competitive price.

Alternatives Analysis: Comparing 55 gal drum dimensions With Other Solutions

Introduction to Alternatives for 55 Gal Drum Dimensions

When it comes to bulk storage and transportation of liquids, solids, or powders, the 55-gallon drum has long been a preferred choice due to its durability and versatility. However, international B2B buyers may find themselves considering alternative solutions that might better suit their specific needs in terms of performance, cost, and operational efficiency. This section will compare the dimensions and functionality of 55-gallon drums with two viable alternatives: Intermediate Bulk Containers (IBCs) and 5-gallon pails.

Comparison Table

| Comparison Aspect | 55 Gal Drum Dimensions | Intermediate Bulk Container (IBC) | 5-Gallon Pail |

|---|---|---|---|

| Performance | Strong, durable, versatile | High capacity, efficient for liquids | Portable, easy to handle |

| Cost | Moderate initial investment | Higher upfront cost | Lower cost per unit |

| Ease of Implementation | Requires manual handling | Needs forklift for movement | Hand-held, requires no special tools |

| Maintenance | Low, easily cleaned | Moderate, requires inspection | Very low, single-use often |

| Best Use Case | Chemicals, oils, food products | Bulk liquids, hazardous materials | Small quantities, food, adhesives |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Intermediate Bulk Containers (IBCs)?

Intermediate Bulk Containers (IBCs) are large containers that can typically hold between 275 to 330 gallons. They are often made from plastic and have a metal cage for added durability.

Pros:

– High Capacity: IBCs can hold significantly more than a 55-gallon drum, making them ideal for large-scale operations.

– Easy Dispensing: Many IBCs come equipped with taps for easy dispensing of liquids.

Cons:

– Higher Cost: The initial investment for IBCs is higher compared to 55-gallon drums.

– Special Handling Equipment Required: Moving IBCs usually requires a forklift, which can be a limitation in smaller facilities.

How Do 5-Gallon Pails Compare to 55-Gallon Drums?

5-gallon pails are smaller containers often used for liquids like paints, adhesives, and food products. They are typically made of plastic or metal.

Pros:

– Cost-Effective: Lower cost per unit makes them accessible for smaller businesses or low-volume needs.

– Portability: Lightweight and easy to handle, making them ideal for small batch applications.

Cons:

– Limited Capacity: The smaller size means that they are not suitable for bulk storage.

– More Frequent Handling: Higher frequency of handling and potential for increased labor costs due to more trips needed for large volumes.

Conclusion: Choosing the Right Solution for Your Needs

For international B2B buyers, the choice between 55-gallon drums, IBCs, and 5-gallon pails ultimately depends on specific operational needs, volume requirements, and budget constraints. While 55-gallon drums provide a balance of capacity and portability, IBCs are better suited for larger volumes, especially in chemical or hazardous material handling. Conversely, 5-gallon pails are ideal for smaller quantities and more frequent handling tasks. Understanding the unique advantages and limitations of each option allows businesses to make informed decisions that optimize their logistics and storage capabilities.

Essential Technical Properties and Trade Terminology for 55 gal drum dimensions

What Are the Key Technical Properties of 55-Gallon Drums?

When considering the purchase of 55-gallon drums, understanding the essential technical properties is crucial for ensuring compatibility with your intended application. Here are some critical specifications:

1. Material Grade

The most common materials for 55-gallon drums are steel, plastic (HDPE), and fiber. Each material has specific properties that affect its suitability for different contents. For instance, steel drums offer high durability and are ideal for hazardous materials, while HDPE drums are preferred for chemicals due to their resistance to corrosion. Choosing the right material is vital for maintaining product integrity and safety during transport and storage.

2. Dimensions and Tolerances

Standard dimensions for 55-gallon drums typically range from 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter. Variations exist between open-head and closed-head designs. Understanding these dimensions helps in optimizing storage space and ensuring compatibility with shipping containers. Tolerances are also important, as slight variations can impact how the drums fit on pallets or within larger shipping systems.

3. Weight Capacity

A filled 55-gallon drum can weigh approximately 500 pounds, depending on the contents. Knowing the weight capacity is essential for logistics planning, especially in regions where transportation regulations may impose weight limits. This knowledge aids in avoiding costly overloading fines and ensures safe handling practices.

4. UN Rating

The UN rating indicates whether a drum is suitable for transporting hazardous materials. This rating is crucial for compliance with international shipping regulations. Buyers must ensure that the drums they procure meet the appropriate UN standards for their specific products, as failure to comply can lead to severe penalties and safety risks.

5. Closure Type

The type of closure—open-head or closed-head—affects the ease of access and the types of materials that can be stored. Open-head drums are suitable for viscous materials, while closed-head drums are better for liquids and require specialized handling equipment. Understanding the closure type helps in selecting the right drum for specific operational needs.

What Are the Common Trade Terms Related to 55-Gallon Drums?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

In the context of drums, OEM refers to manufacturers who produce drums that meet specific standards set by another company. This term is essential when sourcing drums that require specific branding or performance specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a supplier is willing to sell. This term is significant for buyers who need to manage inventory costs and may impact purchasing decisions, especially for small businesses or startups.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products. This process helps buyers compare prices and terms, ensuring they secure the best deal for their needs. It is an essential step in procurement, especially for bulk purchases of 55-gallon drums.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for determining who is responsible for shipping costs, insurance, and risk during transportation. Proper knowledge of Incoterms can prevent disputes and ensure smooth transactions.

5. Lead Time

Lead time refers to the period from placing an order to receiving the goods. This term is particularly important in supply chain management, as it affects inventory levels and production schedules. Buyers must account for lead times when planning their operations to avoid disruptions.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing 55-gallon drums for your business needs.

Navigating Market Dynamics and Sourcing Trends in the 55 gal drum dimensions Sector

What Are the Current Market Dynamics for 55 Gallon Drum Dimensions?

The global market for 55-gallon drums is experiencing dynamic shifts driven by various factors, including increased demand for efficient shipping solutions and stringent regulations on hazardous materials. The popularity of the 55-gallon drum, also known as the 208-liter drum, is attributed to its optimal size, durability, and versatility in transporting a wide range of products. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly leveraging advancements in technology to streamline sourcing processes.

Emerging technologies such as IoT-enabled tracking systems and automated inventory management are reshaping how businesses manage their supply chains. These innovations enhance visibility, reduce lead times, and improve operational efficiency. Additionally, the rise of e-commerce has led to increased competition, prompting suppliers to offer more customized solutions, including tailored dimensions and materials to meet specific industry needs.

Moreover, sustainability considerations are influencing purchasing decisions. As businesses prioritize eco-friendly practices, buyers are seeking suppliers who can provide information on the environmental impact of their products. Understanding local regulations and compliance standards in different regions is also critical for B2B buyers to mitigate risks and ensure smooth operations.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions?

Sustainability is becoming a cornerstone of modern B2B procurement strategies, particularly in the sourcing of 55-gallon drums. The environmental impact of packaging materials is under scrutiny, with a growing emphasis on reducing waste and carbon footprints. International buyers, especially those in Europe, are increasingly inclined to source products that comply with environmental standards and certifications, such as ISO 14001, which addresses effective environmental management systems.

A stock image related to 55 gal drum dimensions.

Ethical sourcing is not just a trend; it is a vital component of corporate social responsibility. Suppliers that can demonstrate their commitment to sustainable practices often gain a competitive edge in the market. For example, utilizing recycled materials in the production of 55-gallon drums or offering reusable packaging solutions can significantly enhance a company’s reputation and appeal to environmentally conscious buyers.

Furthermore, the use of ‘green’ certifications, such as those from the Forest Stewardship Council (FSC) or the Global Recycle Standard (GRS), assures buyers that the materials used in their drums are sourced responsibly. This transparency can foster stronger relationships between suppliers and buyers, as both parties work towards common sustainability goals.

What Is the Historical Context of 55 Gallon Drums in B2B Trade?

The evolution of the 55-gallon drum dates back to the early 20th century, when Standard Oil began mass-producing these cylindrical containers to streamline the shipping of oil. This innovation marked a pivotal shift in how bulk liquids were stored and transported, paving the way for the widespread adoption of the 55-gallon drum across various industries.

A stock image related to 55 gal drum dimensions.

Over the decades, the design and materials used in drum manufacturing have evolved significantly. Originally made of wood, modern 55-gallon drums are primarily produced from steel, plastic, or fiberboard, each offering unique benefits tailored to specific applications. The versatility of the 55-gallon drum has made it a staple in industries ranging from chemicals to food and beverage, reinforcing its status as an essential component in global trade.

Understanding this historical context can provide B2B buyers with insights into the development of industry standards and the continuous improvement in drum designs, enabling them to make informed sourcing decisions that align with both their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 55 gal drum dimensions

-

How do I determine the dimensions of a 55-gallon drum for my specific needs?

To determine the appropriate dimensions of a 55-gallon drum for your needs, consider the type of material (steel, plastic, or fiber) and whether you require an open or closed head. Standard steel drums typically measure 33 to 36.75 inches in height and 22.375 to 24.5 inches in diameter. For plastic drums, the dimensions vary slightly, while fiber drums are generally lighter and may have customizable heights. It’s crucial to consult with your supplier for exact specifications to ensure compatibility with your storage and shipping requirements. -

What is the best type of 55-gallon drum for shipping hazardous materials?

For shipping hazardous materials, a UN-rated closed-head steel drum is typically the best choice. These drums are designed to meet stringent international safety standards and are constructed to prevent leaks. Ensure the drum has a 2” or 3” bunghole for easy filling and dispensing, along with a vent hole to manage pressure. Always verify that your selected drum complies with local regulations and the specific requirements of the materials being transported. -

What are the key factors to consider when sourcing 55-gallon drums internationally?

When sourcing 55-gallon drums internationally, consider the supplier’s compliance with international standards, product certifications, and material quality. It’s also essential to evaluate shipping costs, lead times, and payment terms. Look for suppliers who can provide references or case studies of their experience with clients in your region. Assessing the supplier’s ability to customize drum dimensions or features based on your specific needs can also be a significant advantage. -

How can I vet suppliers for 55-gallon drums in Africa and South America?

To vet suppliers for 55-gallon drums in Africa and South America, start by checking for industry certifications and compliance with international standards. Look for reviews and testimonials from other international buyers, and request samples to assess product quality. Conduct background checks on the supplier’s financial stability and operational history. Additionally, consider visiting their facilities if feasible, or use third-party inspection services to ensure they meet your quality and safety expectations. -

What are the minimum order quantities (MOQ) for 55-gallon drums from European suppliers?

Minimum order quantities (MOQ) for 55-gallon drums can vary widely among European suppliers. Typically, MOQs range from 50 to 500 units, depending on the supplier’s production capacity and the type of drum. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s advisable to negotiate terms that suit your purchasing needs. Always confirm the MOQ before placing an order to avoid unexpected costs or delays. -

What payment terms should I expect when ordering 55-gallon drums internationally?

Payment terms for ordering 55-gallon drums internationally can vary by supplier and region. Common practices include a deposit (typically 30% to 50%) upfront, with the balance due upon delivery or before shipping. Some suppliers may offer letters of credit or other financing options, especially for larger orders. Always clarify payment terms in advance and ensure they are documented in your purchase agreement to avoid any misunderstandings. -

How can I ensure quality assurance (QA) for my 55-gallon drum orders?

To ensure quality assurance for your 55-gallon drum orders, establish clear specifications and standards with your supplier before production begins. Request certificates of compliance and ask for regular updates throughout the manufacturing process. Consider implementing a third-party inspection service to conduct quality checks before shipment. Additionally, inquire about the supplier’s return policy and warranty terms to protect your investment. -

What logistical considerations should I keep in mind when importing 55-gallon drums?

When importing 55-gallon drums, consider factors such as shipping methods, customs regulations, and import duties specific to your country. Ensure you have the appropriate documentation, including bills of lading and customs declarations, to facilitate smooth processing at the border. Additionally, evaluate storage capabilities upon arrival, as the drums may require specific handling or storage conditions. Collaborate with a logistics provider experienced in international trade to streamline the process and reduce risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 55 gal drum dimensions

As international B2B buyers navigate the complexities of sourcing 55-gallon drums, understanding the dimensions and specifications of these containers is crucial for optimizing supply chain efficiency. Key takeaways include recognizing the variations in drum sizes based on material—steel, plastic, or fiber—and configuration—open or closed-head. Each type serves specific applications, impacting storage, transport, and product integrity.

Strategic sourcing of 55-gallon drums not only ensures compliance with international standards but also enhances operational flexibility. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who offer diverse options tailored to their unique needs, ensuring that their products are safely stored and transported.

Looking ahead, the demand for sustainable and reusable packaging solutions is on the rise. By embracing innovative sourcing strategies, businesses can mitigate risks and capitalize on market opportunities. Engage with trusted suppliers to secure the right drum for your applications, and stay ahead in a competitive landscape. As you consider your next procurement, remember that the right choice in 55-gallon drum dimensions can significantly influence your operational success.