Unlock Savings: The Complete Guide to Type I Outlet (2025)

Introduction: Navigating the Global Market for type i outlet

Navigating the complexities of the global market for Type I outlets can present significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the specifications, applications, and regional variations of Type I outlets is crucial for businesses looking to source reliable and compliant electrical solutions. This guide delves into the intricacies of Type I outlets, detailing their design characteristics, compatibility with various electrical systems, and the nuances of sourcing from different global suppliers.

B2B buyers will find actionable insights on identifying reputable manufacturers, evaluating cost structures, and ensuring compliance with local regulations. Additionally, the guide addresses essential considerations such as the electrical standards prevalent in countries like Australia, New Zealand, and parts of Asia, where Type I outlets are commonly used. By equipping buyers with the knowledge needed to navigate the sourcing process effectively, this comprehensive resource empowers them to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are expanding your supply chain or simply looking to optimize your current operations, understanding the nuances of Type I outlets is vital. This guide serves as an essential tool for international buyers seeking to enhance their electrical infrastructure while ensuring safety and compliance in their respective markets.

Understanding type i outlet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type I 10A | Two flat blades at 30° angle, 1.6 mm thick, 10A rating | General electronics, appliances | Pros: Widely used in Australia and New Zealand. Cons: Limited to 10A devices. |

| Type I 15A | Similar design to 10A but with a wider ground pin (8 mm) | Heavy-duty appliances, industrial tools | Pros: Compatible with 10A plugs. Cons: Not compatible with 10A sockets. |

| Type I 20A | Wider prongs than 15A, designed for higher power applications | Commercial equipment, HVAC systems | Pros: Supports high power loads. Cons: Limited availability in some regions. |

| Type I Un-earthed | Two flat prongs, no ground pin, used for double-insulated devices | Lightweight electronics | Pros: Useful for devices that don’t require grounding. Cons: Less safe for high power applications. |

| Type I 32A | Even wider prongs, designed for very high power applications | Industrial machinery, large equipment | Pros: Suitable for heavy industrial use. Cons: Requires specific sockets. |

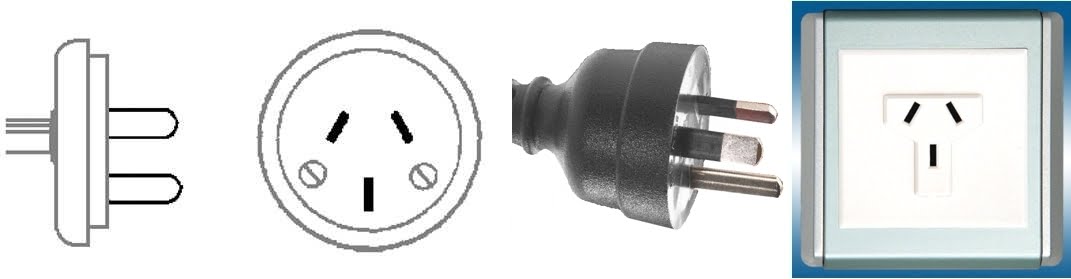

What are the Characteristics of the Type I 10A Outlet?

The Type I 10A outlet is characterized by its two flat blades set at a 30° angle, making it a common choice for general electronic devices and household appliances. It is primarily used in countries like Australia and New Zealand. B2B buyers should consider this outlet for typical office equipment or consumer electronics, as it is widely accepted and readily available. However, its 10A limit may restrict its use for high-power devices.

How Does the Type I 15A Outlet Differ from the 10A Version?

The Type I 15A outlet features a wider ground pin, allowing it to accommodate both 10A and 15A plugs. This versatility makes it suitable for heavy-duty appliances and industrial tools. B2B buyers should consider this option when sourcing equipment that requires higher amperage without needing to replace existing sockets. However, it is important to note that 15A plugs will not fit into standard 10A sockets, which could lead to compatibility issues.

What are the Applications of the Type I 20A Outlet?

Designed for higher power applications, the Type I 20A outlet has wider prongs than its 15A counterpart. This outlet is ideal for commercial equipment and HVAC systems that demand more power. B2B buyers looking for outlets to support heavy machinery should consider the Type I 20A outlet, although its limited availability in certain regions may pose a challenge for procurement.

When Should Buyers Consider the Type I Un-earthed Outlet?

The Type I un-earthed outlet features two flat prongs and is designed for use with double-insulated devices. It is typically used for lightweight electronics that do not require grounding. B2B buyers should consider this option for devices like chargers and small appliances. However, the lack of grounding makes it less safe for high-power applications, which could be a critical consideration for safety-conscious businesses.

What is the Role of the Type I 32A Outlet in Industrial Settings?

The Type I 32A outlet is tailored for very high power applications, featuring even wider prongs than the 20A version. This outlet is commonly used in industrial machinery and large equipment setups. B2B buyers focused on heavy industrial use should prioritize this outlet for its capacity to handle demanding power loads. However, it is essential to ensure that the corresponding sockets are available, as compatibility can limit usage in some facilities.

Key Industrial Applications of type i outlet

| Industry/Sector | Specific Application of type i outlet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and tools in assembly lines | Ensures reliable operation of equipment, reducing downtime | Ensure compatibility with local voltage and frequency standards |

| Hospitality | Providing power in hotel rooms and conference facilities | Enhances guest experience and operational efficiency | Consider safety features and local regulations for installations |

| Telecommunications | Supporting data centers and telecom equipment | Guarantees uninterrupted service and high uptime | Evaluate the need for additional adapters or converters |

| Construction | Temporary power supply at construction sites | Facilitates the operation of tools and equipment | Assess the mobility and durability of outlet solutions |

| Healthcare | Electrical supply for medical devices and equipment | Critical for patient safety and equipment reliability | Confirm compliance with health and safety standards |

How is the Type I Outlet Used in Manufacturing?

In manufacturing, type I outlets are crucial for powering various machinery and tools on assembly lines. These outlets support a range of equipment, from heavy machinery to precision tools, ensuring that operations run smoothly. The use of type I outlets minimizes downtime due to electrical issues, which can be costly for businesses. For international buyers, it is essential to ensure that the equipment is compatible with local voltage and frequency standards, especially in regions like Africa and South America where power supply can vary.

What Role Does the Type I Outlet Play in Hospitality?

In the hospitality sector, type I outlets are commonly used to provide power in hotel rooms and conference facilities. These outlets enhance the guest experience by allowing visitors to charge devices easily and access modern amenities. Additionally, they are vital for operational efficiency in conference settings, where multiple devices may need power simultaneously. Buyers should consider the safety features of type I outlets, such as built-in switches, and ensure compliance with local regulations to avoid any safety hazards.

How is the Type I Outlet Essential for Telecommunications?

Telecommunications companies rely on type I outlets to support data centers and telecom equipment. The reliability of these outlets is paramount, as they guarantee uninterrupted service and high uptime, which are critical in today’s digital landscape. International B2B buyers should evaluate their need for additional adapters or converters when sourcing type I outlets, especially if they are operating in regions with differing electrical standards.

What is the Importance of Type I Outlets in Construction?

Type I outlets are used as temporary power supplies at construction sites, facilitating the operation of various tools and equipment. This flexibility is essential for construction projects that require mobility and adaptability in power solutions. Buyers should assess the mobility and durability of the outlet solutions to ensure they can withstand the rigors of a construction environment, particularly in developing regions where infrastructure may be less stable.

How Does the Type I Outlet Support Healthcare Equipment?

In healthcare settings, type I outlets are vital for supplying power to medical devices and equipment, playing a crucial role in patient safety and equipment reliability. The continuous operation of these devices is essential for effective healthcare delivery. International buyers must confirm that their electrical solutions comply with health and safety standards to ensure the safety of both patients and staff, particularly in regions with stringent regulatory requirements.

3 Common User Pain Points for ‘type i outlet’ & Their Solutions

Scenario 1: Navigating Voltage Compatibility Issues with Type I Outlets

The Problem: B2B buyers often face challenges when importing electronic equipment that operates on different voltage levels. For instance, a company in South America may purchase machinery designed for a 220V supply but needs to connect it to a Type I outlet in Australia, where the voltage may vary. This discrepancy can lead to equipment malfunction or damage, resulting in costly repairs and downtime.

The Solution: To mitigate voltage compatibility issues, it’s crucial for buyers to conduct thorough research on the voltage requirements of their equipment before purchasing. When sourcing Type I outlets, consider investing in voltage converters or transformers that match the specifications of the machinery. Additionally, consult local electrical standards to ensure that the equipment adheres to the voltage regulations of the destination country. Working with local suppliers who understand these dynamics can facilitate smoother transactions and ensure that all equipment is compatible upon arrival.

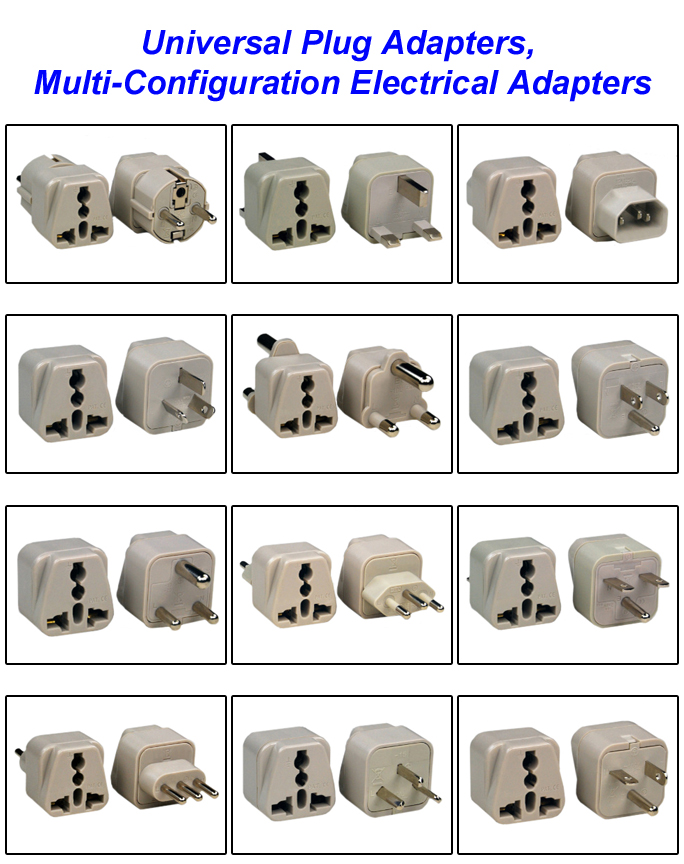

Scenario 2: Dealing with Limited Availability of Type I Adapters

The Problem: International buyers often encounter difficulties finding Type I adapters for their existing electrical equipment. For example, a business based in Europe may need to operate devices that are only compatible with Type I outlets when attending a trade show in Australia. The lack of readily available adapters can disrupt operations and prevent companies from fully utilizing their equipment.

The Solution: To address this issue, buyers should proactively source Type I adapters well in advance of their travel or operational needs. Establishing relationships with reliable suppliers who specialize in international electrical equipment can provide access to necessary adapters. Additionally, consider bulk purchasing options or investing in universal adapters that accommodate multiple plug types, including Type I. This approach not only ensures availability but also enhances operational flexibility, allowing businesses to adapt quickly to various environments.

Scenario 3: Ensuring Safety Compliance with Type I Outlets

The Problem: Ensuring safety compliance is a significant concern for B2B buyers, particularly when dealing with electrical systems across different countries. A company in Africa might import equipment that uses Type I outlets, but if the installation does not meet local electrical safety standards, it can lead to dangerous situations, including electrical fires or equipment damage.

The Solution: Buyers must prioritize safety by consulting with electrical engineers or local regulatory bodies to understand the safety standards relevant to Type I outlets in their region. Implementing a rigorous inspection process for all imported electrical equipment is essential. This includes verifying that all devices are properly grounded and that the wiring meets safety codes. Additionally, investing in professional installation services can ensure that all equipment is set up correctly and safely. Training staff on the proper use of electrical equipment and the importance of adhering to safety protocols will further enhance workplace safety and compliance.

Strategic Material Selection Guide for type i outlet

What Are the Key Materials Used in Type I Outlets?

When selecting materials for Type I outlets, international B2B buyers must consider several options that impact performance, durability, and compliance with local standards. Here, we analyze four common materials used in the manufacturing of Type I outlets: thermoplastics, metals, ceramic, and composite materials.

A stock image related to type i outlet.

How Do Thermoplastics Perform in Type I Outlets?

Thermoplastics, such as polycarbonate and nylon, are widely used in electrical outlet housings. These materials exhibit excellent electrical insulation properties and can withstand a temperature range of -40°C to 85°C, making them suitable for various environments.

Pros: They are lightweight, cost-effective, and resistant to corrosion and impact, which enhances their durability. Thermoplastics also allow for complex shapes, facilitating innovative designs.

Cons: However, thermoplastics may have lower heat resistance compared to metals and can degrade over time under UV exposure. This might limit their use in outdoor applications or areas with high sunlight exposure.

Impact on Application: Thermoplastics are ideal for residential and commercial installations in regions with moderate climates. Buyers should ensure compliance with local standards such as ASTM D638 for tensile properties.

What Are the Benefits of Using Metals in Type I Outlets?

Metals, particularly copper and aluminum, are often employed in the conductive components of Type I outlets. Copper is known for its excellent conductivity and corrosion resistance, while aluminum is lighter and less expensive.

Pros: Metal components can handle higher current loads (up to 15A or more), making them suitable for industrial applications. They also provide robustness and longevity.

Cons: On the downside, metals can corrode if not properly coated or treated, especially in humid environments. Additionally, the manufacturing complexity increases with metal components, leading to higher production costs.

Impact on Application: Metals are preferred in high-demand environments, such as factories or workshops. International buyers should consider compliance with standards like IEC 60884 for safety and performance.

Why Are Ceramics Considered for Type I Outlets?

Ceramic materials are sometimes used for the insulating components of Type I outlets due to their high thermal resistance and electrical insulation properties.

Pros: Ceramics can withstand high temperatures (up to 1,200°C) and are inherently resistant to chemical corrosion, making them suitable for harsh environments.

Cons: However, ceramics are brittle and can break under mechanical stress, which limits their application in high-impact areas. They are also more expensive than thermoplastics.

Impact on Application: Ceramics are ideal for specialized applications, such as in laboratories or industrial settings where high temperatures are common. Buyers should ensure compliance with local safety standards.

How Do Composite Materials Enhance Type I Outlets?

Composite materials, which combine thermoplastics with reinforcing fibers, offer a balance between weight, strength, and cost. These materials are increasingly popular in the electrical industry.

Pros: They provide enhanced mechanical strength and thermal stability compared to standard thermoplastics. Composites are also resistant to UV light and chemical exposure.

Cons: The main drawback is the higher manufacturing complexity and cost associated with producing composite materials. This can affect the overall pricing of the final product.

Impact on Application: Composites are suitable for outdoor applications or regions with extreme weather conditions. Buyers should verify compliance with standards such as ASTM D256 for impact resistance.

Summary of Material Selection for Type I Outlets

| Material | Typical Use Case for type i outlet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Residential and commercial installations | Lightweight and cost-effective | Lower heat resistance | Low |

| Metals | Industrial applications | Excellent conductivity and durability | Prone to corrosion | Medium |

| Ceramics | Specialized applications (labs, etc.) | High thermal resistance | Brittle and expensive | High |

| Composite Materials | Outdoor and extreme environments | Enhanced strength and UV resistance | Higher manufacturing complexity | Medium |

This strategic material selection guide provides insights into the various materials suitable for Type I outlets, enabling international B2B buyers to make informed decisions that align with their specific needs and local compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for type i outlet

What Are the Main Stages of Manufacturing Type I Outlets?

A stock image related to type i outlet.

The manufacturing process of Type I outlets involves several critical stages that ensure the final product meets safety and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing Type I outlets is selecting high-quality materials. Typically, copper is used for the prongs due to its excellent conductivity, while thermoplastic materials are chosen for the housing to provide insulation and durability. In this phase, raw materials undergo quality checks to ensure they meet specific standards, such as tensile strength and thermal resistance.

Forming Techniques for Type I Outlets

Once materials are prepared, the next phase involves forming. This includes the stamping of copper to create the prongs and the molding of thermoplastic for the outlet casing. Advanced techniques like precision stamping and injection molding are commonly employed. Precision stamping ensures the prongs are cut to exact specifications, while injection molding allows for the creation of complex shapes in the outlet casing that adhere to safety standards.

Assembly Process for Type I Outlets

After forming, the components are assembled. This stage may involve automated assembly lines where prongs are inserted into the molded casing. Automated machines ensure consistency and reduce the risk of human error. Manual assembly may also be involved, particularly for quality control checks. Each assembled outlet undergoes visual inspections to identify any defects.

Finishing Touches for Type I Outlets

The final stage is finishing, which includes processes such as plating the prongs to enhance corrosion resistance and applying any necessary labels or markings. After finishing, each outlet is subjected to a thorough cleaning process to remove any residues from manufacturing. This stage is crucial as it ensures the product is not only functional but also aesthetically pleasing.

How Is Quality Assurance Implemented in Type I Outlet Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for Type I outlets. It encompasses a series of standards and checkpoints designed to ensure that each product is safe, reliable, and compliant with international regulations.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with several international standards relevant to Type I outlets, including:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is essential for ensuring consistent product quality.

- CE Marking: This indicates that the product complies with EU safety, health, and environmental protection standards.

- API Standards: While more common in the oil and gas industry, API standards can also apply to electrical components used in hazardous environments.

Understanding these standards helps buyers assess supplier capabilities and ensure compliance with market requirements.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in Type I outlet manufacturing typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint focuses on the raw materials before they enter the production process. Suppliers provide certificates of compliance, and materials undergo testing for conductivity and durability.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken at various stages for dimensional checks and visual inspections. This step ensures that any defects can be addressed immediately.

-

Final Quality Control (FQC): After assembly, the outlets undergo rigorous testing, including electrical tests to verify proper functionality and safety checks to ensure compliance with international standards.

What Common Testing Methods Are Used for Type I Outlets?

B2B buyers should be aware of the various testing methods employed to ensure the quality and safety of Type I outlets. Common methods include:

- Dielectric Strength Testing: This test checks the insulation resistance of the outlet to prevent electrical shocks.

- Temperature Rise Testing: This evaluates how much heat the outlet generates under load conditions, ensuring it operates within safe limits.

- Mechanical Strength Testing: This involves applying stress to the outlet to ensure it can withstand physical impacts without failing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure their suppliers adhere to rigorous quality control practices. Here are some actionable steps to verify QC processes:

-

Supplier Audits: Conducting regular audits of your suppliers’ facilities can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Assurance Reports: Suppliers should be able to provide documentation of their quality control procedures, including results from testing and inspections.

-

Third-Party Inspections: Engaging independent organizations to perform inspections can help validate the integrity of the manufacturing processes and the quality of the products.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Differences: Different regions may have varying regulatory requirements. For instance, products sold in the European Union must comply with CE marking, while other regions may have their own certifications.

-

Cultural Considerations: Understanding cultural attitudes toward quality and safety can help navigate supplier relationships. For example, suppliers in some regions may prioritize cost over quality, which can lead to subpar products.

-

Logistics and Supply Chain Management: Ensure that logistics considerations, such as shipping and handling, do not compromise product integrity. Establishing quality checkpoints throughout the supply chain can mitigate risks.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing Type I outlets, ensuring that they receive high-quality products that comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type i outlet’

In the global marketplace, sourcing Type I outlets requires careful consideration of various factors to ensure compatibility, safety, and reliability. This guide provides a structured checklist for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, helping you navigate the complexities of procuring Type I outlets effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the Type I outlets meet your operational requirements. Consider factors like amperage (10A vs. 15A), voltage (typically 230V), and whether you need grounded or ungrounded versions. Precise specifications will help you avoid costly mismatches later.

Step 2: Research Compliance Standards

Verify that the Type I outlets comply with local and international safety standards, such as AS/NZS 3112 for Australia and New Zealand. Compliance not only ensures safety but also enhances the reliability of your installations. Look for certifications from recognized bodies like IEC or UL to confirm adherence to these standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Conduct background checks to assess their reputation, experience, and reliability in delivering quality electrical components.

- Check for Local Presence: Suppliers with local representatives can provide faster support and address any issues that may arise during installation.

- Assess Lead Times: Understand the supplier’s production and delivery timelines to align with your project schedules.

Step 4: Request Samples for Testing

Always request samples of the Type I outlets before making a bulk purchase. Testing samples allows you to evaluate their quality, compatibility with your equipment, and ease of installation.

- Conduct Performance Tests: Check for heat generation under load, grounding effectiveness, and overall durability.

- Engage Your Technical Team: Have your engineers or technicians assess the samples to ensure they meet all specified requirements.

Step 5: Negotiate Terms and Conditions

Negotiating favorable terms is crucial for maintaining budget control. Discuss pricing, payment terms, and warranty conditions clearly with the supplier.

- Consider Bulk Discounts: If your order volume is significant, inquire about discounts that could lower your overall costs.

- Review Warranty Policies: A robust warranty can protect your investment and provide peace of mind in case of product failure.

Step 6: Plan for Logistics and Import Regulations

Understand the logistics involved in importing Type I outlets into your region, including customs regulations and import duties.

- Engage a Local Freight Forwarder: They can help navigate complex import procedures and ensure timely delivery.

- Prepare Documentation: Ensure all necessary paperwork, such as invoices and compliance certificates, are in order to avoid delays at customs.

Step 7: Establish a Quality Control Process

Implement a quality control process upon receiving the Type I outlets. This step ensures that all products conform to the agreed specifications before installation.

- Conduct a Thorough Inspection: Check for physical damage, proper labeling, and compliance with the agreed standards.

- Document Findings: Keep records of inspections and any issues encountered, which can be useful for future sourcing decisions.

By following this checklist, B2B buyers can effectively navigate the sourcing process for Type I outlets, ensuring that they procure high-quality products that meet their technical and operational needs.

Comprehensive Cost and Pricing Analysis for type i outlet Sourcing

What Are the Key Cost Components for Type I Outlet Sourcing?

When sourcing Type I outlets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials such as plastic, copper for the prongs, and other conductive materials can vary significantly. High-quality materials may lead to higher initial costs but can enhance durability and performance.

-

Labor: Labor costs depend on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this could affect the quality of production.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses incurred during the production process. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in molds and tools required for production can be substantial. However, these costs are typically amortized over larger production runs, making it essential to consider volume when negotiating prices.

-

Quality Control (QC): Ensuring that Type I outlets meet safety standards and certifications (such as AS/NZS standards) involves additional costs. A robust QC process can prevent costly recalls and enhance brand reputation.

-

Logistics: Shipping costs can fluctuate based on the distance from the manufacturer to the buyer’s location. Understanding Incoterms is critical to determining who bears these costs and risks during transportation.

-

Margin: Suppliers will add a margin to cover their costs and profit. This margin can vary based on the supplier’s reputation, market demand, and competition.

How Do Price Influencers Affect Type I Outlet Costs?

Several factors influence the pricing of Type I outlets, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate for better pricing based on anticipated demand.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Clear communication of needs at the outset can help avoid unexpected expenses.

-

Material Quality and Certifications: Outlets that comply with international safety and quality standards may cost more but are essential for ensuring reliability and safety in various applications.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial for managing costs effectively. They determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some actionable tips:

-

Research Market Prices: Before entering negotiations, conduct thorough research on market prices for Type I outlets. This knowledge will empower you to negotiate better deals.

-

Leverage Volume Discounts: If your business can commit to larger orders, use this as leverage to negotiate better pricing. Suppliers are often willing to lower prices for bulk purchases.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with sourcing Type I outlets, including maintenance, reliability, and potential downtime. This broader perspective can justify higher upfront costs for better quality products.

-

Establish Strong Relationships: Building rapport with suppliers can lead to better pricing and terms. Consider long-term partnerships rather than one-off transactions.

-

Be Aware of Pricing Nuances: Understand that prices can vary significantly based on region and supplier. For instance, sourcing from manufacturers in Asia may offer lower prices compared to local suppliers in Europe, but consider shipping costs and lead times.

Disclaimer: Indicative Prices May Vary

It is essential to note that pricing for Type I outlets can vary widely based on the factors discussed above. Always request quotes from multiple suppliers and consider obtaining samples before making bulk purchases to ensure quality and value.

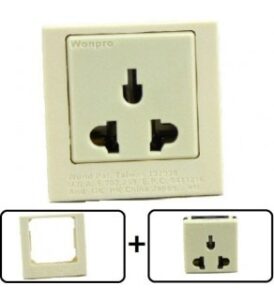

Alternatives Analysis: Comparing type i outlet With Other Solutions

When considering electrical solutions for international operations, particularly in regions utilizing the Type I outlet, B2B buyers should evaluate various alternatives that can meet their specific needs. Each solution has distinct advantages and drawbacks, making it essential to analyze them thoroughly. Below is a comparison of the Type I outlet against other viable alternatives: the Type C outlet and universal power adapters.

| Comparison Aspect | Type I Outlet | Type C Outlet | Universal Power Adapter |

|---|---|---|---|

| Performance | Supports up to 15A, suitable for appliances and electronics | Supports up to 2.5A, mainly for low-power devices | Varies by model, typically supports a range of voltages and currents |

| Cost | Generally low-cost for installation and materials | Low-cost, widely available in many markets | Higher initial cost; varies widely based on features |

| Ease of Implementation | Standard installation process | Simple installation, often pre-installed | Easy to use but may require additional adapters for different plug types |

| Maintenance | Low maintenance; durable design | Low maintenance; simple design | Varies; some models may require regular checks and updates |

| Best Use Case | Ideal for residential and commercial use in Type I regions | Best for low-power devices; common in Europe and Asia | Suitable for travelers or businesses with diverse plug types |

What Are the Advantages and Disadvantages of the Type C Outlet?

The Type C outlet is widely used across Europe and Asia, making it a popular choice for low-power devices such as chargers and small appliances. One of its main advantages is its simplicity and ease of use; however, it only supports devices with lower power requirements (up to 2.5A). This makes it unsuitable for high-power appliances, which could limit its application in industrial settings. Additionally, Type C outlets do not have a grounding pin, which can pose safety risks for certain devices.

How Does a Universal Power Adapter Compare?

Universal power adapters are incredibly versatile, accommodating various plug types and voltage levels. This makes them an excellent choice for international businesses or travelers who require flexibility in their electrical solutions. However, they tend to be more expensive than traditional outlets and may not provide the same level of durability as fixed installations. Moreover, the performance can vary significantly between models, and users must ensure compatibility with their devices to avoid damage.

Conclusion: How Can B2B Buyers Choose the Right Electrical Solution?

When selecting the appropriate electrical solution, B2B buyers should consider their specific operational needs, including the types of devices used, the power requirements, and the geographical areas of operation. The Type I outlet is an excellent choice for reliable, everyday use in regions where it is standard. In contrast, the Type C outlet may be better suited for low-power applications in European markets, while universal power adapters offer flexibility for businesses operating across multiple regions. By carefully weighing these factors, buyers can make informed decisions that align with their operational goals and ensure seamless power management in their business environments.

Essential Technical Properties and Trade Terminology for type i outlet

What Are the Key Technical Properties of Type I Outlets?

When considering Type I outlets for procurement or installation, understanding their technical specifications is crucial for ensuring compatibility and safety. Below are some essential properties that B2B buyers should be aware of:

1. Amperage Rating: What Does It Mean for Your Equipment?

Type I outlets typically come in two amperage ratings: 10 A and 15 A. The 10 A version is commonly used for standard appliances, while the 15 A variant accommodates heavier loads. Selecting the correct amperage is vital to prevent overheating and potential electrical failures in devices. For businesses, this means ensuring that their equipment aligns with the outlet rating to avoid downtime or damage.

2. Voltage Compatibility: Why Is It Critical?

Type I outlets are designed for a standard voltage of 230 V. For international buyers, especially from regions with different voltage standards, it’s essential to ensure that their devices can handle this voltage. Using equipment not rated for this voltage can lead to equipment failure or safety hazards. It’s advisable to consult voltage specifications before making a purchase.

3. Plug Configuration: How Does It Affect Usability?

The Type I plug features two flat blades set at a 30-degree angle, with a third grounding pin. This unique configuration not only ensures a secure fit but also enhances user safety by preventing accidental disconnection. For B2B buyers, understanding this configuration is important for assessing compatibility with existing devices and electrical systems.

4. Material Specifications: What Should You Look For?

The materials used in the construction of Type I outlets, typically thermoplastics for the casing and copper for the contacts, affect both durability and conductivity. Buyers should inquire about material grades to ensure long-lasting performance, especially in commercial settings. High-quality materials can withstand higher wear and tear, reducing maintenance costs in the long run.

5. Insulation Rating: Why It Matters for Safety

Type I outlets are designed with insulated live and neutral pins, which means they are less likely to cause electric shocks when partially inserted. This safety feature is crucial for businesses that operate in environments where electrical safety is paramount. Ensuring compliance with relevant safety standards can also mitigate liability risks.

What Are Common Trade Terms Related to Type I Outlets?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer): What Is Its Relevance?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing Type I outlets, knowing whether you are dealing with an OEM can impact product quality and warranty considerations, as OEM parts are typically designed to meet specific standards.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For Type I outlets, understanding the MOQ can help businesses plan their procurement strategy and manage inventory effectively. It is essential to balance the cost benefits of bulk purchasing with the need for flexibility in operations.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers to solicit price quotes for specific quantities of products. When seeking Type I outlets, submitting an RFQ can help ensure you receive competitive pricing and terms. This process also clarifies your requirements, making it easier for suppliers to provide accurate quotes.

4. Incoterms: What Do They Mean for International Shipping?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for international B2B buyers of Type I outlets, as they dictate who bears the cost of shipping, insurance, and tariffs. Knowing your responsibilities can prevent unexpected costs and delays.

5. Certification Standards: Why Should You Pay Attention?

Certification standards, such as AS/NZS for Type I outlets, ensure that products meet specific safety and quality benchmarks. For B2B buyers, verifying that outlets conform to these standards can safeguard against compliance issues and enhance the reputation of their operations.

By understanding both the technical properties and trade terminology associated with Type I outlets, international B2B buyers can make informed decisions that support their operational needs and ensure compliance with local regulations.

Navigating Market Dynamics and Sourcing Trends in the type i outlet Sector

What Are the Current Market Dynamics for Type I Outlets?

The global market for Type I outlets is driven by several factors, including increasing urbanization, technological advancements, and a growing emphasis on energy efficiency. Countries such as Australia, New Zealand, and parts of Asia and South America are witnessing a surge in the adoption of Type I outlets due to their compatibility with various electrical devices and systems. For international B2B buyers, understanding the regional variations in plug types and electrical standards is crucial. This knowledge allows buyers from Africa, South America, the Middle East, and Europe to navigate the complexities of sourcing electrical components that comply with local regulations.

Emerging trends indicate a shift towards smart electrical systems, including IoT-enabled devices that can provide real-time monitoring and control of electrical consumption. B2B buyers should also pay attention to the rise in demand for versatile power strips and adaptors that accommodate multiple plug types, as this can simplify logistics and reduce costs. Additionally, the trend towards modular and customizable electrical solutions is gaining traction, allowing businesses to tailor their electrical setups to specific operational needs.

How Is Sustainability and Ethical Sourcing Shaping the Type I Outlet Sector?

Sustainability has become a central theme in the sourcing of electrical components, including Type I outlets. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental stewardship. The impact of electrical components on the environment, particularly regarding waste and energy consumption, cannot be overlooked. This is especially relevant as countries ramp up efforts to meet climate goals and reduce carbon footprints.

Buyers should look for suppliers that offer ‘green’ certifications, such as Energy Star or RoHS (Restriction of Hazardous Substances), as these can serve as indicators of a product’s environmental impact. Additionally, sourcing materials that are recyclable or made from sustainable sources can enhance a company’s reputation and appeal to environmentally conscious consumers. Implementing a transparent supply chain that emphasizes sustainability not only fulfills corporate social responsibility but also aligns with global trends towards greener business practices.

A stock image related to type i outlet.

What Is the Historical Context of Type I Outlets for B2B Buyers?

The Type I outlet has its roots in the early 20th century, evolving from designs that were largely influenced by the American electrical system. Patented by Harvey Hubbell II in 1916, the Type I plug was favored in Australia and New Zealand due to its practicality and ease of manufacture. Over the decades, the Type I system has undergone various adaptations, including the introduction of different amperage ratings (10A, 15A, and 20A) to meet the diverse needs of consumers and businesses.

For B2B buyers, understanding this historical context is essential, as it provides insights into the evolution of electrical standards and the importance of compliance with local regulations. The ongoing innovation in plug designs and electrical safety features reflects a broader commitment to improving user experience and operational efficiency, making it crucial for businesses to stay informed about these developments. By leveraging this historical knowledge, international buyers can make more informed decisions when sourcing Type I electrical components.

Frequently Asked Questions (FAQs) for B2B Buyers of type i outlet

-

How do I solve compatibility issues with Type I outlets for my equipment?

To address compatibility issues with Type I outlets, first, check the voltage and frequency specifications of your equipment. Type I outlets typically operate at 230V and 50Hz. If your equipment is designed for different voltage or frequency, consider using a step-up transformer or a voltage converter. Additionally, ensure that your plugs are compatible; if not, a Type I adapter or a plug converter may be necessary. Lastly, consult with your supplier about any potential modifications or custom solutions they can offer. -

What is the best way to source Type I outlets for my business needs?

When sourcing Type I outlets, prioritize suppliers who specialize in electrical components and have a proven track record in your target markets, such as Australia, New Zealand, and Argentina. Evaluate suppliers based on their product certifications, customer reviews, and compliance with local standards. It’s also advisable to request product samples to assess quality before placing bulk orders. Additionally, consider suppliers who can offer customization options to meet specific project requirements. -

What are the standard payment terms for purchasing Type I outlets internationally?

Payment terms for international purchases of Type I outlets can vary widely based on supplier policies and the nature of the transaction. Common terms include advance payment, letter of credit, or net 30/60 days after delivery. It is essential to negotiate terms that provide security for both parties. Ensure that you understand the implications of currency exchange rates and any additional fees that may apply. Always get the payment terms documented in your purchase agreement to avoid misunderstandings. -

How do I vet suppliers for Type I outlet products?

Vetting suppliers for Type I outlets involves several steps. Start by researching the supplier’s background, including their years in business, reputation, and customer feedback. Request references and verify their compliance with international safety standards, such as IEC or UL certifications. Additionally, assess their manufacturing processes and quality control measures. A factory visit can provide firsthand insight into their operations. Finally, consider suppliers who offer warranties or guarantees on their products. -

What is the minimum order quantity (MOQ) for Type I outlets?

Minimum order quantities (MOQs) for Type I outlets typically depend on the supplier and the specific product line. Many suppliers set MOQs ranging from 100 to 1,000 units to justify production costs. However, some manufacturers may offer lower MOQs for custom or specialized orders. It’s advisable to communicate directly with suppliers to discuss your needs and see if they can accommodate smaller orders, particularly if you are a startup or entering a new market. -

What logistics considerations should I keep in mind when importing Type I outlets?

When importing Type I outlets, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder who can navigate import duties and taxes specific to your region. Ensure that your shipments are adequately insured and that you have all necessary documentation, including invoices and certificates of origin. Additionally, plan for potential delays due to customs inspections, especially in regions with strict import regulations. -

How can I ensure quality assurance for Type I outlets?

To ensure quality assurance for Type I outlets, implement a robust quality control process that includes pre-shipment inspections. Work with suppliers who adhere to international quality standards and can provide documentation of their testing procedures. Additionally, consider third-party quality assurance services for independent evaluations. Establish clear specifications and acceptance criteria in your contracts to avoid discrepancies in quality upon receipt. -

Are there customization options available for Type I outlets?

Yes, many suppliers offer customization options for Type I outlets to meet specific needs. Customization can include variations in amperage, plug configurations, or even branding elements like logos and color schemes. When discussing customization with suppliers, provide detailed specifications and requirements. Be aware that custom orders may have higher MOQs and longer lead times, so plan accordingly in your procurement strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type i outlet

In conclusion, the strategic sourcing of Type I outlets presents significant opportunities for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. Understanding the specifications and compatibility of Type I plugs—widely used in regions such as Australia, New Zealand, and Argentina—ensures that businesses can make informed decisions when sourcing electrical components. Buyers should prioritize suppliers who can provide not only the standard 10 amp configurations but also the variations like 15 amp and 20 amp plugs, which are essential for accommodating diverse electrical needs.

What are the benefits of establishing strong supplier relationships for Type I outlets? By partnering with reliable manufacturers, businesses can secure quality products while also benefiting from competitive pricing and enhanced customer support. This proactive approach to sourcing will mitigate risks associated with electrical compatibility and safety standards, thus ensuring smoother operations.

As we look ahead, the demand for Type I outlets is expected to grow, driven by global trade and increased connectivity. International buyers should act now—evaluate their sourcing strategies, engage with suppliers, and stay updated on evolving standards to maximize their market potential. Embrace this opportunity to enhance your electrical infrastructure and propel your business forward.