Unlock Quality & Cost Savings: Steel and Stainless Guide (2025)

Introduction: Navigating the Global Market for steel and stainless

In today’s competitive landscape, sourcing high-quality steel and stainless products is a critical challenge for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. As industries evolve and demand for durable materials rises, understanding the intricacies of the global steel and stainless market becomes imperative. This guide is tailored to provide comprehensive insights into the various types of steel and stainless products, their applications across different sectors, and the essential strategies for vetting suppliers effectively.

Navigating the complexities of pricing, availability, and quality assurance can be daunting for businesses looking to make informed purchasing decisions. This guide addresses these challenges head-on, offering actionable insights on how to select the best materials that meet your specific needs while optimizing costs. From understanding the nuances of different grades of steel to evaluating the reputation and reliability of suppliers, this resource lays the groundwork for successful procurement strategies.

By equipping B2B buyers from diverse regions, including Colombia and Kenya, with the knowledge to make data-driven decisions, this guide empowers you to navigate the global market with confidence. Whether you are a manufacturer, construction firm, or distributor, understanding the steel and stainless landscape is crucial for ensuring that your business thrives in this dynamic environment. Prepare to transform your sourcing strategies and elevate your operational efficiency.

Understanding Search Intent for ‘steel and stainless’

When users search for **”steel and stainless”**, Google’s results indicate a strong **informational intent**. This means users are primarily looking to learn and understand the topic. They want definitions, explanations, and foundational knowledge about ‘steel and stainless’.

Our analysis of the search engine results page (SERP) reveals several key features that shape this article:

* **Presence of Video Content:** No.

* **Shopping Ad Integration:** No.

* **’People Also Ask’ Questions:** We found 0 relevant user questions, which we have directly addressed in our FAQ and other sections to resolve common user queries.

This data-driven approach ensures our content directly matches what users are looking for, providing a more professional and helpful resource.

Understanding steel and stainless Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Steel | High carbon content, strong and durable | Construction, automotive, machinery | Pros: Cost-effective, strong; Cons: Prone to rust, less ductile. |

| Stainless Steel | Alloyed with chromium, resistant to corrosion | Food processing, pharmaceuticals, construction | Pros: Corrosion-resistant, aesthetically pleasing; Cons: Higher cost, less strong than carbon steel. |

| Alloy Steel | Contains additional elements for enhanced properties | Aerospace, oil and gas, automotive | Pros: Improved mechanical properties; Cons: More expensive, requires specific processing. |

| Tool Steel | Designed for manufacturing tools, high hardness | Tool making, die casting, machining | Pros: High wear resistance, durable; Cons: Expensive, requires heat treatment. |

| High-Strength Low-Alloy (HSLA) Steel | Enhanced strength with less weight | Structural applications, automotive | Pros: Lightweight, strong; Cons: Limited availability, can be more expensive. |

What are the Key Characteristics of Carbon Steel?

Carbon steel is characterized by its high carbon content, which contributes to its strength and durability. It is commonly used in construction, automotive, and machinery applications due to its excellent tensile strength and affordability. For B2B buyers, the primary consideration should be its susceptibility to rust and corrosion, which necessitates protective coatings or regular maintenance. Understanding the specific grades of carbon steel can help buyers select the right material for their projects.

How Does Stainless Steel Stand Out in the Market?

Stainless steel is distinguished by its chromium content, which provides exceptional resistance to corrosion and oxidation. This makes it an ideal choice for industries such as food processing, pharmaceuticals, and construction, where hygiene and durability are paramount. B2B buyers should weigh the higher initial investment against the long-term benefits of reduced maintenance costs and longevity. The aesthetic appeal of stainless steel also makes it suitable for applications where appearance is important.

What Additional Benefits Does Alloy Steel Offer?

Alloy steel is enhanced with elements like nickel, chromium, and molybdenum to improve its mechanical properties, making it suitable for demanding applications in aerospace, oil and gas, and automotive industries. Buyers should consider the specific alloying elements and their effects on the steel’s properties when making purchasing decisions. While alloy steel can be more expensive than standard steel, its performance in high-stress environments can justify the investment.

Why Choose Tool Steel for Manufacturing Needs?

Tool steel is specifically engineered for manufacturing cutting tools and dies, offering high hardness and wear resistance. It is essential in tool making, die casting, and machining applications where precision and durability are critical. For B2B buyers, the cost of tool steel can be higher, and it often requires heat treatment to achieve optimal properties. Understanding the different grades of tool steel and their specific applications can help buyers select the most appropriate type for their manufacturing processes.

What are the Advantages of High-Strength Low-Alloy (HSLA) Steel?

HSLA steel is designed to provide high strength with reduced weight, making it an excellent option for structural applications and automotive components. Buyers should consider the trade-offs between strength and weight, as well as the availability of HSLA grades in their region. While HSLA steel can be more expensive than traditional steel types, its performance benefits often lead to cost savings in terms of material usage and overall project efficiency.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of steel and stainless

| Industry/Sector | Specific Application of steel and stainless | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural frameworks and reinforcements | Enhances durability and safety of buildings and infrastructure | Ensure compliance with local regulations and quality standards |

| Oil and Gas | Pipelines and storage tanks | Corrosion resistance and longevity under extreme conditions | Consider sourcing from certified suppliers with proven track records |

| Automotive | Chassis and engine components | Lightweight yet strong materials improve fuel efficiency | Look for suppliers with advanced manufacturing capabilities |

| Food and Beverage | Processing equipment and storage solutions | Hygiene and safety standards met with stainless steel | Verify certifications for food safety compliance |

| Renewable Energy | Wind turbine components and solar panel frames | Contribution to sustainable energy solutions | Assess sourcing logistics and material traceability |

How is Steel and Stainless Used in the Construction Industry?

In the construction sector, steel and stainless steel are integral to creating robust structural frameworks and reinforcements. These materials provide the strength required to support large buildings and infrastructure projects, ensuring safety and longevity. For international buyers, especially in regions like Africa and South America, understanding local building codes and quality standards is essential. Suppliers should be vetted for compliance with these regulations to prevent costly project delays.

What Role Do Steel and Stainless Play in the Oil and Gas Sector?

Steel and stainless steel are vital in the oil and gas industry for constructing pipelines and storage tanks. Their corrosion resistance and ability to withstand extreme temperatures make them ideal for transporting hazardous materials safely. B2B buyers should prioritize sourcing from suppliers with certifications that guarantee the materials can endure the harsh conditions typical in this sector, particularly in the Middle East, where environmental factors can be challenging.

How Are Steel and Stainless Utilized in the Automotive Industry?

In the automotive industry, steel is commonly used for chassis and engine components due to its lightweight yet strong properties. This application not only enhances vehicle performance but also improves fuel efficiency, meeting the increasing demand for sustainable automotive solutions. Buyers from Europe and South America should seek suppliers that employ advanced manufacturing processes to ensure precision and quality in their automotive parts.

Why is Stainless Steel Important in the Food and Beverage Industry?

Stainless steel is crucial in the food and beverage sector for manufacturing processing equipment and storage solutions. Its non-reactive nature ensures that food safety and hygiene standards are met, preventing contamination. For international buyers, particularly in regions with strict food safety regulations, verifying a supplier’s compliance with these standards is vital to maintaining product integrity and safety.

How is Steel and Stainless Contributing to Renewable Energy?

Steel and stainless steel are essential in the renewable energy sector, specifically for wind turbine components and solar panel frames. These materials contribute to the durability and efficiency of renewable energy solutions, which are increasingly important in global sustainability efforts. B2B buyers should consider sourcing logistics and material traceability to ensure that the components are produced sustainably and ethically, aligning with the growing demand for responsible sourcing practices.

Related Video: Welding and Polishing Process | StainLess Steel | Super Smooth | JC’s Metal Works

3 Common User Pain Points for ‘steel and stainless’ & Their Solutions

Scenario 1: Sourcing Quality Materials Amidst Global Supply Chain Disruptions

The Problem: In today’s volatile market, B2B buyers often face challenges in sourcing high-quality steel and stainless materials due to global supply chain disruptions. Issues such as fluctuating prices, delays in shipment, and quality inconsistencies can lead to project delays and increased costs. For international buyers in regions like Africa or South America, where local suppliers may be limited, this challenge can be particularly daunting.

The Solution: To mitigate sourcing challenges, buyers should establish relationships with multiple suppliers across different regions to diversify their sources. Engaging in long-term contracts with key suppliers can also help stabilize prices and ensure consistent quality. Additionally, utilizing online platforms that aggregate supplier information can streamline the identification of reliable vendors. Buyers should prioritize suppliers with robust quality assurance processes and certifications, such as ISO standards, which can significantly reduce the risk of dealing with subpar materials.

Scenario 2: Navigating Regulatory Compliance and Standards

The Problem: B2B buyers often grapple with the complexities of regulatory compliance when importing steel and stainless products. Each country has distinct standards regarding material specifications, environmental regulations, and safety requirements. For instance, a buyer in the Middle East may face different compliance challenges than one in Europe, making it difficult to ensure that the materials meet necessary legal and industry standards.

The Solution: To navigate these regulatory hurdles effectively, buyers should invest time in understanding the compliance requirements specific to their target markets. Collaborating with local legal experts or compliance consultants can provide valuable insights into the regulatory landscape. Additionally, buyers should seek suppliers who are well-versed in international standards and can provide documentation that certifies compliance. Keeping abreast of changes in regulations through industry associations and trade organizations can also be beneficial, allowing buyers to adapt quickly to any new requirements.

Scenario 3: Managing Cost Fluctuations in Steel and Stainless Markets

The Problem: The pricing of steel and stainless products is notoriously volatile, influenced by factors such as raw material costs, currency fluctuations, and geopolitical tensions. For B2B buyers, particularly in regions like Europe or Africa, this unpredictability can complicate budgeting and financial forecasting. Unexpected price hikes may lead to project overruns and affect profit margins.

The Solution: To manage cost fluctuations effectively, buyers should adopt strategic purchasing methods, such as bulk buying or forward contracts, which lock in prices for future purchases. Implementing a flexible pricing strategy that allows for dynamic adjustments based on market conditions can also help mitigate risks. Regular communication with suppliers about market trends can provide buyers with insights that inform their purchasing decisions. Additionally, leveraging technology, such as data analytics tools, can help buyers monitor market trends and make informed purchasing decisions, minimizing the impact of price volatility on their operations.

Strategic Material Selection Guide for steel and stainless

When selecting materials for steel and stainless applications, international B2B buyers must consider various factors that impact product performance, cost, and suitability for specific applications. Below, we analyze four common materials used in steel and stainless steel applications, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Carbon Steel?

Carbon Steel is a widely used material, known for its high strength and versatility. It typically has a temperature rating of up to 400°C and can withstand high pressure, making it suitable for structural applications. Its corrosion resistance is moderate, which can be enhanced with coatings.

Pros: Carbon steel is generally more affordable than stainless steel and is readily available. It is easy to manufacture and weld, making it suitable for various applications, including construction and automotive.

Cons: The primary limitation is its susceptibility to rust and corrosion, particularly in humid or corrosive environments. This makes it less suitable for applications involving exposure to water or chemicals without protective measures.

Impact on Application: Carbon steel is compatible with many media but should be avoided in highly corrosive environments unless properly treated. Buyers should consider local climate conditions when selecting carbon steel for their projects.

How Does Stainless Steel Compare in Terms of Performance?

Stainless Steel is renowned for its excellent corrosion resistance, making it ideal for applications in food processing, pharmaceuticals, and marine environments. It can withstand temperatures up to 870°C and offers good pressure ratings.

Pros: Its durability and resistance to corrosion and staining make stainless steel a preferred choice for high-end applications. The aesthetic appeal of stainless steel also adds value in consumer-facing products.

Cons: The primary drawback is its higher cost compared to carbon steel. Additionally, manufacturing processes can be more complex, requiring specialized skills and equipment.

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic and alkaline substances. Buyers must ensure compliance with international standards such as ASTM and ISO, especially in regulated industries.

What are the Benefits of Alloy Steel?

Alloy Steel includes various elements like chromium, nickel, and molybdenum, enhancing its mechanical properties. It is suitable for high-stress applications, with temperature ratings often exceeding 500°C.

Pros: Alloy steel offers superior strength and toughness, making it ideal for heavy-duty applications such as oil and gas pipelines and construction equipment. Its resistance to wear and fatigue is also a significant advantage.

Cons: The complexity of manufacturing alloy steel can lead to higher costs. Additionally, specific alloy compositions may be required for certain applications, complicating sourcing.

Impact on Application: Alloy steel is compatible with a variety of media but may require careful selection based on the specific alloying elements. Buyers should be aware of local regulations regarding alloy compositions and sourcing.

Why Choose Tool Steel for Specialized Applications?

Tool Steel is designed for high-performance applications, particularly in manufacturing tools and dies. It can withstand extreme temperatures and pressures, making it suitable for cutting and shaping materials.

Pros: Tool steel is known for its hardness and ability to retain a sharp edge, making it ideal for machining applications. Its durability reduces the need for frequent replacements.

Cons: The cost of tool steel can be significantly higher than other materials, and it may require specialized processing techniques. Additionally, its brittleness can be a concern in certain applications.

Impact on Application: Tool steel is compatible with a range of media, but its application is typically limited to specific industries such as manufacturing and aerospace. Compliance with industry standards is crucial for international buyers.

Summary Table of Material Selection

| Material | Typical Use Case for steel and stainless | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive components | Cost-effective and easy to manufacture | Susceptible to rust and corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Alloy Steel | Oil and gas pipelines, construction | Superior strength and toughness | Higher manufacturing complexity | Medium |

| Tool Steel | Manufacturing tools and dies | Exceptional hardness and durability | High cost and brittleness | High |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials available for steel and stainless applications, helping them make informed decisions that align with their specific needs and regional considerations.

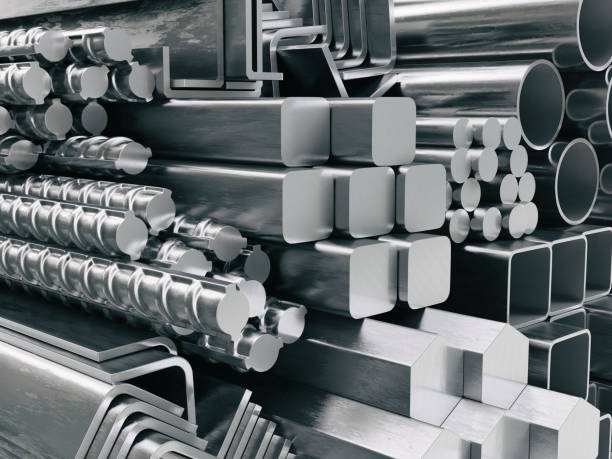

A stock image related to steel and stainless.

In-depth Look: Manufacturing Processes and Quality Assurance for steel and stainless

What Are the Main Stages of Manufacturing Steel and Stainless Steel?

The manufacturing of steel and stainless steel involves several critical stages that ensure the final product meets industry specifications and customer requirements. Understanding these processes is crucial for international B2B buyers looking to source high-quality materials.

Material Preparation: How is Raw Material Processed?

The first step in manufacturing is material preparation, which involves sourcing high-quality raw materials, typically iron ore, scrap metal, and alloying elements such as chromium and nickel for stainless steel. The materials are then subjected to processes such as:

- Melting: The raw materials are melted in a furnace, which can be an electric arc or induction furnace, depending on the desired steel grade.

- Refining: This step removes impurities and adjusts the chemical composition to meet specific standards. Techniques like oxygen blowing (for carbon steel) or argon-oxygen decarburization (for stainless steel) are common.

For B2B buyers, ensuring that suppliers use high-grade raw materials is crucial, as this directly impacts the quality and performance of the final product.

Forming: What Techniques Are Used for Shaping Steel?

After the materials are prepared, the next stage is forming, where the molten metal is shaped into semi-finished products such as slabs, billets, or blooms. Key techniques include:

- Casting: This involves pouring molten metal into molds to create specific shapes. Continuous casting is widely used for better efficiency and consistency.

- Hot Rolling: The castings are heated and passed through rollers to produce thinner sheets or bars. This process enhances the material’s properties through grain refinement.

International buyers should inquire about the forming techniques used by suppliers, as this can affect the mechanical properties of the steel or stainless steel, such as tensile strength, ductility, and corrosion resistance.

What Is the Role of Assembly in Steel Manufacturing?

In some cases, particularly for complex components, assembly is a crucial stage in manufacturing. This step involves joining different parts through:

- Welding: Various welding techniques, such as MIG/TIG or submerged arc welding, are used to join components. Quality welding is critical for structural integrity.

- Machining: This process includes cutting, drilling, and milling to achieve precise dimensions and surface finishes.

For B2B buyers, understanding the assembly methods can help assess the reliability and durability of the final products, especially for applications requiring high-performance materials.

How Is Finishing Applied to Steel and Stainless Steel Products?

Finishing is the final stage of manufacturing, where the product undergoes surface treatment to enhance aesthetics and performance. Common finishing processes include:

- Surface Treatments: Techniques like galvanizing, passivation, and powder coating improve corrosion resistance and durability.

- Quality Inspection: A thorough inspection is conducted to ensure that the products meet specified standards and customer requirements.

Buyers should verify the finishing processes used by suppliers to ensure that the products will perform adequately in their intended applications.

What Quality Assurance Standards Should B2B Buyers Know?

Quality assurance is paramount in steel and stainless steel manufacturing, with various international and industry-specific standards guiding the process.

Which International Standards Apply to Steel Manufacturing?

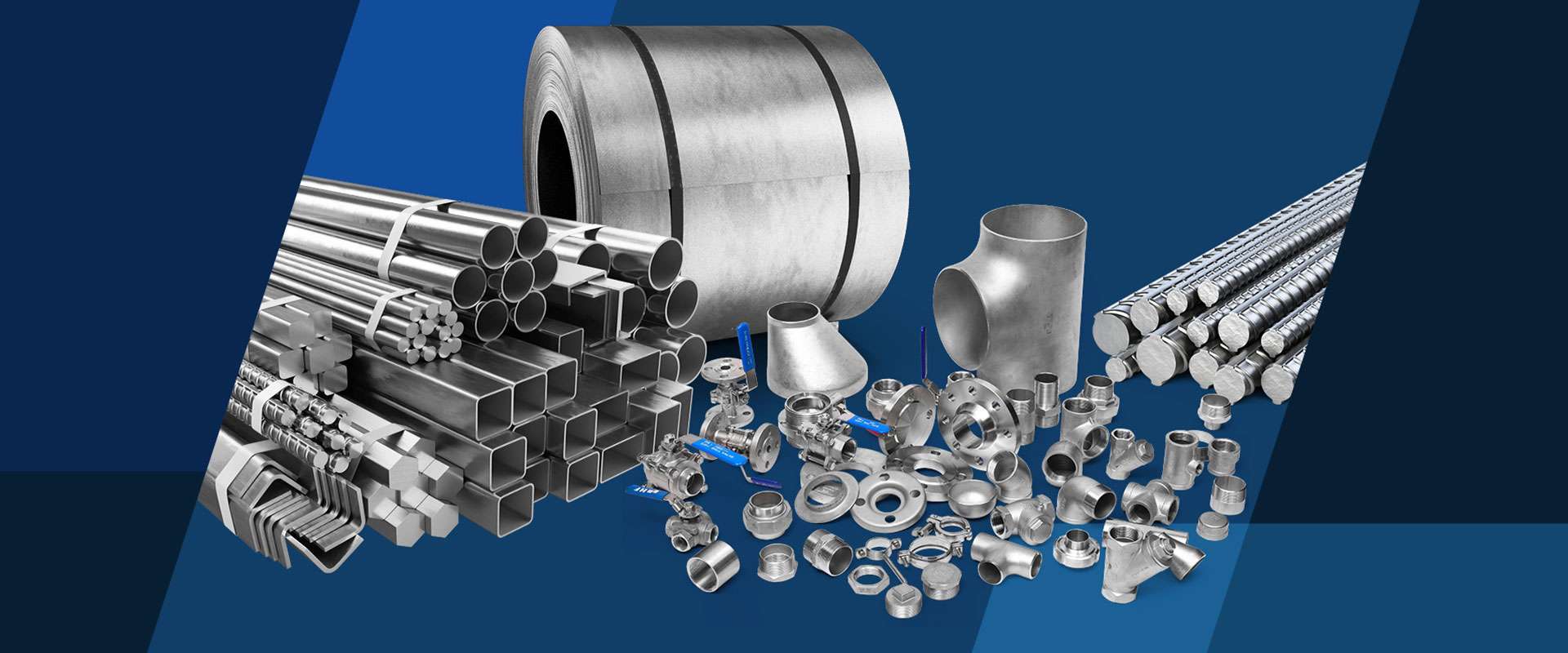

A stock image related to steel and stainless.

One of the most recognized quality management systems is ISO 9001, which outlines requirements for a quality management system (QMS) focused on meeting customer needs and enhancing satisfaction. Other relevant standards include:

- ISO 14001: Environmental management, ensuring sustainable practices.

- ISO 45001: Occupational health and safety, protecting workers during the manufacturing process.

For buyers, checking suppliers’ certifications against these standards can provide assurance of quality and compliance.

What Industry-Specific Standards Should Be Considered?

In addition to general standards, there are industry-specific certifications that may be relevant:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for products used in the oil and gas industry.

Understanding these certifications can help buyers from regions such as Europe and the Middle East ensure that products meet specific regulatory requirements.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality Control (QC) is an integral part of the manufacturing process, ensuring that products meet established standards at various stages. The main checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors processes during production to catch any deviations from quality standards.

- Final Quality Control (FQC): Conducts a final inspection before shipment, ensuring that products meet customer specifications.

B2B buyers should inquire about the QC processes employed by their suppliers to understand how they manage quality throughout the manufacturing cycle.

What Testing Methods Are Commonly Used in Steel Quality Control?

Several testing methods are employed to verify the quality and performance of steel and stainless steel products:

- Mechanical Testing: Includes tensile testing, hardness testing, and impact testing to assess strength, ductility, and toughness.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to detect defects without damaging the product.

Buyers should request testing reports from suppliers to validate the quality claims and ensure the products will perform as expected in their applications.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, rigorous verification of supplier quality assurance practices is essential. Here are actionable strategies:

- Conduct Audits: Regularly scheduled audits of suppliers can help assess their compliance with quality standards and manufacturing processes.

- Request Quality Reports: Suppliers should provide comprehensive quality reports, including inspection and testing results, to demonstrate their commitment to quality.

- Engage Third-Party Inspectors: Hiring third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality assurance processes.

By implementing these strategies, B2B buyers can mitigate risks and ensure they are sourcing high-quality steel and stainless steel products that meet industry standards. Understanding the nuances of quality control and manufacturing processes will enable buyers from regions like Africa, South America, the Middle East, and Europe to make informed purchasing decisions.

Related Video: Stainless Steel Water Bottle Manufacturing Process︱Auland Bottle Factory

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel and stainless’

This checklist serves as a practical sourcing guide for international B2B buyers seeking to procure steel and stainless steel products. By following these steps, buyers can ensure they make informed decisions, minimize risks, and establish successful supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes dimensions, grades of steel or stainless steel, and any specific industry standards that need to be met. Defining these specifications early on prevents misunderstandings with suppliers and ensures that the products you receive will meet your project’s needs.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing is essential for effective budgeting and negotiation. Conduct thorough market research to identify fluctuations in steel prices, which can be influenced by global supply chains, tariffs, and demand. Utilize industry reports and trade publications to gather relevant data that can inform your sourcing strategy.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in steel and stainless steel products. Utilize online platforms, trade shows, and industry networks to identify reputable suppliers. Ensure that these suppliers have a proven track record in your target markets, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 4: ✅ Verify Supplier Certifications

It is critical to verify that potential suppliers hold the necessary certifications and comply with international standards. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications not only demonstrate a commitment to quality but also help mitigate risks associated with sourcing from less-regulated markets.

Step 5: Evaluate Supplier Experience and Reputation

Before making a commitment, assess the experience and reputation of your shortlisted suppliers. Request case studies, customer references, and testimonials to gauge their reliability. A supplier with a history of successful transactions in your industry is more likely to meet your expectations and provide quality products.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, negotiate the terms and conditions of your agreement. This includes pricing, payment terms, delivery schedules, and any warranties or guarantees. Clear and mutually agreed terms help prevent disputes and misunderstandings down the line.

Step 7: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Establish a communication plan that outlines how often you will check-in with the supplier, preferred communication channels, and points of contact. Regular updates and open lines of communication can help address any issues promptly and strengthen your partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing steel and stainless steel products with greater confidence, ensuring they select the right suppliers who can meet their specific needs.

Comprehensive Cost and Pricing Analysis for steel and stainless Sourcing

What are the Key Cost Components in Steel and Stainless Sourcing?

Understanding the cost structure of steel and stainless steel sourcing is crucial for international B2B buyers. The primary components include:

-

Materials: The base cost of raw steel or stainless steel is influenced by market conditions, including demand and supply dynamics. Prices can fluctuate significantly based on global commodity trends.

-

Labor: Labor costs vary widely across regions. For instance, countries in Africa may have lower labor costs compared to Europe. However, the skill level of the workforce can impact productivity and, consequently, the overall cost.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can minimize overhead, leading to more competitive pricing.

-

Tooling: Custom tooling can be a substantial upfront investment, especially for specialized steel products. Buyers should evaluate whether the tooling costs are justified by the anticipated volume and specific requirements.

-

Quality Control (QC): Ensuring product quality may necessitate additional investments in QC processes and certifications. International buyers often require specific industry certifications which can add to the overall cost.

-

Logistics: Shipping costs can vary based on distance and mode of transport. Incoterms play a vital role in determining who bears these costs, impacting the final pricing for the buyer.

-

Margin: The supplier’s margin is influenced by their operating costs and market conditions. Understanding typical margins for your specific market can aid in effective negotiation.

How Do Price Influencers Impact Steel and Stainless Steel Sourcing?

Several factors directly influence pricing in the steel and stainless steel markets:

-

Volume and Minimum Order Quantity (MOQ): Buying in bulk often leads to significant cost savings. Suppliers may offer better pricing tiers for larger orders, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Customized products typically come at a premium. Buyers should evaluate whether the additional costs align with their project requirements and budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can increase costs, but they may be necessary for specific applications. Buyers should weigh the value of certifications against potential savings.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to capture market share.

-

Incoterms: Understanding Incoterms is essential for managing costs related to shipping and insurance. Different terms (e.g., FOB, CIF) can shift the financial responsibility and affect overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Steel and Stainless Sourcing?

International B2B buyers can adopt several strategies to optimize their sourcing costs:

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing, especially for larger orders. Building a relationship can lead to better terms and potential discounts.

-

Consider Total Cost of Ownership (TCO): TCO goes beyond the initial purchase price. Buyers should factor in logistics, maintenance, and potential downtime when assessing the overall cost of sourcing steel products.

-

Stay Informed on Pricing Trends: Regularly monitoring market conditions and price trends can empower buyers to make informed purchasing decisions and negotiate better deals.

-

Understand Pricing Nuances: Different regions may have unique pricing structures influenced by local regulations, tariffs, and labor costs. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these nuances to avoid unexpected costs.

Disclaimer on Indicative Prices

Pricing in the steel and stainless steel markets can fluctuate frequently due to various economic factors. Buyers should consider this variability when planning their sourcing strategies and engage with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing steel and stainless With Other Solutions

Understanding Alternatives to Steel and Stainless: Key Considerations for B2B Buyers

In the competitive landscape of materials for industrial applications, steel and stainless steel are often considered the go-to options for their durability and versatility. However, various alternatives might offer specific advantages depending on the application, cost considerations, and operational requirements. This section provides a comparative analysis of steel and stainless steel against two viable alternatives: aluminum and carbon fiber.

Comparison Table of Steel and Stainless with Alternatives

| Comparison Aspect | Steel and Stainless | Aluminum | Carbon Fiber |

|---|---|---|---|

| Performance | High strength and durability; excellent corrosion resistance in stainless | Moderate strength; lightweight but less durable | Superior strength-to-weight ratio; excellent fatigue resistance |

| Cost | Generally more affordable; stainless is pricier | Lower initial cost; can be cost-effective for lightweight applications | Higher initial investment; cost per pound is significant |

| Ease of Implementation | Widely available; requires standard tools for fabrication | Easy to work with; can be fabricated using standard techniques | Requires specialized tools and expertise for fabrication |

| Maintenance | Low maintenance; stainless offers higher corrosion resistance | Moderate; may require protective coatings in certain environments | Low maintenance; resistant to corrosion and fatigue |

| Best Use Case | Construction, automotive, and heavy machinery | Aerospace, automotive, and consumer goods | High-performance applications such as sports equipment and aerospace |

What Are the Advantages and Disadvantages of Aluminum Compared to Steel and Stainless?

Aluminum stands out primarily due to its lightweight nature, making it ideal for applications where reducing weight is critical, such as in the aerospace and automotive industries. Its lower initial cost can be appealing for large-scale projects. However, aluminum’s strength is generally lower compared to steel, which may limit its use in high-stress applications. Additionally, while it is easier to fabricate, aluminum may require protective coatings to enhance its durability in harsh environments.

How Does Carbon Fiber Compare to Steel and Stainless in Performance and Cost?

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it an excellent choice for industries requiring lightweight materials that do not compromise on strength, such as aerospace and high-end sports equipment. Its fatigue resistance is superior, leading to longer service life under stress. However, the cost is a significant drawback; carbon fiber’s higher price point can limit its adoption in cost-sensitive applications. Additionally, its fabrication requires specialized skills and equipment, posing challenges for companies without the necessary infrastructure.

Conclusion: How to Choose the Right Material for Your B2B Needs

When selecting between steel, stainless steel, aluminum, and carbon fiber, B2B buyers must assess their specific project requirements, including performance needs, budget constraints, and long-term maintenance considerations. Steel and stainless steel remain strong contenders for many applications due to their balance of cost and performance. However, for projects prioritizing weight reduction without sacrificing strength, aluminum or carbon fiber may present viable alternatives. Ultimately, understanding the nuances of each material will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for steel and stainless

What Are the Key Technical Properties of Steel and Stainless Steel?

Understanding the technical properties of steel and stainless steel is crucial for international B2B buyers. These properties directly influence material performance, durability, and suitability for specific applications. Here are some essential specifications to consider:

1. Material Grade

Material grade indicates the chemical composition and mechanical properties of steel or stainless steel. Common grades include ASTM A36 (carbon steel) and AISI 304 (stainless steel). For B2B buyers, selecting the correct grade ensures that the material meets the specific requirements of their projects, impacting both safety and longevity.

2. Yield Strength

Yield strength is the maximum stress that a material can withstand while still returning to its original shape. For example, structural steel typically has a yield strength of around 250 MPa. Knowing the yield strength helps buyers determine if a material can support the loads it will face in practical applications, such as construction or manufacturing.

3. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For instance, a tolerance of ±0.01 mm in thickness is critical for parts that must fit together precisely. Understanding tolerance is vital for B2B buyers to ensure that components will assemble correctly, minimizing the risk of costly rework or failures.

4. Corrosion Resistance

Corrosion resistance is a significant property of stainless steel, influenced by its alloying elements like chromium and nickel. Stainless steels such as AISI 316 provide higher corrosion resistance, making them suitable for environments exposed to moisture or chemicals. B2B buyers operating in corrosive environments must prioritize this property to ensure their materials will last.

5. Hardness

Hardness measures a material’s resistance to deformation and wear. It is often assessed using scales like Rockwell or Brinell. For example, a hardness rating of 60 HRC indicates a very hard material. In B2B transactions, understanding hardness is essential for applications involving wear resistance, such as tooling and machinery.

What Are Common Trade Terms in the Steel and Stainless Industry?

Familiarity with industry jargon can significantly streamline negotiations and procurement processes. Here are several essential trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with reputable OEMs ensures they receive high-quality materials that meet specific standards, which is particularly crucial in industries like automotive or aerospace.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of goods a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs and ensure they are not overcommitting to a supplier. For instance, if a steel manufacturer sets an MOQ of 1,000 kg, buyers need to assess whether they can utilize that quantity effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to provide price quotes for specific products or services. B2B buyers should prepare detailed RFQs that include specifications, quantities, and delivery requirements to receive accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping and delivery. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs and risk at various stages of the transaction. B2B buyers must understand these terms to negotiate better shipping agreements and avoid unexpected costs.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the goods. For B2B buyers, understanding lead time is crucial for project planning and inventory management. Longer lead times can impact production schedules, so it’s essential to factor this into procurement strategies.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their purchasing power and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the steel and stainless Sector

What Are the Current Market Dynamics and Key Trends in the Steel and Stainless Sector?

The steel and stainless sector is experiencing significant transformations driven by several global factors. Firstly, the demand for sustainable and eco-friendly materials is reshaping sourcing strategies. As nations implement stricter environmental regulations, international B2B buyers are increasingly seeking suppliers that can demonstrate compliance with these standards. Countries in Africa, South America, the Middle East, and Europe are prioritizing local sourcing to reduce carbon footprints and support regional economies.

Emerging technologies such as blockchain and IoT are revolutionizing supply chain transparency and efficiency. These technologies allow B2B buyers to track the provenance of steel and stainless products, ensuring authenticity and ethical sourcing. Additionally, advancements in manufacturing processes, such as electric arc furnaces (EAF), are gaining traction due to their lower emissions compared to traditional methods. Buyers should consider partnerships with suppliers who are early adopters of these technologies to gain a competitive edge.

The market is also witnessing a shift towards customization, with buyers looking for tailored solutions that meet specific project requirements. This trend is particularly pronounced in Europe and South America, where industries like construction and automotive demand specialized products. Buyers can leverage this trend by engaging in collaborative relationships with suppliers to co-develop innovative solutions.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in Steel and Stainless?

The environmental impact of steel production is significant, with traditional methods contributing to high levels of CO2 emissions. As awareness of climate change grows, international B2B buyers must consider sustainability as a core component of their sourcing strategies. This includes evaluating the carbon footprint of suppliers and their production methods.

Ethical supply chains are becoming increasingly vital in the steel and stainless sector. Buyers are encouraged to seek suppliers that adhere to ethical practices, ensuring fair labor conditions and minimal environmental degradation. Certifications such as ISO 14001 for environmental management and LEED for sustainable building practices are indicators of a supplier’s commitment to sustainability.

Furthermore, the rise of “green” steel, produced through renewable energy sources or innovative processes like hydrogen reduction, offers an opportunity for buyers to enhance their brand image. By sourcing materials that are certified as sustainable, companies can improve their market position and appeal to environmentally conscious consumers.

What Is the Historical Context of Steel and Stainless Production Relevant to B2B Buyers?

The production of steel and stainless materials has evolved significantly since its inception in the 19th century. Initially, steel was produced through labor-intensive methods, but the introduction of the Bessemer process revolutionized production efficiency and quality. The latter half of the 20th century saw the rise of stainless steel, which became essential for its corrosion resistance and aesthetic appeal.

Understanding this historical context is crucial for B2B buyers. It highlights the continuous innovation within the sector and the importance of adapting to changing market needs. Today, buyers must navigate an increasingly complex landscape shaped by technological advancements, environmental concerns, and evolving consumer preferences. By recognizing these trends, international buyers can make informed sourcing decisions that align with both current market dynamics and their own sustainability goals.

Related Video: Is global trade transforming? | Counting the Cost

Frequently Asked Questions (FAQs) for B2B Buyers of steel and stainless

-

How do I solve issues with sourcing steel and stainless steel from international suppliers?

To effectively solve sourcing issues, start by conducting thorough market research to identify reliable suppliers within your target regions, such as Africa, South America, the Middle East, and Europe. Utilize platforms like Alibaba or Global Sources to find vetted suppliers. Establish clear communication regarding specifications, lead times, and minimum order quantities (MOQ). Building a relationship through regular updates and visits (if possible) can foster trust and mitigate potential challenges. Lastly, consider employing a local intermediary who understands the market dynamics and can facilitate smoother transactions. -

What is the best type of stainless steel for industrial applications?

The best type of stainless steel for industrial applications often depends on the intended use. For general-purpose applications, 304 stainless steel is widely favored due to its excellent corrosion resistance and formability. However, for environments exposed to harsher conditions, such as saltwater or chemicals, 316 stainless steel is recommended for its superior corrosion resistance. Always assess the specific environmental conditions and mechanical requirements of your project to select the most appropriate grade. -

What are the key factors to consider when vetting international steel suppliers?

When vetting international steel suppliers, prioritize the following factors: reputation and experience in the industry, compliance with international quality standards (e.g., ISO certifications), financial stability, and customer reviews. Request samples to evaluate the product quality and conduct site visits if feasible. Additionally, verify their production capacity and lead times to ensure they can meet your demand. It’s also advisable to review their logistics capabilities to understand how they manage shipping and customs clearance. -

How can I ensure the quality of steel and stainless steel products?

To ensure product quality, request certifications and test reports (e.g., mill test certificates) that demonstrate compliance with industry standards. Implement a quality assurance process that includes inspecting shipments upon arrival for any defects or discrepancies. Establish clear quality control agreements with your suppliers that outline your expectations and the consequences of non-compliance. Regularly review supplier performance and conduct audits to maintain high standards consistently. -

What are the common payment terms in international steel transactions?

Common payment terms in international steel transactions include letter of credit (LC), advance payment, and open account. A letter of credit is often preferred as it protects both parties by ensuring payment is only made upon meeting specified conditions. Advance payment can be risky for buyers, while open accounts are more common for established relationships. It’s crucial to negotiate payment terms that align with your risk tolerance and financial strategy, taking into account the supplier’s reliability. -

What should I know about minimum order quantities (MOQ) when sourcing steel?

Minimum order quantities (MOQ) vary widely among suppliers and can significantly impact your procurement strategy. Some suppliers may impose high MOQs to cover production costs, which can be challenging for smaller buyers. When negotiating, clarify whether the MOQ can be adjusted based on your needs or if there are options for shared shipments with other buyers. Understanding the supplier’s pricing structure and potential for bulk discounts can help you make informed purchasing decisions. -

How do logistics and shipping impact my steel procurement strategy?

Logistics and shipping play a critical role in your steel procurement strategy, influencing costs, lead times, and overall supply chain efficiency. Evaluate the shipping options available, including air freight for urgent deliveries or sea freight for cost-effective bulk shipments. Consider the supplier’s location relative to your operations to minimize transportation time and costs. Additionally, stay informed about customs regulations and tariffs in your region to avoid unexpected delays and fees. -

What are the best practices for negotiating contracts with steel suppliers?

When negotiating contracts with steel suppliers, begin by clearly defining your requirements, including specifications, delivery timelines, and payment terms. Research market prices to establish a baseline for negotiations. Foster a collaborative approach by being open to compromises that benefit both parties. Ensure that all agreed-upon terms are documented to avoid misunderstandings. Lastly, maintain a long-term perspective on the relationship, as successful negotiations can lead to favorable terms in future transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steel and stainless

In conclusion, strategic sourcing in the steel and stainless sectors is not merely a procurement process; it is a critical component of competitive advantage for international B2B buyers. Organizations in Africa, South America, the Middle East, and Europe must prioritize relationships with reliable suppliers who can deliver quality materials consistently. This involves understanding market trends, assessing supplier capabilities, and leveraging technology to enhance procurement efficiency.

How can B2B buyers adapt to changing market dynamics? By integrating data analytics and market intelligence into their sourcing strategies, companies can make informed decisions that mitigate risks associated with supply chain disruptions and price volatility. Additionally, fostering partnerships with local suppliers can enhance resilience and support regional economic growth.

Looking ahead, the demand for sustainable and innovative steel solutions will only grow. International B2B buyers are encouraged to invest in research and development initiatives that align with environmental standards and technological advancements. By doing so, they can position themselves as leaders in responsible sourcing and capitalize on emerging opportunities in the global market. Embrace the future of sourcing—your strategic decisions today will shape the success of your business tomorrow.