Unlock Efficiency: The Ultimate Bevel Gear Guide (2025)

Introduction: Navigating the Global Market for bevel gear

Navigating the global market for bevel gears can be a daunting challenge for international B2B buyers, especially when it comes to sourcing reliable suppliers and ensuring quality standards. Bevel gears, essential components in various mechanical applications, facilitate power transmission between intersecting shafts. The complexity of selecting the right type, understanding manufacturing processes, and evaluating cost implications can overwhelm even seasoned buyers.

This comprehensive guide delves into the multifaceted world of bevel gears, covering everything from the various types—such as straight and spiral bevel gears—to their specific applications across industries. It also addresses critical factors such as supplier vetting, material selection, and pricing strategies, equipping B2B buyers with the knowledge they need to make informed purchasing decisions.

International buyers from regions like Africa, South America, the Middle East, and Europe, including Turkey and the UAE, will find tailored insights that cater to their unique market dynamics. By providing actionable information and practical tips, this guide empowers businesses to navigate the complexities of sourcing bevel gears effectively, ensuring they can meet their operational needs while optimizing their supply chain. Whether you are a procurement manager or a project engineer, this guide is designed to support your strategic purchasing efforts in the global marketplace.

Understanding bevel gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | No helix angle, simple design | General machinery, low-speed applications | Pros: Cost-effective; Cons: Noisy operation, less efficient. |

| Spiral Bevel Gears | Helical design, smoother operation, better load distribution | Automotive, aerospace, heavy machinery | Pros: Quieter, efficient; Cons: Higher manufacturing costs. |

| Hypoid Gears | Offset shafts, allows for high-speed applications | Robotics, conveyor systems | Pros: High torque capacity; Cons: Complex design, expensive. |

| Plastic Bevel Gears | Made from engineering plastics, lightweight | Consumer products, low-load applications | Pros: Corrosion-resistant, lightweight; Cons: Limited load capacity. |

| Miter Gears | 1:1 ratio, straight teeth, compact design | Compact machinery, robotics | Pros: Simple design, easy to install; Cons: Limited speed ratios. |

What are the characteristics of Straight Bevel Gears?

Straight bevel gears feature a simple design without helix angles, making them easy to manufacture and install. They are typically used in low-speed applications such as general machinery. While they offer a cost-effective solution, buyers should consider their noisy operation and lower efficiency compared to other types. When purchasing, look for compatibility with existing systems and the specific load requirements of your application.

Why choose Spiral Bevel Gears for your applications?

Spiral bevel gears are characterized by their helical teeth, which provide smoother operation and better load distribution. Commonly used in automotive and aerospace applications, they excel in high-speed environments. The advantages of reduced noise and increased efficiency come at a higher manufacturing cost, so buyers should assess their budget against the operational benefits. Ensure you select the right material and finish to match your application’s requirements.

What makes Hypoid Gears suitable for high-speed applications?

Hypoid gears feature offset shafts, which allow for high-speed applications and significant torque capacity. They are frequently used in robotics and conveyor systems where high performance is crucial. While they offer excellent load-bearing capabilities, their complex design can lead to higher costs. Buyers should evaluate their specific needs and consider the potential for increased maintenance due to the intricacies of the gear design.

When are Plastic Bevel Gears the right choice?

Plastic bevel gears are made from lightweight engineering plastics, making them ideal for low-load applications in consumer products. Their corrosion resistance and reduced weight can provide significant advantages in certain contexts. However, their limited load capacity should be a key consideration for buyers. It’s essential to assess the environmental conditions and the specific performance requirements to ensure they meet operational demands.

Why consider Miter Gears for compact machinery?

Miter gears are known for their 1:1 ratio and compact design, making them suitable for applications where space is limited, such as in robotics. They are simple to install and provide effective torque transfer. However, their limited speed ratios may restrict their use in high-speed applications. Buyers should consider the application’s spatial constraints and speed requirements when selecting miter gears for their machinery.

Key Industrial Applications of bevel gear

| Industry/Sector | Specific Application of bevel gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power transmission in differential systems | Enhances vehicle performance and efficiency | Material quality, load capacity, and manufacturing method |

| Manufacturing | CNC machine tools for precision cutting | Improves accuracy and reduces operational downtime | Tolerance levels, gear finish, and compatibility with existing systems |

| Aerospace | Flight control systems | Ensures reliability and safety in critical operations | Compliance with aerospace standards, weight considerations, and durability |

| Mining and Construction | Equipment for material handling and processing | Increases operational efficiency and reduces wear | Resistance to harsh environments, gear ratio options, and maintenance support |

| Renewable Energy | Wind turbine gearboxes | Maximizes energy capture and operational lifespan | Efficiency ratings, noise levels, and adaptability to varying loads |

How is Bevel Gear Used in the Automotive Sector?

In the automotive industry, bevel gears are crucial for power transmission, particularly in differential systems. These gears allow for the transfer of torque between intersecting shafts, which is vital for vehicle handling and performance. For international buyers, especially from regions like Africa and South America, sourcing high-quality bevel gears that can withstand varying load conditions is essential. Buyers should focus on materials that offer durability and resistance to wear, ensuring that they meet the specific requirements of their vehicle models.

What Role Does Bevel Gear Play in Manufacturing?

Bevel gears are integral to CNC machine tools, where they facilitate precision cutting and machining processes. Their ability to transmit power efficiently enables manufacturers to achieve high levels of accuracy while minimizing operational downtime. B2B buyers in Europe and the Middle East must consider tolerance levels and the gear finish when sourcing these components, as precision is critical in manufacturing environments. Additionally, compatibility with existing systems should be assessed to ensure seamless integration.

How Does Bevel Gear Contribute to Aerospace Applications?

In the aerospace sector, bevel gears are utilized in flight control systems, where reliability and safety are paramount. These gears are designed to endure extreme conditions while providing precise control over aircraft movements. International buyers, particularly those from Turkey and the UAE, must ensure that the bevel gears they source comply with stringent aerospace standards. Weight considerations and durability are also vital factors, as they directly impact aircraft performance and safety.

What is the Importance of Bevel Gear in Mining and Construction?

Bevel gears are extensively used in mining and construction equipment for material handling and processing. They enhance operational efficiency by allowing machinery to function smoothly under heavy loads. Buyers from Africa, where mining operations are prevalent, should prioritize sourcing bevel gears that exhibit resistance to harsh environmental conditions. Additionally, gear ratio options should be evaluated to match the specific operational demands of their equipment.

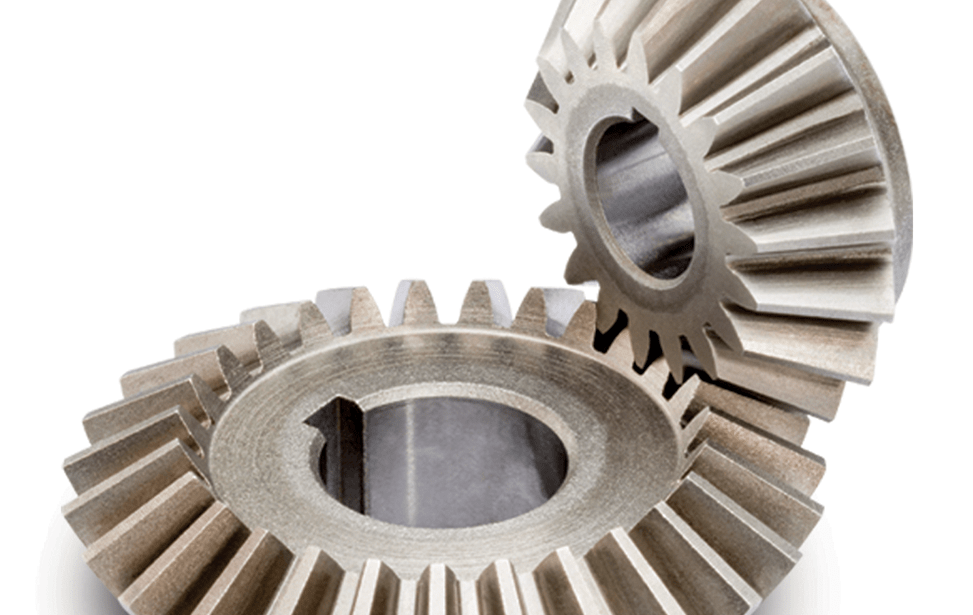

A stock image related to bevel gear.

How is Bevel Gear Beneficial in Renewable Energy?

In the renewable energy sector, particularly in wind turbine gearboxes, bevel gears play a significant role in maximizing energy capture. Their design allows for efficient torque transmission, which is crucial for the effective operation of turbines. For international buyers in Europe and the Middle East, sourcing high-efficiency bevel gears that minimize noise levels and adapt to varying loads is essential. These factors contribute to the longevity and operational lifespan of wind energy systems, making careful selection critical.

3 Common User Pain Points for ‘bevel gear’ & Their Solutions

Scenario 1: Inconsistent Gear Performance Leading to Downtime

The Problem:

Many B2B buyers, especially in industries like manufacturing and automotive, encounter issues with bevel gears that lead to inconsistent performance. This often manifests as unexpected wear and tear or misalignment, resulting in machine downtime. For companies in Africa or South America, where operational efficiency is critical due to limited resources, such downtime can translate to significant financial losses and reduced competitiveness. Additionally, sourcing replacement parts can be challenging, especially if local suppliers lack the specific bevel gear specifications needed.

The Solution:

To combat these issues, it’s essential for buyers to conduct thorough performance assessments before selecting bevel gears. This involves understanding the specific load, speed, and torque requirements of their applications. Utilize CAD software to simulate the gear system and analyze how different bevel gear types (straight vs. spiral) will perform under various conditions. Furthermore, establishing a relationship with reputable manufacturers who can provide high-quality, standardized bevel gears will ensure consistency. Consider implementing a preventative maintenance program that includes regular inspections and timely replacements of worn gears. This proactive approach will minimize unexpected failures and extend the lifespan of the machinery.

Scenario 2: Difficulty in Selecting the Right Bevel Gear Type

The Problem:

B2B buyers often struggle with selecting the appropriate type of bevel gear for their specific applications. With various options available—such as straight, spiral, and hypoid gears—each with different performance characteristics, the decision-making process can be overwhelming. This complexity is exacerbated in regions like the Middle East and Europe, where strict engineering standards must be adhered to. Misselection can lead to inefficiencies, increased energy consumption, and potential safety hazards.

The Solution:

To simplify the selection process, buyers should create a detailed specification sheet that outlines the specific requirements of their applications. This should include factors such as the angle of intersection, load capacity, and desired speed ratios. Engaging with gear manufacturers or suppliers who offer consultation services can provide valuable insights into which bevel gear type is best suited for your needs. Additionally, utilizing online tools and resources, such as gear calculators, can help determine the right gear ratio and type based on your operational parameters. Regular training for engineering teams on gear technology advancements will also keep your selection process aligned with industry standards.

Scenario 3: High Costs of Custom Bevel Gears

The Problem:

International B2B buyers frequently face the challenge of high costs associated with custom bevel gears, especially when off-the-shelf solutions do not meet their specific requirements. This is particularly pertinent for companies in Africa and South America, where budget constraints are common. High custom manufacturing costs can lead to project delays and impact overall profitability, making it crucial for buyers to find cost-effective alternatives.

The Solution:

One effective strategy is to explore the possibility of using standard bevel gear sizes and specifications that can be sourced from multiple suppliers. This increases competition among vendors and often leads to better pricing. Additionally, consider forming partnerships or alliances with local manufacturers to share production costs. Another option is to look into alternative materials for bevel gears, such as engineering plastics, which can provide adequate performance at a lower cost compared to traditional metals. Regularly reviewing and updating your sourcing strategies to include both local and international suppliers can also yield significant savings while ensuring quality and reliability.

Strategic Material Selection Guide for bevel gear

What Are the Key Properties of Common Materials Used in Bevel Gears?

When selecting bevel gears for various applications, the choice of material significantly influences performance, durability, and overall cost. Below, we analyze four common materials used in bevel gear manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Carbon Steel Impact Bevel Gear Performance?

Key Properties: Carbon steel, particularly grades like S45C, is widely used for bevel gears due to its excellent strength and hardness. It typically exhibits good wear resistance and can withstand moderate to high temperatures. However, it has limited corrosion resistance unless treated.

Pros & Cons: Carbon steel gears offer high durability and are relatively easy to machine, making them suitable for a variety of applications. The main drawback is their susceptibility to rust and corrosion, which can be a significant issue in humid or corrosive environments. Additionally, while they are cost-effective, they may require additional surface treatments to enhance corrosion resistance.

Impact on Application: Carbon steel bevel gears are ideal for applications involving moderate loads and where cost-effectiveness is crucial. However, in regions with high humidity or exposure to corrosive substances, buyers should consider protective coatings.

What Advantages Do Stainless Steel Bevel Gears Offer?

Key Properties: Stainless steel, particularly SUS303, is known for its excellent corrosion resistance and good mechanical properties. It can operate effectively in a wide range of temperatures and is less prone to rusting compared to carbon steel.

Pros & Cons: The primary advantage of stainless steel bevel gears is their longevity and ability to maintain performance in harsh environments. However, they are generally more expensive than carbon steel options and may require more complex manufacturing processes, which can lead to higher costs.

Impact on Application: Stainless steel gears are suitable for applications in food processing, pharmaceuticals, and marine environments where hygiene and corrosion resistance are paramount. Buyers from regions with strict compliance standards, such as the EU, should prioritize stainless steel for such applications.

Why Are Engineering Plastics Gaining Popularity in Bevel Gear Manufacturing?

Key Properties: Engineering plastics, such as polyacetal and nylon, offer lightweight and low-friction characteristics. They are resistant to corrosion and can operate in a wide temperature range, making them suitable for various applications.

Pros & Cons: The advantages of using engineering plastics include low weight, reduced noise during operation, and lower manufacturing costs. However, they may not withstand high loads or temperatures as well as metals, which limits their application in heavy-duty environments.

Impact on Application: Engineering plastics are ideal for applications requiring lightweight components, such as in consumer electronics or automotive sectors. B2B buyers should consider the specific load and temperature requirements of their applications when opting for plastic gears.

How Do Brass and Zinc Die-Cast Materials Fit into Bevel Gear Applications?

Key Properties: Brass and zinc die-cast materials are often used for their excellent machinability and corrosion resistance. They can handle moderate loads and are typically used in lower-stress applications.

Pros & Cons: The key advantage of brass and zinc die-cast gears is their ease of production and cost-effectiveness. However, they may not provide the same strength and durability as steel options, making them unsuitable for high-load applications.

Impact on Application: These materials are commonly used in consumer goods and light machinery where strength is less critical. Buyers should evaluate the specific demands of their applications, especially in regions with varying climate conditions.

Summary Table of Material Selection for Bevel Gears

| Material | Typical Use Case for bevel gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General machinery, automotive applications | High strength and durability | Susceptible to corrosion | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Engineering Plastics | Consumer electronics, automotive parts | Lightweight and low friction | Limited load capacity | Low |

| Brass/Zinc Die-Cast | Consumer goods, light machinery | Cost-effective and easy to machine | Lower strength compared to steel | Low |

This guide provides valuable insights for international B2B buyers, enabling informed decisions based on material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for bevel gear

What Are the Key Stages in the Manufacturing Process of Bevel Gears?

The manufacturing of bevel gears involves several critical stages, each designed to ensure precision and functionality. Understanding these stages is essential for B2B buyers looking to procure high-quality bevel gears.

1. Material Preparation

The first step in the bevel gear manufacturing process is material preparation. The choice of material significantly impacts the gear’s performance and durability. Common materials include:

- Carbon Steel (S45C): Known for its strength and hardness, making it suitable for high-load applications.

- Alloy Steel (SCM415): Offers enhanced toughness and fatigue resistance, ideal for heavy-duty applications.

- Engineering Plastics (e.g., MC901): Used for lightweight applications where noise reduction and lubrication-free operation are priorities.

Materials are often procured from certified suppliers to ensure compliance with international standards.

2. Forming Techniques: How Are Bevel Gears Shaped?

Once the materials are prepared, the next stage involves shaping the bevel gears through various forming techniques. The primary methods include:

- Gleason Method: This widely used technique involves cutting the gear teeth using specialized machines, providing high precision and efficiency. It is particularly favored for producing spiral bevel gears.

- Klingelnberg Method: This method also offers high accuracy but is less common due to the complexity of the equipment required.

These techniques ensure that the gears meet the specific tooth profiles and dimensions required for their intended applications.

3. Assembly: How Are Bevel Gears Assembled?

After forming, gears undergo an assembly process, which may involve:

- Pairing Gears: Ensuring that the bevel gears are correctly matched with their corresponding pinions for optimal performance.

- Testing Fit: Checking for proper engagement and alignment to minimize noise and wear during operation.

This stage is crucial for ensuring that the assembled gears function effectively in their applications.

4. Finishing: What Finishing Processes Enhance Gear Performance?

Finishing processes play a vital role in enhancing the performance and longevity of bevel gears. Common finishing techniques include:

- Grinding: Used for gears that require high precision. Ground gears have improved surface finishes, reducing noise and increasing efficiency.

- Polishing: Particularly for spiral bevel gears, polishing helps in achieving smoother surfaces, which contributes to quieter operation.

- Heat Treatment: Processes such as carburizing or induction hardening are applied to increase hardness and wear resistance.

These finishing processes are tailored to the specific requirements of the application, ensuring optimal performance.

What Are the International Quality Assurance Standards for Bevel Gears?

Quality assurance (QA) is essential in the manufacturing of bevel gears, as it ensures that the products meet the necessary standards for safety, reliability, and performance. Various international standards are applicable, including:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers to ensure consistent quality in their products and services.

- CE Marking: Particularly relevant for products sold in the European market, indicating compliance with EU safety, health, and environmental protection standards.

- API Standards: Relevant for gears used in the oil and gas industry, ensuring that products meet specific performance criteria.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are implemented throughout the manufacturing process to ensure that bevel gears meet the required specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): During the manufacturing process, various checks are performed to monitor the progress and quality of the gears being produced.

- Final Quality Control (FQC): After manufacturing, a comprehensive inspection is conducted to ensure that the finished gears meet all specifications and standards.

These checkpoints help identify any issues early in the manufacturing process, reducing waste and ensuring high-quality outcomes.

What Testing Methods Are Commonly Used for Bevel Gears?

Various testing methods are employed to verify the quality and performance of bevel gears. Common methods include:

- Dimensional Inspection: Utilizing precision measuring tools to ensure that the gear dimensions conform to specifications.

- Hardness Testing: Conducted to verify that the material has been treated correctly and possesses the necessary hardness for its application.

- Functional Testing: Simulating the operating conditions to assess performance, noise levels, and wear characteristics.

These tests are essential for ensuring that the gears will perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and adherence to international standards.

- Quality Reports: Requesting quality assurance reports can provide insights into the supplier’s testing methods, results, and overall quality performance.

- Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

By taking these steps, buyers can ensure that they are partnering with reliable manufacturers who prioritize quality in their production processes.

Conclusion: Ensuring Quality in Bevel Gear Manufacturing

Understanding the manufacturing processes and quality assurance practices for bevel gears is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control, buyers can make informed decisions and ensure they receive high-quality products that meet their specific needs. Engaging in thorough supplier verification processes further enhances the likelihood of successful procurement, especially in international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bevel gear’

This guide serves as a comprehensive checklist for international B2B buyers looking to source bevel gears effectively. Understanding the various aspects of sourcing will enhance your procurement strategy, ensuring you select the right products that meet your operational needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications required for your bevel gears. This includes the gear type (straight or spiral), material (steel, stainless steel, plastic), and operational parameters like load capacity and speed ratio.

– Why it matters: Defining these specifications helps narrow down your options and ensures compatibility with your machinery.

– What to look for: Detailed specifications will help suppliers provide accurate quotes and relevant products.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers specializing in bevel gears. Look for suppliers with a strong market presence, positive reviews, and a wide range of products.

– Why it matters: Supplier reputation is critical for ensuring product quality and reliability.

– What to look for: Check online platforms, industry directories, and trade shows for recommendations. Pay attention to suppliers’ experience in your specific industry.

Step 3: Evaluate Supplier Certifications and Quality Standards

Before proceeding with any supplier, verify their certifications and adherence to quality standards (such as ISO 9001).

– Why it matters: Certifications demonstrate a supplier’s commitment to quality and operational excellence.

– What to look for: Request documentation that confirms their compliance with international standards relevant to your industry, especially if you’re importing.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, lead times, and terms of service.

– Why it matters: A clear understanding of costs and timelines helps in budgeting and planning.

– What to look for: Ensure that quotations are itemized, showing costs for different gear types, materials, and any additional services, such as customizations.

Step 5: Assess After-Sales Support and Warranty Policies

Inquire about the after-sales support offered by suppliers, including warranty terms and maintenance services.

– Why it matters: Good after-sales support can save costs and time in the long run, especially if issues arise post-purchase.

– What to look for: Look for suppliers who offer comprehensive warranties and responsive customer service.

Step 6: Conduct a Trial Order

Before committing to a large order, consider placing a trial order for a smaller quantity of bevel gears.

– Why it matters: A trial order allows you to evaluate product quality and supplier reliability without significant investment.

– What to look for: Assess the performance of the bevel gears in your application and the supplier’s responsiveness to any issues.

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your selected supplier throughout the sourcing process.

– Why it matters: Effective communication minimizes misunderstandings and ensures that both parties are aligned on expectations.

– What to look for: Set regular check-ins and ensure that contact details are exchanged for quick resolution of any queries or concerns.

By following these steps, you can streamline your sourcing process for bevel gears, ensuring that you select the right products from reliable suppliers while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for bevel gear Sourcing

What Are the Key Cost Components in Bevel Gear Sourcing?

When sourcing bevel gears, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of material significantly impacts cost. Common materials for bevel gears include carbon steel (S45C, SCM415), stainless steel (SUS303), and engineering plastics (e.g., MC901). Each material comes with different price points and performance characteristics.

-

Labor: Labor costs encompass both direct and indirect labor associated with manufacturing. This includes skilled labor for precision machining and assembly, which can vary widely by region. For instance, labor costs may be lower in some African or South American countries compared to Europe.

-

Manufacturing Overhead: This refers to indirect costs associated with production, such as utilities, rent, and equipment maintenance. Effective management of overhead can reduce overall costs.

-

Tooling: Tooling expenses include the design and production of molds or dies for gear shaping. This is especially relevant for custom orders, where specialized tooling may be required.

-

Quality Control (QC): Ensuring the gears meet required specifications involves QC processes that can add to the overall cost. Certifications and testing (e.g., ISO standards) may also be necessary, especially for international buyers.

-

Logistics: Transportation and warehousing costs can vary depending on the supplier’s location and the destination market. Shipping methods (air vs. sea) and Incoterms (e.g., CIF, FOB) can significantly affect logistics costs.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can fluctuate based on market demand and competition.

How Do Pricing Influencers Affect Bevel Gear Costs?

Several factors influence the pricing of bevel gears, which can vary widely across different markets:

-

Volume/MOQ: Larger orders often qualify for bulk discounts. Buyers should assess their needs to optimize order sizes and negotiate better terms.

-

Specifications and Customization: Custom bevel gears with unique specifications may incur additional costs. Providing precise specifications upfront can help in receiving accurate quotes.

-

Material Selection: The choice of material not only affects the price but also the performance and durability of the bevel gears. For instance, stainless steel gears may have a higher upfront cost but offer better longevity.

-

Quality and Certifications: Gears that meet higher quality standards or come with certifications may carry a premium price. Buyers should weigh the importance of these certifications against their operational requirements.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and location can influence pricing. Established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: Understanding shipping terms and conditions can significantly impact the final price. Buyers should clarify responsibility for costs and risks associated with transport.

What Are the Best Practices for Negotiating Bevel Gear Prices?

Effective negotiation strategies can lead to cost savings and better terms for international B2B buyers:

-

Research and Benchmarking: Conduct market research to understand typical pricing for bevel gears in your region. This knowledge can strengthen your negotiation position.

-

Emphasize Long-Term Relationships: Building a long-term partnership with suppliers can lead to better pricing and service. Suppliers may be more willing to negotiate on price if they see a potential for future orders.

-

Explore Total Cost of Ownership (TCO): Assess the TCO, which includes not only the purchase price but also maintenance, operational efficiency, and lifespan of the bevel gears. A higher upfront cost may be justified if the gears offer greater durability and efficiency.

-

Leverage Competitive Quotes: Obtaining quotes from multiple suppliers can provide leverage in negotiations. Presenting competitive offers can encourage suppliers to match or beat prices.

-

Be Clear on Payment Terms: Clarifying payment terms upfront can prevent misunderstandings and help manage cash flow effectively.

Conclusion: Navigating Bevel Gear Sourcing in International Markets

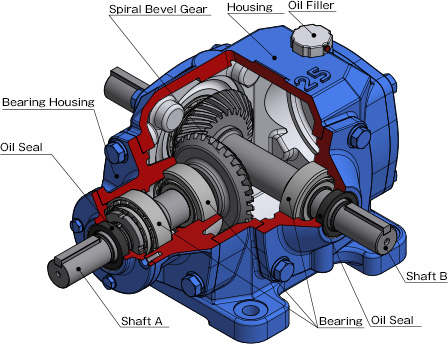

A stock image related to bevel gear.

In conclusion, sourcing bevel gears involves navigating a complex landscape of costs and pricing factors. By understanding the key cost components, recognizing the influences on pricing, and employing effective negotiation strategies, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing decisions. Always remember to account for the indicative nature of prices, as fluctuations in material costs and market conditions can affect final pricing.

Alternatives Analysis: Comparing bevel gear With Other Solutions

Understanding the Importance of Alternative Solutions in Gear Systems

When evaluating gear systems for mechanical applications, it’s essential to consider not only bevel gears but also viable alternatives that might suit specific operational needs. This analysis aims to provide international B2B buyers with a clear comparison of bevel gears against other technologies, including worm gears and planetary gears. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their operational requirements and budget constraints.

Comparison Table of Bevel Gears and Alternative Solutions

| Comparison Aspect | Bevel Gear | Worm Gear | Planetary Gear |

|---|---|---|---|

| Performance | Excellent for high-speed applications; smooth power transmission between non-parallel shafts. | High torque transmission; effective for speed reduction. | High efficiency and compact design; suitable for high load applications. |

| Cost | Moderate to high, depending on materials and manufacturing methods. | Generally lower cost, especially for simpler designs. | Typically higher due to complexity and precision engineering. |

| Ease of Implementation | Requires precise alignment; installation can be complex. | Easier to install, with fewer alignment issues. | Installation can be complex, requiring precise assembly. |

| Maintenance | Low to moderate; needs periodic checks for wear. | Generally low maintenance, but lubrication is essential. | Requires regular maintenance; gears must be kept clean and lubricated. |

| Best Use Case | Ideal for applications needing directional changes in motion, like automotive steering systems. | Best for applications requiring high torque and low speed, like conveyor systems. | Suitable for applications requiring compact design with high torque and speed ratios, like robotics. |

What Are the Pros and Cons of Worm Gears?

Worm gears are an alternative that excels in applications requiring high torque and reduced speed. Their design allows for significant gear reduction in a compact size, making them ideal for scenarios such as conveyors or hoisting systems. One of the primary advantages of worm gears is their ability to self-lock, preventing back-driving, which is crucial in many industrial applications. However, they can have lower efficiency due to sliding friction, which may lead to increased heat generation and wear over time.

How Do Planetary Gears Compare?

Planetary gears stand out for their high efficiency and compact design, making them a favorite in applications where space is at a premium. These gears offer an excellent power-to-weight ratio and can handle high loads effectively, making them suitable for robotics and automotive applications. However, the complexity of planetary gear systems can lead to higher costs and more intricate installation processes. Regular maintenance is also critical to ensure optimal performance and longevity.

Conclusion: How to Choose the Right Gear Solution for Your Needs

For international B2B buyers, selecting the appropriate gear solution involves balancing performance, cost, ease of implementation, and maintenance. Bevel gears offer unique advantages in applications requiring smooth power transmission at high speeds, while worm gears provide a cost-effective solution for high-torque, low-speed needs. Planetary gears, although typically more expensive, deliver exceptional efficiency and compactness. Assessing the specific requirements of your application, including load conditions and space constraints, will guide you in making the best choice for your operational needs. Consider reaching out to suppliers for technical support and further insights tailored to your unique situation.

Essential Technical Properties and Trade Terminology for bevel gear

What Are the Key Technical Properties of Bevel Gears?

Understanding the essential technical properties of bevel gears is crucial for international B2B buyers who need reliable and efficient components for their machinery. Here are some critical specifications:

1. Material Grade: What Should You Look For?

Bevel gears can be manufactured from various materials, including carbon steel (like S45C), alloy steel (SCM415), stainless steel (SUS303), and engineering plastics (MC901). The choice of material impacts durability, wear resistance, and performance under different loads. For instance, stainless steel is preferred for applications requiring rust resistance, while carbon steel is cost-effective for general use. Buyers should align material selection with their operational environment to ensure longevity and efficiency.

2. Tooth Finish: Why Is It Important?

The tooth finish of bevel gears can significantly affect performance and noise levels. Tooth finishes range from “cut” (non-ground) to “ground” finishes, with the latter providing superior accuracy and lower noise during operation. Buyers should consider the application’s noise sensitivity and precision requirements when selecting tooth finishes to optimize performance.

3. Speed Ratio: How Does It Affect Performance?

The speed ratio of bevel gears indicates how the input and output speeds relate, usually expressed in ratios like 1:1 or 1:4. This specification is vital for determining the gear’s effectiveness in power transmission. A higher speed ratio can provide rapid acceleration, while a lower ratio often results in higher torque. Understanding the required speed ratio helps buyers choose the right gear for their specific mechanical needs.

4. Module Size: What Is Its Role?

The module size refers to the size of the teeth on the gear and is expressed in millimeters. It is crucial for ensuring compatibility between mating gears. A correct module size ensures smooth operation, efficient load distribution, and reduced wear. Buyers must verify module sizes when selecting bevel gears to prevent operational issues and ensure seamless integration into their machinery.

5. Hardening Process: What Are Your Options?

Bevel gears undergo various hardening processes, such as carburizing or induction hardening, to enhance their strength and wear resistance. The choice of hardening process can affect the gear’s lifespan and performance under stress. Buyers should inquire about hardening methods to ensure the selected gear meets their operational demands.

What Are Common Trade Terms Related to Bevel Gears?

Familiarizing yourself with industry jargon can streamline purchasing and enhance communication with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces components that are used in another company’s end product. In the context of bevel gears, understanding whether a supplier is an OEM can impact the quality and reliability of the parts being purchased, as OEMs typically adhere to strict quality standards.

2. MOQ (Minimum Order Quantity): Why Is It Significant?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budget management, as it can affect overall procurement costs. International buyers should negotiate MOQs to ensure they can purchase the necessary quantities without incurring excess expenses.

3. RFQ (Request for Quotation): How Should You Use It?

An RFQ is a formal document sent to suppliers to obtain price quotes for specific products. Crafting a detailed RFQ for bevel gears can help buyers receive accurate pricing and lead times, facilitating better decision-making and budgeting.

4. Incoterms (International Commercial Terms): How Do They Affect Shipping?

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is crucial for international B2B transactions, as they dictate who is responsible for shipping costs, insurance, and risk during transit. Familiarity with Incoterms can prevent misunderstandings and ensure smooth transactions.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing bevel gears, ultimately optimizing their procurement processes and enhancing operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the bevel gear Sector

What Are the Current Market Dynamics Influencing the Bevel Gear Sector?

The bevel gear sector is experiencing a robust transformation driven by several global trends. One of the primary drivers is the increasing demand for precision machinery across various industries, including automotive, aerospace, and manufacturing. As companies strive for efficiency, the need for high-performance bevel gears that can withstand extreme conditions is paramount. Furthermore, advancements in manufacturing technologies, such as CNC machining and additive manufacturing, are enabling the production of more complex and precise bevel gear designs, allowing for customization that meets specific client needs.

Emerging technologies like Industry 4.0 and IoT are reshaping the sourcing landscape by enabling real-time monitoring and predictive maintenance of gear systems. This results in reduced downtime and improved operational efficiency for international B2B buyers. Additionally, global supply chains are becoming more interconnected, which allows buyers from regions like Africa, South America, the Middle East, and Europe to source bevel gears from various manufacturers worldwide. However, this interconnectedness also means that buyers must navigate fluctuating tariffs and trade regulations, which can impact sourcing strategies.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Bevel Gear Sector?

Sustainability and ethical sourcing have become critical considerations for international B2B buyers in the bevel gear market. The environmental impact of manufacturing processes, particularly in metalworking and plastic production, necessitates the adoption of greener practices. Buyers should prioritize suppliers who utilize sustainable materials, such as recycled metals and biodegradable plastics, in their bevel gear production.

Additionally, ethical supply chains are essential for maintaining corporate responsibility. Buyers are increasingly looking for suppliers that adhere to fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Investing in suppliers with ‘green’ certifications not only enhances brand reputation but also mitigates risks associated with environmental regulations. By aligning sourcing strategies with sustainability goals, buyers can contribute positively to the global push for environmental stewardship while ensuring the longevity of their supply chains.

What is the Historical Evolution of Bevel Gears in B2B Applications?

The history of bevel gears dates back to ancient times when they were first used in simple machines. However, it was during the Industrial Revolution that their design and manufacturing processes began to evolve significantly. The introduction of the Gleason method in the early 20th century revolutionized bevel gear production by allowing for more precise and efficient manufacturing. This method has since become the standard in the industry, enabling the production of high-quality gears that meet the demands of modern machinery.

Over the decades, advancements in material science have also played a crucial role in the evolution of bevel gears. The transition from traditional materials to advanced alloys and engineering plastics has improved the performance and durability of these components. Today, bevel gears are integral to various high-tech applications, further solidifying their importance in the global B2B marketplace. By understanding the historical context, international buyers can appreciate the technological advancements that have shaped the bevel gear sector and can make informed decisions when sourcing these critical components.

Frequently Asked Questions (FAQs) for B2B Buyers of bevel gear

-

How do I choose the right bevel gear for my application?

Selecting the right bevel gear involves understanding your specific application requirements, including load capacity, speed ratio, and space constraints. Consider the type of bevel gear—straight or spiral—as spiral gears generally offer better noise reduction and smoother operation. Evaluate the materials used, as this affects durability and performance. Additionally, consult with suppliers who provide detailed specifications and CAD drawings to ensure compatibility with your machinery. It’s also advisable to review the gear’s manufacturing process to confirm quality standards. -

What is the best material for bevel gears used in harsh environments?

For harsh environments, stainless steel bevel gears are often the best choice due to their corrosion resistance and strength. If weight is a concern, consider engineering plastics like polyacetal, which can also provide adequate durability and lower noise levels. Evaluate the specific environmental factors such as temperature and exposure to chemicals, as these will affect material selection. It is essential to consult with your supplier about the best materials suited for your particular application and environment. -

What customization options are available for bevel gears?

Many manufacturers offer customization options for bevel gears, including specific tooth profiles, sizes, and materials. Customization can also extend to the heat treatment processes used to enhance gear strength and durability. If your application requires unique specifications, communicate these needs early in the procurement process to your supplier. They can provide insights into feasible modifications and associated costs, ensuring that the final product meets your operational demands. -

What are the minimum order quantities (MOQ) for bevel gears?

Minimum order quantities for bevel gears can vary significantly between suppliers and depend on the type and complexity of the gear. Some manufacturers may offer lower MOQs for standard products, while custom gears typically require larger orders to justify production costs. When sourcing, inquire about MOQs upfront to align your purchasing strategy with your production needs. If you have smaller requirements, consider collaborating with other buyers to meet MOQ thresholds. -

What payment terms should I expect when purchasing bevel gears internationally?

Payment terms for international purchases of bevel gears can vary based on supplier policies and your relationship with them. Common terms include upfront payments, letter of credit, or net 30/60 days after delivery. Always clarify payment methods, currency considerations, and potential fees associated with international transactions. It is prudent to establish a clear agreement before proceeding with an order to avoid misunderstandings that could impact your supply chain.

A stock image related to bevel gear.

-

How can I ensure the quality of bevel gears from international suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001 to verify their quality management systems. Ask for samples or prototypes to assess manufacturing quality firsthand. Additionally, consider suppliers who provide comprehensive technical documentation and quality assurance measures, including testing protocols for durability and performance. Building a strong relationship and maintaining open communication can further enhance your quality assurance efforts. -

What logistics considerations should I keep in mind when importing bevel gears?

Logistics play a crucial role in importing bevel gears. Evaluate shipping methods, costs, and transit times, as these can significantly impact your supply chain. Understand customs regulations and duties applicable to your imports to avoid unexpected expenses. Collaborating with a reliable freight forwarder can help navigate the complexities of international shipping. Finally, ensure that your supplier provides proper packaging to prevent damage during transit. -

What are the common applications for bevel gears in various industries?

Bevel gears are widely used across industries such as automotive, aerospace, manufacturing, and robotics. They facilitate power transmission between intersecting shafts, making them ideal for applications requiring directional changes in motion. Common uses include gearboxes, conveyor systems, and machinery that demand precise torque and speed control. Understanding the specific needs of your industry can help you select the right bevel gear type and configuration for optimal performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bevel gear

In conclusion, strategic sourcing of bevel gears is essential for optimizing operational efficiency and ensuring the longevity of machinery across various industries. International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize understanding the different types of bevel gears available, including straight and spiral variants, and their respective materials and manufacturing methods.

Investing in high-quality bevel gears not only enhances performance but also reduces maintenance costs and downtime. Buyers should consider suppliers that offer customization options and comprehensive technical support, ensuring that the selected gears meet specific application requirements.

As global supply chains evolve, engaging with local and international manufacturers can provide access to innovative solutions and competitive pricing. By leveraging strategic sourcing practices, businesses can secure reliable gear solutions that align with their operational goals.

Looking ahead, the demand for precision-engineered bevel gears is likely to grow, driven by advancements in technology and increased automation. Now is the time to reassess your sourcing strategy and partner with trusted suppliers who can deliver value and quality. Embrace this opportunity to enhance your competitive edge and drive sustainable growth in your operations.