Unlock Jet Pulse Technology: The Ultimate Buying Guide (2025)

Introduction: Navigating the Global Market for jet pulse

Navigating the complexities of sourcing jet pulse engines can be a daunting challenge for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. With their unique advantages—like minimal moving parts and high thrust-to-weight ratios—pulse jet engines present innovative solutions for various applications, including unmanned aerial vehicles (UAVs) and model engineering. This comprehensive guide delves into the intricacies of the jet pulse market, covering essential topics such as types of pulse jet designs, applications across industries, effective supplier vetting strategies, and cost considerations.

As buyers aim to make informed purchasing decisions, this guide serves as a vital resource, equipping them with the knowledge needed to navigate the global market effectively. By understanding the specific benefits and limitations of different pulse jet technologies, B2B purchasers can identify the right solutions that meet their operational requirements. Moreover, insights into supplier reliability and market trends will empower buyers to establish successful partnerships, ultimately enhancing their competitive edge. Whether you are in Brazil exploring lightweight propulsion options or in France evaluating innovative UAV systems, this guide is tailored to facilitate your journey toward sourcing the best jet pulse engines available in today’s dynamic marketplace.

Understanding jet pulse Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Valved Pulse Jet | Incorporates mechanical valves for airflow control | Military drones, target drones | Pros: Reliable performance, effective thrust generation. Cons: Higher maintenance due to moving parts. |

| Valveless Pulse Jet | No moving parts; airflow controlled by engine geometry | UAVs, research applications | Pros: Lower maintenance, lightweight design. Cons: Requires precise engineering for optimal performance. |

| Ram Jet | Utilizes high-speed air intake for thrust; no moving parts | Supersonic vehicles, missiles | Pros: Simple design, effective at high speeds. Cons: Limited to high-speed applications, less efficient at lower speeds. |

| Wave Jet | Uses shockwave dynamics for enhanced thrust | High-speed UAVs, advanced military applications | Pros: Increased efficiency and power output. Cons: Complex design may require specialized knowledge. |

| Pulse Detonation Engine | Employs detonations for thrust; operates at supersonic speeds | Advanced military and aerospace applications | Pros: High efficiency and thrust output. Cons: Complex design with significant engineering challenges. |

What are the Key Characteristics of Valved Pulse Jets?

Valved pulse jets are characterized by their mechanical valves that regulate airflow, providing a reliable method for thrust generation. These engines are commonly used in military applications, such as drones and target drones, where performance and reliability are paramount. When considering a purchase, buyers should weigh the reliability of valved designs against the necessity for regular maintenance, as the moving parts can lead to increased wear and require more frequent checks.

Why Choose Valveless Pulse Jets for B2B Applications?

Valveless pulse jets stand out due to their lack of moving parts, which minimizes maintenance and enhances reliability. They are particularly suitable for UAVs and research applications where operational longevity is essential. Buyers should focus on the engineering quality of the design, as the performance is heavily reliant on the precise geometry of the engine. This makes them an attractive option for businesses looking for efficient and low-maintenance propulsion solutions.

How Do Ram Jets Function in High-Speed Applications?

Ram jets operate by compressing incoming air through the engine’s design, utilizing the high speed of the vehicle to generate thrust without any moving parts. These engines are ideal for supersonic vehicles and missiles. When considering a ram jet, B2B buyers should understand that while they are efficient at high speeds, their performance diminishes at lower velocities. Thus, they are best suited for specialized applications rather than general-purpose use.

What are the Advantages of Wave Jets in Modern Applications?

Wave jets utilize shockwave dynamics to enhance thrust output while maintaining a low-complexity design. This makes them particularly effective for high-speed UAVs and advanced military systems. Buyers should be aware that while wave jets offer increased efficiency, their design complexity may necessitate specialized knowledge for maintenance and operation. Understanding the balance between performance and operational expertise is crucial for potential purchasers.

Why Consider Pulse Detonation Engines for Aerospace Projects?

Pulse detonation engines (PDEs) represent a more advanced category of pulse jet technology, using controlled detonations for thrust at supersonic speeds. These engines are favored in military and aerospace applications due to their high efficiency and thrust capabilities. However, the complexity of their design poses significant engineering challenges, making them less accessible for general applications. Buyers should assess their organizational capability to handle such advanced technology before committing to a purchase.

Key Industrial Applications of jet pulse

| Industry/Sector | Specific Application of jet pulse | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | UAV Propulsion Systems | High thrust-to-weight ratio; reduced maintenance | Supplier reliability; compliance with aviation standards |

| Defense | Target Drones | Cost-effective and high-speed military training | Performance metrics; durability in harsh environments |

| Environmental Monitoring | Airborne Sensors for Environmental Data Collection | Lightweight and efficient data collection | Sensor integration; operational range and endurance |

| Automotive | Testing of Aerodynamic Models | Real-time performance analysis; cost-effective | Compatibility with testing equipment; precision calibration |

| Research & Development | Experimental Engine Designs | Innovative propulsion solutions; rapid prototyping | Access to advanced materials; engineering support |

How is ‘jet pulse’ utilized in aerospace applications?

In the aerospace sector, jet pulse engines are primarily used in unmanned aerial vehicles (UAVs). Their design allows for high thrust-to-weight ratios, making them ideal for missions requiring efficient propulsion. The absence of moving parts reduces maintenance needs, which is crucial for UAVs operating in remote or hostile environments. International buyers, particularly from Africa and South America, should consider suppliers that can meet stringent aviation standards and provide reliable, high-performance engines.

What are the benefits of jet pulse in defense applications?

In defense, jet pulse engines power target drones utilized for military training exercises. Their cost-effectiveness and ability to achieve high speeds make them invaluable for simulating various aerial scenarios. Buyers from the Middle East and Europe should focus on suppliers who can deliver robust engines capable of withstanding rigorous testing conditions, ensuring reliability and performance during critical training operations.

How does jet pulse technology enhance environmental monitoring?

Jet pulse engines serve as propulsion systems for airborne sensors used in environmental data collection. Their lightweight design allows for longer flight durations, enabling extensive monitoring of ecological changes. Businesses in South America and Africa looking to invest in environmental monitoring solutions should prioritize suppliers who offer customization options for sensor integration, ensuring optimal performance in diverse climatic conditions.

In what ways does jet pulse contribute to automotive testing?

In the automotive industry, jet pulse technology is applied in wind tunnel testing to evaluate aerodynamic models. These engines provide real-time performance data, allowing for precise analysis of vehicle designs. For international buyers in Europe, sourcing jet pulse systems requires attention to compatibility with existing testing infrastructure and the ability to provide accurate calibration services.

What role does jet pulse play in research and development?

Research and development sectors leverage jet pulse engines for experimental propulsion systems, allowing engineers to innovate and prototype new designs. The simplicity and efficiency of these engines facilitate rapid testing and iteration. Buyers from all regions, particularly Europe and the Middle East, should seek suppliers that offer advanced materials and engineering support to enhance their R&D capabilities, ensuring the development of cutting-edge technologies.

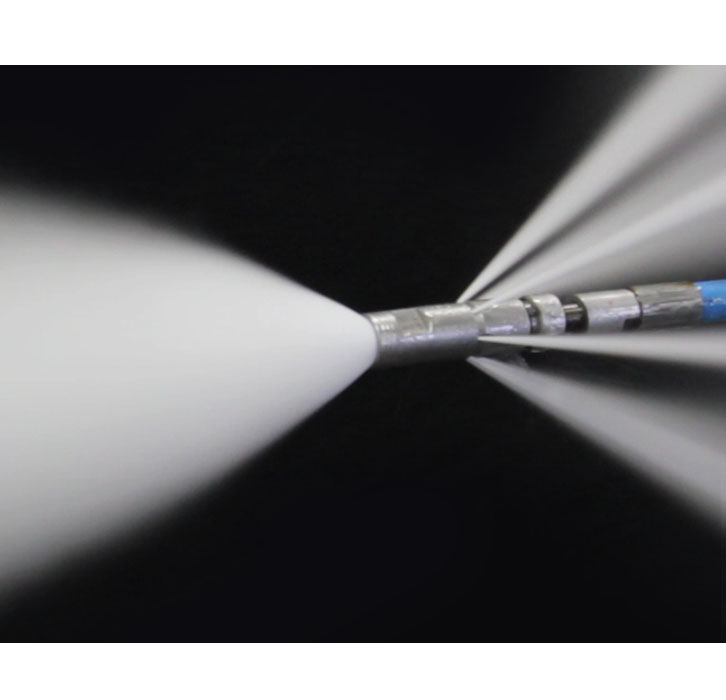

A stock image related to jet pulse.

3 Common User Pain Points for ‘jet pulse’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Jet Pulse Engines

The Problem:

B2B buyers in sectors like unmanned aerial vehicles (UAVs) often struggle with sourcing reliable jet pulse engines that meet their specific needs. This issue is compounded for buyers from regions like Africa and South America, where access to reputable suppliers can be limited. Many suppliers may offer low-quality engines that do not meet safety standards or fail to provide adequate support post-purchase. The result is a frustrating procurement process that can delay projects and increase costs due to unscheduled maintenance and replacements.

The Solution:

To effectively source reliable jet pulse engines, buyers should conduct thorough research into potential suppliers. Start by looking for manufacturers with established reputations and verified customer reviews. Networking through industry forums and attending trade shows can also provide insights into trusted suppliers. When evaluating suppliers, consider requesting product samples or demonstration units to assess quality firsthand.

Moreover, establish clear specifications for your jet pulse engines, detailing performance requirements, materials, and safety standards. This clarity will help suppliers provide accurate quotes and reduce the likelihood of receiving subpar products. Engaging with suppliers that offer comprehensive after-sales support, including maintenance training and troubleshooting assistance, can further ensure operational reliability and longevity of the engines.

Scenario 2: Managing Maintenance and Operational Reliability

The Problem:

Another common challenge faced by B2B buyers is managing the maintenance of jet pulse engines, especially in remote or challenging environments. Buyers often find that while jet pulse engines are simpler than traditional turbine engines, they still require regular maintenance to ensure optimal performance. In regions with limited access to technical expertise, this can lead to prolonged downtimes and operational inefficiencies.

The Solution:

To address maintenance challenges, buyers should prioritize purchasing valveless pulse jet engines, which are designed with fewer moving parts and thus require less frequent maintenance. Additionally, implementing a preventive maintenance schedule can help mitigate the risks associated with engine failures.

Training local technicians on the specific maintenance needs of jet pulse engines is crucial. Consider partnering with suppliers who offer training programs as part of their service. This investment in local expertise can empower teams to perform routine checks and minor repairs, significantly reducing downtime.

Furthermore, leveraging technology such as predictive maintenance tools can enhance operational reliability. These tools use data analytics to anticipate potential failures before they occur, allowing for timely interventions and minimizing disruptions.

Scenario 3: Understanding Performance Metrics and Specifications

The Problem:

B2B buyers often face confusion regarding the performance metrics and specifications of jet pulse engines. Inconsistent terminology and varying performance standards across suppliers can lead to misalignment with project requirements. For buyers in Europe, where regulatory standards are stringent, ensuring that engines meet these requirements is essential for compliance and safety.

The Solution:

To navigate the complexities of performance metrics, buyers should familiarize themselves with key performance indicators such as thrust-to-weight ratio, fuel efficiency, and acoustic signature. Engaging with technical experts or consultants who specialize in jet propulsion can provide valuable insights into selecting the right engine for specific applications.

When reviewing specifications, always request detailed performance data from suppliers. It is advisable to compare these metrics against industry benchmarks to ensure compliance with regional regulations. Additionally, establish a dialogue with suppliers to clarify any ambiguities in their product specifications. This proactive approach not only enhances understanding but also fosters a collaborative relationship with suppliers, facilitating better support and service in the long run.

By addressing these common pain points with actionable solutions, international B2B buyers can streamline their procurement processes, enhance operational efficiency, and ultimately achieve greater success in their projects involving jet pulse engines.

Strategic Material Selection Guide for jet pulse

What Are the Key Materials for Jet Pulse Engines?

When selecting materials for jet pulse engines, it is crucial to consider properties that enhance performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of jet pulse engines, focusing on their properties, pros and cons, and implications for international B2B buyers.

How Does Stainless Steel Perform in Jet Pulse Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance and high-temperature performance, typically rated for temperatures up to 1,200°F (649°C). It also has good mechanical strength, making it suitable for high-pressure applications.

Pros & Cons: The durability of stainless steel is one of its main advantages, as it withstands harsh environments and reduces maintenance needs. However, it can be more expensive than other materials and may require advanced manufacturing techniques, which can increase production costs.

Impact on Application: Stainless steel is compatible with various fuels and combustion environments, making it versatile for different jet pulse applications. Its resistance to oxidation is particularly beneficial in high-temperature scenarios.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with ASTM or DIN standards for stainless steel grades. The availability of specific grades may vary by region, impacting supply chain logistics.

Why Choose Aluminum Alloys for Jet Pulse Engines?

Key Properties: Aluminum alloys are lightweight and have good thermal conductivity, typically rated for temperatures up to 600°F (316°C). They also exhibit excellent machinability, allowing for intricate designs.

Pros & Cons: The primary advantage of aluminum alloys is their low weight, which is critical for applications requiring high thrust-to-weight ratios. However, they are less durable than stainless steel and can be prone to corrosion unless properly treated.

Impact on Application: Aluminum alloys are suitable for applications where weight savings are paramount, such as in UAVs. However, they may not perform well in extremely high-temperature environments without additional coatings.

Considerations for International Buyers: Buyers should be aware of specific alloy designations and corresponding standards (like JIS in Japan or EN in Europe) to ensure compatibility and performance. Additionally, surface treatments may be necessary to enhance corrosion resistance.

What Role Does Titanium Play in Jet Pulse Engine Construction?

Key Properties: Titanium alloys are known for their exceptional strength-to-weight ratio and corrosion resistance, withstanding temperatures up to 1,800°F (982°C). They are also highly resistant to fatigue.

Pros & Cons: The main advantage of titanium is its ability to perform in extreme conditions, making it ideal for high-performance applications. However, it is significantly more expensive than both stainless steel and aluminum, and its manufacturing processes can be complex and costly.

Impact on Application: Titanium’s properties make it suitable for high-stress components in jet pulse engines, especially in military or high-speed applications. Its compatibility with various fuels adds to its versatility.

Considerations for International Buyers: Buyers should ensure that titanium components meet international standards (such as ASTM or ISO) to guarantee quality and performance. The higher cost may necessitate careful budgeting for projects.

How Do Composite Materials Enhance Jet Pulse Engine Design?

Key Properties: Composite materials, often made from carbon fiber or fiberglass, offer high strength with low weight and excellent thermal resistance. They can withstand temperatures up to 500°F (260°C) depending on the resin used.

Pros & Cons: Composites provide significant weight savings and can be tailored for specific performance characteristics. However, they can be more expensive to manufacture and may require specialized knowledge for design and production.

Impact on Application: Composite materials are particularly advantageous in applications where weight reduction is critical, such as in UAVs. Their thermal properties can also enhance engine efficiency.

Considerations for International Buyers: Buyers should be aware of the specific resin systems and manufacturing techniques required for composites. Compliance with international standards is essential to ensure product reliability and performance.

Summary of Material Selection for Jet Pulse Engines

| Material | Typical Use Case for jet pulse | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-temperature applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum Alloys | UAVs requiring weight savings | Lightweight and good machinability | Less durable and corrosion-prone | Medium |

| Titanium | High-performance components | Exceptional strength-to-weight ratio | Very high cost and complex processing | High |

| Composite Materials | Lightweight UAV structures | Significant weight reduction | Expensive and requires specialized knowledge | Medium to High |

This strategic material selection guide provides valuable insights for international B2B buyers seeking to optimize their jet pulse engine designs while considering performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for jet pulse

What Are the Key Manufacturing Processes for Jet Pulse Engines?

Manufacturing jet pulse engines involves several critical stages, each requiring precise engineering and quality assurance to ensure optimal performance and reliability. The primary stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Jet Pulse Engines?

The first step in the manufacturing process is material preparation, which involves selecting high-grade materials that can withstand extreme temperatures and pressures. Common materials used include high-strength steel alloys and heat-resistant composites. During this phase, materials are often subjected to rigorous testing for tensile strength and thermal resistance to ensure they meet the required specifications.

After selection, materials are cut and shaped into specific dimensions using advanced machining techniques such as CNC (Computer Numerical Control) machining. This ensures precision and consistency, which are crucial for the performance of jet pulse engines.

What Forming Techniques Are Commonly Used in Jet Pulse Manufacturing?

The forming stage is where the raw materials are transformed into functional components. Techniques such as welding, forging, and casting are frequently employed.

- Welding: This method is particularly important for assembling the combustion chamber and exhaust systems, where integrity is paramount to withstand high temperatures and pressures.

- Forging: Used to create components that require superior strength, forging helps enhance the material’s properties through deformation.

- Casting: This technique allows for the creation of complex shapes that are difficult to achieve through other methods. It is often used for parts like the engine casing.

Each forming method requires strict adherence to design specifications to ensure that components fit perfectly together, which is crucial for the engine’s overall efficiency.

How Is the Assembly Process Conducted for Jet Pulse Engines?

During the assembly phase, various components are brought together to create the final product. This involves meticulous attention to detail and adherence to engineering tolerances.

The assembly process typically follows a systematic approach:

1. Initial Assembly: Components such as the combustion chamber, fuel injectors, and exhaust nozzles are fitted together.

2. Integration of Systems: Electrical systems and control mechanisms are integrated, ensuring that the pulse jet can operate effectively.

3. Final Assembly Checks: Each assembly stage is followed by inspections to confirm that all components meet operational specifications.

Utilizing modular assembly techniques can enhance efficiency, allowing for easier repairs and upgrades in the future.

What Finishing Processes Are Essential for Jet Pulse Engines?

Finishing processes are critical for enhancing the engine’s durability and performance. Common finishing techniques include:

– Surface Treatment: Processes such as anodizing or powder coating protect components from corrosion and wear.

– Quality Polishing: This ensures that surfaces are smooth, reducing drag and improving overall engine efficiency.

– Final Inspections: After finishing, each engine undergoes thorough inspections to verify that all specifications are met, and any surface defects are addressed.

What Quality Assurance Practices Are Crucial for Jet Pulse Engines?

Quality assurance (QA) in the manufacturing of jet pulse engines is paramount to ensure that the final product meets international standards and customer expectations.

Which International Standards Should B2B Buyers Look For?

B2B buyers should ensure that their suppliers comply with relevant international standards, such as:

– ISO 9001: This standard focuses on quality management systems and helps organizations ensure they meet customer and regulatory requirements.

– CE Marking: Particularly important for products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

– API Standards: For buyers in the oil and gas sector, compliance with American Petroleum Institute standards ensures that components are suitable for use in harsh environments.

What Are the Key Quality Control Checkpoints in Jet Pulse Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process, ensuring that any defects are identified and rectified promptly. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to confirm they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to ensure that processes are running within specified limits and that components are being fabricated correctly.

- Final Quality Control (FQC): Before shipping, each engine undergoes comprehensive testing and inspection to ensure it meets all operational and safety standards.

What Testing Methods Are Commonly Used in Jet Pulse Quality Assurance?

Testing methods are crucial for validating the performance and reliability of jet pulse engines. Common methods include:

– Performance Testing: Engines are tested under simulated operating conditions to measure thrust output and fuel efficiency.

– Durability Testing: Components are subjected to extreme conditions to assess their longevity and performance over time.

– Acoustic Testing: Given the noise concerns associated with pulse jet engines, acoustic testing helps ensure that the engine operates within acceptable noise levels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Buyers should consider the following methods:

- Supplier Audits: Conducting on-site audits helps assess the manufacturing processes and quality control measures in place. This also allows buyers to evaluate the supplier’s adherence to international standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s performance metrics, defect rates, and corrective actions taken for any issues identified.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of the supplier’s quality control practices and product reliability.

What Are the QC Certification Nuances for International B2B Buyers?

When sourcing jet pulse engines internationally, buyers should be aware of the nuances in quality control certification:

– Regional Standards: Different regions may have specific standards that must be met. For example, buyers in Europe will place significant emphasis on CE marking, while those in the Middle East may prioritize compliance with local regulations.

– Documentation: Ensure that all certifications and quality control documents are up-to-date and verifiable. This includes material certifications, inspection reports, and compliance documentation.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing jet pulse engines, ensuring they partner with suppliers that adhere to the highest standards of quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jet pulse’

To successfully procure jet pulse engines, particularly for applications in UAVs or other specialized projects, it’s essential to follow a structured approach. This guide provides a comprehensive checklist to ensure that international B2B buyers, especially from Africa, South America, the Middle East, and Europe, make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial for successful procurement. Consider aspects such as thrust-to-weight ratio, fuel type, and operational environment. Detailed specifications will help you communicate effectively with suppliers and ensure that the jet pulse engine meets your operational needs.

Step 2: Conduct Market Research for Suppliers

Understanding the landscape of potential suppliers is vital. Research various manufacturers that specialize in pulse jet technology, focusing on their product offerings, market reputation, and geographic reach. Utilize industry forums, such as those dedicated to pulse jet enthusiasts, to gather insights and reviews from other buyers.

- What to look for:

- Supplier experience in the industry.

- Range of products available.

- Customer testimonials and case studies.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is essential. Request detailed company profiles, including their history, production capabilities, and any certifications. It’s beneficial to ask for references from other companies within your industry or region to gauge reliability and performance.

- Key considerations:

- Supplier certifications (ISO, CE, etc.).

- Past project examples relevant to your needs.

- Feedback on after-sales support.

Step 4: Request and Compare Quotes

Once you’ve shortlisted potential suppliers, request detailed quotations that include not only prices but also terms of delivery, warranty, and maintenance support. Comparing quotes side-by-side will help you identify the best value for your investment.

- Checklist for quotes:

- Breakdown of costs (unit price, shipping, taxes).

- Payment terms and conditions.

- Lead times and delivery schedules.

Step 5: Assess Compliance with International Standards

Ensure that the pulse jet engines comply with the relevant international and local regulations for safety and environmental standards. Compliance not only mitigates risk but also enhances the credibility of your procurement process.

- What to verify:

- Emission standards (if applicable).

- Safety certifications and testing results.

- Any specific regulatory requirements in your country.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a preferred supplier, engage in negotiations to finalize terms. This includes pricing, payment schedules, delivery timelines, and warranties. Clear agreements will protect both parties and foster a strong business relationship.

- Important negotiation points:

- Flexibility in payment methods.

- Penalties for late delivery.

- Warranty terms and conditions.

Step 7: Plan for Post-Purchase Support and Maintenance

After procurement, ensure you have a clear plan for maintenance and support. Establish communication channels with your supplier for ongoing technical support, spare parts availability, and any necessary training for your team.

- Support considerations:

- Availability of replacement parts.

- Supplier’s responsiveness to service requests.

- Training programs for operational staff.

By following this structured checklist, B2B buyers can streamline their procurement process for jet pulse engines, ensuring they make informed decisions that align with their operational requirements and market conditions.

Comprehensive Cost and Pricing Analysis for jet pulse Sourcing

What Are the Key Cost Components in Jet Pulse Engine Manufacturing?

When sourcing jet pulse engines, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials used significantly impact pricing. Common materials include high-grade metals for durability and heat resistance, which can vary in price depending on market conditions.

-

Labor: Skilled labor is essential for manufacturing jet pulse engines. Labor costs can vary by region, with countries in Europe generally having higher wages compared to those in Africa or South America. The complexity of the engine design also influences labor costs, as more intricate designs require specialized skills.

-

Manufacturing Overhead: This includes utilities, facility costs, and other operational expenses. Efficient manufacturing processes can help reduce these overheads, thereby lowering the overall cost of production.

-

Tooling: Initial investment in tooling can be significant, especially for custom designs. Tooling costs should be factored into the total price, particularly for low-volume orders.

-

Quality Control (QC): Ensuring compliance with international standards requires thorough QC processes. The costs associated with testing and certification can vary based on the level of scrutiny required by the buyer’s region.

-

Logistics: Shipping costs can fluctuate based on the distance and mode of transport. International buyers should consider logistics when evaluating the total cost of ownership.

-

Margin: Suppliers typically apply a markup to cover their costs and achieve profitability. This margin can vary widely, influenced by competition and the uniqueness of the product.

How Do Price Influencers Impact Jet Pulse Engine Costs?

Several factors can influence the pricing of jet pulse engines:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to benefit from economies of scale.

-

Specifications and Customization: Custom-engineered solutions can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Selection: The choice of materials can impact both performance and price. High-performance materials may offer benefits but come at a premium.

-

Quality and Certifications: Engines that meet specific industry standards or certifications may command higher prices. Buyers should assess whether these certifications are necessary for their application.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may offer reliability but at a higher cost.

-

Incoterms: Understanding the implications of Incoterms can help buyers manage logistics costs effectively. Different terms can shift responsibilities and costs between buyer and seller.

What Are Essential Tips for Negotiating Jet Pulse Engine Prices?

For international B2B buyers, effective negotiation strategies can lead to significant savings:

-

Conduct Market Research: Understand the market rates for jet pulse engines in your region. This knowledge will empower you during negotiations.

-

Leverage Volume Discounts: If feasible, consider consolidating orders to reach higher volumes that can reduce unit prices.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, consider maintenance, logistics, and operational costs to get a true picture of expenses over the product’s lifespan.

-

Be Transparent About Requirements: Clearly articulate your specifications and expectations to avoid costly changes later in the process.

-

Establish Strong Supplier Relationships: Building a good rapport with suppliers can lead to better pricing, priority service, and potential for future collaboration.

-

Negotiate Payment Terms: Favorable payment terms can improve cash flow and reduce financial strain, making it easier to commit to larger orders.

What Should Buyers Know About Pricing Nuances in Different Regions?

When sourcing jet pulse engines from diverse markets like Africa, South America, the Middle East, and Europe, buyers should be aware of regional pricing nuances:

-

Currency Fluctuations: International buyers must account for exchange rate variations that can affect final costs.

-

Local Regulations: Import duties and local taxes may apply, impacting the overall expenditure.

-

Cultural Considerations: Different regions have distinct negotiation styles and business practices. Understanding these can facilitate smoother transactions.

Disclaimer on Indicative Prices

The prices for jet pulse engines can vary widely based on numerous factors mentioned above. It is advisable for buyers to seek quotations from multiple suppliers and conduct thorough due diligence to ensure they are getting competitive pricing reflective of their specific needs.

Alternatives Analysis: Comparing jet pulse With Other Solutions

Understanding the Importance of Alternative Solutions in Jet Pulse Technology

When evaluating propulsion solutions for applications such as unmanned aerial vehicles (UAVs) or other aerospace needs, understanding the alternatives to jet pulse technology is crucial for making informed purchasing decisions. Each propulsion method has unique advantages and disadvantages that may cater to specific operational requirements. This comparison aims to provide international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, with actionable insights into the various technologies available.

Comparison Table of Jet Pulse and Alternatives

| Comparison Aspect | Jet Pulse | Ram Jet | Pulse Detonation Engine |

|---|---|---|---|

| Performance | High thrust-to-weight ratio; efficient for high-speed applications | Effective at supersonic speeds; high thrust | Superior efficiency at high speeds; complex design |

| Cost | Generally lower manufacturing costs; simple design | Moderate costs; requires precise materials | Higher costs due to complexity and materials |

| Ease of Implementation | Simple to manufacture; low technical barriers | Requires expertise in aerodynamics | High technical barrier; specialized knowledge needed |

| Maintenance | Low maintenance; few moving parts | Moderate maintenance; mechanical components present | High maintenance; sensitive to detonation pressures |

| Best Use Case | Ideal for small UAVs and model aircraft | Suited for high-speed military applications | Best for advanced aerospace projects requiring efficiency |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Ram Jet Technology?

Ram jets utilize the forward motion of the vehicle to compress incoming air, making them effective for supersonic speeds. Their design allows for high thrust outputs, making them suitable for military applications, such as missile propulsion. However, ram jets require a significant initial speed to operate efficiently, which can limit their use in certain environments. Additionally, their construction can be more complex than jet pulse engines, leading to moderate manufacturing costs and maintenance needs.

How Do Pulse Detonation Engines Compare?

Pulse detonation engines (PDEs) represent a more advanced form of jet propulsion that utilizes rapid detonations of fuel-air mixtures to produce thrust. Their efficiency at high speeds is unmatched, making them a compelling choice for specialized aerospace applications. However, PDEs come with considerable challenges, including higher costs and a complex maintenance regime due to the extreme conditions involved in detonation. This complexity may pose a barrier for organizations without the necessary technical expertise.

Making the Right Choice for Your B2B Needs

When selecting a propulsion solution, international B2B buyers should consider the specific operational requirements of their applications. If low cost, ease of implementation, and minimal maintenance are priorities, jet pulse technology stands out as a favorable option. Conversely, if the application demands high-speed performance and can accommodate more complex maintenance, investing in ram jet or pulse detonation technology may be justified. Ultimately, understanding the trade-offs between these technologies will empower buyers to choose the most suitable propulsion system for their unique needs.

Essential Technical Properties and Trade Terminology for jet pulse

What Are the Key Technical Properties of Jet Pulse Engines?

When considering jet pulse engines, it’s crucial for B2B buyers to understand specific technical properties that can significantly affect performance, reliability, and overall value. Here are some critical specifications:

-

Material Grade

The materials used in manufacturing jet pulse engines, such as high-temperature alloys or composites, determine the engine’s durability and weight. For instance, using titanium or stainless steel can enhance resistance to heat and corrosion, which is essential for engines operating in extreme conditions. Buyers should evaluate material grades to ensure they meet the operational demands of their specific applications. -

Thrust-to-Weight Ratio

This specification measures the engine’s thrust output relative to its weight. A higher thrust-to-weight ratio indicates better performance, especially in UAV applications where agility and speed are critical. Buyers should prioritize engines with optimal thrust-to-weight ratios to ensure efficiency and effectiveness in deployment. -

Combustion Efficiency

This property refers to how effectively the engine converts fuel into thrust. Higher combustion efficiency leads to reduced fuel consumption, lower operational costs, and increased flight endurance. B2B buyers should seek engines that provide detailed efficiency metrics to assess long-term cost savings. -

Operating Temperature Range

Understanding the maximum and minimum temperatures an engine can withstand is vital. This range affects the engine’s reliability and performance in various environmental conditions. Buyers should select engines with a suitable operating temperature range for their geographical and operational contexts. -

Maintenance Interval

The frequency and complexity of maintenance required for jet pulse engines can vary significantly. An engine that requires less frequent maintenance can lead to lower operational downtime and overall costs. Buyers should inquire about the recommended maintenance intervals and the potential impact on long-term operational efficiency.

What Are Common Trade Terms Used in Jet Pulse Transactions?

Navigating the procurement process involves understanding industry-specific terminology. Here are some common terms relevant to jet pulse engines:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or systems that are used in another company’s end products. Understanding OEM relationships is critical for buyers looking to source high-quality components for jet pulse engines. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers to know, as it can impact inventory management and overall procurement costs. Buyers should negotiate MOQs that align with their project requirements. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process helps buyers compare prices and terms from different vendors, ensuring they secure the best deal for jet pulse engines. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to clarify their obligations and reduce risks associated with international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This metric is crucial for project planning and ensuring timely delivery of jet pulse engines, especially for industries that require quick deployment. -

Warranty Period

The warranty period indicates how long a manufacturer will cover repairs or replacements for defects. This term is vital for buyers as it reflects the manufacturer’s confidence in their product and can influence purchasing decisions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers in Africa, South America, the Middle East, and Europe can make informed decisions when sourcing jet pulse engines for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the jet pulse Sector

What Are the Current Market Dynamics and Key Trends in the Jet Pulse Sector?

The jet pulse sector is witnessing a transformative phase driven by technological advancements and evolving market demands. One of the primary global drivers is the increasing need for efficient and lightweight propulsion systems, particularly in the UAV (Unmanned Aerial Vehicle) market. Pulse jet engines are gaining traction due to their simplicity, high thrust-to-weight ratio, and minimal moving parts, making them an attractive option for international B2B buyers in diverse sectors, including defense, agriculture, and logistics.

Emerging B2B tech trends include the integration of advanced materials and innovative design methodologies, such as valveless pulse jets, which enhance reliability and reduce maintenance costs. Additionally, the adoption of wave jet technology is on the rise, as it allows for improved thrust performance while maintaining the low complexity associated with traditional pulse jets. For buyers from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed procurement decisions, especially as the market expands into regions with growing aerospace industries.

Moreover, the jet pulse market is characterized by a competitive landscape where suppliers are increasingly focusing on sustainability and ethical sourcing practices. Buyers should prioritize suppliers who demonstrate a commitment to environmental responsibility and innovation in their product offerings, ensuring they remain competitive in a rapidly evolving global market.

How Is Sustainability Influencing Sourcing Decisions in the Jet Pulse Sector?

The importance of sustainability in the jet pulse sector cannot be overstated. As global awareness of environmental impacts rises, B2B buyers are increasingly seeking suppliers who prioritize ethical sourcing and sustainable manufacturing practices. This shift is particularly relevant in regions like Europe and parts of Africa, where regulatory frameworks and consumer demand are pushing for greener solutions.

Sourcing jet pulse engines made from recyclable materials or those that utilize low-impact production processes can significantly reduce the environmental footprint of procurement activities. Furthermore, certifications such as ISO 14001 for environmental management systems and adherence to sustainability standards can serve as indicators of a supplier’s commitment to responsible practices.

Buyers should also consider the lifecycle analysis of jet pulse products, evaluating their energy efficiency and potential for waste reduction. By partnering with suppliers who emphasize sustainability, B2B buyers not only align with market trends but also enhance their corporate social responsibility profiles, which can be a competitive advantage in their respective industries.

What Is the Historical Evolution of Jet Pulse Technology?

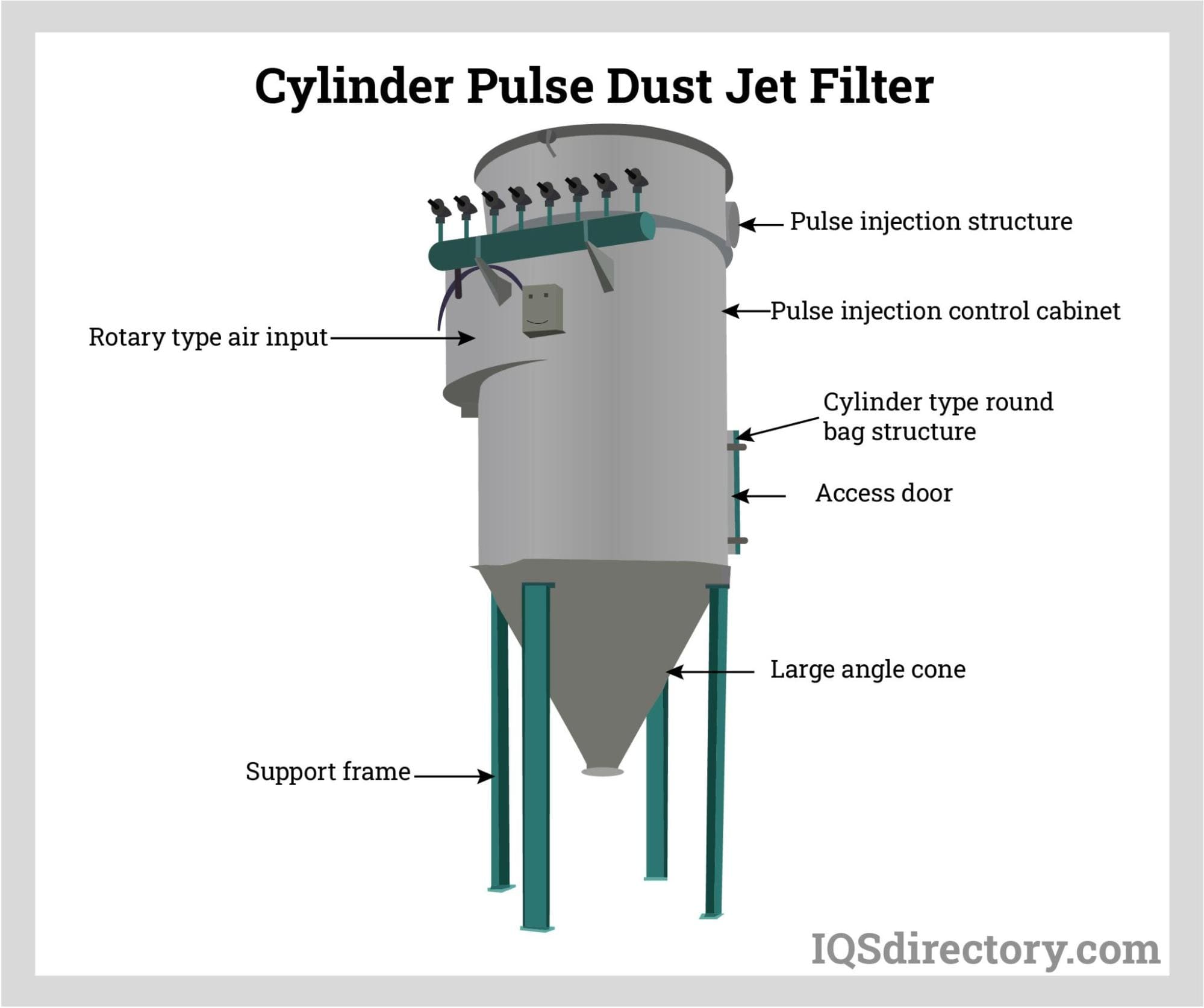

A stock image related to jet pulse.

The evolution of jet pulse technology dates back to the mid-20th century when engineers began exploring alternative propulsion methods that could offer simplicity and efficiency. Initial developments focused on the basic principles of combustion and aerodynamics, leading to the creation of the first pulse jet engines. Over the decades, advancements in materials science and engineering have refined these designs, resulting in more reliable and powerful engines.

The introduction of valveless designs marked a significant milestone, eliminating the need for mechanical components that often led to failures. This innovation paved the way for broader applications, particularly in UAVs, where weight and maintenance are critical factors. As technology continues to evolve, the jet pulse sector is set to expand further, driven by innovations that cater to the growing demands of modern industries while maintaining a focus on sustainability and efficiency.

By understanding the historical context, B2B buyers can better appreciate the advancements that have shaped the jet pulse market and make strategic decisions that align with future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of jet pulse

-

How do I select the right jet pulse engine for my application?

Choosing the right jet pulse engine involves understanding your specific application requirements, such as thrust, weight, and operational environment. For UAVs, consider factors like payload capacity, flight duration, and the need for stealth. Additionally, evaluate the engine’s design—valved versus valveless pulse jets may offer different performance characteristics. Consulting with manufacturers and reviewing technical specifications can help in making an informed decision tailored to your operational needs. -

What are the advantages of using a valveless pulse jet engine?

Valveless pulse jet engines are known for their simplicity and reliability, as they contain no moving parts that can wear out. This design minimizes maintenance needs, which is particularly advantageous for UAVs operating in remote or challenging environments. They also provide a higher thrust-to-weight ratio, making them ideal for applications requiring rapid acceleration and sustained flight. Their lightweight construction allows for increased payload capacity and longer operational ranges. -

What factors should I consider when vetting jet pulse engine suppliers?

When vetting suppliers, assess their manufacturing capabilities, industry experience, and technical expertise. Review customer testimonials and case studies to gauge their reliability and performance. Additionally, inquire about their quality assurance processes and certifications, such as ISO standards. It’s also beneficial to engage in direct communication to discuss your specific needs and evaluate their responsiveness and willingness to customize solutions. -

What is the typical minimum order quantity (MOQ) for jet pulse engines?

MOQs for jet pulse engines can vary significantly based on the supplier and the complexity of the engine design. Generally, manufacturers may set MOQs ranging from a few units for standard models to larger quantities for custom orders. It’s advisable to discuss your requirements with suppliers upfront to negotiate terms that align with your operational needs and budget constraints, especially if you are entering new markets in Africa, South America, the Middle East, or Europe. -

What payment terms are commonly offered for international B2B transactions in jet pulse engines?

Payment terms for international purchases typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit upfront, with the balance due before shipment or upon delivery. It’s essential to clarify these terms during negotiations to ensure they align with your financial processes. Consider the implications of exchange rates and transaction fees when dealing with international suppliers. -

How can I ensure quality assurance when purchasing jet pulse engines?

To ensure quality assurance, request detailed documentation of the manufacturing processes, including material certifications and testing protocols. Reputable suppliers should provide evidence of compliance with international standards and offer warranties for their products. Additionally, consider conducting third-party inspections or audits of the manufacturing facility, especially if you are placing a large order or are unfamiliar with the supplier’s reputation. -

What logistics considerations should I keep in mind when sourcing jet pulse engines internationally?

When sourcing internationally, consider the logistics of shipping, including lead times, customs clearance, and potential tariffs or duties. Assess the reliability of the supplier’s shipping partners and inquire about their experience with international deliveries. It’s also prudent to clarify who will be responsible for shipping costs and insurance during transit. Effective communication regarding logistics can help prevent delays and ensure a smooth procurement process. -

What are the common applications of jet pulse engines in various industries?

Jet pulse engines are widely used in applications such as unmanned aerial vehicles (UAVs), model aircraft, and educational kits for engineering projects. In the military sector, they serve in target drones and surveillance platforms due to their high thrust and lightweight design. Additionally, the simplicity of pulse jet engines makes them suitable for experimental research and development in propulsion technologies across various industries, from aerospace to automotive sectors.

A stock image related to jet pulse.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for jet pulse

In conclusion, strategic sourcing of jet pulse technology offers significant advantages for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding the unique benefits of pulse jet engines—such as their lightweight design, minimal moving parts, and high thrust-to-weight ratios—businesses can make informed decisions that enhance operational efficiency and reduce long-term costs.

Investing in pulse jet technology not only supports innovation in unmanned aerial vehicles (UAVs) but also opens avenues for cost-effective production and rapid deployment across diverse applications, from surveillance to military training. The streamlined manufacturing process coupled with the reliability of valveless pulse jets makes them an ideal choice for organizations looking to optimize their propulsion systems.

As we look ahead, international B2B buyers should actively engage with suppliers and industry forums to stay abreast of the latest advancements and applications in pulse jet technology. By doing so, companies can harness the full potential of these engines, driving competitive advantage in their respective markets. Embrace the future of propulsion technology and position your business for success in an evolving landscape.