Unlock Savings: The Complete Power Transformer Guide (2025)

Introduction: Navigating the Global Market for power transfromer

In today’s global market, sourcing power transformers poses significant challenges for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for efficient and reliable energy solutions, understanding the various types of power transformers and their applications is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource for navigating the complexities of power transformer procurement, covering essential topics including transformer types, applications, supplier vetting processes, cost considerations, and the impact of local regulations.

The global landscape of power transformers is vast and multifaceted, with each region exhibiting unique energy needs and market dynamics. Buyers will benefit from insights on selecting appropriate transformer types—such as step-up, step-down, single-phase, and three-phase transformers—tailored to their specific operational requirements. Additionally, this guide will highlight best practices for evaluating suppliers, ensuring product quality, and understanding the total cost of ownership, which can significantly influence long-term investment returns.

By leveraging the knowledge presented in this guide, international B2B buyers can enhance their purchasing strategies, mitigate risks, and optimize their energy infrastructure investments. Whether you are in France, Saudi Arabia, or elsewhere, this resource empowers you to make strategic decisions that align with your organization’s growth and sustainability goals.

Understanding power transfromer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Step-Up Transformer | Increases voltage from primary to secondary winding. | Power generation, renewable energy systems. | Pros: Reduces transmission losses, improves efficiency. Cons: Higher initial costs. |

| Step-Down Transformer | Decreases voltage from primary to secondary winding. | Industrial plants, commercial buildings. | Pros: Provides suitable voltage for end-use applications. Cons: Limited to lower voltage applications. |

| Three-Phase Transformer | Contains three sets of windings for balanced loads. | Large-scale industrial operations. | Pros: Efficient power distribution, supports heavy loads. Cons: Requires more space and maintenance. |

| Autotransformer | Shares a common winding for both primary and secondary. | Voltage regulation in power systems. | Pros: Compact design, cost-effective for small voltage changes. Cons: Limited isolation between circuits. |

| Dry-Type Transformer | Uses air for cooling instead of oil. | Indoor applications, urban settings. | Pros: Safer, less maintenance, environmentally friendly. Cons: Limited capacity compared to oil-cooled types. |

What are the Characteristics of Step-Up Transformers?

Step-up transformers are essential in increasing voltage levels from the primary to the secondary winding, making them crucial in power generation and renewable energy systems. They are particularly effective in reducing transmission losses over long distances. For B2B buyers, the initial investment may be higher; however, the long-term efficiency gains often justify this cost. When purchasing, consider the specific voltage requirements and the operational environment, as well as the transformer’s capacity to handle peak loads.

How Do Step-Down Transformers Function?

Step-down transformers perform the opposite function of step-up transformers by decreasing voltage levels, making them ideal for industrial plants and commercial buildings where equipment requires lower voltages. They ensure that electrical devices operate safely and efficiently. Buyers should assess the voltage requirements of their equipment and the transformer’s capacity to avoid overloading. Additionally, understanding the transformer’s location and its thermal management capabilities is vital for effective operation.

Why Choose Three-Phase Transformers?

Three-phase transformers feature three sets of windings that provide balanced power distribution, making them suitable for large-scale industrial operations. They enhance efficiency and support heavy loads, which is crucial for manufacturing and processing plants. While they offer significant advantages in power distribution, buyers must consider the space requirements and maintenance needs. It’s important to evaluate the total cost of ownership, including installation and operational expenses.

What are the Benefits of Autotransformers?

Autotransformers utilize a single winding for both primary and secondary circuits, making them compact and cost-effective for applications where only small voltage changes are required. They are commonly used for voltage regulation in power systems. However, they offer limited electrical isolation, which may not be suitable for all applications. Buyers should consider the specific isolation requirements of their systems and whether the cost savings align with their operational needs.

Why Opt for Dry-Type Transformers?

Dry-type transformers are designed to use air for cooling instead of oil, making them a safer and more environmentally friendly option for indoor applications, especially in urban settings. They require less maintenance and are less prone to leaks. However, they typically have a lower capacity than oil-cooled transformers. B2B buyers should evaluate their cooling needs, installation space, and the specific capacity requirements of their electrical systems when considering dry-type transformers.

Key Industrial Applications of power transfromer

| Industry/Sector | Specific Application of Power Transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy Generation | Generator Step-Up Transformers | Enhanced efficiency in electricity transmission | Voltage ratings, environmental conditions, regulatory compliance |

| Manufacturing | Industrial Equipment Power Supply | Reliable power supply for machinery operations | Load capacity, cooling method, maintenance support |

| Renewable Energy | Wind Turbine Transformers | Optimized energy conversion from wind to grid | Compatibility with turbine specifications, efficiency ratings |

| Utilities | Substation Transformers | Improved grid reliability and reduced transmission losses | Customization options, installation services, service life |

| Transportation & Logistics | Rail Electrification Transformers | Efficient power supply for electric trains | Voltage requirements, safety standards, weight considerations |

How Are Power Transformers Used in Energy Generation?

In the energy generation sector, generator step-up transformers play a crucial role by increasing voltage levels from generators to minimize power loss during transmission. This application is vital for ensuring that electricity generated from sources like hydro, thermal, or wind energy reaches consumers efficiently. International B2B buyers, particularly in regions like Africa and South America, should consider factors such as voltage ratings, environmental conditions, and adherence to local regulatory compliance when sourcing these transformers to ensure optimal performance and reliability.

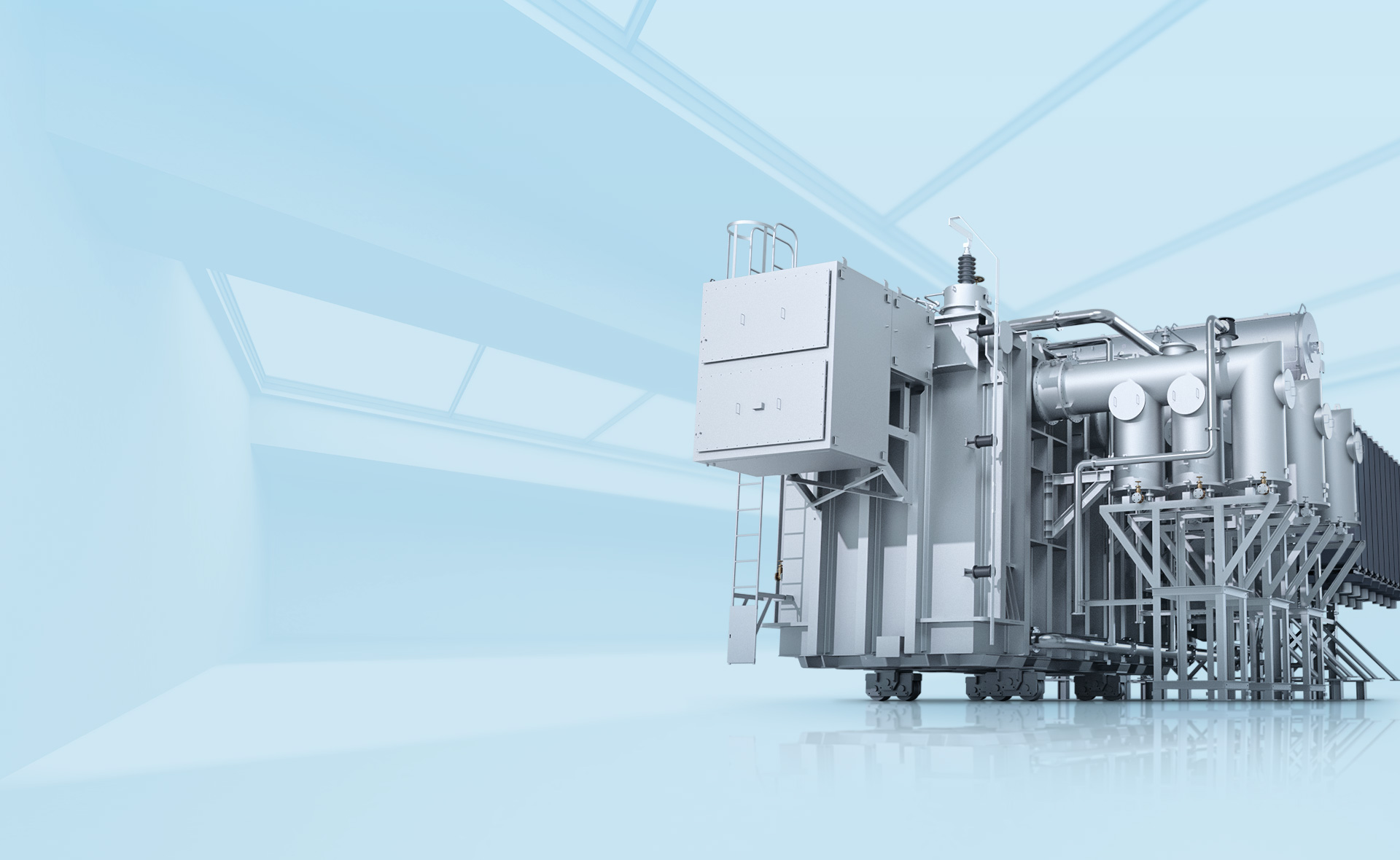

A stock image related to power transfromer.

What Role Do Power Transformers Play in Manufacturing?

In manufacturing, power transformers are essential for supplying reliable electrical energy to industrial machinery. These transformers ensure that equipment operates smoothly, thus minimizing downtime and enhancing productivity. Buyers should pay attention to load capacity, cooling methods (oil-cooled vs. dry-type), and available maintenance support when sourcing transformers, especially in regions with fluctuating power quality, such as the Middle East and parts of Europe.

How Are Power Transformers Essential for Renewable Energy Solutions?

Wind turbine transformers are specifically designed to optimize the energy conversion from wind to the electrical grid. These transformers ensure that the generated power is at the correct voltage and frequency for efficient transmission. For international buyers in Europe, where renewable energy initiatives are robust, sourcing transformers that meet turbine specifications and efficiency ratings is critical for maximizing energy output and ensuring sustainability.

Why Are Power Transformers Important for Utilities?

Utilities utilize substation transformers to step down high transmission voltages to levels suitable for local distribution. This application is vital for improving grid reliability and reducing transmission losses, which is especially important in regions with extensive distribution networks. When sourcing these transformers, businesses should consider customization options to meet specific regional requirements, installation services for complex setups, and the expected service life of the equipment.

How Do Power Transformers Support Transportation and Logistics?

In the transportation sector, rail electrification transformers provide efficient power supply to electric trains, enhancing operational efficiency and reducing carbon emissions. These transformers must meet specific voltage requirements and safety standards to ensure reliable performance. Buyers should also consider weight and space constraints when sourcing transformers for rail applications, particularly in regions with established rail networks in Europe and the Middle East.

3 Common User Pain Points for ‘power transfromer’ & Their Solutions

Scenario 1: Inadequate Voltage Regulation in Power Systems

The Problem: Many B2B buyers face the challenge of inadequate voltage regulation in their power systems, which can lead to equipment malfunctions, decreased efficiency, and increased operational costs. For instance, a manufacturing facility in South Africa might experience fluctuating voltage levels due to an aging transformer, resulting in inconsistent performance of sensitive machinery. This situation not only disrupts production but also raises concerns about the longevity of equipment, leading to costly repairs and downtime.

The Solution: To address voltage regulation issues, buyers should consider sourcing power transformers with advanced voltage control capabilities. When selecting a transformer, ensure that it features a tap changer, which allows for real-time adjustments to the voltage levels based on load conditions. It’s essential to engage with reputable manufacturers that provide transformers designed for specific operational environments. Furthermore, investing in monitoring and control systems that integrate with the transformer can help predict and manage voltage fluctuations, ultimately enhancing reliability and reducing costs.

Scenario 2: High Operational Costs Due to Inefficient Transformers

The Problem: In regions such as South America, where energy costs can be significant, businesses often struggle with high operational expenses due to inefficient power transformers. An energy provider in Brazil might use outdated transformers that consume excessive energy, leading to inflated electricity bills and reduced profit margins. These inefficiencies not only affect the bottom line but also contribute to environmental concerns due to higher carbon footprints.

The Solution: To mitigate high operational costs, businesses should evaluate their current transformer systems and consider upgrading to energy-efficient models. Look for transformers that comply with international energy efficiency standards, such as IEC 60076-1, which emphasizes low losses during operation. Additionally, consider implementing smart transformers equipped with digital monitoring capabilities that can optimize energy usage and provide insights into performance. Collaborating with engineering consultants can also help in assessing existing systems and identifying cost-effective upgrades that align with sustainability goals.

Scenario 3: Challenges with Transformer Maintenance and Downtime

The Problem: Frequent maintenance and unexpected downtime due to transformer failures are common pain points for B2B buyers, particularly in the Middle East, where extreme temperatures can exacerbate wear and tear. A power utility company in Saudi Arabia may face operational disruptions when a power transformer requires unscheduled maintenance, leading to substantial financial losses and service interruptions for customers.

The Solution: To improve maintenance and reduce downtime, businesses should adopt a proactive maintenance strategy that incorporates predictive analytics. This involves using advanced monitoring technologies, such as temperature and vibration sensors, to continuously assess the health of the transformer. By partnering with manufacturers that offer robust service contracts and expert support, buyers can ensure timely maintenance and repairs. Additionally, investing in training for in-house technicians can empower teams to perform routine inspections and minor repairs, thus minimizing the risk of major failures and enhancing overall operational efficiency.

Strategic Material Selection Guide for power transfromer

What Are the Key Materials Used in Power Transformers?

When selecting materials for power transformers, it is crucial to consider their properties, advantages, disadvantages, and overall impact on application performance. This analysis will focus on four common materials: silicon steel, copper, aluminum, and insulating oil.

How Does Silicon Steel Affect Power Transformer Performance?

Silicon steel is widely used in the core of power transformers due to its excellent magnetic properties. The addition of silicon enhances the electrical resistivity of the steel, reducing energy losses during magnetic flux changes. Key properties include high permeability and low hysteresis loss, making it ideal for efficient energy transfer.

Pros: Silicon steel is durable and provides high efficiency, which is essential for reducing operational costs in the long run. It is relatively easy to manufacture, allowing for consistent quality across production batches.

Cons: The main drawback is its susceptibility to corrosion, which can affect longevity if not properly coated or maintained. Additionally, while it is cost-effective, the initial investment can be higher compared to other materials.

Impact on Application: Silicon steel’s magnetic efficiency makes it suitable for high-voltage applications, ensuring minimal energy loss during transmission.

Considerations for International Buyers: Compliance with international standards like ASTM A677 or DIN 46212 is essential. Buyers from regions such as Europe and the Middle East should ensure that suppliers adhere to these standards to maintain quality and performance.

What Role Do Copper and Aluminum Play in Power Transformers?

Copper and aluminum are primarily used for windings in power transformers. Copper offers superior conductivity, making it the preferred choice for high-performance transformers. Its key properties include high thermal and electrical conductivity, which enhances efficiency.

Pros: Copper windings provide better performance and lower energy losses, leading to higher efficiency in power transmission.

Cons: The main disadvantage is the higher cost of copper compared to aluminum. Additionally, copper is heavier, which can complicate installation and transportation.

Impact on Application: Copper is ideal for applications requiring high reliability and efficiency, while aluminum can be used in less demanding environments.

Considerations for International Buyers: Buyers should be aware of the fluctuating prices of copper and aluminum in global markets. Compliance with standards such as JIS C 4004 for copper and JIS C 4010 for aluminum is crucial for ensuring quality.

How Does Insulating Oil Contribute to Power Transformer Functionality?

Insulating oil is essential for cooling and insulating the transformer windings. The key properties of insulating oil include high dielectric strength and low viscosity, which are vital for effective heat dissipation and electrical insulation.

Pros: Insulating oil enhances the transformer’s performance by providing efficient cooling and preventing electrical breakdowns.

Cons: The primary limitation is that insulating oil can degrade over time, leading to potential failures if not regularly monitored and replaced.

Impact on Application: The choice of insulating oil affects the transformer’s operational temperature range and overall reliability, particularly in extreme environments.

Considerations for International Buyers: It is important to select insulating oils that meet regional standards, such as IEC 60296. Buyers in Africa and South America should consider the local climate and environmental regulations when selecting insulating oil.

Summary Table of Material Selection for Power Transformers

| Material | Typical Use Case for power transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Transformer core | High efficiency and durability | Susceptible to corrosion | Medium |

| Copper | Transformer windings | Superior conductivity and performance | Higher cost and weight | High |

| Aluminum | Transformer windings | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Insulating Oil | Cooling and insulation | Effective cooling and insulation | Degrades over time | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in power transformers, enabling informed decisions that enhance performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for power transfromer

What Are the Main Stages of Manufacturing Power Transformers?

The manufacturing process for power transformers involves several critical stages, ensuring that each unit meets the stringent performance and safety standards required in the industry. The main stages include:

Material Preparation

This initial phase involves sourcing high-quality raw materials, which are essential for the performance and longevity of power transformers. Common materials include:

- Silicon Steel: Used for core laminations, silicon steel minimizes energy loss.

- Copper or Aluminum: These metals are typically used for windings due to their excellent electrical conductivity.

- Insulating Materials: High-grade insulation, such as paper, oil, and resin, is crucial for electrical safety and performance.

Selecting suppliers who adhere to international standards for these materials is vital for ensuring overall product quality.

Forming

The forming stage is where the raw materials are shaped into their final form. This includes:

- Core Construction: The core is constructed from laminated sheets of silicon steel, which are cut, stacked, and assembled to form the magnetic circuit. The precision in this stage affects the transformer’s efficiency and performance.

- Winding: Copper or aluminum wires are wound around the core to create the primary and secondary coils. The winding process must be executed with precision to maintain the desired voltage ratio.

Assembly

Once the core and windings are prepared, the assembly process begins:

- Integration of Components: The core and windings are assembled together, and various components like bushings, tap changers, and cooling systems are integrated.

- Testing During Assembly: Electrical and mechanical tests may occur at this stage to ensure that components are functioning correctly.

Finishing

The finishing stage enhances both the durability and aesthetic quality of the transformer:

- Insulation and Sealing: Insulating materials are applied, and the unit is sealed to protect against environmental factors. This can include oil filling for cooling and insulation.

- Final Testing: After assembly, comprehensive testing is conducted to validate the transformer’s performance under operational conditions.

What Quality Assurance Practices Are Essential for Power Transformers?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures reliability and safety. Here’s an in-depth look at QA practices relevant to power transformers:

What International Standards Are Applicable?

B2B buyers should be aware of several international standards that govern the manufacturing and quality assurance of power transformers:

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continual improvement.

- IEC 60076: This is the international standard specifically for power transformers, covering aspects such as testing, performance, and safety.

- CE Marking: This certification indicates compliance with European health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic checks at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected for quality and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to ensure that processes adhere to defined standards. This may include checks on winding tension and insulation resistance.

- Final Quality Control (FQC): Once manufacturing is complete, comprehensive testing is conducted to verify the transformer’s operational integrity. This includes high-voltage testing and thermal imaging to identify potential issues.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks. Here are several actionable steps:

Conduct Supplier Audits

Regular audits can help assess a supplier’s adherence to quality standards. Buyers should establish a schedule for audits, focusing on:

- Manufacturing Facilities: Inspecting the production environment and equipment.

- Quality Management Systems: Evaluating the implementation of ISO 9001 and other relevant standards.

Request Quality Assurance Reports

Buyers should request detailed QC reports that include:

- Test Results: Documentation of all tests performed, including electrical and thermal performance metrics.

- Non-Conformance Reports: Any deviations from established standards should be documented, along with corrective actions taken.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and quality control measures. This is especially useful for buyers who may not have the expertise or resources to conduct thorough inspections themselves.

What Are the Quality Certification Nuances for International Buyers?

Navigating the certification landscape can be complex for international B2B buyers. Here are key considerations:

- Local Regulations: Different regions may have specific regulations regarding electrical equipment. Buyers should ensure that suppliers comply with local laws in their target markets.

- Documentation: Ensure that all quality certifications are available in a language that is understandable to the buyer. This facilitates better communication and reduces misunderstandings.

- Cultural Sensitivity: Understand that quality assurance practices may vary by region. Building relationships with suppliers can help navigate these differences effectively.

Conclusion: Maximizing Quality Assurance in Power Transformer Procurement

For B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for power transformers is crucial. By focusing on material quality, robust manufacturing processes, and stringent QC measures, buyers can enhance their procurement strategies and ensure reliable, high-performance transformers for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power transfromer’

To support international B2B buyers in procuring power transformers effectively, this step-by-step checklist outlines essential actions to ensure a successful sourcing process. Each step is tailored to help buyers from regions such as Africa, South America, the Middle East, and Europe make informed decisions.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is crucial. Identify the type of transformer needed (step-up, step-down, single-phase, or three-phase) and consider the voltage levels, capacity (in kVA), and application (e.g., industrial, commercial, or renewable energy). This foundational step ensures that suppliers can provide equipment that meets your precise needs.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers. Focus on manufacturers with a solid reputation in the industry and a proven track record of delivering quality transformers. Utilize resources such as industry publications, trade shows, and online platforms to compile a list of candidates.

- Key considerations:

- Supplier experience in your specific market.

- Positive client testimonials and case studies.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities and quality assurance processes to ensure they can meet your specifications.

- Important checks:

- Look for certifications like ISO 9001 or IEC standards.

- Consider their after-sales support and warranty offerings.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations. Ensure that these quotes outline all costs, including shipping, installation, and any additional services. Comparing quotes will help you identify the best value for your investment.

- What to include in your request:

- Technical specifications.

- Delivery timelines and payment terms.

Step 5: Assess Compliance with Local Regulations

Understanding local regulations regarding electrical equipment is crucial. Ensure that your selected suppliers comply with these regulations, including safety standards and certification requirements specific to your region. This step helps avoid potential legal issues and ensures safe operation.

Step 6: Conduct Site Visits and Inspections

If possible, conduct site visits to the manufacturing facilities of your shortlisted suppliers. This provides an opportunity to inspect their production processes, quality control measures, and overall operational capabilities.

- What to look for:

- Cleanliness and organization of the facility.

- Equipment and technology used in manufacturing.

Step 7: Finalize the Contract and Terms

Once you’ve selected a supplier, finalize the contract. Ensure all terms are clearly defined, including delivery schedules, payment terms, warranty conditions, and service agreements. A well-documented contract protects your interests and clarifies expectations on both sides.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing power transformers effectively, ensuring they make informed decisions that align with their operational needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for power transfromer Sourcing

What Are the Key Cost Components in Power Transformer Sourcing?

When sourcing power transformers, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials, such as copper, silicon steel, and insulating oil, significantly impacts pricing. Higher-grade materials often lead to improved efficiency and longevity, justifying a higher upfront cost.

-

Labor: Labor costs vary by region and can influence the overall price. Skilled labor is necessary for the assembly and quality control of transformers, especially for custom or high-specification units.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, including utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can reduce overhead and contribute to lower prices.

-

Tooling: Specialized tools and dies are often required for transformer production. The cost of tooling can be amortized over the production volume, impacting the pricing for smaller orders.

-

Quality Control (QC): Rigorous testing and quality assurance protocols are vital in ensuring transformer reliability. The costs of these measures can vary, with higher investment in QC leading to better product performance.

-

Logistics: Shipping and handling costs can vary greatly depending on the distance, weight, and dimensions of the transformers. Incoterms and freight arrangements also play a crucial role in determining logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin may vary based on market competition, supplier reputation, and additional services provided.

How Do Price Influencers Impact Power Transformer Costs?

Several factors influence the pricing of power transformers, which can significantly affect the total cost for buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQs) often dictate pricing. Larger orders typically result in lower unit prices due to economies of scale, making bulk purchases more cost-effective.

-

Specifications and Customization: Custom-designed transformers tailored to specific applications can lead to higher costs. Buyers should assess whether standard models can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Transformers with higher quality materials and certifications (like ISO or IEC standards) may come at a premium. However, these investments often translate to lower maintenance and replacement costs over time.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge higher prices but offer better warranties, service, and product consistency.

-

Incoterms: Understanding the terms of shipment can help buyers manage costs. For example, choosing DDP (Delivered Duty Paid) means the supplier covers shipping and customs, while EXW (Ex Works) places the logistics burden on the buyer, potentially increasing costs.

What Tips Can Help International Buyers Optimize Transformer Pricing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Leverage your purchasing power by negotiating terms, including payment schedules, delivery timelines, and pricing based on order volume. Building a strong relationship with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price. Evaluate the long-term operational costs, including energy efficiency, maintenance, and potential downtime. Investing in higher-quality transformers can reduce TCO.

-

Stay Informed on Pricing Trends: Understanding market fluctuations in raw materials and labor costs can provide leverage in negotiations. Keeping abreast of global market trends can help anticipate price changes.

-

Evaluate Local and Regional Suppliers: Sourcing from local or regional suppliers can reduce logistics costs and lead to faster delivery times. Additionally, local suppliers may have a better understanding of regional regulations and standards.

-

Request Detailed Quotations: Always ask for a breakdown of costs in supplier quotations. This transparency helps in comparing offers and understanding where savings can be made.

Disclaimer on Pricing Information

Please note that the prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough due diligence and obtain multiple quotations to ensure the best pricing for your needs.

Alternatives Analysis: Comparing power transfromer With Other Solutions

Introduction to Alternative Solutions for Power Transformers

In the realm of electrical power distribution, power transformers are a cornerstone technology, facilitating efficient voltage adjustments between generating stations and consumers. However, several alternative technologies can also fulfill similar roles, each with its own unique advantages and drawbacks. Understanding these alternatives is essential for international B2B buyers seeking the most effective solution for their specific operational requirements.

Comparison Table: Power Transformers vs. Alternative Solutions

| Comparison Aspect | Power Transformer | Voltage Regulators | Static Frequency Converters |

|---|---|---|---|

| Performance | High efficiency, reliable | Moderate efficiency; effective for voltage stabilization | High efficiency for frequency conversion |

| Cost | Higher initial investment | Lower initial cost; ongoing operational costs can add up | Moderate to high initial investment |

| Ease of Implementation | Requires specialized installation and integration | Easier to install, often plug-and-play | Complex installation; requires skilled personnel |

| Maintenance | Regular maintenance needed; long lifespan | Minimal maintenance; simpler design | Requires periodic checks; can be complex |

| Best Use Case | Large-scale power transmission | Local voltage stabilization | Converting between different frequency systems |

Detailed Breakdown of Alternatives

Voltage Regulators

Voltage regulators are devices that automatically maintain a constant voltage level. They are particularly useful for applications requiring stable voltage without significant fluctuation.

Pros:

– Cost-effective for smaller systems or localized applications.

– Generally easier to install compared to power transformers, making them a suitable choice for quick upgrades or retrofits.

– Minimal maintenance requirements, which can lead to lower long-term costs.

Cons:

– They may not handle large power loads efficiently, making them less suitable for industrial-scale applications.

– Performance can be limited under extreme load conditions, leading to potential voltage instability.

Static Frequency Converters

Static frequency converters (SFCs) are used to convert electrical power from one frequency to another, enabling the integration of equipment that operates on different frequency standards.

Pros:

– High efficiency in converting power, making them ideal for renewable energy applications or situations where frequency conversion is necessary.

– Flexible in terms of application, as they can adapt to various frequency requirements.

Cons:

– Installation can be complex and may require specialized knowledge, which can lead to higher upfront costs.

– Regular maintenance is essential to ensure reliable operation, particularly in demanding environments.

Conclusion: Choosing the Right Solution for Your Needs

For international B2B buyers, the selection of the appropriate technology hinges on specific operational requirements, budget considerations, and the scale of application. Power transformers excel in large-scale power transmission and are indispensable for high-voltage applications. However, for localized voltage control, voltage regulators present a cost-effective alternative. In scenarios requiring frequency conversion, static frequency converters offer efficient solutions but may involve higher complexity and costs. A thorough evaluation of these factors will guide buyers in making an informed decision that aligns with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for power transfromer

What Are the Key Technical Properties of Power Transformers?

Understanding the technical specifications of power transformers is crucial for international B2B buyers looking to invest in reliable energy solutions. Here are some essential properties to consider:

1. Material Grade

The materials used in the construction of a power transformer significantly affect its performance and longevity. Common materials include silicon steel for the core, which enhances magnetic properties, and copper or aluminum for windings, which influence conductivity. Selecting the right material grade can lead to reduced energy losses and improved efficiency.

2. Voltage Rating

Voltage rating is a critical specification that defines the maximum voltage a transformer can handle safely. It is vital for ensuring that the transformer can operate effectively within the intended application, whether for step-up or step-down purposes. For B2B buyers, understanding voltage ratings helps in selecting transformers that match the operational requirements of their electrical systems.

3. Impedance

Impedance is a measure of resistance within the electrical circuit of a transformer, typically expressed as a percentage. It affects voltage regulation and short-circuit performance. A lower impedance can lead to better voltage regulation, while higher impedance helps in limiting fault currents. For buyers, knowing the impedance helps in assessing compatibility with existing systems and ensuring reliability during peak loads.

4. Cooling Method

Power transformers can be cooled using various methods, such as oil-cooled or dry-type systems. Oil-cooled transformers are generally more efficient in heat dissipation, while dry-type transformers are preferable for indoor applications due to safety and environmental considerations. Buyers must evaluate the cooling method based on their installation environment and maintenance capabilities.

5. Efficiency Rating

Efficiency ratings indicate how much of the input energy is converted into useful output energy without losses. High-efficiency transformers can reduce operational costs and enhance energy savings over time. For B2B buyers, understanding efficiency ratings is crucial for long-term financial planning and sustainability goals.

What Are Common Trade Terms in Power Transformer Transactions?

Familiarity with industry jargon is essential for navigating power transformer procurement. Here are some key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are then marketed and sold under another company’s brand name. In the context of power transformers, partnering with reputable OEMs ensures quality and reliability, as these manufacturers adhere to industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and budgeting. It can also influence negotiations, especially for smaller companies or those testing new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit pricing and terms for specific products or services. This process allows buyers to compare offers and negotiate better deals. For B2B buyers, a well-structured RFQ can lead to significant cost savings and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and insurance requirements, which are crucial for smooth logistics.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with the purchase and operation of a transformer over its entire lifecycle, including acquisition, maintenance, and energy costs. B2B buyers should consider TCO when evaluating different transformer options, as it provides a more comprehensive view of long-term financial implications.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the power transfromer Sector

What Are the Current Market Dynamics and Key Trends in the Power Transformer Sector?

The global power transformer market is experiencing significant growth, driven by an increasing demand for electricity, infrastructure upgrades, and the expansion of renewable energy sources. Notably, regions such as Africa and South America are investing heavily in electrification projects and grid modernization, creating substantial opportunities for international B2B buyers. In the Middle East, the push for smart grid technologies is leading to innovative transformer designs, while Europe focuses on decarbonization and energy efficiency.

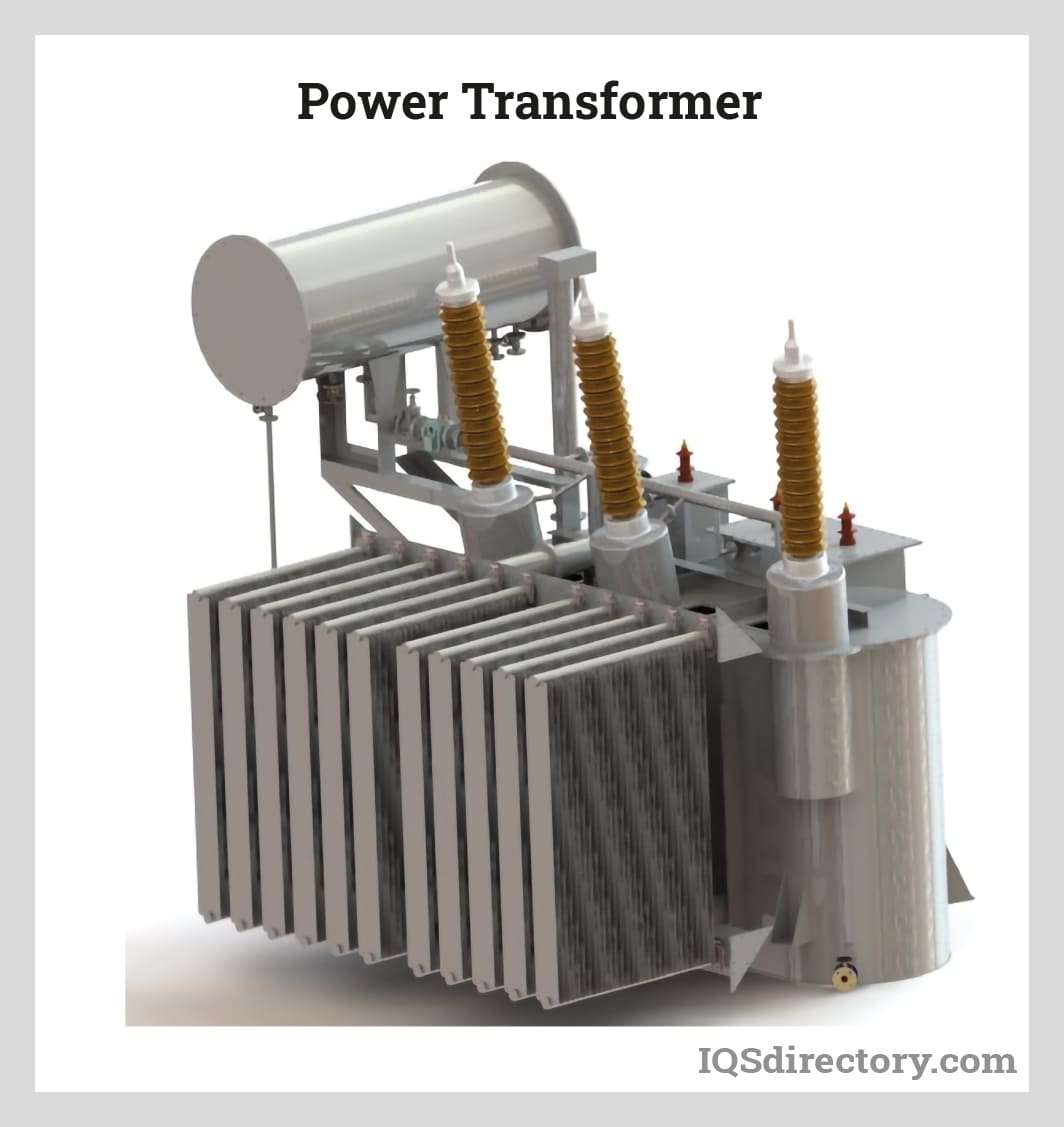

A stock image related to power transfromer.

Emerging trends include the adoption of digital technologies, such as IoT-enabled transformers that enhance monitoring and predictive maintenance capabilities. This shift toward smart infrastructure allows companies to optimize their operations and reduce downtime, a critical factor for businesses in competitive markets. Furthermore, the demand for compact and lightweight designs, especially in urban and offshore applications, is reshaping product offerings.

B2B buyers must also consider the impact of local regulations and standards on procurement strategies. Understanding these dynamics can help buyers navigate the complexities of the market and make informed decisions about sourcing power transformers from reputable suppliers that align with their operational needs and compliance requirements.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Power Transformer Sector?

The importance of sustainability in the power transformer sector cannot be overstated. As environmental concerns continue to rise, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their ecological footprint. This includes sourcing materials that have minimal environmental impact and implementing processes that promote recycling and waste reduction.

Ethical supply chains are becoming a significant factor in procurement decisions. Buyers are encouraged to engage with manufacturers who adhere to responsible sourcing practices, ensuring that materials are obtained without harm to communities or ecosystems. Certifications such as ISO 14001 for environmental management and Green Seal for sustainable products can serve as indicators of a supplier’s commitment to sustainability.

In addition, the transition to renewable energy sources necessitates the use of power transformers that can efficiently integrate with technologies such as wind and solar. This shift not only enhances energy reliability but also aligns with global sustainability goals. By prioritizing ethical sourcing and sustainability, international B2B buyers can contribute to a greener future while ensuring that their supply chains are resilient and responsible.

What Is the Historical Context of Power Transformers and Its Relevance to Today’s B2B Landscape?

The evolution of power transformers dates back to the late 19th century, coinciding with the advent of electrical distribution systems. Originally designed to facilitate long-distance power transmission, transformers have undergone significant advancements in design and technology. The introduction of materials such as amorphous steel and advancements in insulation technology have improved efficiency and reduced energy losses.

In today’s B2B landscape, understanding the historical context of power transformers provides insights into current technological advancements and their implications for supply chain management. The shift towards digital solutions and the emphasis on sustainability trace their roots to the industry’s need for efficiency and reliability. B2B buyers can leverage this historical knowledge to identify innovative suppliers who are not only advancing technology but also aligning with modern values of sustainability and ethical sourcing.

By recognizing these trends and historical developments, international buyers can make strategic decisions that enhance their operational capabilities while supporting the broader goals of environmental stewardship and social responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of power transfromer

-

How do I determine the right power transformer for my application?

To select the appropriate power transformer, assess your specific requirements, including voltage levels, power capacity (measured in kVA or MVA), and the nature of your electrical load. Consider whether you need a step-up or step-down transformer based on your generation and consumption points. Additionally, evaluate the environmental conditions, such as temperature and humidity, which may influence the choice between oil-cooled and dry-type transformers. Consulting with a supplier who can provide detailed specifications and application insights can also streamline the selection process. -

What is the best type of power transformer for industrial use?

For industrial applications, three-phase transformers are typically the best choice due to their efficiency in handling high loads and balanced power distribution. Depending on your requirements, you may need step-up transformers to elevate voltage for transmission or step-down transformers for distribution. Additionally, consider factors such as efficiency ratings, cooling methods, and the transformer’s ability to withstand short circuits. Engaging with manufacturers who specialize in industrial transformers can provide tailored solutions that meet your operational needs. -

What are the key factors to consider when sourcing a power transformer supplier?

When sourcing a supplier, prioritize their experience and reputation in the industry. Look for manufacturers with a proven track record of delivering high-quality transformers and comprehensive customer support. Assess their production capabilities, including testing protocols to ensure reliability and longevity. Additionally, review their certifications and adherence to international standards. Engaging with suppliers who offer customization options can also ensure that the transformer meets your specific operational requirements. -

What are typical payment terms for international purchases of power transformers?

Payment terms for power transformers can vary significantly based on the supplier and the size of the order. Common arrangements include advance payments, letters of credit, or a percentage upfront with the balance due upon delivery. It’s crucial to clarify these terms during negotiations to avoid misunderstandings. Additionally, consider the impact of currency fluctuations and international transaction fees, and explore options for securing favorable terms, especially for large orders or long-term contracts. -

How can I ensure the quality and reliability of the power transformers I purchase?

To ensure quality, request detailed specifications and certifications from your supplier, including ISO standards and third-party testing results. Engage suppliers who offer warranties and after-sales support, as these can be indicators of their commitment to quality. Additionally, consider conducting site visits to the manufacturing facilities or requesting samples for testing. Implementing a robust quality assurance process that includes inspections during production can also help mitigate risks associated with international purchases.

A stock image related to power transfromer.

-

What logistics considerations should I keep in mind when importing power transformers?

Logistics for importing power transformers involve several key considerations, including shipping methods, customs clearance, and delivery timelines. Choose reliable logistics partners familiar with heavy and oversized cargo. Ensure that all shipping documentation is accurate and complete to facilitate smooth customs clearance. Additionally, factor in storage requirements upon arrival and any necessary installation services. Understanding local regulations and tariffs can also help you budget effectively for the total cost of acquisition. -

What are the minimum order quantities (MOQs) for power transformers from manufacturers?

Minimum order quantities for power transformers can vary widely based on the manufacturer and the type of transformer. Some suppliers may have MOQs as low as one unit for standard models, while custom or specialized transformers may require larger orders. It’s essential to discuss your needs directly with suppliers to find a solution that aligns with your project scope and budget. Some manufacturers may be willing to negotiate MOQs, particularly for long-term partnerships. -

Can power transformers be customized to meet specific operational needs?

Yes, many manufacturers offer customization options for power transformers to meet specific operational requirements. Customizations can include adjustments to voltage ratings, cooling methods, physical dimensions, and insulation materials. Engaging with a supplier early in the design process allows for collaboration on specifications that enhance performance and efficiency. Ensure that the manufacturer has the technical expertise and capability to deliver customized solutions that adhere to industry standards and regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power transfromer

Why Is Strategic Sourcing Crucial for Power Transformers?

Strategic sourcing plays a pivotal role in optimizing the procurement of power transformers, ensuring that international B2B buyers can secure high-quality, reliable, and cost-effective solutions. By carefully evaluating suppliers based on their technological capabilities, manufacturing quality, and after-sales support, companies can enhance their operational efficiencies and minimize risks associated with transformer failures.

How Can International Buyers Benefit from Understanding Market Trends?

Understanding current market trends, such as the shift towards sustainable and digitally enabled transformers, empowers buyers from Africa, South America, the Middle East, and Europe to make informed purchasing decisions. This knowledge allows organizations to select transformers that not only meet their immediate needs but also align with future energy efficiency goals and grid modernization initiatives.

What’s Next for Buyers in the Power Transformer Market?

As the demand for reliable power infrastructure continues to grow, international buyers must adopt a proactive sourcing strategy that includes evaluating long-term supplier partnerships. Engaging with manufacturers who prioritize innovation and sustainability will be essential for navigating the evolving landscape of power transformers.

In conclusion, by leveraging strategic sourcing practices and staying attuned to industry developments, B2B buyers can position themselves for success in a competitive market. Now is the time to take action—invest in relationships with forward-thinking suppliers to secure a sustainable energy future.