Unlock Efficiency: The Ultimate Graphite Rod Guide (2025)

Introduction: Navigating the Global Market for graphite rod

Navigating the complexities of sourcing graphite rods can be a daunting challenge for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. With a multitude of suppliers, varying grades, and diverse applications, understanding how to identify the right product for specific industrial needs is crucial. This guide offers a comprehensive overview of graphite rods, detailing the different types available—including JC3 and JC4 grades—and their applications in sectors like electrochemistry and heat treating.

Moreover, we delve into critical aspects such as supplier vetting processes, cost considerations, and logistics tailored to specific regions, including the UAE and Vietnam. By equipping buyers with essential knowledge and actionable insights, this guide empowers you to make informed purchasing decisions that align with your operational requirements and budget constraints. Whether you are a manufacturer looking for reliable components or a project manager seeking to optimize your supply chain, understanding the global market for graphite rods will enhance your procurement strategy and help you secure the best deals.

In the subsequent sections, we will explore the specifications and benefits of graphite rods, practical tips for supplier engagement, and strategic considerations to ensure you navigate the global market effectively.

Understanding graphite rod Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| JC3 Graphite Rod | High-density, fine-grained, rated for high temperatures (up to 3000℃) | Electrochemical applications, heat treating | Pros: Excellent thermal conductivity, machinable to close tolerances. Cons: Higher cost due to specialized use. |

| JC4 Graphite Rod | Strong fine-grained, rated for medium temperatures (up to 735℃) | Mechanical applications, fixtures | Pros: Good density and strength, cost-effective. Cons: Limited to lower temperature applications. |

| Spectroscopic Pure Graphite Rod | High purity for specific applications, available in various diameters | Evaporation processes, scientific research | Pros: High-quality material, precise dimensions. Cons: Premium pricing may not suit all budgets. |

| Fine Extruded Graphite Rod | Uniform cross-section, excellent machinability | Electrical contacts, support structures | Pros: Consistent performance, easy to customize. Cons: May require additional machining for specific applications. |

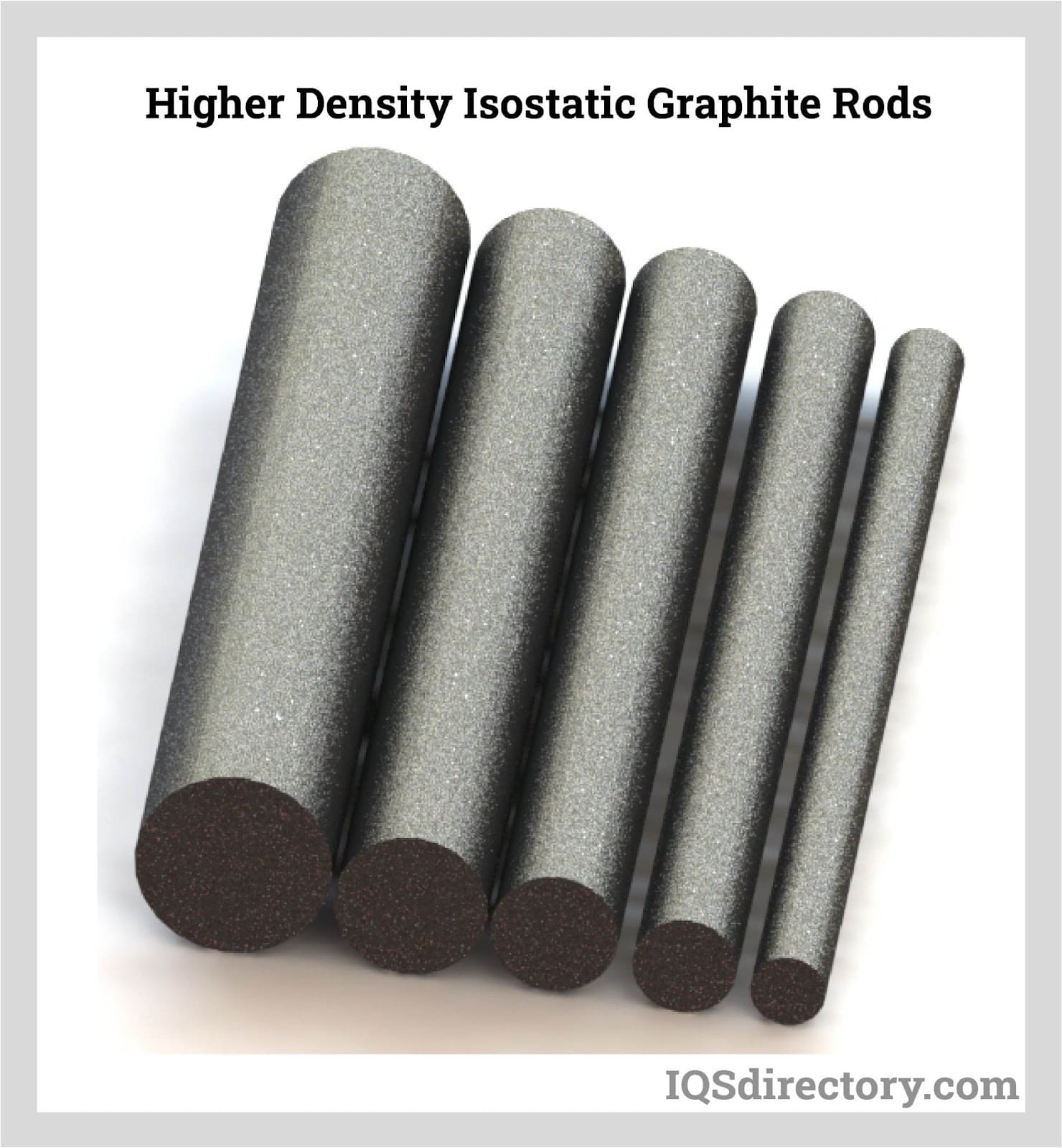

| Isographite Rod | High conductivity, isotropic properties | High-performance electrical applications | Pros: Superior electrical performance, versatile. Cons: Limited availability and potentially higher costs. |

What are the Characteristics of JC3 Graphite Rods?

JC3 graphite rods are characterized by their high density and fine-grained structure, making them suitable for high-temperature applications, rated up to 3000℃. These rods exhibit excellent electrical conductivity and thermal resistance, which is crucial in electrochemical processes and heat treating. B2B buyers should consider the specific temperature requirements of their applications, as well as the necessity for precision machining, which may justify the higher cost associated with JC3 rods.

How Do JC4 Graphite Rods Compare for Mechanical Applications?

JC4 graphite rods are designed for medium-temperature environments, rated up to 735℃. They offer a strong and machinable option for various mechanical applications, including fixtures and support structures. Their good density and strength make them a cost-effective choice for businesses that do not require the extreme performance of JC3 rods. Buyers should assess their operational temperature limits and mechanical stress factors when selecting JC4 rods to ensure optimal performance.

Why Choose Spectroscopic Pure Graphite Rods?

Spectroscopic pure graphite rods are distinguished by their high purity levels, making them ideal for specialized applications such as evaporation processes in scientific and industrial settings. These rods are available in various diameters and are manufactured to precise specifications. While they offer superior quality, buyers should be prepared for a higher price point and consider the specific requirements of their applications to justify the investment.

What are the Benefits of Fine Extruded Graphite Rods?

Fine extruded graphite rods are known for their uniform cross-section and excellent machinability, making them versatile for applications like electrical contacts and structural supports. Their consistent performance allows for easy customization, which is beneficial for businesses with specific needs. However, buyers should be aware that additional machining might be necessary to meet unique application requirements, potentially increasing overall costs.

When to Consider Isographite Rods for Electrical Applications?

Isographite rods are recognized for their high conductivity and isotropic properties, making them suitable for high-performance electrical applications. These rods can be a great asset for businesses requiring superior electrical performance. However, their limited availability and potentially higher costs may require careful consideration of budget and supply chain factors before making a purchase decision.

Key Industrial Applications of graphite rod

| Industry/Sector | Specific Application of graphite rod | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace and Defense | Electrodes for plasma arc welding | High thermal and electrical conductivity | Ensure high purity and specific dimensions for precision work |

| Chemical Processing | Support structures in high-temperature reactors | Enhanced thermal stability and corrosion resistance | Look for rods with high compressive strength and thermal ratings |

| Manufacturing | Molds for casting metals | Excellent heat resistance and durability | Verify compatibility with specific metal types and sizes |

| Energy Sector | Components for nuclear reactors | Resistance to thermal shock and radiation | Source from certified suppliers with experience in nuclear applications |

| Electronics | Conductive paths in electronic devices | Reliable electrical conductivity and low resistance | Focus on high-purity graphite to minimize impurities in circuits |

How is Graphite Rod Used in Aerospace and Defense?

In the aerospace and defense sectors, graphite rods serve as electrodes for plasma arc welding, a critical process for joining materials in aircraft and military vehicles. Their high thermal and electrical conductivity ensures efficient welding, reducing the risk of defects and enhancing structural integrity. B2B buyers in this sector must prioritize sourcing rods that meet strict purity standards and precise dimensions to ensure optimal performance in demanding applications.

What Role Do Graphite Rods Play in Chemical Processing?

Graphite rods are utilized in the chemical processing industry as support structures in high-temperature reactors. They provide exceptional thermal stability and corrosion resistance, essential for maintaining safety and efficiency in chemical reactions. International buyers should focus on sourcing rods with high compressive strength and thermal ratings to withstand the harsh environments typically found in chemical plants, particularly in regions with extreme conditions.

Why Are Graphite Rods Important for Manufacturing?

In manufacturing, graphite rods are commonly used to create molds for casting metals, leveraging their excellent heat resistance and durability. These rods enable precise shaping and forming of molten metals, ensuring high-quality end products. Buyers in this sector should verify compatibility with specific metal types and sizes to ensure efficient production processes, especially in regions with diverse manufacturing capabilities.

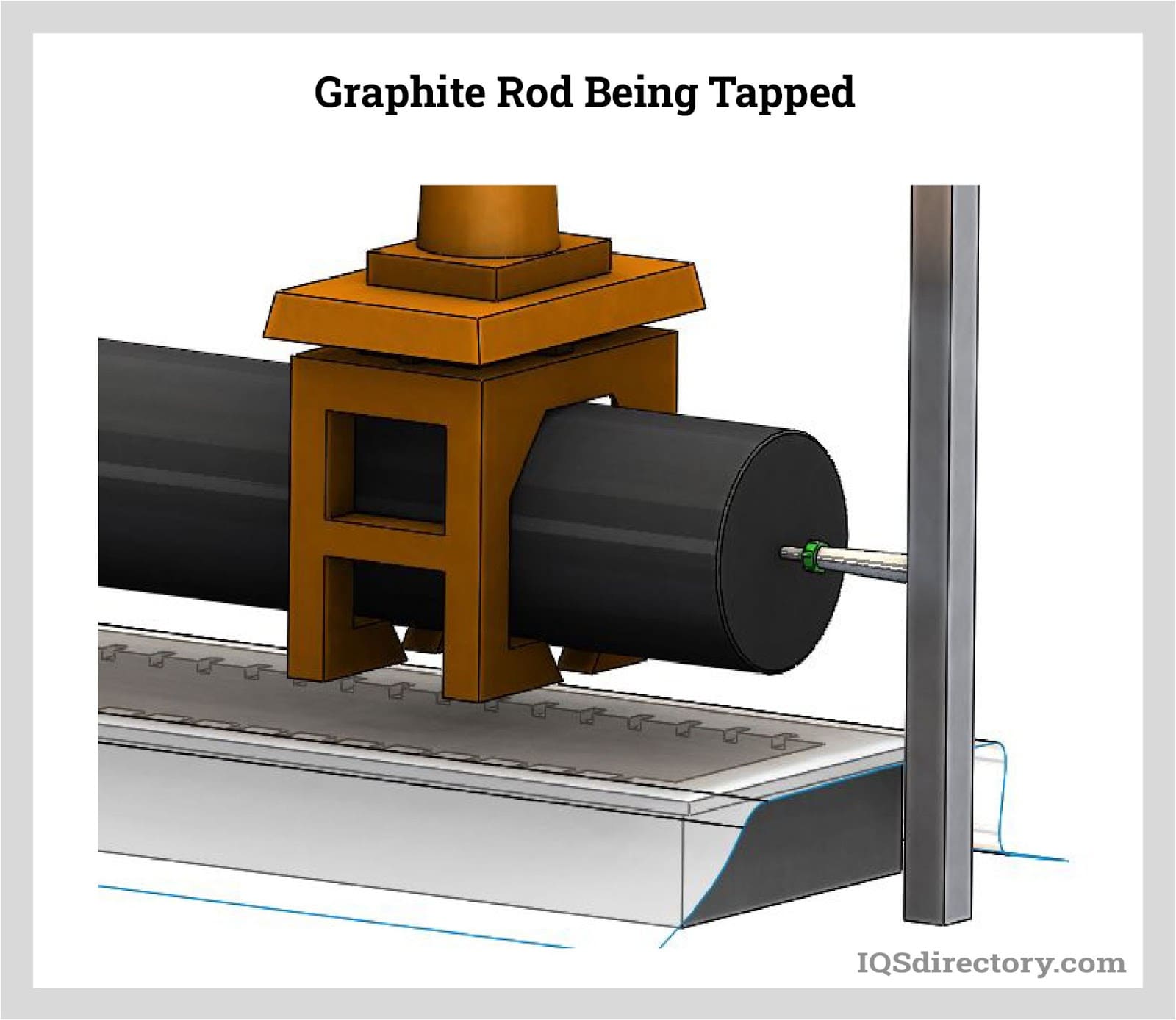

A stock image related to graphite rod.

How Do Graphite Rods Benefit the Energy Sector?

Graphite rods are critical components in nuclear reactors, where they provide resistance to thermal shock and radiation. Their unique properties help maintain structural integrity under extreme conditions, making them indispensable in energy production. B2B buyers in this field must source from certified suppliers with experience in nuclear applications, ensuring compliance with stringent safety and quality standards.

What Is the Significance of Graphite Rods in Electronics?

In the electronics industry, graphite rods are used as conductive paths in various electronic devices, providing reliable electrical conductivity and low resistance. This is vital for the performance of circuits and components. Buyers should focus on high-purity graphite to minimize impurities that could affect the functionality of electronic devices, particularly in markets like Europe and the Middle East, where technological standards are high.

3 Common User Pain Points for ‘graphite rod’ & Their Solutions

Scenario 1: Managing Thermal Shock in High-Temperature Applications

The Problem: In industries such as metal processing and heat treatment, graphite rods are frequently subjected to extreme temperature fluctuations. A B2B buyer might encounter issues where their current graphite rods are not resilient enough to withstand rapid temperature changes, leading to cracks, breakage, or reduced operational efficiency. This problem not only results in increased costs due to downtime and replacement but also impacts the quality of the end product, creating a ripple effect throughout the supply chain.

The Solution: To effectively manage thermal shock, it’s crucial to select high-quality graphite rods designed for high-temperature applications, such as JC3 graphite rods, which are rated to withstand temperatures up to 3000°C. B2B buyers should prioritize sourcing from reputable suppliers who can provide detailed specifications regarding thermal properties and material composition. Additionally, implementing gradual temperature adjustments during operational changes can significantly reduce stress on the graphite rods. Buyers can also consider using impregnants to fill the porosity of the rods, enhancing their thermal shock resistance and longevity. Regular monitoring of operational temperatures and environmental conditions will further help maintain the integrity of the graphite rods.

Scenario 2: Ensuring Consistent Electrical Conductivity

The Problem: In applications like electrochemistry and electronic components, the electrical conductivity of graphite rods is paramount. A buyer may find that their current graphite rods exhibit inconsistent conductivity, leading to inefficiencies or failures in performance. This inconsistency can stem from manufacturing defects, variations in material quality, or improper handling during installation, resulting in costly project delays and compromised product reliability.

The Solution: Buyers should conduct thorough due diligence when selecting suppliers, ensuring they provide rods with guaranteed specifications for electrical conductivity. Opting for graphite rods specifically designed for electrochemical applications, such as those with a lower resistance rating (like JC3), can mitigate these issues. It’s also advisable to request samples for testing before making bulk purchases. Implementing best practices for handling and installation—such as using appropriate connectors and ensuring clean contact surfaces—will further enhance conductivity. Regular maintenance checks and conductivity testing can help identify and rectify issues before they escalate.

Scenario 3: Overcoming Sourcing Challenges and MOQ Constraints

The Problem: International buyers, particularly from regions like Africa and South America, may face significant challenges when trying to source graphite rods due to minimum order quantity (MOQ) restrictions and shipping complexities. These barriers can lead to increased costs and delays, ultimately impacting project timelines and budgets.

The Solution: To navigate these sourcing challenges, buyers should look for suppliers that offer flexibility in their MOQs. Engaging with local distributors or suppliers who understand the regional market can be beneficial. Additionally, forming partnerships with other companies to consolidate orders can help meet MOQ requirements while reducing overall shipping costs. Buyers should also explore alternative sourcing options, such as custom manufacturing services that cater to specific needs without imposing strict MOQs. Leveraging technology, such as online platforms that connect buyers with multiple suppliers, can streamline the procurement process and provide access to a broader range of products and pricing options. Prioritizing suppliers who offer transparent shipping quotes and timely delivery schedules will enhance supply chain reliability and efficiency.

Strategic Material Selection Guide for graphite rod

What are the Key Properties of Different Graphite Rod Materials?

When selecting graphite rods for specific applications, understanding the properties of various materials is crucial. Here, we analyze four common types of graphite rods: JC3, JC4, Isographite, and Spectroscopic Pure Graphite. Each material has unique characteristics that can significantly influence performance in diverse industrial applications.

What are the Key Properties of JC3 Graphite Rods?

JC3 graphite rods are known for their high density and fine grain structure, making them suitable for applications requiring excellent electrical conductivity and thermal resistance. They can withstand temperatures up to 3000°C (5432°F) and have a compressive strength ranging from 11,000 to 38,000 lbs/in². This material is particularly advantageous in electrochemical applications and heat treating processes.

Pros:

– Exceptional machinability and tolerance.

– High thermal conductivity and corrosion resistance.

– Built-in lubrication properties that prevent galling.

Cons:

– Higher cost compared to lower-grade options.

– Requires careful handling due to its high temperature capabilities.

Impact on Application:

JC3 rods are ideal for environments that involve extreme heat and require electrical conductivity, such as in the manufacturing of electrodes and fixtures.

How Do JC4 Graphite Rods Compare?

JC4 graphite rods are similar to JC3 but are designed for applications where lower temperature resistance (up to 735°C) is acceptable. They offer good density and strength, making them suitable for mechanical applications.

Pros:

– Cost-effective for less demanding applications.

– Good machinability and strength.

Cons:

– Limited thermal resistance compared to JC3.

– Less suitable for high-temperature electrochemical applications.

Impact on Application:

JC4 rods are often used in mechanical support roles and where thermal expansion is a concern, making them a versatile option for various industries.

What is Isographite and Its Applications?

Isographite is a specialized form of graphite that is engineered for high-performance applications. It typically features a very low porosity and high purity, making it suitable for demanding environments.

Pros:

– Superior thermal and electrical conductivity.

– Excellent resistance to chemical corrosion.

Cons:

– Higher manufacturing complexity and costs.

– Limited availability in certain regions.

Impact on Application:

Isographite is particularly useful in the aerospace and semiconductor industries, where precision and reliability are paramount.

Why Choose Spectroscopic Pure Graphite Rods?

Spectroscopic pure graphite rods are manufactured for high-purity applications, often used in scientific and analytical settings. They have low electrical resistance and excellent thermal stability.

Pros:

– High purity ensures minimal contamination.

– Good thermal and electrical properties.

Cons:

– Typically more expensive due to the manufacturing process.

– May not be necessary for less critical applications.

Impact on Application:

These rods are ideal for laboratory use and applications requiring precise measurements, such as in spectroscopic analysis.

Summary Table of Graphite Rod Materials

| Material | Typical Use Case for graphite rod | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| JC3 | Electrochemical applications | High thermal resistance and conductivity | Higher cost compared to lower-grade options | High |

| JC4 | Mechanical support applications | Cost-effective for less demanding applications | Limited thermal resistance | Medium |

| Isographite | Aerospace and semiconductor industries | Superior conductivity and chemical resistance | Higher manufacturing complexity and costs | High |

| Spectroscopic Pure Graphite | Laboratory and analytical applications | High purity minimizes contamination | More expensive due to manufacturing processes | High |

This strategic material selection guide provides essential insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Understanding the properties, advantages, and limitations of each graphite rod type will enable informed purchasing decisions that align with specific application needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite rod

What Are the Key Stages in the Manufacturing Process of Graphite Rods?

The manufacturing of graphite rods involves several critical stages that ensure the end product meets the required specifications and standards. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. High-quality graphite powder is sourced, which can be either natural or synthetic. The choice of material often depends on the intended application of the graphite rod. The graphite is then mixed with a binding agent, usually a resin or pitch, to enhance its properties and ensure better cohesion during the forming stage.

2. Forming Techniques

After material preparation, the next phase is forming the graphite rods. Common techniques include:

-

Extrusion: This involves forcing the prepared graphite mixture through a die to create the desired rod shape. Extrusion is favored for its efficiency and ability to produce rods of uniform cross-section.

-

Molding: Another technique involves placing the graphite mixture into molds. This method is often used for producing rods with complex geometries or larger diameters.

-

Machining: For precision applications, solid graphite blocks are machined into rods. This is essential for achieving tight tolerances and specific dimensions.

3. Assembly and Consolidation

In some cases, multiple components may be assembled to create a composite rod. This is particularly relevant for applications requiring enhanced properties, such as increased strength or conductivity. The consolidation process ensures that all parts adhere well and perform as a single unit.

4. Finishing

The final stage involves finishing processes that enhance the rod’s surface characteristics. Common techniques include:

-

Grinding: This refines the surface finish and dimensions of the rod.

-

Impregnation: To reduce porosity, rods may be impregnated with resins or oils, making them impervious to liquids and gases.

-

Coating: In certain applications, a protective coating is applied to enhance corrosion resistance.

How Is Quality Assurance Implemented in Graphite Rod Manufacturing?

Quality assurance is vital in the graphite rod manufacturing process to ensure the products meet international standards and customer expectations. Here are the key elements of a robust QC system:

International Standards and Compliance

A stock image related to graphite rod.

Manufacturers often adhere to internationally recognized standards, such as ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with these standards is crucial for ensuring consistent quality and reliability. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the application of the graphite rods.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process via several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Testing may include assessing the purity and granulation of graphite powder.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and material consistency are monitored. This ensures that the manufacturing process remains within specified limits.

-

Final Quality Control (FQC): Once the rods are produced, they undergo final inspections. This includes dimensional checks, surface finish evaluations, and performance testing.

What Testing Methods Are Commonly Used for Graphite Rods?

Various testing methods are employed to validate the quality and performance of graphite rods. These include:

-

Mechanical Testing: This assesses properties like tensile strength, compressive strength, and hardness. Such tests are crucial for applications where structural integrity is paramount.

-

Thermal Conductivity Testing: Given graphite’s applications in heat management, testing its thermal conductivity is essential. This ensures that the rods can effectively dissipate heat in their intended applications.

-

Electrical Conductivity Testing: For applications involving electrochemical processes, verifying electrical conductivity is critical. This ensures that the rods will perform efficiently in their roles.

-

Porosity Testing: Since porosity can affect performance, testing methods like mercury intrusion porosimetry may be used to quantify the porosity levels of the rods.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are actionable steps to verify supplier QC:

Supplier Audits

Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality assurance measures, and compliance with international standards firsthand. This is particularly important when sourcing from regions like Africa, South America, the Middle East, and Europe, where standards may vary.

Requesting Quality Reports

Buyers should request quality control reports from suppliers, detailing the results of various tests performed on the graphite rods. This transparency helps buyers assess the reliability and performance of the products.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can verify compliance with international standards and assess the quality of the products before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

When engaging in international trade, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

-

Cultural Differences: Understanding local business practices and communication styles can facilitate smoother negotiations and collaborations.

-

Regulatory Compliance: Buyers must ensure that suppliers comply with both local and international regulations, which can vary significantly by region.

-

Documentation: Proper documentation is crucial for import/export processes. Buyers should ensure that suppliers provide all necessary certificates, quality reports, and compliance documents.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing graphite rods, ensuring they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite rod’

To effectively procure graphite rods for your business needs, following a structured approach can save time and ensure quality. This guide outlines key steps for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for your graphite rods, including dimensions, grades (e.g., JC3, JC4), and thermal conductivity ratings. This step is crucial as it influences the performance of the rods in your specific application, such as heat treating or electrical conductivity. Ensure to consider the maximum operating temperature and any specific industry standards.

Step 2: Research Market Trends and Supplier Options

Explore current market trends and potential suppliers. Understanding the demand for graphite rods in your region helps you identify reliable sources. Look for suppliers who specialize in the specific type of graphite you require, as they will have better expertise and product options.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Check online reviews and testimonials to gauge their reliability and customer service.

- Key Considerations:

- Ensure they have experience supplying to your industry.

- Verify their production capabilities and lead times.

Step 4: Check Certifications and Quality Standards

Verify that suppliers comply with relevant quality standards and certifications. This could include ISO certifications or specific industry-related compliance. High-quality graphite rods are essential for ensuring performance and longevity in applications, so this step can significantly reduce risks associated with subpar materials.

Step 5: Request Samples for Testing

Before placing a bulk order, request samples of the graphite rods. Testing samples allow you to evaluate the material’s performance in your specific application and verify that they meet your technical specifications. This step is particularly important for ensuring that the rods can withstand the necessary thermal and mechanical stress.

Step 6: Negotiate Pricing and Payment Terms

Engage in negotiations to secure the best pricing and favorable payment terms. Understand the minimum order quantities (MOQs) and inquire about bulk purchase discounts. Clear payment terms can also help avoid potential financial disputes down the line.

Step 7: Plan for Logistics and Delivery

Finally, discuss logistics and delivery timelines with your chosen supplier. Understand the shipping methods available and any additional costs involved. Ensure that the supplier can meet your delivery deadlines to avoid disruptions in your operations.

By following this checklist, international B2B buyers can streamline their sourcing process for graphite rods and make informed purchasing decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for graphite rod Sourcing

What Are the Key Cost Components in Graphite Rod Sourcing?

Understanding the cost structure of graphite rod sourcing is essential for international B2B buyers. The primary cost components include:

-

Materials: The quality of graphite used directly impacts the price. High-purity or specialized graphite types, such as JC3 and JC4, can command higher prices due to their enhanced properties.

-

Labor: Labor costs vary significantly based on geographical location and the skill level required for machining and finishing graphite rods. Regions with skilled labor pools may offer competitive rates, but this must be weighed against shipping costs.

-

Manufacturing Overhead: This includes costs related to production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can lower overhead, making it essential to assess suppliers’ operational efficiencies.

-

Tooling: Custom tooling for specific rod specifications can increase upfront costs. However, investing in the right tooling can lead to long-term savings through enhanced production efficiency.

-

Quality Control (QC): Rigorous QC processes ensure that the rods meet required specifications and certifications. While this adds to the cost, it is crucial for maintaining product integrity, especially for applications requiring high reliability.

-

Logistics: Shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Import duties and tariffs should also be considered, particularly when sourcing from regions like Europe to Africa or South America.

-

Margin: Suppliers typically add a margin to cover their costs and desired profit. Understanding the market dynamics can help buyers negotiate better margins.

How Do Pricing Influencers Affect Graphite Rod Costs?

Several factors can influence the pricing of graphite rods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing discounts. Buyers should assess their needs to determine the optimal order size to benefit from these discounts.

-

Specifications and Customization: Custom specifications, such as dimensions or material grades, can increase costs. It’s important for buyers to clearly communicate their requirements to avoid unexpected price hikes.

-

Materials and Quality Certifications: Higher quality materials or specific certifications (ISO, ASTM) can significantly affect pricing. Buyers must weigh the benefits of higher-quality rods against their budget constraints.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may offer better quality assurance but at a premium.

-

Incoterms: The agreed Incoterms (International Commercial Terms) dictate responsibilities for shipping costs, insurance, and tariffs. Buyers should understand these terms to avoid unexpected expenses.

What Tips Can Help Buyers Optimize Their Graphite Rod Sourcing Costs?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency in graphite rod sourcing:

-

Negotiate Terms: Always negotiate pricing and terms with suppliers. Leverage volume commitments or long-term contracts for better rates.

-

Consider Total Cost of Ownership (TCO): Evaluate the TCO instead of just the purchase price. Factors such as durability, performance, and maintenance can significantly impact long-term expenses.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers. Compare pricing, quality, and service offerings to identify the best value.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, international shipping complexities, and potential delays. These can all impact the final cost.

-

Evaluate Logistics Options: Explore various shipping options and routes to minimize logistics costs. Consider working with a freight forwarder experienced in international B2B transactions to streamline the process.

Disclaimer on Pricing

Prices for graphite rods can vary significantly based on the factors outlined above. The indicative prices mentioned in various sources may not reflect current market conditions or specific supplier quotes. Buyers are encouraged to obtain updated quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing graphite rod With Other Solutions

When considering the optimal material for various industrial applications, it is essential to evaluate alternatives to graphite rods. Graphite rods are renowned for their thermal conductivity, machinability, and corrosion resistance, making them popular in sectors such as electrochemistry and heat treatment. However, other solutions may offer competitive advantages in specific scenarios. Here, we compare graphite rods with two viable alternatives: ceramic rods and metal rods, providing international B2B buyers with comprehensive insights for decision-making.

| Comparison Aspect | Graphite Rod | Ceramic Rod | Metal Rod |

|---|---|---|---|

| Performance | High thermal conductivity, good for electrochemical applications | Excellent thermal and electrical insulation, high hardness | Good thermal and electrical conductivity, strong |

| Cost | Moderate cost, varies by grade and size | Higher initial cost, durability offsets long-term expense | Generally lower cost, but varies by alloy type |

| Ease of Implementation | Machinable, requires specific tools | Requires specialized cutting tools, more challenging to shape | Easy to machine and fabricate with standard tools |

| Maintenance | Low maintenance, resistant to most chemicals | Brittle, can require careful handling | Moderate maintenance, corrosion resistance varies by alloy |

| Best Use Case | Electrodes, heat treating, mechanical applications | High-temperature applications, electrical insulators | Structural applications, high-load bearing components |

What are the Pros and Cons of Ceramic Rods Compared to Graphite Rods?

Ceramic Rods:

Ceramic rods are known for their exceptional hardness and high-temperature resistance, making them ideal for applications that require electrical insulation and mechanical strength. They outperform graphite rods in environments where extreme heat and wear are factors. However, their brittleness can lead to challenges during handling and installation. While the initial cost is higher, the longevity and reduced wear can justify the investment in high-demand applications.

How Do Metal Rods Stack Up Against Graphite Rods?

Metal Rods:

Metal rods, such as those made from stainless steel or aluminum, are often more cost-effective than graphite rods. They are easy to machine and suitable for various structural applications, providing good thermal and electrical conductivity. However, they may not perform as well in high-temperature environments or in applications that require non-reactive materials. Their maintenance needs can also vary significantly based on the specific metal alloy used, especially concerning corrosion resistance.

How Can B2B Buyers Choose the Right Solution for Their Needs?

In selecting the right solution for their specific requirements, B2B buyers should consider several factors, including the operational environment, required material properties, and budget constraints. Graphite rods are preferable for applications demanding high thermal conductivity and corrosion resistance, particularly in electrochemical settings. Conversely, ceramic rods might be more suitable for high-temperature applications where insulation is critical. Metal rods serve well in structural applications where cost and ease of fabrication are paramount. Ultimately, understanding the unique demands of your application will guide you to the most appropriate material choice, ensuring optimal performance and cost-effectiveness in your operations.

Essential Technical Properties and Trade Terminology for graphite rod

What Are the Key Technical Properties of Graphite Rods?

Understanding the essential technical properties of graphite rods is crucial for international B2B buyers, particularly in industries like manufacturing, electronics, and metallurgy. Here are some of the most important specifications to consider:

1. Material Grade: What Grade of Graphite Rod Should You Choose?

Graphite rods are typically classified into various grades, such as JC3 and JC4. The JC3 grade is dense and fine-grained, offering excellent machinability and high-temperature resistance up to 3000℃ (5432℉). In contrast, JC4 is suitable for applications requiring lower temperatures (up to 735℃ or 1355℉) and has superior density and strength. Selecting the right grade is vital for ensuring optimal performance in specific applications, impacting durability and efficiency.

A stock image related to graphite rod.

2. Tolerance: Why Is Tolerance Important in Graphite Rods?

Tolerance refers to the allowable deviation from a specified dimension. In the context of graphite rods, tight tolerances ensure that the rods fit precisely in their applications, reducing the risk of failure or inefficiency. For industries like aerospace or electronics, where precision is critical, understanding tolerance specifications is essential for quality control and performance reliability.

3. Compressive Strength: How Does Compressive Strength Affect Your Application?

Compressive strength measures how much load a material can withstand before deforming. Graphite rods can have compressive strengths ranging from 11,000 to 38,000 lbs/in², making them suitable for applications that involve high pressure. For B2B buyers, selecting rods with adequate compressive strength is vital to prevent material failure during operation, especially in heavy machinery or structural applications.

4. Thermal Conductivity: Why Should You Consider Thermal Conductivity?

Graphite is known for its excellent thermal conductivity, which can range from 57 W/mK to 114 W/mK, depending on the grade. This property makes graphite rods ideal for applications requiring efficient heat transfer, such as electrodes in electrochemical processes. Buyers should consider thermal conductivity when evaluating performance in high-temperature environments or processes that demand quick heat dissipation.

5. Porosity: How Does Porosity Influence Performance?

Porosity refers to the presence of voids within a material. Graphite rods can be porous, which can affect their strength and thermal conductivity. Impregnants can be used to fill these pores, resulting in varying levels of imperviousness. Understanding porosity is crucial for buyers who need specific performance characteristics, especially in applications involving liquids or gases.

What Are Common Trade Terms Used in Graphite Rod Transactions?

Familiarity with trade terminology is essential for smooth transactions and negotiations in the graphite rod market. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean for Your Purchase?

OEM refers to companies that manufacture products that are then sold under another company’s brand. In the context of graphite rods, OEMs often produce custom rods tailored to specific industry needs. Understanding OEM relationships can help buyers identify reliable suppliers who can meet their unique specifications.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important in Procurement?

MOQ is the minimum number of units a supplier is willing to sell. For graphite rods, MOQs can vary by supplier and product type, often requiring buyers to commit to a larger purchase. Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller businesses.

3. RFQ (Request for Quotation): How Can RFQs Streamline Your Buying Process?

An RFQ is a document sent to suppliers requesting a price quote for specific products. Submitting an RFQ for graphite rods can help buyers gather information on pricing, lead times, and availability, facilitating informed decision-making and negotiations.

4. Incoterms: What Are Incoterms and Why Should You Understand Them?

Incoterms (International Commercial Terms) are standardized terms used in international trade to define the responsibilities of buyers and sellers. They clarify aspects like shipping costs, insurance, and delivery points. Familiarity with Incoterms is vital for B2B buyers to avoid misunderstandings and ensure smooth logistics in their transactions.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their purchases of graphite rods align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the graphite rod Sector

What Are the Current Market Dynamics and Key Trends in the Graphite Rod Sector?

The graphite rod sector is experiencing notable growth driven by the increasing demand for high-performance materials across various industries, including electronics, aerospace, and energy. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly influenced by several key trends. First, the rise of electric vehicles and renewable energy technologies is propelling the need for efficient thermal management solutions, where graphite rods play a crucial role due to their excellent thermal conductivity and stability at high temperatures.

Moreover, the adoption of advanced manufacturing technologies, such as additive manufacturing and precision machining, is reshaping sourcing strategies. Buyers are increasingly looking for suppliers who can provide customizable graphite rods that meet specific dimensional and performance specifications. This trend highlights the importance of collaboration between manufacturers and buyers to ensure quality and precision.

Another significant dynamic is the shift towards digital procurement platforms. Buyers are leveraging online marketplaces and B2B e-commerce solutions to streamline their sourcing processes, improve transparency, and enhance supply chain efficiency. This digital transformation enables international buyers to access a wider range of suppliers, compare prices, and evaluate product specifications quickly.

How Is Sustainability and Ethical Sourcing Addressed in the Graphite Rod Sector?

Sustainability has become a critical consideration for B2B buyers in the graphite rod sector. The environmental impact of graphite mining, including habitat destruction and water pollution, underscores the importance of ethical sourcing. International buyers are increasingly demanding suppliers who adhere to sustainable practices and transparent supply chains.

Certifications such as ISO 14001 (Environmental Management) and adherence to the United Nations Sustainable Development Goals (SDGs) are becoming crucial indicators of a supplier’s commitment to sustainability. Buyers should prioritize partnerships with suppliers who can demonstrate compliance with these standards, ensuring that their sourcing decisions contribute positively to environmental preservation.

Furthermore, the development of ‘green’ graphite materials, which are produced using eco-friendly methods, is gaining traction. These materials not only reduce the carbon footprint but also cater to the growing demand for environmentally responsible products. Buyers should explore options for sustainably sourced graphite rods, as this can enhance their brand reputation and align with their corporate social responsibility (CSR) objectives.

What Is the Historical Context of the Graphite Rod Sector That Buyers Should Know?

The graphite rod sector has evolved significantly over the past century. Initially used primarily in electrical applications, graphite rods have expanded their utility across diverse industries due to advancements in material science and manufacturing techniques. Early uses of graphite were largely confined to basic applications such as lubricants and electrodes.

The introduction of high-performance graphite materials, particularly in the 20th century, revolutionized their applications. The development of extruded and machined graphite rods allowed for more precise and versatile uses, making them essential in sectors like aerospace, automotive, and electronics. Today, as technology continues to evolve, the graphite rod sector is poised for further innovation, driven by the need for lightweight and efficient materials in advanced manufacturing and energy solutions. International B2B buyers must understand this historical context to appreciate the ongoing changes and opportunities within the market.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite rod

-

How do I choose the right graphite rod for my application?

Choosing the right graphite rod involves considering several factors, including the rod’s temperature rating, density, and intended use. For high-temperature applications, rods like JC3 are preferable due to their ability to withstand temperatures up to 3000℃. If your application involves mechanical support without extreme heat, JC4 might suffice. Additionally, evaluate the rod’s electrical conductivity and compressive strength based on the specific demands of your project. Always consult with suppliers to get recommendations tailored to your unique requirements. -

What are the different grades of graphite rods available?

Graphite rods are typically categorized into various grades based on their composition and properties. For instance, JC3 and JC4 are popular grades, where JC3 is dense and suited for high temperatures, while JC4 is ideal for lower temperature applications. Other grades may vary in terms of purity, porosity, and machinability. Understanding these distinctions is crucial for selecting the right rod for applications such as electrochemical processes, heat treating, or mechanical support. -

What minimum order quantities (MOQ) should I expect when sourcing graphite rods?

Minimum order quantities can vary significantly between suppliers. Commonly, suppliers may have a MOQ of 100 units or a minimum order value, often around $100. For customized orders, the MOQ might be higher. It’s essential to clarify these terms before placing an order, especially if you are testing a new supplier or product. Ensure you communicate your requirements clearly to avoid unexpected costs. -

What payment terms should I consider when sourcing graphite rods internationally?

When engaging in international trade, payment terms can vary. Common options include advance payment, letters of credit, or payment upon delivery. Consider your cash flow and risk tolerance when selecting a payment method. It’s prudent to negotiate terms that protect both parties, such as partial upfront payments and the balance upon delivery. Additionally, ensure that the payment method is compatible with your supplier’s capabilities, particularly in regions like Africa and South America. -

How can I verify the credibility of a graphite rod supplier?

Verifying a supplier’s credibility involves checking their business history, customer reviews, and certifications. Look for suppliers with a proven track record in the graphite industry and those who can provide references from other international clients. Additionally, request samples to assess product quality and consistency. Engaging in direct communication can also provide insights into their customer service and responsiveness, critical factors in establishing a reliable partnership. -

What logistical considerations should I keep in mind when importing graphite rods?

Logistical considerations include shipping methods, customs clearance, and potential tariffs. Determine the best shipping method based on cost and delivery time—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that your supplier provides necessary documentation for customs clearance, including invoices and certificates of origin. Be aware of any tariffs or import duties applicable in your country to avoid unexpected expenses. -

Can I customize graphite rods to meet specific dimensions or properties?

Yes, many suppliers offer customization options for graphite rods. This can include adjustments to dimensions, density, or specific grades tailored to your application needs. It’s advisable to discuss your requirements in detail with potential suppliers to understand their capabilities and any associated costs. Custom orders may have longer lead times, so plan accordingly to avoid delays in your project timelines. -

What quality assurance measures should I expect from graphite rod suppliers?

Quality assurance measures can vary, but reputable suppliers typically conduct rigorous testing on their products. Look for suppliers that provide certifications for their graphite rods, indicating compliance with industry standards. Testing may include assessments of thermal conductivity, density, and structural integrity. Request documentation that outlines their quality control processes, and consider conducting your own inspections or third-party audits for added assurance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for graphite rod

As the global demand for graphite rods continues to rise, strategic sourcing has become essential for international B2B buyers. Understanding the unique properties and applications of different graphite rod grades, such as JC3 and JC4, enables businesses to select the right materials that meet their operational needs. Graphite’s high thermal conductivity, strength, and corrosion resistance make it indispensable in various industries, from heat treating to electrochemical applications.

How Can Strategic Sourcing Enhance Your Supply Chain?

By adopting a strategic sourcing approach, buyers can establish long-term partnerships with reliable suppliers across Africa, South America, the Middle East, and Europe. This fosters not only cost efficiency but also ensures consistent quality and supply stability. Engaging with suppliers who offer customizable solutions can further tailor products to specific operational requirements.

What Does the Future Hold for Graphite Rod Procurement?

Looking ahead, the increasing emphasis on sustainable practices and advanced manufacturing technologies will shape the graphite rod market. Buyers should remain proactive, exploring innovative sourcing strategies that prioritize both quality and environmental responsibility. Embrace the opportunity to enhance your competitive edge by leveraging strategic sourcing for graphite rods—transform your supply chain today!