Unlock Savings: The Complete Guide to Mean Switch (2025)

Introduction: Navigating the Global Market for mean switch

Navigating the global market for mean switches presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Sourcing reliable mean switches can often feel overwhelming due to the diverse applications across industries such as telecommunications, transportation, and manufacturing. This guide is designed to demystify the complexities of mean switch procurement, providing insights into various types, their applications, and essential considerations for supplier vetting.

In this comprehensive resource, you will find detailed analyses of the different mean switch types available, including mechanical, electronic, and software-based solutions. We will explore practical applications, highlighting their roles in facilitating efficient operations and enhancing productivity. Additionally, this guide will cover critical aspects such as cost analysis, market trends, and best practices for selecting suppliers that meet your specific needs.

By equipping B2B buyers with actionable insights and a structured approach to sourcing mean switches, this guide empowers you to make informed purchasing decisions. Whether you’re navigating regulatory environments in South Africa, assessing suppliers in Mexico, or seeking innovative solutions in the Middle East, our aim is to simplify your procurement process and enhance your competitive edge in the global market.

Understanding mean switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Switch | Operated manually; includes toggle and push-button | Industrial machinery, HVAC systems | Pros: Simple design, low cost. Cons: Limited automation, wear over time. |

| Electronic Switch | Uses electronic signals; can be remote-controlled | Smart buildings, automation systems | Pros: High precision, remote operation. Cons: Higher initial cost, potential for electronic failure. |

| Relay Switch | Electromechanical; activates circuits through coils | Telecommunications, automotive systems | Pros: Versatile, can handle high voltages. Cons: Slower response time, potential mechanical failure. |

| DIP Switch | Small, multi-position switches; often used in arrays | Electronics, embedded systems | Pros: Compact, easy to configure. Cons: Manual adjustment needed, limited to low power applications. |

| Smart Switch | Integrates with IoT; allows for app-based control | Home automation, energy management | Pros: Energy-efficient, remote monitoring. Cons: Requires internet, security vulnerabilities. |

What Are the Characteristics of Mechanical Switches and Their Suitability for B2B Buyers?

Mechanical switches are simple devices that rely on manual operation. They are commonly found in industrial machinery and HVAC systems, where reliability is paramount. Their straightforward design makes them cost-effective, but they may require frequent maintenance due to wear and tear. B2B buyers should consider the operational environment, as mechanical switches may not be suitable for highly automated or remote applications.

How Do Electronic Switches Enhance Automation in B2B Applications?

Electronic switches utilize electronic signals for operation, which allows for high precision and remote control capabilities. They are ideal for smart buildings and automation systems, providing seamless integration with other electronic devices. Although they come with a higher initial investment, their long-term efficiency and reduced labor costs make them an attractive option for businesses looking to modernize operations. Buyers should evaluate their existing infrastructure to ensure compatibility.

What Role Do Relay Switches Play in Telecommunications and Automotive Systems?

Relay switches are electromechanical devices that control circuits through coils. They are widely used in telecommunications and automotive systems due to their ability to handle high voltages and currents. While they offer versatility, relay switches can have a slower response time and may be prone to mechanical failure. B2B buyers should assess the critical nature of the application and consider whether speed or reliability is more important.

Why Are DIP Switches Valuable for Electronics and Embedded Systems?

DIP (Dual In-line Package) switches are compact, multi-position switches that are often used in electronics and embedded systems. Their small size makes them ideal for devices with limited space. While they are easy to configure, DIP switches require manual adjustment, which can be a drawback in environments that demand frequent changes. B2B buyers should weigh the need for compactness against the operational efficiency of their systems.

What Advantages Do Smart Switches Offer for Energy Management in B2B Settings?

Smart switches are designed for integration with IoT devices, allowing for app-based control and monitoring. They are particularly beneficial in home automation and energy management applications. These switches can significantly enhance energy efficiency, but their reliance on internet connectivity raises concerns about security vulnerabilities. B2B buyers should consider the potential for energy savings against the risks associated with networked devices when making purchasing decisions.

Key Industrial Applications of mean switch

| Industry/Sector | Specific Application of mean switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Network Switching Equipment | Enhanced network reliability and reduced downtime | Supplier reputation, compliance with international standards |

| Manufacturing | Automation in Production Lines | Increased efficiency and reduced labor costs | Availability of technical support, customization options |

| Transportation & Logistics | Rail Switching Systems | Improved safety and optimized logistics operations | Durability, compatibility with existing infrastructure |

| Energy & Utilities | Power Distribution Systems | Enhanced energy management and reduced operational costs | Energy efficiency certifications, local regulations compliance |

| Agriculture | Irrigation Control Systems | Improved water management and crop yield optimization | Availability of localized support, environmental impact assessments |

How is the Mean Switch Used in Telecommunications?

In telecommunications, mean switches are integral to network switching equipment. They facilitate the routing of data across various channels, ensuring efficient communication. By implementing mean switches, businesses can significantly enhance network reliability and minimize downtime, which is crucial for maintaining service quality. International buyers should consider suppliers with a strong reputation and compliance with international standards to ensure compatibility and performance.

What Role Does Mean Switch Play in Manufacturing?

In the manufacturing sector, mean switches are used to automate production lines, allowing for seamless transitions between processes. This automation increases operational efficiency and reduces labor costs, enabling companies to scale operations effectively. Buyers should prioritize sourcing mean switches that offer robust technical support and customization options to fit specific production needs, especially in diverse markets across Africa and South America.

How Do Mean Switches Improve Safety in Transportation & Logistics?

Mean switches are vital in rail switching systems, enhancing safety and optimizing logistics operations. They allow trains to switch tracks seamlessly, reducing the risk of accidents and improving the efficiency of freight transport. For international buyers, sourcing durable mean switches that are compatible with existing railway infrastructure is essential, as this ensures long-term operational reliability.

In What Ways Do Mean Switches Contribute to Energy Management?

In the energy and utilities sector, mean switches are essential in power distribution systems. They help manage electrical loads effectively, leading to enhanced energy management and reduced operational costs. Buyers in this sector should focus on sourcing switches that meet energy efficiency certifications and comply with local regulations, ensuring that their operations are both cost-effective and sustainable.

How Can Mean Switches Optimize Irrigation in Agriculture?

Mean switches are increasingly used in irrigation control systems within the agriculture industry. They allow for precise control over water distribution, leading to improved water management and optimized crop yields. International buyers should consider the availability of localized support and conduct environmental impact assessments when sourcing mean switches, ensuring that their agricultural practices align with sustainable development goals.

3 Common User Pain Points for ‘mean switch’ & Their Solutions

Scenario 1: Difficulty in Integrating Mean Switch into Existing Systems

The Problem: Many international B2B buyers encounter significant hurdles when attempting to integrate mean switch technology into their existing systems. This challenge is particularly pronounced in regions with varying levels of technology infrastructure, such as parts of Africa and South America. Buyers often face compatibility issues with legacy systems, which can result in downtime, increased costs, and frustration among team members who are eager to see the benefits of the new technology. The lack of technical expertise in-house can further complicate the integration process, leading to delays and inefficiencies.

The Solution: To overcome integration challenges, it is crucial for B2B buyers to conduct a thorough needs assessment before selecting a mean switch solution. Begin by mapping out existing systems and identifying integration points. Engage with vendors who offer comprehensive support, including technical assistance during the setup phase. Additionally, consider solutions that provide APIs or are designed for ease of integration with legacy systems. Investing in training for your IT team can also facilitate smoother integration, ensuring that they possess the skills necessary to troubleshoot any issues that arise. Furthermore, establish a phased implementation plan to minimize disruptions, allowing for adjustments based on feedback from the initial deployment.

Scenario 2: Lack of Understanding of Mean Switch Capabilities

The Problem: A common pain point for B2B buyers is the insufficient understanding of the full capabilities of mean switch technology. Many companies are unaware of how mean switches can optimize their operations, leading to underutilization of features. This is especially true in industries that are traditionally less tech-savvy or in regions where educational resources about emerging technologies are scarce. As a result, businesses may fail to leverage the potential cost savings and efficiency improvements that mean switches can provide.

The Solution: To bridge the knowledge gap, B2B buyers should actively seek out educational resources and training opportunities. This can include attending industry webinars, workshops, or trade shows focused on mean switch technology. Additionally, collaborating with vendors who can provide tailored demonstrations and use-case scenarios specific to your industry can enhance understanding. Encourage your team to participate in discussions and forums where they can learn from peers who have successfully implemented mean switches. Developing a culture of continuous learning will empower your staff to utilize the technology more effectively and innovate processes that can lead to significant operational improvements.

Scenario 3: Navigating Regulatory Compliance with Mean Switch Implementations

The Problem: For B2B buyers operating in regions with stringent regulatory requirements, navigating compliance issues when implementing mean switch technology can be a daunting task. This is particularly relevant in sectors such as telecommunications and energy, where regulations can vary significantly by country or region. Failure to comply with these regulations can result in hefty fines, project delays, and damage to the company’s reputation.

The Solution: To ensure compliance, it is essential for buyers to conduct thorough research into the regulatory landscape relevant to mean switch technology in their respective regions. Engaging legal and compliance experts early in the planning process can provide invaluable insights into what is required. Additionally, choose vendors who are familiar with compliance issues and can assist in ensuring that their products meet necessary standards. Regularly review compliance requirements as regulations can change, and maintaining open communication with regulatory bodies can help preemptively address any concerns. Implementing a compliance checklist specific to mean switch technology will also help in tracking adherence throughout the implementation process, ensuring that your organization remains in good standing.

Strategic Material Selection Guide for mean switch

When selecting materials for mean switches, international B2B buyers must consider a variety of factors that impact performance, cost, and compliance with regional standards. Below is a detailed analysis of four common materials used in mean switches, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Plastic in Mean Switch Applications?

Plastic, particularly thermoplastics like polycarbonate and polypropylene, is widely used in mean switches due to its versatility and lightweight nature.

- Key Properties: Plastics generally have good electrical insulation properties and can withstand temperatures up to 120°C. They are resistant to corrosion and can be molded into complex shapes.

- Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing, allowing for high-volume production. However, plastics may not perform well under extreme temperatures or mechanical stress, leading to potential failures in demanding environments.

- Impact on Application: Plastics are suitable for non-corrosive environments and applications requiring lightweight components. However, they may not be suitable for high-temperature or high-pressure applications.

- Considerations for International Buyers: Buyers should ensure that the selected plastic complies with regional standards such as ASTM or DIN. In regions like Africa and South America, the availability of specific plastic grades may vary, affecting procurement strategies.

How Does Metal Compare as a Material for Mean Switches?

Metals, such as stainless steel and brass, are frequently used in mean switches due to their strength and durability.

- Key Properties: Metals typically offer high mechanical strength, excellent thermal conductivity, and resistance to wear and corrosion, especially in the case of stainless steel.

- Pros & Cons: The key advantage of using metal is its durability and reliability in harsh environments. However, metals can be more expensive to manufacture and may require additional treatments (like plating) to enhance corrosion resistance.

- Impact on Application: Metals are ideal for applications involving high temperatures and pressures, making them suitable for industrial environments. However, their weight can be a disadvantage in applications where lightweight components are preferred.

- Considerations for International Buyers: Compliance with international standards such as JIS or ASTM is crucial. Buyers should also consider the sourcing of metals, as fluctuations in global metal prices can impact overall costs.

What Role Does Ceramic Play in Mean Switch Design?

Ceramics are increasingly being used in specialized mean switch applications due to their unique properties.

- Key Properties: Ceramics exhibit excellent thermal stability, high hardness, and resistance to chemical corrosion. They can operate effectively at temperatures exceeding 200°C.

- Pros & Cons: The primary advantage of ceramics is their ability to withstand extreme environments without degrading. However, ceramics are brittle and can be prone to cracking under mechanical stress, which limits their applications.

- Impact on Application: Ceramics are suitable for high-temperature applications and environments where chemical exposure is a concern. However, their fragility may restrict their use in dynamic applications.

- Considerations for International Buyers: Buyers must ensure that ceramic components meet relevant international standards and consider the logistics of sourcing and transporting fragile materials.

How Do Composites Enhance Mean Switch Performance?

Composite materials, often a combination of plastics and metals, are becoming popular in mean switch applications.

- Key Properties: Composites combine the lightweight nature of plastics with the strength of metals, offering enhanced performance in various conditions.

- Pros & Cons: The key advantage of composites is their tailored properties, allowing for specific performance characteristics. However, they can be more complex and costly to manufacture, which may deter some buyers.

- Impact on Application: Composites are suitable for applications where both strength and weight savings are critical, such as in aerospace and automotive industries. However, their manufacturing complexity can lead to longer lead times.

- Considerations for International Buyers: Buyers should be aware of the specific certifications required for composites and ensure that suppliers can meet these standards consistently.

| Material | Typical Use Case for mean switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Lightweight switches in consumer electronics | Low cost and easy to manufacture | Limited performance under extreme conditions | Low |

| Metal | Heavy-duty industrial switches | High durability and strength | Higher manufacturing costs | High |

| Ceramic | High-temperature applications | Excellent thermal stability | Brittle and prone to cracking | Medium |

| Composite | Aerospace and automotive switches | Tailored properties for performance | Complex and costly to manufacture | High |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in mean switches, helping them make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mean switch

What Are the Key Stages in the Manufacturing Process of a Mean Switch?

The manufacturing process of a mean switch involves several critical stages that ensure the device meets the necessary functional and safety standards. Understanding these stages can help B2B buyers assess the reliability and quality of potential suppliers.

Material Preparation: What Materials Are Used for Mean Switches?

The first step in manufacturing a mean switch is material preparation. Common materials include:

- Conductive Metals: Copper and aluminum are often used for their excellent electrical conductivity.

- Insulating Materials: Plastics and ceramics are selected for their insulating properties to prevent electrical leakage.

- Mechanical Components: Springs and levers made from durable metals are integral for the switch’s operational mechanisms.

Buyers should inquire about the sourcing and quality of these materials, as they directly impact the switch’s performance and longevity.

How Are Mean Switches Formed and Assembled?

Following material preparation, the next phase is forming and assembling the components. This involves several techniques:

- Stamping: Used to create the metal parts of the switch. High-precision stamping ensures uniformity and reduces material waste.

- Injection Molding: This technique is employed to create plastic housing and insulation components. It allows for complex shapes that enhance the switch’s functionality.

- Assembly: Components are assembled using automated machinery or manual labor, depending on the complexity of the switch design. Automated assembly can enhance consistency and reduce labor costs.

Buyers should consider the automation level in the manufacturing process, as higher automation often correlates with fewer defects and lower costs.

What Finishing Techniques Are Commonly Used for Mean Switches?

Once the assembly is complete, finishing processes are applied to enhance the switch’s durability and aesthetics. Common finishing techniques include:

- Surface Treatment: Processes like electroplating or anodizing improve corrosion resistance and electrical conductivity.

- Quality Coating: Applying a protective coating helps to prevent wear and tear, especially in environments with high humidity or exposure to chemicals.

- Labeling and Branding: Proper labeling ensures compliance with regulatory standards and enhances product traceability.

Understanding the finishing techniques can help buyers determine the longevity and maintenance requirements of the switches.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in manufacturing, especially for electrical devices like mean switches. Buyers must ensure that suppliers adhere to relevant international standards.

Which International Standards Are Relevant for Mean Switch Manufacturing?

- ISO 9001: This standard sets the criteria for a quality management system. It helps ensure that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking signifies conformity with health, safety, and environmental protection standards.

- API Standards: If the switches are used in oil and gas applications, compliance with API standards ensures safety and reliability.

Buyers from Africa, South America, the Middle East, and Europe should verify that their suppliers meet these standards to avoid potential legal and operational issues.

What Are the Key Quality Control Checkpoints in Mean Switch Manufacturing?

Quality control (QC) is integrated into various stages of manufacturing to catch defects early and ensure compliance with standards. Key QC checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify and rectify issues before they escalate.

- Final Quality Control (FQC): This final inspection assesses the completed switches for functionality, safety, and compliance with specifications.

B2B buyers should inquire about the frequency and methodology of these inspections to gauge the supplier’s commitment to quality.

What Testing Methods Are Commonly Used for Mean Switches?

Testing is crucial for verifying the performance and safety of mean switches. Common testing methods include:

- Electrical Testing: Measures conductivity, insulation resistance, and operational performance under various conditions.

- Mechanical Testing: Assesses the durability of physical components, such as spring tension and switch actuation force.

- Environmental Testing: Evaluates how well switches perform under extreme temperatures, humidity, and exposure to corrosive substances.

Buyers should request detailed testing reports to ensure that products have been rigorously evaluated.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are effective methods:

- Audits: Conducting supplier audits can provide insights into their quality management practices. Buyers can assess whether suppliers adhere to relevant standards and maintain their QC processes.

- Quality Reports: Requesting regular quality reports can help buyers track performance trends and identify any recurring issues.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing process and product quality.

Buyers should establish a clear communication channel with suppliers to facilitate these quality verification processes.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing mean switches, buyers must be aware of specific nuances related to quality control and certification:

- Regional Regulations: Different regions may have unique regulations affecting quality standards. Understanding these can help avoid compliance issues.

- Certification Validity: Ensure that the certifications held by suppliers are up-to-date and relevant to the specific product being purchased.

- Cultural Considerations: Recognize that quality perception may vary across regions. Building strong relationships with suppliers can help bridge these gaps.

By being informed about these nuances, B2B buyers can make more confident purchasing decisions and mitigate risks associated with product quality.

In conclusion, understanding the manufacturing processes and quality assurance protocols for mean switches is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By focusing on material preparation, manufacturing stages, quality standards, and testing methods, buyers can significantly enhance their procurement strategies and ensure they source high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mean switch’

To assist international B2B buyers in the procurement of ‘mean switch’, this practical sourcing guide outlines essential steps to ensure a successful sourcing process. This checklist will help you navigate through the complexities of selecting the right switch for your specific business needs.

Step 1: Define Your Technical Specifications

Before initiating any procurement process, it’s vital to clearly define the technical specifications of the mean switch you require. This includes understanding the electrical requirements, dimensions, compatibility with existing systems, and any specific features needed for your operations.

– Consider factors such as: voltage ratings, current ratings, and the type of control mechanism (manual, automatic, etc.).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in mean switches. Utilize online marketplaces, industry directories, and trade shows to compile a list of vendors.

– Key considerations include: supplier reputation, product range, and market presence in your region (Africa, South America, the Middle East, or Europe).

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is crucial to ensure compliance with international standards. Check for certifications such as ISO 9001 for quality management and any specific electrical safety standards relevant to your region.

– Look for: proof of compliance with regional regulations, which can vary significantly across continents.

Step 4: Request Samples and Technical Documentation

Before making a bulk purchase, request samples of the mean switch and any accompanying technical documentation. This will allow you to assess the quality of the product firsthand and ensure that it meets your specifications.

– Documentation to request includes: user manuals, installation guides, and technical data sheets.

Step 5: Compare Pricing and Payment Terms

Once you have narrowed down your options, compare pricing structures and payment terms from different suppliers. Ensure that you are getting value for your investment while also considering the total cost of ownership, which includes installation, maintenance, and potential downtime.

– Important factors: negotiate payment terms that are favorable to your cash flow, such as extended payment periods or discounts for early payments.

Step 6: Check References and Customer Reviews

Before finalizing your decision, reach out to other businesses that have previously worked with the suppliers you are considering. Customer reviews and references can provide insights into the supplier’s reliability, product quality, and after-sales support.

– Questions to ask: How responsive is the supplier to issues? Did they meet delivery timelines?

Step 7: Finalize Contract Terms and Conditions

Once you have selected a supplier, ensure that all terms and conditions are clearly defined in a written contract. This should include delivery schedules, warranty details, and after-sales support commitments.

– Be clear about: penalties for non-compliance and procedures for returns or exchanges in case the product does not meet your expectations.

By following this step-by-step checklist, international B2B buyers can make informed decisions when sourcing mean switches, ultimately leading to successful procurement outcomes that meet their operational needs.

Comprehensive Cost and Pricing Analysis for mean switch Sourcing

What Are the Key Cost Components in Mean Switch Sourcing?

When sourcing mean switches, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The quality and type of materials significantly impact cost. Common materials for mean switches include various metals and plastics, which can vary in price based on market fluctuations and availability.

-

Labor: Labor costs can vary by region and manufacturing process. Skilled labor in countries with higher wage standards will increase the overall cost. It’s important to consider the labor efficiency of the supplier.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and indirect labor. Efficient manufacturing processes can help lower these costs.

-

Tooling: Tooling costs are associated with the equipment required for production. Custom tooling may be necessary for specific designs, which can add to upfront expenses.

-

Quality Control (QC): Implementing a robust QC process ensures the reliability of the switches. Suppliers that invest in quality management systems may charge more, but this can lead to lower defect rates and better performance.

-

Logistics: Shipping costs can fluctuate based on distance, shipping method, and current fuel prices. Incoterms also play a significant role in defining who bears these costs.

-

Margin: Suppliers will apply a profit margin to cover their costs and generate profit. This can vary widely depending on the supplier’s market position and the competitiveness of the product.

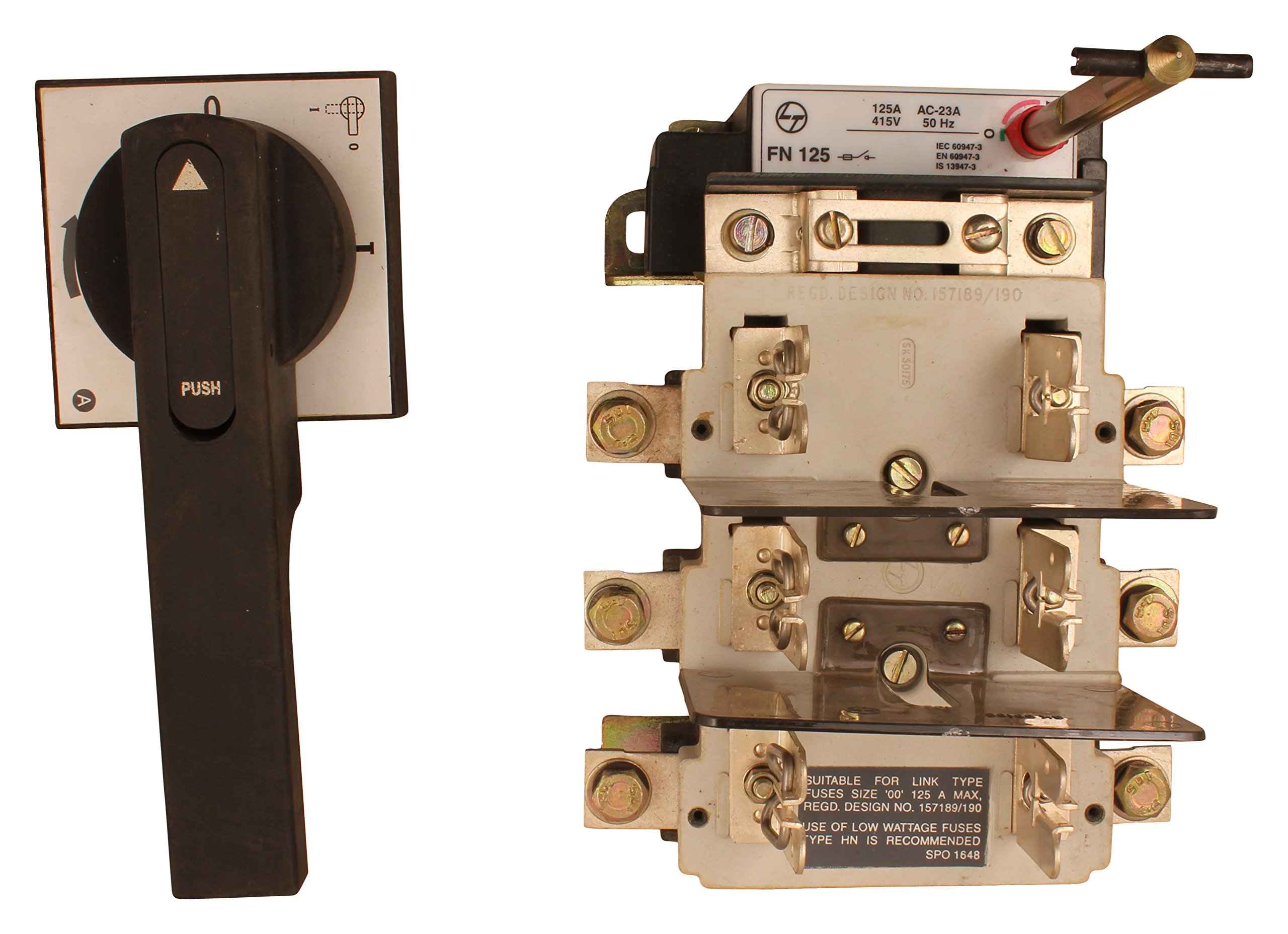

A stock image related to mean switch.

How Do Price Influencers Affect Mean Switch Costs?

Several factors can influence the pricing of mean switches, which international B2B buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract discounts. Understanding a supplier’s MOQ is essential to calculate total costs effectively.

-

Specifications and Customization: Custom switches designed to meet specific requirements may incur higher costs due to additional design and production efforts.

-

Materials: The choice of materials can significantly affect pricing. For instance, switches made from specialized materials may have a premium price tag.

-

Quality and Certifications: Compliance with international standards (e.g., ISO certifications) can elevate costs but assures buyers of the product’s quality and reliability.

-

Supplier Factors: Relationships with suppliers, their geographical location, and their operational efficiencies can all influence pricing. A local supplier might offer better logistics costs but may not have the same pricing flexibility as an overseas supplier.

-

Incoterms: These terms define responsibilities and costs for shipping. Understanding the implications of each term can help buyers make more informed purchasing decisions.

What Are the Best Negotiation Tips for B2B Buyers in Mean Switch Sourcing?

Negotiating effectively can lead to cost savings and better terms. Here are some actionable tips for international buyers, particularly from regions like Africa, South America, the Middle East, and Europe:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the upfront price, but also long-term costs associated with maintenance, energy efficiency, and lifespan. This holistic view can justify a higher initial investment.

-

Leverage Market Research: Being informed about market prices and competitor offerings enables buyers to negotiate more effectively. Collect data on recent trends in mean switch pricing.

-

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time. Suppliers are often more willing to negotiate with partners they trust.

-

Be Clear About Requirements: Clearly communicate specifications and expectations. This reduces misunderstandings and helps suppliers provide accurate pricing.

-

Explore Multiple Suppliers: Having alternatives can strengthen your negotiating position. It allows you to compare offers and choose the best value for your requirements.

Conclusion: What Should Buyers Keep in Mind?

While sourcing mean switches, international buyers must navigate a complex cost structure influenced by various factors. Understanding these elements will empower buyers to make informed decisions that align with their budget and quality requirements. Always consider the indicative nature of prices, as they can vary significantly based on the aforementioned components and regional factors.

Alternatives Analysis: Comparing mean switch With Other Solutions

When evaluating options for a business solution, understanding the alternatives to a product or method can help B2B buyers make informed decisions. In the context of the ‘mean switch’, it’s essential to compare it with other viable solutions that serve similar functions. This analysis will focus on two alternative solutions: Multi-Channel Switching Systems and Integrated Circuit Solutions.

| Comparison Aspect | Mean Switch | Multi-Channel Switching Systems | Integrated Circuit Solutions |

|---|---|---|---|

| Performance | High reliability and speed | Excellent for high-volume data | High efficiency in processing |

| Cost | Moderate initial investment | Higher upfront costs | Generally lower due to mass production |

| Ease of Implementation | Requires technical expertise | Complex setup | Easier integration into existing systems |

| Maintenance | Regular updates needed | Higher maintenance requirements | Low maintenance |

| Best Use Case | Simple data transfer and routing | Large-scale data management | Complex processing applications |

What are Multi-Channel Switching Systems and Their Benefits?

Multi-Channel Switching Systems are designed to handle a high volume of data across various channels simultaneously. They excel in environments where rapid data transfer and switching are critical, such as telecommunications and data centers. The primary advantage of this system is its capacity for handling large datasets with minimal latency. However, the complexity of setup and higher initial costs can be a drawback for smaller businesses or those with limited budgets.

How Do Integrated Circuit Solutions Compare?

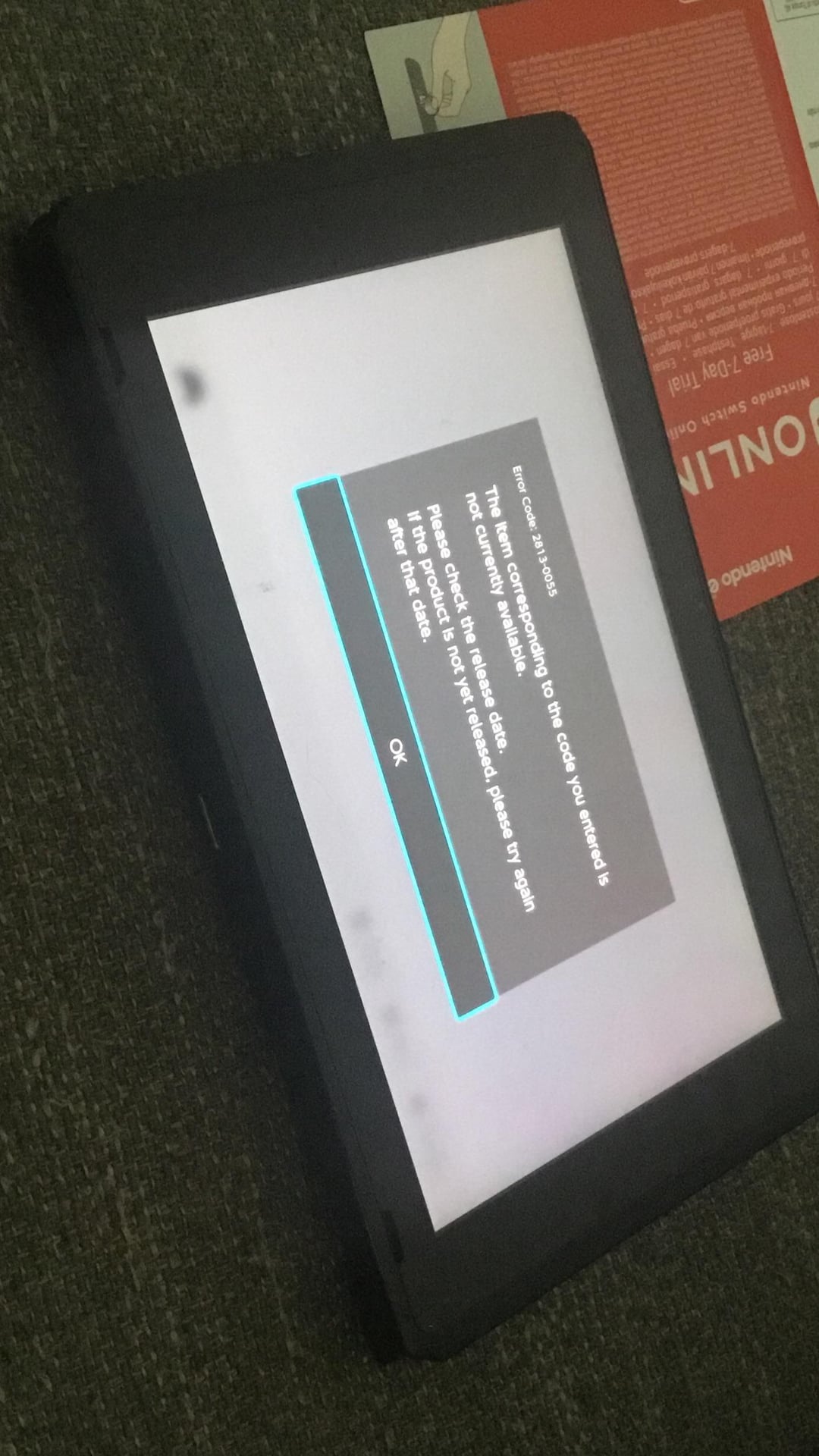

A stock image related to mean switch.

Integrated Circuit Solutions, often found in modern electronic devices, provide a compact and efficient means of processing data. These solutions are typically easier to integrate into existing systems, making them attractive for businesses looking to upgrade without overhauling their entire infrastructure. The lower maintenance needs also add to their appeal. However, their performance might not match the speed of dedicated switching systems, particularly in high-demand scenarios.

How Can B2B Buyers Choose the Right Solution?

When deciding between ‘mean switch’ and its alternatives, B2B buyers should consider their specific operational needs and constraints. If speed and reliability are paramount in high-volume environments, Multi-Channel Switching Systems may be the best fit despite their complexity. Conversely, for businesses looking for a cost-effective and easy-to-implement solution, Integrated Circuit Solutions may offer the right balance of performance and efficiency. Ultimately, understanding the unique requirements of your business will guide you in selecting the most appropriate solution.

Essential Technical Properties and Trade Terminology for mean switch

A stock image related to mean switch.

What Are the Essential Technical Properties of a Mean Switch?

Understanding the technical properties of a mean switch is crucial for B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe. Here are the key specifications to consider:

1. Material Grade

The material grade of a mean switch significantly affects its durability and performance. Common materials include high-grade plastics and metals like brass or stainless steel. Selecting the right material is essential for ensuring the switch can withstand environmental conditions such as humidity, temperature fluctuations, and mechanical stress. For buyers, this means sourcing switches that meet specific operational requirements, thus minimizing maintenance costs and downtime.

2. Electrical Rating

The electrical rating, often specified in volts and amps, indicates the maximum electrical load a switch can handle. This property is critical for ensuring that the switch will function properly within the intended application. Buyers must ensure that the electrical rating aligns with their machinery or equipment to avoid failures that could lead to costly repairs or safety hazards.

3. Tolerance Levels

Tolerance refers to the permissible limits of variation in the dimensions and performance of the switch. High tolerance levels ensure that the switch functions correctly within specified parameters, which is vital in precision applications. For B2B buyers, understanding tolerance is essential for selecting switches that will seamlessly integrate with existing systems, thereby improving operational efficiency.

4. Actuation Mechanism

The actuation mechanism describes how the switch is activated (e.g., toggle, push-button, rotary). The choice of actuation mechanism can influence user experience and operational efficiency. Buyers should consider how the switch will be used in their applications and choose an actuation type that best suits their operational needs.

5. Lifecycle and Reliability

The lifecycle of a mean switch indicates its expected operational lifespan, which is important for planning maintenance and replacements. Reliable switches reduce the frequency of replacements, leading to cost savings over time. Buyers should seek switches with proven reliability metrics, particularly for critical applications where downtime is not an option.

6. Environmental Ratings

Environmental ratings, such as IP (Ingress Protection) ratings, indicate the switch’s resistance to dust and water. This is particularly important for installations in harsh environments. Buyers must ensure that the switches meet the necessary environmental standards to prevent failures caused by external conditions.

Which Trade Terms Should B2B Buyers Understand When Sourcing Mean Switches?

Navigating the procurement process can be complex, especially with specific trade terminology. Here are essential terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source mean switches that are compatible with their existing systems or machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for budgeting and inventory management. Buyers should clarify MOQs to avoid overcommitting to stock that may not be needed.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. This process allows buyers to compare costs and negotiate better terms. It’s essential for securing competitive pricing and ensuring budget adherence.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for managing logistics, costs, and risks associated with international trade.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. Buyers should be aware of lead times to plan their projects effectively and avoid delays in production or implementation.

6. Certification Standards

Certification standards indicate compliance with specific industry regulations or quality benchmarks. Familiarity with these standards helps buyers ensure that the switches meet necessary safety and performance criteria, which is particularly important in regulated markets.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that they select the right mean switches for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the mean switch Sector

What Are the Key Market Drivers in the Mean Switch Sector?

The mean switch sector is experiencing significant growth, driven by various global factors. One of the primary drivers is the increasing demand for automation across industries, which necessitates reliable and efficient switching mechanisms. As businesses strive for operational efficiency, the integration of smart technologies and IoT devices has become critical, thus elevating the need for advanced mean switches that can handle complex electrical circuits and provide seamless connectivity.

Emerging trends also highlight a shift towards digital solutions in mean switch applications. The rise of Industry 4.0 and smart manufacturing is influencing the design and functionality of mean switches, making them integral to modern industrial systems. International B2B buyers, particularly from regions like Africa and South America, should pay attention to suppliers who offer adaptable and scalable solutions that can meet the specific requirements of their local markets.

In addition to automation, sustainability initiatives are shaping sourcing decisions. Buyers are increasingly looking for products that not only meet technical specifications but also comply with environmental standards. This trend is particularly pronounced in Europe, where regulatory pressures are driving manufacturers to innovate and produce eco-friendly switching solutions.

How Can Sustainability and Ethical Sourcing Influence Your Purchasing Decisions?

Sustainability is no longer a secondary consideration but a core aspect of the B2B purchasing process in the mean switch sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek out suppliers who prioritize ethical sourcing and sustainability. This includes evaluating the lifecycle of products and their materials, ensuring that they are recyclable and produced with minimal ecological footprints.

Ethical supply chains are essential for fostering trust and transparency in business relationships. Suppliers that demonstrate a commitment to sustainable practices are more likely to attract international buyers who value corporate responsibility. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s dedication to ethical practices in the production of mean switches.

Furthermore, the demand for ‘green’ materials is rising. Buyers should inquire about the use of sustainable materials in mean switch production, including alternatives that reduce environmental harm. By prioritizing suppliers with strong sustainability credentials, buyers can enhance their brand reputation and appeal to an increasingly eco-conscious market.

What Is the Brief History and Evolution of Mean Switch Technology?

The evolution of mean switch technology has been influenced by advancements in electrical engineering and the growing complexity of electrical systems. Initially, switches were simple mechanical devices designed to turn circuits on and off. However, as electrical applications became more sophisticated, the demand for more versatile switching solutions emerged.

In the late 20th century, the introduction of digital technology revolutionized the mean switch sector. The development of microcontroller-based switches allowed for greater control and flexibility, paving the way for smart switches that integrate seamlessly with automation systems. This transformation has enabled businesses across sectors to enhance operational efficiency and connectivity.

Today, the mean switch sector continues to evolve with innovations in materials and design, responding to the increasing demands for sustainability and smart technology integration. For international B2B buyers, understanding this historical context is crucial for making informed purchasing decisions that align with current market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of mean switch

-

How do I choose the right mean switch for my business needs?

Selecting the appropriate mean switch involves evaluating several key factors, including the specific applications you intend to use it for, the required voltage and current ratings, and any environmental conditions it must withstand. Consider consulting with suppliers who can provide technical specifications and offer insights based on industry standards. Additionally, reviewing customer feedback and case studies can help you understand how different switches perform in real-world scenarios, ensuring you make an informed decision that aligns with your operational requirements. -

What is the best way to source a reliable mean switch supplier?

Start by conducting thorough research to identify potential suppliers. Look for manufacturers with a strong reputation in the industry, verified certifications, and positive customer reviews. Attending trade shows and industry conferences can also provide networking opportunities to meet suppliers face-to-face. Consider utilizing platforms like Alibaba or ThomasNet to find verified suppliers. Always request samples and conduct quality checks before committing to larger orders, as this helps ensure that the supplier can meet your quality and reliability standards. -

What customization options are available for mean switches?

Many manufacturers offer customization options for mean switches, including size, shape, and electrical specifications. Depending on your specific needs, you can request features such as weatherproofing, different mounting styles, or specific terminal types. It’s essential to communicate your requirements clearly to the supplier, as this ensures they can provide a solution that meets your unique operational demands. Inquire about the lead times for customized products to align with your project timelines. -

What are the typical minimum order quantities (MOQs) for mean switches?

Minimum order quantities for mean switches can vary significantly between suppliers, typically ranging from 100 to 1,000 units. Smaller suppliers may offer lower MOQs, while larger manufacturers may require higher volumes to justify production costs. When negotiating with suppliers, consider discussing your anticipated future needs, as they may offer more favorable terms for long-term partnerships. If you are unsure about your needs, some suppliers may provide a sample order to help you assess the product before committing to larger quantities. -

What payment terms should I expect when purchasing mean switches internationally?

Payment terms can differ based on supplier policies and the nature of your agreement. Common options include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days). When dealing with international suppliers, it’s crucial to clarify these terms upfront to avoid misunderstandings. Additionally, consider utilizing secure payment methods such as PayPal or escrow services to protect your investment, especially when dealing with new suppliers. -

How can I ensure quality assurance (QA) for mean switches?

Establishing a robust quality assurance process is vital when sourcing mean switches. Request detailed specifications and quality certifications (like ISO 9001) from your suppliers. Conduct factory visits or audits when feasible, and consider third-party inspection services to verify product quality before shipment. Moreover, implementing a clear return policy and warranty terms can protect your business in case of defective products, allowing for replacements or refunds as necessary. -

What logistics considerations should I be aware of when importing mean switches?

Logistics play a critical role in international sourcing. Be aware of shipping methods (air vs. sea freight), which can impact delivery times and costs. Understand customs regulations and duties in your country, as these can affect overall expenses. Collaborating with a reliable freight forwarder can streamline the process, helping you navigate paperwork and ensuring timely delivery. Always factor in lead times for manufacturing and shipping when planning your procurement schedule. -

What are the common challenges faced when sourcing mean switches internationally?

International sourcing of mean switches can present challenges such as language barriers, varying quality standards, and differences in regulatory compliance. Additionally, time zone differences can complicate communication and negotiation processes. To mitigate these issues, establish clear communication channels with your suppliers and consider hiring local representatives who understand the market. Conducting thorough due diligence and maintaining a flexible approach can help navigate these challenges effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mean switch

As the global market for mean switches continues to evolve, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging strategic sourcing, businesses can enhance their operational efficiency, reduce costs, and ensure a reliable supply chain. This is particularly important for buyers in diverse regions such as Africa, South America, the Middle East, and Europe, where varying market dynamics and regulatory environments can impact procurement strategies.

How Can International Buyers Leverage Strategic Sourcing for Mean Switches?

Understanding the unique needs of your market and aligning them with the right suppliers can lead to significant advantages. Buyers should focus on establishing long-term partnerships with manufacturers that demonstrate reliability and innovation. Additionally, adopting a data-driven approach to sourcing can help identify the best opportunities for cost savings and quality improvements.

What Does the Future Hold for Mean Switches in B2B Markets?

Looking ahead, the demand for mean switches is expected to grow, driven by advancements in technology and increasing applications across various industries. International B2B buyers should remain proactive, continuously exploring new suppliers and technologies that can enhance their offerings.

In conclusion, embracing strategic sourcing practices not only prepares businesses for future challenges but also positions them to capitalize on emerging opportunities. Engage with your suppliers today to ensure you remain competitive in this dynamic landscape.