Unlock Efficiency: The Complete Guide to Planetary Gear (2025)

Introduction: Navigating the Global Market for planetary gear

Navigating the intricate landscape of the global market for planetary gears can be daunting for international B2B buyers, especially when seeking reliable suppliers and high-quality products. As businesses in Africa, South America, the Middle East, and Europe (such as Colombia and the UAE) increasingly adopt advanced machinery and automated systems, understanding the nuances of planetary gear systems becomes crucial. This guide aims to demystify the complexities associated with sourcing planetary gears, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

With an emphasis on actionable insights, this comprehensive resource empowers B2B buyers to make informed purchasing decisions. We delve into the various configurations of planetary gear systems, highlighting their applications in industries ranging from automotive to renewable energy. Furthermore, we provide detailed criteria for evaluating potential suppliers, ensuring you can identify those who meet stringent quality and reliability standards.

By equipping you with the knowledge to navigate the global market effectively, this guide not only saves time and resources but also enhances your operational efficiency. Whether you are looking to optimize your supply chain or integrate cutting-edge technology into your operations, understanding planetary gears will position your business for success in a competitive environment.

Understanding planetary gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Planetary Gear | Features a sun gear, planet gears, and a ring gear. Compact design with high torque density. | Automotive transmissions, industrial machinery, robotics | Pros: High efficiency, compact size; Cons: Complex design may require specialized knowledge. |

| Solar Gear | Sun gear fixed while the internal gear serves as input, allowing for variable output speeds. | Electric vehicles, conveyor systems | Pros: Versatile speed control; Cons: Limited torque capacity compared to other types. |

| Star Gear | Carrier fixed; planet gears act as idlers, leading to opposite rotations between input and output. | Aerospace applications, machine tools | Pros: Simple design; Cons: Loses planetary characteristics, limiting its applications. |

| Hypocycloid Gear | Unique mechanism with minimal teeth difference, achieving high reduction ratios in compact setups. | High-precision machinery, robotics | Pros: Exceptional reduction ratios; Cons: Requires precise manufacturing tolerances. |

| Constrained Gear | Closed-loop system with four gears, providing efficient power transmission. | Heavy machinery, automotive applications | Pros: Enhanced load handling; Cons: Complexity in design and assembly. |

What Are the Key Characteristics of Planetary Gears?

Planetary gears are renowned for their compact design, featuring a central sun gear surrounded by planet gears and an encircling ring gear. This configuration allows for high torque density and efficient load distribution. B2B buyers should consider their application needs, as planetary gears excel in automotive transmissions and industrial machinery where space and load capacity are critical.

How Do Solar Gears Differ From Other Types?

In a solar gear configuration, the sun gear is fixed while the internal gear acts as the input. This setup allows for variable output speeds, making it ideal for applications such as electric vehicles and conveyor systems. Buyers must weigh the benefits of speed versatility against the potential limitations in torque capacity when selecting solar gears for their operations.

Why Choose Star Gears for Aerospace Applications?

Star gears, where the carrier is fixed and planet gears function as idlers, are suited for aerospace applications due to their straightforward design and reliability. While they simplify construction, they also lose some of the advantages of planetary systems, such as torque multiplication. B2B buyers in aerospace should assess the trade-off between simplicity and performance based on their specific needs.

What Advantages Do Hypocycloid Gears Offer?

Hypocycloid gears stand out for their ability to achieve high reduction ratios with minimal teeth differences, making them ideal for high-precision machinery and robotics. However, the manufacturing process requires stringent tolerances, which can be a challenge for some buyers. Understanding the precision requirements is essential for industries that demand accuracy.

When to Consider Constrained Gears for Heavy Machinery?

Constrained gears, characterized by their closed-loop design, provide efficient power transmission and enhanced load handling capabilities. They are particularly beneficial in heavy machinery applications. However, their complexity in design and assembly can pose challenges. Buyers should evaluate the operational requirements and assembly capabilities before opting for constrained gear systems.

Key Industrial Applications of planetary gear

| Industry/Sector | Specific Application of Planetary Gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Automatic Transmissions | Enhances fuel efficiency and smooth gear shifts | Quality certifications, compatibility with existing systems, local regulations |

| Industrial Machinery | Heavy Lifting Equipment | Provides high torque for lifting heavy loads | Load capacity ratings, durability under extreme conditions, maintenance support |

| Aerospace | Aircraft Engine Systems | Compact design for weight-sensitive applications | Aerospace standards compliance, reliability, and testing certifications |

| Renewable Energy | Wind Turbine Gearboxes | Maximizes energy capture with efficient torque | Environmental resistance, efficiency ratings, local sourcing options |

| Robotics and Automation | Robotic Arms and Manipulators | Precise movement control and compact design | Precision engineering, customization options, after-sales support |

How is Planetary Gear Used in the Automotive Sector?

In the automotive industry, planetary gear systems are integral to automatic transmissions. They allow for seamless shifting between gears, which enhances both performance and fuel efficiency. For international buyers, especially in regions like Africa and South America, sourcing high-quality planetary gears that meet local automotive standards is crucial. Additionally, understanding the compatibility with existing vehicle models and the availability of after-sales support can significantly impact operational success.

What Role Does Planetary Gear Play in Industrial Machinery?

Planetary gears are widely used in heavy lifting equipment such as cranes and excavators, where high torque is essential for moving substantial loads. The design of planetary systems allows for effective load distribution, which minimizes wear and prolongs equipment life. Buyers in the Middle East and Europe should consider sourcing gears that meet specific load capacity ratings and durability standards, ensuring they can withstand harsh operating conditions common in construction environments.

How are Planetary Gears Applied in Aerospace?

In aerospace applications, planetary gears are utilized in aircraft engine systems and landing gear, where space constraints and reliability are paramount. Their compact design allows for weight savings, which is critical in aviation. International B2B buyers must prioritize suppliers that comply with strict aerospace standards and provide reliability testing certifications, ensuring safety and performance in flight operations.

Why are Planetary Gears Important for Renewable Energy?

Planetary gearboxes are essential in wind turbines, where they optimize energy capture by providing high torque output. This efficiency is vital for maximizing the return on investment in renewable energy projects. Buyers from regions like Europe, which are heavily investing in renewable energy, should focus on sourcing gear systems that demonstrate high efficiency ratings and environmental resistance, ensuring longevity and reliability in diverse weather conditions.

How Do Planetary Gears Enhance Robotics and Automation?

In robotics, planetary gears are crucial for controlling the precise movements of robotic arms and manipulators. Their compact design and ability to handle high torque make them ideal for applications requiring accuracy and efficiency. B2B buyers in the robotics sector should seek out suppliers that offer precision-engineered gears with customization options to meet specific application requirements, as well as robust after-sales support to address any operational challenges.

3 Common User Pain Points for ‘planetary gear’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Existing Systems

The Problem: Many B2B buyers face the challenge of integrating new planetary gear systems into existing machinery. This integration can lead to compatibility issues, particularly when the specifications of the new gears do not align with the existing components. Buyers often find themselves stuck with gears that do not mesh properly, leading to inefficiencies, increased wear, and potential failure of the system.

The Solution: To ensure compatibility, it is crucial for buyers to perform a thorough compatibility assessment before purchasing. This involves analyzing the existing gear ratios, load requirements, and physical space constraints. Engage with a supplier who offers customization options, allowing for adjustments in gear specifications to meet your unique requirements. Utilizing CAD software for simulation can also help visualize how new planetary gears will fit within your current system. Additionally, consider suppliers who provide detailed technical support and documentation to assist in the integration process.

Scenario 2: Managing High Load and Torque Requirements

The Problem: In industries such as construction and manufacturing, planetary gears are often subjected to high loads and torque. A common pain point for buyers is the gear’s ability to handle these demands without failure or excessive maintenance. This issue can lead to unplanned downtime and increased operational costs, which are critical for businesses aiming to maintain efficiency and profitability.

The Solution: When sourcing planetary gears, prioritize those with a proven track record in high-load applications. Request data on load capacity and fatigue testing from suppliers to ensure the gears meet your operational needs. Implementing regular maintenance schedules and using advanced lubricants can also extend the lifespan of the gears. Consider collaborating with manufacturers that offer comprehensive warranty and support services, as this can provide additional peace of mind regarding the reliability of the gear systems.

Scenario 3: Complexity in Gear Ratio Selection and Configuration

The Problem: Another significant pain point for B2B buyers is the complexity involved in selecting the appropriate gear ratios for specific applications. The myriad of configurations available in planetary gear systems can be overwhelming, leading to miscalculations that affect performance. This often results in inefficient energy use and unexpected operational challenges.

The Solution: Buyers should take advantage of resources that facilitate gear ratio selection, such as online calculators or simulation tools offered by gear manufacturers. Engaging with engineering consultants who specialize in gear systems can also provide valuable insights tailored to your application. When ordering, specify the required output speed and torque to allow the manufacturer to recommend the most suitable gear configuration. Additionally, consider investing in adjustable planetary gear systems that offer flexibility in gear ratios, enabling future adjustments without the need for complete system overhauls.

Strategic Material Selection Guide for planetary gear

What Are the Common Materials Used for Planetary Gears?

When selecting materials for planetary gears, international B2B buyers must consider various factors that influence the performance and longevity of these components. The choice of material can significantly affect the gear’s durability, efficiency, and suitability for specific applications. Below, we analyze four common materials used in planetary gear manufacturing: steel, aluminum, plastic, and composite materials.

How Does Steel Perform as a Material for Planetary Gears?

Steel is one of the most widely used materials for planetary gears due to its excellent mechanical properties. High-strength steel alloys, such as carbon steel and alloy steel, exhibit superior fatigue resistance, hardness, and tensile strength, making them ideal for high-load applications.

Pros: Steel gears are highly durable and can withstand significant stress and wear, which is essential for applications in heavy machinery and automotive systems. They also have excellent temperature and pressure ratings, allowing them to perform well in demanding environments.

Cons: The primary drawback of steel is its weight, which can be a disadvantage in applications where weight reduction is critical. Additionally, the manufacturing process for steel gears can be complex and costly, especially when precision machining is required.

Impact on Application: Steel gears are compatible with various media, including oil and grease, which enhances their longevity. However, they may require additional treatments to improve corrosion resistance, especially in humid or corrosive environments.

Considerations for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM and DIN. They should also consider the availability of high-quality steel suppliers in their regions.

What Advantages Does Aluminum Offer for Planetary Gears?

Aluminum is another popular choice for planetary gears, particularly in applications where weight is a critical factor. Aluminum alloys, such as 6061 and 7075, are known for their lightweight properties and good corrosion resistance.

Pros: The primary advantage of aluminum gears is their low weight, which can lead to improved energy efficiency in applications like aerospace and automotive. Aluminum also has good thermal conductivity, which can help dissipate heat during operation.

Cons: While aluminum is lightweight, it is generally less durable than steel and may not withstand high loads as effectively. This can limit its use in heavy-duty applications. Additionally, aluminum gears may require surface treatments to enhance wear resistance.

Impact on Application: Aluminum gears are suitable for applications where weight savings are essential, but they may not be ideal for environments with extreme temperatures or heavy loads.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet their application requirements and ensure compliance with relevant standards. Additionally, the sourcing of aluminum components may vary significantly by region.

How Do Plastic Gears Compare in Performance?

Plastic gears, made from materials like nylon or acetal, are increasingly being used in planetary gear applications due to their unique properties. They offer a lightweight alternative with good wear resistance and low friction.

Pros: Plastic gears are inherently corrosion-resistant and can operate in environments where metal gears might fail. They are also quieter during operation, making them suitable for consumer products and applications where noise reduction is important.

Cons: The main limitation of plastic gears is their lower load-bearing capacity compared to metal gears. They may also have a limited temperature range, which can restrict their use in high-heat applications.

Impact on Application: Plastic gears are ideal for applications such as robotics and small machinery where weight and noise are critical, but they may not be suitable for high-torque applications.

Considerations for International Buyers: Buyers should consider the specific plastic materials that meet their needs and ensure compliance with international quality standards. The availability of high-performance plastics may vary across regions.

What Role Do Composite Materials Play in Gear Design?

Composite materials, which combine polymers with reinforcing fibers, are gaining traction in the manufacturing of planetary gears. These materials offer a balance between strength and weight.

Pros: Composite gears are lightweight and can be engineered to provide high strength and stiffness. They also exhibit excellent corrosion resistance and can be tailored for specific application needs.

Cons: The primary drawback is the higher cost associated with composite materials and their manufacturing processes. Additionally, they may not be as widely available as traditional materials like steel and aluminum.

Impact on Application: Composite gears can be used in specialized applications, such as aerospace and automotive, where weight savings and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their regions and consider the cost implications. Compliance with international standards is also essential for ensuring quality.

Summary Table of Material Selection for Planetary Gears

| Material | Typical Use Case for planetary gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High durability and load capacity | Heavy and complex manufacturing | High |

| Aluminum | Aerospace, automotive | Lightweight and good corrosion resistance | Lower durability under high loads | Medium |

| Plastic | Robotics, consumer products | Corrosion-resistant and quieter | Limited load-bearing capacity | Low |

| Composite | Aerospace, specialized machinery | Tailored strength and lightweight | Higher cost and limited availability | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for planetary gear

What Are the Key Stages in the Manufacturing Process of Planetary Gears?

The manufacturing of planetary gears involves several critical stages that ensure precision and quality. Understanding these stages can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: What Materials Are Used for Planetary Gears?

The first step in manufacturing planetary gears is material selection. Common materials include high-strength steel alloys, aluminum, and composite materials, depending on the application requirements. Buyers should look for suppliers that utilize materials with high tensile strength and fatigue resistance to ensure durability under load.

Once selected, the material undergoes processes such as forging or casting to create the initial shape. This is followed by heat treatment to enhance the material properties, increasing hardness and wear resistance.

How Are Planetary Gears Formed?

What Techniques Are Commonly Used in Forming Planetary Gears?

After material preparation, the forming process begins. This typically involves several machining techniques:

-

CNC Machining: Computer Numerical Control (CNC) machining is essential for achieving the precise dimensions required for the sun gear, planet gears, and ring gear. This process often includes turning, milling, and grinding to create the gear teeth.

-

Hobbing: This is a popular method for generating the gear teeth profiles. The hob cutter is used to shape the teeth accurately, ensuring they meet the required specifications.

-

Shaping and Broaching: These methods are utilized for achieving specific tooth shapes and can be crucial for ensuring proper meshing between gears.

-

Heat Treatment: Post-forming, heat treatment processes such as carburizing or nitriding are employed to improve hardness and wear resistance of the gears, which is vital for longevity and performance.

What Assembly Processes Are Involved in Planetary Gear Production?

How Is the Assembly of Planetary Gears Conducted?

The assembly of planetary gears is a meticulous process that involves the following:

-

Carrier Assembly: The planet gears are mounted on a carrier, which can rotate and is crucial for load distribution.

-

Meshing: The planet gears are positioned between the sun gear and the internal ring gear. Ensuring correct alignment during this stage is vital for the smooth operation of the gear system.

-

Final Assembly: Once all components are in place, the complete planetary gear system is assembled. This may include additional components such as bearings and seals, which enhance performance and reliability.

How Are Finishing Processes Applied to Planetary Gears?

What Finishing Techniques Ensure Quality in Planetary Gears?

Finishing processes are critical in enhancing the performance and longevity of planetary gears. Common techniques include:

-

Surface Grinding: This process ensures a smooth surface finish, which reduces friction and wear during operation.

-

Polishing: Polishing is often employed to minimize surface roughness, further improving the gear’s efficiency.

-

Coating: Some manufacturers apply protective coatings to resist corrosion and wear, which is particularly beneficial in harsh environments.

What Quality Assurance Practices Are Essential for Planetary Gear Production?

Which International Standards Should B2B Buyers Look For?

Quality assurance (QA) is paramount in the manufacturing of planetary gears. B2B buyers should ensure that their suppliers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for the European market or API (American Petroleum Institute) for oil and gas applications are crucial indicators of a supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints During Production?

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is integrated at various stages of the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections are conducted throughout the manufacturing process to monitor critical parameters such as dimensions, surface finish, and gear tooth profiles.

-

Final Quality Control (FQC): Upon completion, the entire planetary gear system undergoes rigorous testing to verify performance, including load testing and noise analysis.

What Common Testing Methods Are Used for Planetary Gears?

How Can B2B Buyers Ensure the Quality of Planetary Gears?

Common testing methods include:

-

Load Testing: This involves applying operational loads to ensure the gear system can handle the specified torque and load conditions.

-

Vibration Analysis: This method helps identify potential issues related to imbalance or misalignment in the gear system.

-

Dimensional Inspection: Utilizing tools such as coordinate measuring machines (CMM), dimensional checks are performed to confirm that all components meet the required tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

What Steps Should Be Taken to Ensure Supplier Reliability?

B2B buyers can take several steps to verify the QC practices of their suppliers:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices.

-

Requesting Quality Reports: Buyers should request detailed QC reports that outline testing methods and results, ensuring transparency in the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product reliability.

What Are the Quality Certification Nuances for International Buyers?

How Do Regional Standards Affect Planetary Gear Purchases?

International buyers should be aware of regional variations in quality standards. For instance, European buyers may prioritize CE certifications, while buyers in the Middle East may focus on adherence to local industry standards. Understanding these nuances is crucial for ensuring compliance and quality assurance in planetary gear purchases.

Conclusion

The manufacturing processes and quality assurance practices for planetary gears are complex and multi-faceted. For B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions. By focusing on material quality, manufacturing techniques, and robust quality control measures, buyers can ensure they procure high-performing planetary gear systems tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘planetary gear’

To assist international B2B buyers in effectively sourcing planetary gears, this practical guide outlines essential steps to ensure a successful procurement process. Understanding the complexities of planetary gear systems and the market landscape is crucial for making informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as gear ratios, load capacity, and dimensions. Additionally, specify the materials required for durability and compatibility with your application, as these details will guide potential suppliers in providing accurate quotes.

Step 2: Research Market Trends and Applications

Understanding the current market trends and applications for planetary gears can enhance your sourcing strategy. Research industries utilizing these gears, such as automotive, aerospace, and renewable energy. This knowledge will help you identify leading suppliers and innovative solutions that meet your specific needs.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who demonstrate experience with planetary gear systems and can provide technical support, ensuring they understand your requirements.

- Check for Certifications: Verify if the suppliers hold relevant quality certifications (e.g., ISO 9001) that indicate their commitment to manufacturing standards.

- Assess Production Capabilities: Ensure the supplier has the capability to produce the required quantity and quality of planetary gears in a timely manner.

Step 4: Request Samples and Test Performance

Before finalizing your order, request samples to evaluate the quality and performance of the planetary gears. Testing the samples in real-world applications can help you ascertain their reliability and effectiveness.

- Conduct Load Testing: Assess how the gears perform under expected loads and conditions to ensure they meet your operational requirements.

- Evaluate Compatibility: Check that the gears integrate well with your existing machinery or systems.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms and pricing. Consider factors such as payment terms, delivery schedules, and warranty options.

- Explore Bulk Discounts: If you plan to order large quantities, inquire about bulk pricing and any potential discounts.

- Discuss After-Sales Support: Ensure the supplier provides adequate support post-purchase, including maintenance services or replacement parts.

Step 6: Finalize Contracts and Agreements

After successful negotiations, finalize contracts that clearly outline all terms and conditions. This legal document should include specifications, pricing, delivery timelines, and warranty details to protect both parties.

- Include Performance Clauses: Consider adding clauses that address performance metrics and penalties for non-compliance to ensure accountability.

- Review Legal Compliance: Ensure that the contract adheres to international trade regulations relevant to your region and the supplier’s location.

Step 7: Monitor and Evaluate Supplier Performance

After the procurement process, continuously monitor the performance of the supplier and the quality of the planetary gears delivered. Establish a feedback loop to address any issues promptly and maintain a strong supplier relationship.

- Schedule Regular Reviews: Conduct periodic evaluations to assess the supplier’s adherence to quality standards and delivery schedules.

- Provide Feedback: Share insights on gear performance and service quality to help the supplier improve and adapt to your needs.

By following these steps, international B2B buyers can navigate the sourcing process for planetary gears with confidence, ensuring they secure high-quality components that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for planetary gear Sourcing

What Are the Key Cost Components in Planetary Gear Sourcing?

When sourcing planetary gears, understanding the detailed cost structure is crucial for effective budget management. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. High-quality steel or specialized alloys may be required for durability and performance, which can increase the base price. Buyers should consider sourcing materials that offer a balance between performance and cost.

-

Labor: Labor costs vary by region and can impact the final pricing of planetary gears. In regions such as Africa and South America, labor costs may be lower, but the skill level and expertise required for manufacturing high-precision gears can affect overall pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, maintenance, and factory management. Efficient manufacturing processes can help minimize these costs, making it essential to evaluate potential suppliers based on their operational efficiency.

-

Tooling: The costs related to specialized tools and machinery for gear production can be significant, particularly for custom designs. Buyers should inquire about tooling charges, especially if they require unique specifications.

-

Quality Control (QC): Ensuring the quality of planetary gears is paramount, particularly in applications with high-stress environments. The costs associated with quality assurance processes, testing, and certifications must be factored into the overall cost.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the chosen Incoterms. Buyers should assess logistics costs carefully, particularly for international shipments, to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin to the production costs. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect Planetary Gear Costs?

Several factors can influence the pricing of planetary gears, including:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant cost reductions. Suppliers are often willing to provide discounts for larger orders, making it advantageous for buyers to evaluate their needs and potential for volume purchasing.

-

Specifications and Customization: Custom designs or specific requirements can lead to increased costs. Buyers should clearly define their specifications to ensure accurate pricing and avoid unexpected costs later in the process.

-

Material Quality and Certifications: Higher quality materials and recognized certifications (e.g., ISO) can elevate costs. However, investing in quality can lead to long-term savings through enhanced performance and reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their quality assurance processes and proven track record, while newer suppliers might offer competitive rates to gain market share.

-

Incoterms: The choice of Incoterms will determine who bears the shipping costs and risks. Understanding the implications of different Incoterms can help buyers negotiate more favorable terms.

What Are Essential Buyer Tips for Cost-Efficiency in Planetary Gear Sourcing?

-

Negotiate Effectively: Don’t hesitate to negotiate prices, especially for larger orders. Establishing a good rapport with suppliers can lead to better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, replacement, and performance. A cheaper option may result in higher TCO due to frequent failures or inefficiencies.

-

Understand Pricing Nuances for International Sourcing: Different regions have varying pricing structures influenced by labor costs, material availability, and economic conditions. For instance, buyers from the UAE may find different pricing dynamics compared to those from Colombia. Researching local market conditions can yield valuable insights.

-

Request Detailed Quotes: Ensure that quotes break down all cost components. This transparency will help in comparing suppliers and understanding where potential savings can be achieved.

-

Consider Supplier Partnerships: Building a long-term relationship with suppliers can lead to better pricing, priority service, and tailored solutions that meet specific needs over time.

Disclaimer on Indicative Prices

Please note that pricing for planetary gears can vary widely based on the factors discussed above. Always seek updated quotes from multiple suppliers to ensure competitive pricing tailored to your specific needs and circumstances.

Alternatives Analysis: Comparing planetary gear With Other Solutions

Understanding Alternatives to Planetary Gear Systems

In the realm of mechanical engineering, especially for international B2B buyers, choosing the right gear system is critical for optimizing performance and cost. While planetary gears are renowned for their compact design and high efficiency, there are alternative solutions that may better fit specific applications or budget constraints. This section explores and compares planetary gears with two viable alternatives: Worm Gear Systems and Spur Gear Systems.

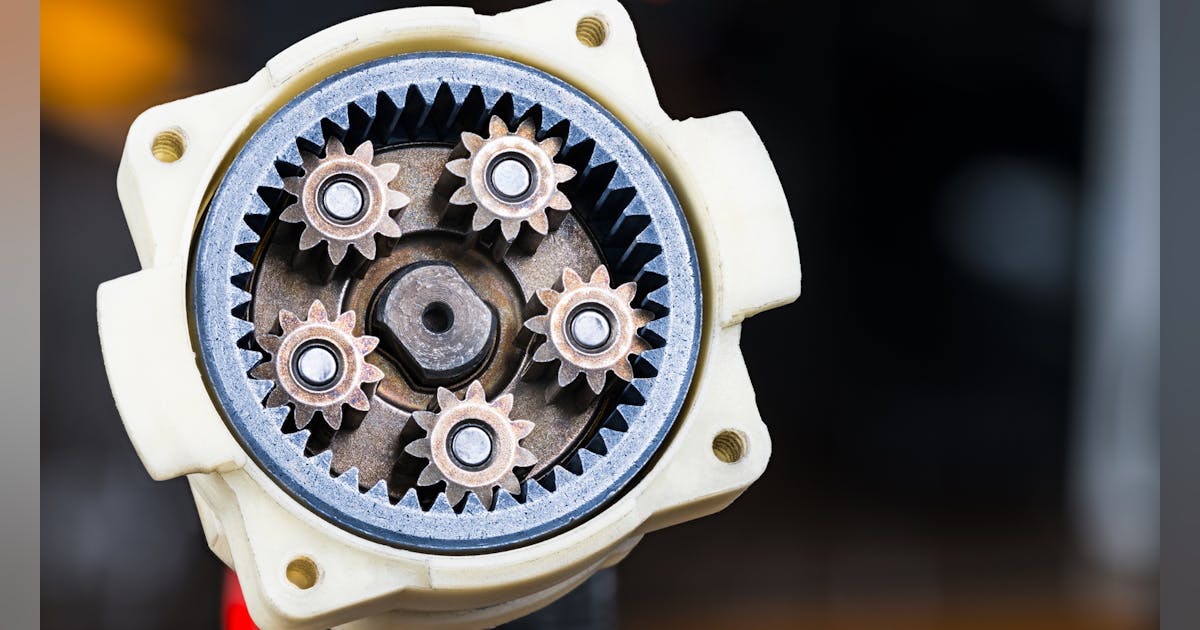

A stock image related to planetary gear.

Comparison of Planetary Gear with Alternative Gear Systems

| Comparison Aspect | Planetary Gear | Worm Gear System | Spur Gear System |

|---|---|---|---|

| Performance | High torque density, compact design | High torque but lower efficiency | Good efficiency, high speed capability |

| Cost | Higher initial investment | Generally lower cost | Moderate cost, widely available |

| Ease of Implementation | Complex design requires precise manufacturing | Simple design, easy to install | Straightforward installation |

| Maintenance | Requires specialized knowledge | Low maintenance needs | Moderate maintenance requirements |

| Best Use Case | Automotive, aerospace, industrial machinery | Lifting heavy loads at low speeds | General-purpose applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Worm Gear Systems?

Worm gear systems are characterized by their unique design, featuring a screw-like worm meshing with a gear. They excel in applications requiring high torque at low speeds, making them suitable for hoists and conveyor systems. The simplicity of their design translates to lower costs and easier installation, which can be appealing for budget-conscious buyers. However, they often suffer from lower efficiency due to friction losses, which may not be ideal for applications demanding high-speed operation. Additionally, their maintenance is generally low, making them a practical choice for continuous operations.

How Do Spur Gear Systems Compare to Planetary Gears?

Spur gears are the most straightforward type of gear system, consisting of cylindrical gears that mesh directly. They are known for their efficiency and capability to transmit motion at high speeds, making them widely used in various applications, including automotive and industrial machinery. The moderate cost of spur gears and their ease of implementation make them an attractive option for many buyers. However, spur gears typically require more space compared to planetary gears and may not provide the same level of torque density, which can limit their use in compact applications.

Conclusion: How to Choose the Right Gear Solution

For international B2B buyers, selecting the right gear system hinges on understanding the specific requirements of their applications. Planetary gears offer superior torque density and compactness, making them ideal for high-performance environments like automotive and aerospace. In contrast, if budget constraints are a primary concern, worm gears may provide a cost-effective solution with adequate performance for low-speed applications. Meanwhile, spur gears serve as a versatile option for general-purpose needs. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for planetary gear

What Are the Key Technical Properties of Planetary Gears?

When sourcing planetary gears, international B2B buyers must be familiar with specific technical properties that can significantly influence performance and compatibility in various applications. Below are critical specifications to consider:

1. Material Grade: What is the Best Material for Planetary Gears?

The material composition of planetary gears is vital for their durability and performance. Common materials include carbon steel, alloy steel, and sometimes plastics for lightweight applications. The choice of material affects wear resistance, strength, and the ability to withstand high loads. A higher-grade material can lead to longer service life and reduced maintenance costs, which are crucial for industries such as automotive and aerospace.

2. Tolerance: Why Is Precision Tolerance Important?

Tolerance refers to the allowable deviation in dimensions during manufacturing. For planetary gears, tight tolerances (often within microns) are essential to ensure smooth meshing and minimize backlash. High precision is particularly important in applications where efficiency and accuracy are paramount, such as robotics and precision machinery. Poor tolerance can lead to increased wear and potential system failures.

3. Gear Ratio: How Does Gear Ratio Affect Performance?

The gear ratio is a critical parameter that determines the speed and torque output of the planetary gear system. This ratio is defined as the ratio of the number of teeth on the input gear to the number of teeth on the output gear. Understanding the gear ratio is essential for buyers to ensure the gear system meets the specific requirements of their applications, allowing for optimal performance and efficiency.

4. Load Capacity: What Load Capacity Should You Expect?

Load capacity indicates the maximum load that a planetary gear can handle without failure. It is influenced by the design, material, and manufacturing quality of the gear. Buyers must assess the expected operational loads in their applications to select a planetary gear with an appropriate load capacity, ensuring reliability and safety in demanding environments.

5. Efficiency: Why Is Efficiency a Key Consideration?

The efficiency of a planetary gear system is a measure of how much input energy is converted into useful output energy. Higher efficiency results in less energy loss, which is crucial for applications requiring high performance with minimal energy consumption. This is particularly important in sectors like renewable energy and automotive, where operational costs can significantly impact the bottom line.

What Are Common Trade Terms Used in Planetary Gear Transactions?

In addition to understanding the technical properties, familiarity with industry-specific terminology is essential for effective communication and negotiation. Here are some common terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean in Gear Supply?

An OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of planetary gears, working with OEMs ensures that buyers receive high-quality components that meet specific design standards. This is particularly relevant for sectors like automotive and industrial machinery, where reliability is critical.

2. MOQ (Minimum Order Quantity): Why Is MOQ Significant?

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory and budget effectively. For international buyers, negotiating MOQs can lead to cost savings, especially when sourcing large components like planetary gear systems.

3. RFQ (Request for Quotation): What Is the Purpose of an RFQ?

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. For planetary gears, issuing an RFQ allows buyers to compare offers, ensuring they receive competitive pricing and favorable terms, which is vital for project budgeting and planning.

4. Incoterms: How Do Incoterms Affect International Shipping?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for international buyers to understand shipping costs, risk transfer, and delivery responsibilities, impacting overall procurement strategy.

5. Lead Time: Why Is Lead Time Critical in Gear Supply?

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for planning and inventory management, especially for projects with tight deadlines. Buyers should inquire about lead times during negotiations to avoid production delays.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing planetary gears, ensuring they select the right components for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the planetary gear Sector

What Are the Key Drivers Influencing the Planetary Gear Market Today?

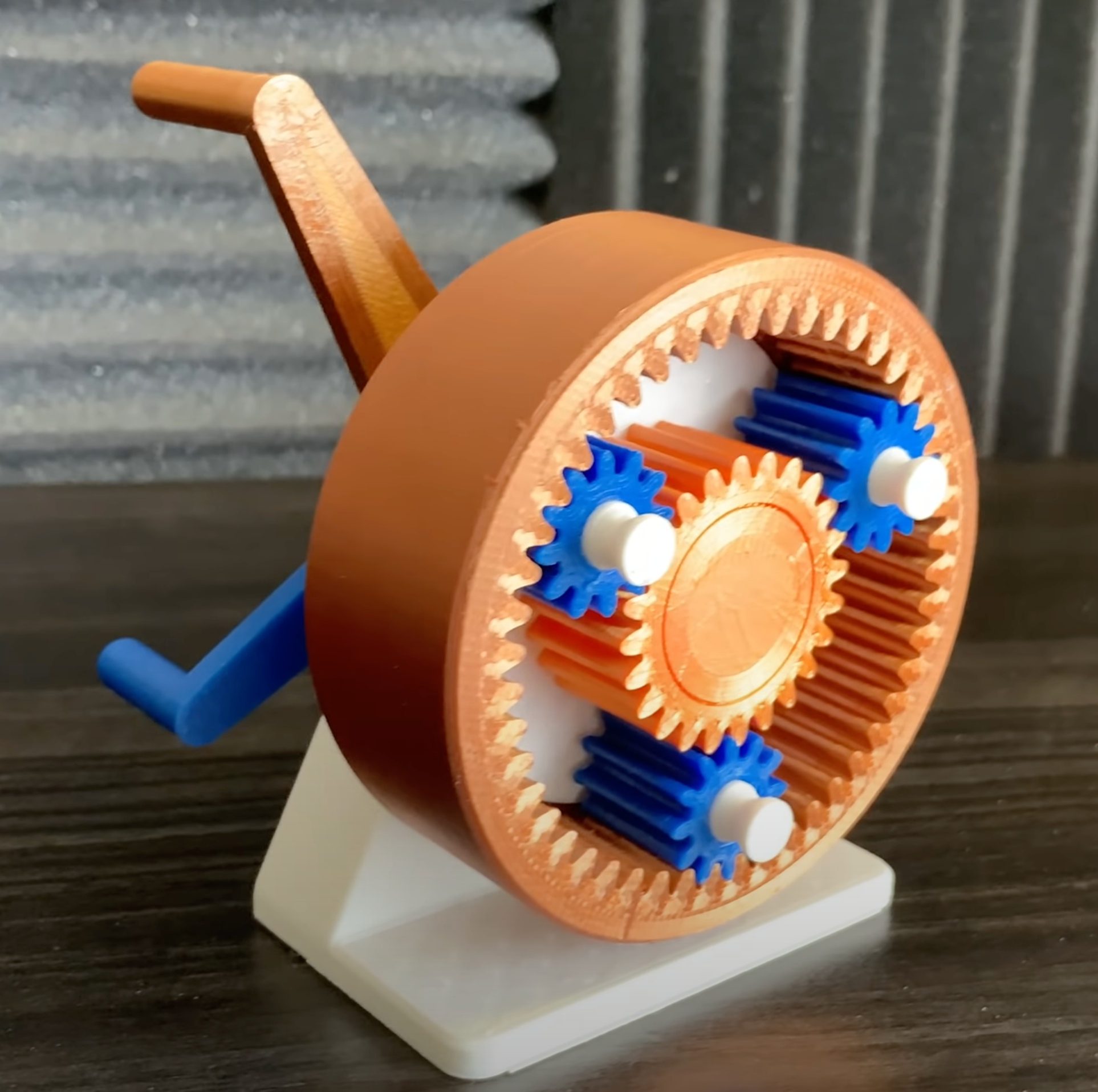

A stock image related to planetary gear.

The planetary gear market is experiencing dynamic shifts driven by technological advancements, increasing automation, and the demand for energy-efficient solutions. Globally, industries are leaning towards compact and high-efficiency gear systems that offer superior torque density. This trend is particularly pronounced in sectors such as automotive, aerospace, and renewable energy, where planetary gears are essential for enhancing performance and reducing space requirements.

In regions like Africa and South America, the growth of infrastructure projects is propelling the demand for robust machinery that utilizes planetary gears. Similarly, in the Middle East, investments in industrial automation and smart technologies are creating new opportunities for B2B buyers looking to source advanced gear systems. European manufacturers are also focusing on innovation, developing gear systems that can operate under extreme conditions, which is crucial for sectors like oil and gas.

Emerging technologies, such as Industry 4.0, are facilitating real-time monitoring and predictive maintenance of gear systems, further enhancing their reliability and efficiency. For international buyers, this means sourcing from suppliers who not only understand these technological shifts but also offer adaptable solutions that align with evolving market needs.

How Is Sustainability Impacting the Sourcing of Planetary Gears?

Sustainability is becoming a critical factor in B2B sourcing strategies, particularly for planetary gear systems. With growing environmental concerns, buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption during production.

A stock image related to planetary gear.

The importance of ethical supply chains cannot be overstated. International B2B buyers are now more than ever scrutinizing their suppliers’ practices to ensure compliance with environmental regulations and ethical standards. Certifications like ISO 14001 for environmental management and the use of ‘green’ materials are becoming essential criteria in the selection process.

Moreover, as industries pivot towards renewable energy solutions, the demand for planetary gear systems that are designed for efficiency and longevity is rising. This shift not only helps reduce the carbon footprint but also aligns with global efforts to promote sustainable practices. Buyers should actively seek partnerships with manufacturers that invest in research and development focused on sustainable gear technology.

What Is the Historical Context of Planetary Gears in B2B Applications?

The evolution of planetary gears dates back to ancient times, with early applications found in various mechanical devices. However, it was during the Industrial Revolution that their use became widespread, particularly in steam engines and machinery. The unique design of planetary gear systems, characterized by their compactness and efficiency, allowed for significant advancements in mechanical engineering.

Over the decades, the application of planetary gears has expanded into modern fields such as automotive transmissions, robotics, and aerospace systems. The continuous improvement in materials and manufacturing processes has further enhanced their capabilities, making them indispensable in high-performance environments. For international B2B buyers, understanding the historical context of planetary gears can provide valuable insights into their reliability and adaptability in various industrial applications.

Conclusion

In conclusion, navigating the planetary gear market requires an understanding of the key drivers shaping its dynamics, the significance of sustainability in sourcing, and the historical context that underscores its evolution. International B2B buyers must leverage this knowledge to make informed decisions that align with their operational needs and ethical standards, ultimately enhancing their competitive advantage in an increasingly complex marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of planetary gear

-

How do I select the right planetary gear system for my application?

To select the right planetary gear system, consider the specific requirements of your application such as torque, speed, and space constraints. Evaluate the gear ratio needed, which is determined by the desired output speed and torque. Additionally, assess the load capacity and the efficiency of the gear system. Collaborate with your supplier to discuss your application details, ensuring they provide tailored recommendations based on your operational conditions. -

What are the advantages of using planetary gears in industrial applications?

Planetary gears offer several advantages, including high torque density and compact design, making them ideal for applications with limited space. Their ability to distribute load across multiple gears enhances efficiency and durability. Furthermore, planetary gear systems can achieve variable gear ratios without physical reconfiguration, allowing for greater versatility in machinery operation, particularly in automotive and industrial machinery sectors. -

How can I ensure the quality of planetary gears from international suppliers?

To ensure quality, conduct thorough supplier vetting by reviewing their certifications, manufacturing processes, and customer testimonials. Request samples for testing and evaluate their adherence to international quality standards, such as ISO 9001. Establish clear quality assurance protocols, including inspections and testing methods, to monitor the performance of the planetary gears before full-scale production. -

What is the minimum order quantity (MOQ) for planetary gears from suppliers?

The minimum order quantity (MOQ) for planetary gears varies by supplier and can depend on factors like production costs and material availability. Generally, MOQs may range from a few units to hundreds. Discuss your specific needs with potential suppliers to negotiate favorable terms. Smaller orders might incur higher per-unit costs, while bulk orders could provide significant savings. -

What payment terms should I expect when sourcing planetary gears internationally?

Payment terms can vary widely among suppliers. Common options include upfront payments, letters of credit, or payment on delivery. It’s crucial to negotiate terms that protect your financial interests while ensuring the supplier’s commitment. Be aware of any additional costs, such as taxes or tariffs, that may arise from international transactions, particularly when importing to regions like Africa, South America, or the Middle East. -

How do I handle logistics and shipping for planetary gear purchases?

When managing logistics for international purchases, coordinate closely with your supplier to understand shipping options, costs, and estimated delivery times. Consider using freight forwarders to streamline the process and ensure compliance with customs regulations. Additionally, choose reliable shipping methods that suit your budget and timeline, and factor in any potential delays due to customs clearance. -

What customization options are available for planetary gear systems?

Many suppliers offer customization options to meet specific application needs, including variations in gear ratios, sizes, and materials. Discuss your requirements with the supplier to understand their capabilities. Customization can enhance performance but may affect lead times and costs, so ensure that you clarify these aspects during the negotiation process. -

What common issues should I be aware of when sourcing planetary gears internationally?

Common issues include language barriers, cultural differences, and varying quality standards. Ensure clear communication regarding specifications and expectations. Be cautious of potential delays in shipping and customs clearance, which can affect project timelines. Additionally, consider fluctuations in currency exchange rates that may impact costs. Establishing strong relationships with suppliers and having a clear contract can mitigate many of these risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for planetary gear

As international B2B buyers navigate the complexities of sourcing planetary gears, understanding the strategic implications of their choices is essential. The unique advantages of planetary gear systems, including their compact design, high efficiency, and capacity for multiple gear ratios, make them indispensable across various industries. By prioritizing strategic sourcing, businesses can optimize procurement processes, ensuring access to high-quality components that meet specific operational needs.

What Should B2B Buyers Consider When Sourcing Planetary Gears?

Buyers should evaluate suppliers based on their manufacturing capabilities, quality assurance processes, and experience in catering to diverse markets, particularly in regions like Africa, South America, the Middle East, and Europe. Establishing long-term partnerships with reliable manufacturers can lead to enhanced product performance and reduced costs.

Looking Ahead: What is the Future of Planetary Gear Systems?

With advancements in technology and increasing demand for efficient machinery, the future of planetary gear systems appears promising. Buyers are encouraged to stay informed about innovations in gear design and manufacturing processes. Engaging with industry leaders and participating in trade shows can provide valuable insights and foster connections that drive growth. Embrace the opportunity to enhance your operations through informed sourcing decisions today.