Unlocking Value: The Complete Iron Periodic Table Guide (2025)

Introduction: Navigating the Global Market for iron periodic table

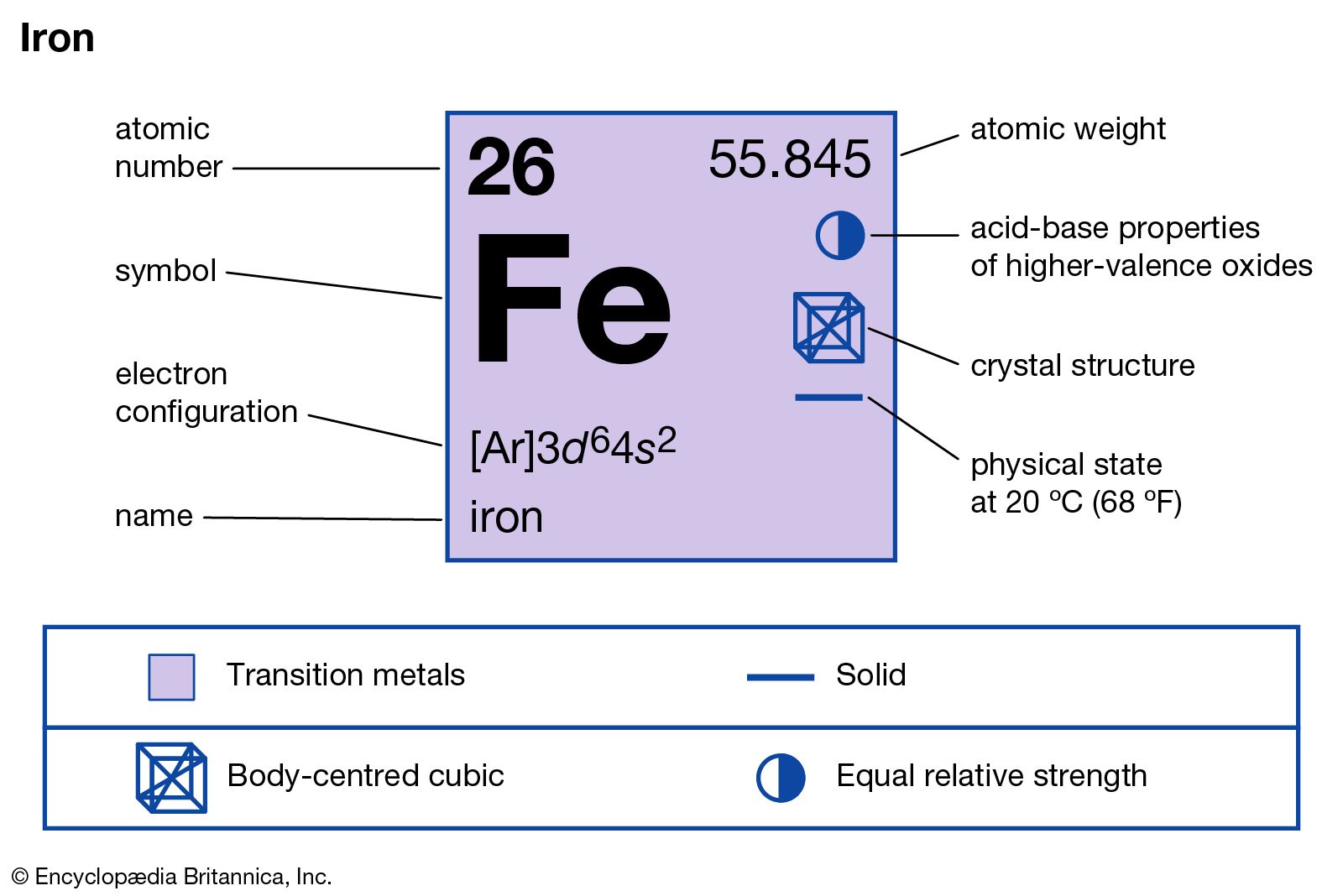

Navigating the global market for iron can present significant challenges for international B2B buyers, particularly when it comes to understanding the diverse applications and sourcing strategies associated with this essential element. Iron, represented by the atomic number 26 on the periodic table, serves as a foundational material in various industries, from construction and manufacturing to electronics and automotive sectors. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Turkey—with the knowledge needed to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore the various types of iron and its alloys, including carbon steel, stainless steel, and cast iron, highlighting their specific applications and properties. Additionally, we will delve into supplier vetting processes, pricing strategies, and the environmental impact of iron production and recycling. By understanding these critical elements, B2B buyers can mitigate risks, optimize costs, and identify reliable suppliers.

This guide empowers you to navigate the complexities of the iron market with confidence, ensuring that your procurement strategies align with industry standards and sustainability practices. Whether you are sourcing for large-scale construction projects or specialized manufacturing needs, the insights contained herein will help you forge successful partnerships and enhance your supply chain efficiency.

Understanding iron periodic table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Steel | Alloy of iron and carbon; varying carbon content | Construction, automotive, machinery | Pros: Cost-effective; versatile. Cons: Prone to corrosion without treatment. |

| Alloy Steel | Contains additional elements like nickel, chromium | Heavy machinery, pipelines, bridges | Pros: Enhanced strength and toughness. Cons: Higher cost than carbon steel. |

| Stainless Steel | Contains at least 10.5% chromium; corrosion-resistant | Medical instruments, kitchenware, architecture | Pros: Durable and resistant to rust. Cons: More expensive; requires specialized machining. |

| Cast Iron | High carbon content (3-5%); brittle but strong | Pipes, automotive parts, cookware | Pros: Excellent castability; cost-effective. Cons: Brittle; less malleable than steel. |

| Wrought Iron | Low carbon content; malleable and ductile | Decorative items, railings, gates | Pros: High tensile strength; corrosion-resistant. Cons: More expensive; limited applications compared to steel. |

What are the Characteristics and Suitability of Carbon Steel?

Carbon steel is primarily composed of iron and carbon, with carbon content ranging from 0.1% to 2%. It is widely used in construction, automotive, and machinery applications due to its excellent tensile strength and affordability. When purchasing carbon steel, buyers should consider the specific carbon content required for their application, as this affects the material’s hardness and ductility. Additionally, appropriate corrosion protection methods, such as galvanizing, may be necessary to enhance durability in humid environments.

How Does Alloy Steel Differ from Other Types?

Alloy steel incorporates various elements, such as nickel, chromium, and molybdenum, to improve its mechanical properties. This type of steel is ideal for heavy machinery, pipelines, and structural applications where strength and resistance to wear are critical. Buyers should evaluate the specific alloying elements based on their application needs, as these can significantly influence the material’s performance and cost. The investment in alloy steel often leads to longer-lasting products, justifying the higher price point.

Why Choose Stainless Steel for Your Applications?

Stainless steel contains a minimum of 10.5% chromium, which imparts excellent corrosion resistance and durability. It is commonly used in medical instruments, kitchenware, and architectural applications. When sourcing stainless steel, B2B buyers should consider the grade of stainless steel required, as different grades offer varying levels of corrosion resistance and strength. While stainless steel tends to be more expensive than carbon steel, its longevity and low maintenance requirements can result in cost savings over time.

What Makes Cast Iron a Viable Option?

Cast iron is characterized by its high carbon content (3-5%), which grants it exceptional castability and strength. This material is frequently used in pipes, automotive parts, and cookware. Buyers should be mindful of cast iron’s brittleness, which can limit its applications. However, its cost-effectiveness and ability to withstand high temperatures make it an attractive option for specific industries. It is essential to assess the intended use to ensure that cast iron meets performance requirements.

What are the Benefits of Wrought Iron?

Wrought iron is known for its low carbon content, making it malleable and ductile. It is often used for decorative items, railings, and gates due to its aesthetic appeal and high tensile strength. When considering wrought iron, B2B buyers should factor in its cost and the limited applications compared to more commonly used steels. Despite its higher price point, wrought iron’s resistance to corrosion and ability to be shaped into intricate designs make it a valuable choice for specialized applications.

Key Industrial Applications of iron periodic table

| Industry/Sector | Specific Application of Iron Periodic Table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Steel production for buildings and bridges | Provides structural integrity and durability | Quality of iron ore, local regulations, and transportation costs |

| Automotive | Manufacturing of vehicle frames and components | Enhances safety and performance of vehicles | Availability of high-grade steel and alloy specifications |

| Heavy Machinery | Production of cast iron parts for machinery | Ensures longevity and reliability of equipment | Sourcing from reputable foundries and alloy composition |

| Energy & Utilities | Iron catalysts in ammonia production and renewable energy systems | Improves efficiency in energy production processes | Compliance with environmental standards and supplier reliability |

| Consumer Goods | Production of kitchenware and appliances using stainless steel | Offers corrosion resistance and aesthetic appeal | Certification of food-grade materials and durability tests |

How is Iron Used in Construction & Infrastructure Projects?

In the construction and infrastructure sector, iron is primarily utilized to produce steel, which is essential for building structures like skyscrapers and bridges. The strength of iron allows for thinner and lighter constructions without compromising safety. International buyers need to consider the quality of iron ore, as impurities can affect the final product’s integrity. Additionally, understanding local regulations regarding construction materials is crucial, especially in regions like the Middle East and Africa, where standards may vary significantly.

What Role Does Iron Play in the Automotive Industry?

Iron’s role in the automotive industry is predominantly in the form of steel, which is used to manufacture vehicle frames and components. This application enhances the safety and performance of vehicles, making them more durable in various conditions. For B2B buyers, sourcing high-grade steel that meets specific automotive standards is critical. Availability of materials and the ability to meet just-in-time delivery schedules can significantly impact production timelines, especially in South America and Europe.

Why is Cast Iron Important for Heavy Machinery?

In heavy machinery, cast iron is favored for its excellent wear resistance and durability. It is used to produce various components such as engine blocks and machine bases. This application ensures that equipment can withstand harsh operating conditions, leading to reduced maintenance costs. Buyers should focus on sourcing from reputable foundries that can provide consistent quality and adhere to specific alloy compositions to meet machinery performance requirements.

How is Iron Utilized in Energy Production?

Iron serves as a catalyst in various energy production processes, including ammonia synthesis and renewable energy systems. This application is vital for improving efficiency in producing fertilizers and alternative fuels. International buyers, particularly from regions like Africa and the Middle East, should ensure that suppliers comply with environmental standards and possess a reliable track record. Understanding the specific requirements for catalyst performance can also help in selecting the right sourcing partners.

What are the Benefits of Using Iron in Consumer Goods?

In the consumer goods sector, iron is predominantly used in the form of stainless steel for kitchenware and appliances. This application provides corrosion resistance and enhances the aesthetic appeal of products. For B2B buyers, it is essential to source materials that are certified for food safety and durability. Conducting thorough supplier evaluations to ensure compliance with quality standards can significantly influence product success in competitive markets across Europe and South America.

3 Common User Pain Points for ‘iron periodic table’ & Their Solutions

Scenario 1: Understanding Iron Allotropes and Their Impact on Applications

The Problem: B2B buyers often face confusion regarding the different allotropes of iron, such as alpha-iron (ferrite) and gamma-iron (austenite), and how these variations affect the properties of steel. This lack of clarity can lead to miscommunication with suppliers, resulting in ordering the wrong type of iron for specific applications. For example, using ferrite in a situation that requires the toughness of austenite can compromise the integrity of the final product, leading to costly production delays or failures.

The Solution: To effectively navigate the complexities of iron allotropes, B2B buyers should invest in comprehensive training for their procurement teams focused on the properties and applications of different iron forms. This training should include understanding the phase diagram of iron, which illustrates the transitions between different allotropes at varying temperatures and carbon concentrations. Additionally, establishing close relationships with suppliers who can provide detailed material specifications will help ensure accurate ordering. Buyers should also utilize advanced materials characterization techniques to confirm the properties of iron before finalizing any purchase, minimizing the risk of costly errors.

Scenario 2: Addressing Corrosion Resistance in Iron Products

The Problem: One of the most significant challenges B2B buyers encounter is the susceptibility of iron to corrosion, particularly in humid or corrosive environments. This issue is critical for industries such as construction and manufacturing, where the longevity and durability of materials directly impact safety and operational efficiency. Buyers may find that standard iron products do not meet the necessary corrosion resistance, leading to premature failure and increased maintenance costs.

The Solution: To combat corrosion issues, B2B buyers should consider sourcing corrosion-resistant alloys, such as stainless steel, which contains at least 10.5% chromium. They should work closely with suppliers to specify the right alloying elements based on the environmental conditions of their projects. Additionally, implementing protective coatings or galvanization processes can significantly enhance the lifespan of iron products. Buyers should also regularly review and adapt their material specifications based on evolving industry standards and technological advancements in corrosion protection.

Scenario 3: Ensuring Consistency in Iron Supply Chains

The Problem: International B2B buyers often struggle with inconsistent supply chains for iron, particularly when sourcing from different regions like Africa or South America. Fluctuations in availability can lead to production delays, increased costs, and even project cancellations. Additionally, varying quality standards across suppliers can result in discrepancies that affect product performance and compliance with local regulations.

The Solution: To mitigate supply chain inconsistencies, B2B buyers should establish long-term partnerships with reliable suppliers who demonstrate a commitment to quality and transparency. Conducting regular audits and quality checks of suppliers’ facilities can help ensure adherence to international standards. Furthermore, buyers should diversify their sourcing strategies by engaging multiple suppliers across different regions to reduce dependency on any single source. Implementing a robust supply chain management system that tracks inventory levels and supplier performance can also enhance operational efficiency and responsiveness to market changes. Regular communication with suppliers about demand forecasts and potential disruptions will foster a collaborative approach to problem-solving, ensuring a steady supply of high-quality iron products.

Strategic Material Selection Guide for iron periodic table

What Are the Key Properties of Iron and Its Alloys for B2B Buyers?

Iron and its alloys are fundamental materials in various industries, particularly in construction, manufacturing, and engineering. Understanding the properties of different iron materials is essential for international B2B buyers to make informed purchasing decisions.

Ductile Iron: What Are Its Key Properties and Applications?

Ductile iron, also known as nodular cast iron, is characterized by its high ductility and strength. It typically has a tensile strength of 60,000 psi and excellent fatigue resistance. Ductile iron is also resistant to corrosion and has good wear resistance, making it suitable for applications in automotive components, pipes, and heavy machinery.

Pros: Ductile iron offers high durability and can withstand significant stress, making it ideal for high-performance applications. Its manufacturing process is relatively straightforward, allowing for cost-effective production.

Cons: While ductile iron is strong, it can be more expensive than traditional cast iron. Additionally, its production requires careful control of the alloying elements to achieve the desired properties.

Impact on Application: Ductile iron is compatible with various media, including water and gases, making it a preferred choice for piping systems.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, especially when sourcing for infrastructure projects.

Carbon Steel: How Does It Compare in Terms of Performance?

Carbon steel is an alloy of iron and carbon, with varying carbon content influencing its properties. Low-carbon steel is malleable and ductile, while high-carbon steel is stronger and harder. Carbon steel is widely used in construction, automotive, and manufacturing applications due to its excellent strength-to-weight ratio.

Pros: Carbon steel is relatively inexpensive and easy to manufacture, making it a popular choice for various applications. Its versatility allows for a wide range of uses, from structural beams to cutting tools.

Cons: Carbon steel is prone to rusting and requires protective coatings or treatments to enhance corrosion resistance.

Impact on Application: Carbon steel is suitable for structural applications but may not be ideal for environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers: Buyers should be aware of the specific grades of carbon steel that meet international standards and local regulations, especially in Europe and South America, where compliance is crucial.

Stainless Steel: What Are Its Advantages for Corrosion Resistance?

Stainless steel is an alloy that contains a minimum of 10.5% chromium, which provides excellent corrosion resistance. It is widely used in food processing, pharmaceuticals, and architectural applications due to its aesthetic appeal and hygienic properties.

Pros: The primary advantage of stainless steel is its resistance to corrosion and staining, making it ideal for environments that require cleanliness and durability. It also has a long lifespan, reducing replacement costs over time.

Cons: Stainless steel can be more expensive than carbon steel and may require specialized welding techniques during fabrication.

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic and alkaline substances, making it suitable for chemical processing industries.

Considerations for International Buyers: Buyers in Turkey and Europe should consider the specific grades of stainless steel that comply with local standards, such as EN or ASTM, to ensure quality and performance.

Cast Iron: What Are Its Unique Properties and Uses?

Cast iron is known for its excellent castability and machinability. It typically contains 2-4% carbon and is used in applications such as engine blocks, pipes, and cookware. Cast iron is durable and can withstand high temperatures.

Pros: Cast iron is cost-effective and has excellent wear resistance, making it suitable for heavy-duty applications.

Cons: It is brittle and can crack under stress, limiting its use in high-impact applications.

Impact on Application: Cast iron is compatible with various media but may require protective coatings in corrosive environments.

Considerations for International Buyers: Buyers should ensure that cast iron products meet relevant standards, as specifications can vary significantly across regions.

Summary Table of Iron Materials for B2B Buyers

| Material | Typical Use Case for iron periodic table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ductile Iron | Automotive components, pipes, heavy machinery | High durability and stress resistance | Higher cost than traditional cast iron | Medium |

| Carbon Steel | Structural beams, cutting tools | Inexpensive and versatile | Prone to rust without coatings | Low |

| Stainless Steel | Food processing, pharmaceuticals, architecture | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Cast Iron | Engine blocks, pipes, cookware | Cost-effective and wear resistant | Brittle and limited impact resistance | Low |

This guide provides a comprehensive overview of the key materials related to iron, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for iron periodic table

What Are the Key Stages in Iron Manufacturing Processes?

The manufacturing of iron involves several critical stages that ensure the production of high-quality iron suitable for various applications. Understanding these stages is essential for B2B buyers looking to source iron products from international suppliers.

1. Material Preparation

The first step in the manufacturing process is material preparation, which involves the extraction and processing of iron ore. The most common ores are hematite and magnetite, which are subjected to crushing and grinding to liberate the iron content. This is followed by concentration techniques, such as magnetic separation or flotation, to enhance the iron concentration before moving to the smelting stage.

2. Smelting

Smelting is the process where concentrated iron ore is transformed into molten iron, typically using a blast furnace. In this stage, coke (a form of carbon) is used as a reducing agent along with limestone, which acts as a flux to remove impurities. The resultant pig iron, which contains about 3% carbon, is collected at the bottom of the furnace. This step is critical, as the quality of the pig iron directly impacts the final product’s properties.

3. Forming

Once the pig iron is produced, it undergoes various forming processes to create different iron products. This can include casting, where molten iron is poured into molds to create specific shapes, or forging, which involves shaping the iron using compressive forces. Techniques such as rolling and extrusion may also be employed to produce sheets, bars, and other shapes required for construction and manufacturing.

4. Finishing

The finishing stage encompasses several processes aimed at enhancing the iron’s properties and preparing it for end-use. This may include heat treatment to improve strength and ductility, surface treatments to prevent rust (such as galvanizing), and machining to achieve precise dimensions. Each finishing technique contributes to the overall performance and lifespan of iron products.

How Is Quality Assurance Implemented in Iron Manufacturing?

Quality assurance (QA) is crucial in ensuring that iron products meet international standards and customer requirements. B2B buyers should be familiar with the QA processes and standards applicable to their suppliers.

Relevant International Standards for Iron Quality

The primary international standard for quality management systems is ISO 9001, which provides a framework for consistent quality in manufacturing. Additionally, industry-specific certifications, such as CE marking for European markets and API (American Petroleum Institute) certifications for oil and gas applications, are significant indicators of quality assurance. Suppliers who comply with these standards demonstrate their commitment to quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in iron manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials (iron ore, additives) to ensure they meet specified quality criteria before production begins.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to check the quality of the product at various stages, such as during smelting and forming. This includes regular sampling and testing to detect any deviations from quality standards.

-

Final Quality Control (FQC): After the manufacturing process, the final products are subjected to thorough testing and inspection to ensure they meet the required specifications before being shipped to customers.

What Common Testing Methods Are Used in Iron Quality Assurance?

Several testing methods are employed to verify the quality of iron products:

-

Chemical Analysis: This involves determining the composition of iron and its alloys to ensure that they meet specified chemical properties.

-

Mechanical Testing: Tests such as tensile strength, hardness, and impact resistance are conducted to assess the material’s performance under stress.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and magnetic particle inspection are used to detect internal and surface defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability.

Conducting Supplier Audits

Buyers should conduct regular audits of their suppliers’ manufacturing processes and quality control systems. This can include on-site visits to observe operations and assess compliance with international standards.

Requesting Quality Reports

Suppliers should provide detailed quality reports that outline their QA processes, results of testing, and certifications. These documents serve as evidence of the supplier’s commitment to quality and can help buyers make informed decisions.

Utilizing Third-Party Inspections

Engaging third-party inspection services can further enhance confidence in the quality of products. These independent entities can conduct audits and testing, providing an unbiased assessment of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances when it comes to quality control in different regions.

-

Understanding Local Standards: Different regions may have varying standards and regulations governing iron production. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Considerations: Communication and business practices can differ across cultures. Establishing clear quality expectations and maintaining open lines of communication with suppliers can mitigate misunderstandings.

-

Logistical Challenges: International shipping can introduce additional quality control challenges, such as damage during transit. Buyers should work with suppliers to establish proper packaging and handling procedures to protect products.

In summary, understanding the manufacturing processes and quality assurance practices in the iron industry is vital for B2B buyers. By focusing on these areas, buyers can ensure they source high-quality iron products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘iron periodic table’

The procurement of iron and its alloys is critical for a wide range of industries, from construction to manufacturing. This guide provides B2B buyers, especially those from Africa, South America, the Middle East, and Europe, with actionable steps to ensure an efficient and effective sourcing process.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for your iron procurement. This includes the type of iron (e.g., cast iron, wrought iron, or steel), desired grades, and specific properties such as tensile strength and corrosion resistance. Defining these parameters helps streamline the sourcing process and ensures that you receive materials that meet your operational needs.

- Consider alloying elements: Specify any necessary alloying elements (e.g., carbon, chromium) that might be essential for your application.

- Identify industry standards: Familiarize yourself with relevant industry standards and certifications that the iron must meet.

Step 2: Conduct Market Research

Research the current market landscape to identify potential suppliers and understand pricing trends. This includes analyzing regional markets, especially if sourcing from Africa or South America, where local suppliers may offer competitive rates.

- Assess supply chain dynamics: Understand factors that could affect supply, such as local mining laws or export regulations.

- Explore different sourcing regions: Compare suppliers from various regions, including Europe and the Middle East, to find the best quality and price.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. This involves checking their backgrounds, production capabilities, and customer testimonials.

- Request documentation: Ask for company profiles, production certifications, and quality assurance processes.

- Seek references: Contact other businesses that have sourced from these suppliers to gauge their reliability and product quality.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold necessary certifications that guarantee quality and compliance with international standards. Certifications may include ISO standards or specific industry certifications related to metal production.

- Check for environmental compliance: Especially relevant in regions like Europe, where sustainability practices are increasingly scrutinized.

- Ensure safety standards: Confirm that suppliers comply with safety and health regulations during production.

Step 5: Negotiate Terms of Purchase

Once you have selected a supplier, it’s time to negotiate the terms of purchase. This includes price, payment terms, delivery schedules, and return policies.

- Establish clear agreements: Document all agreements to avoid misunderstandings and ensure accountability.

- Consider long-term contracts: If you anticipate ongoing needs, explore the benefits of long-term contracts that might provide cost savings.

Step 6: Plan for Quality Control

Implement a robust quality control process to assess the iron upon delivery. This ensures that the material meets the specified requirements and standards.

- Conduct inspections: Arrange for third-party inspections if necessary, to validate quality before acceptance.

- Establish testing protocols: Define testing methods to assess properties like hardness, tensile strength, and chemical composition.

Step 7: Establish a Relationship with Suppliers

Building a strong relationship with your suppliers can lead to better service, improved pricing, and priority access to new products.

- Maintain open communication: Regularly communicate your needs and feedback to suppliers to foster a collaborative partnership.

- Consider strategic alliances: Forming alliances with key suppliers can provide a competitive edge in the market.

By following this comprehensive sourcing checklist, B2B buyers can enhance their procurement strategies for iron, ensuring they secure quality materials that meet their operational demands efficiently.

Comprehensive Cost and Pricing Analysis for iron periodic table Sourcing

What Are the Key Cost Components in Iron Sourcing?

When sourcing iron for industrial applications, understanding the cost structure is critical. The primary cost components include:

-

Materials: The primary cost driver is the iron ore itself, which varies based on purity and market demand. The most common ores are haematite and magnetite, with prices fluctuating based on global supply and demand dynamics.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as certain regions in Africa and South America, this can provide a competitive advantage.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and other operational expenses incurred during the production process. Efficient production processes can help minimize these costs.

-

Tooling: Investment in specialized machinery and equipment is necessary for producing high-quality iron products. The cost of tooling is often amortized over the production run, affecting pricing.

-

Quality Control (QC): Ensuring compliance with international quality standards incurs additional costs but is essential for maintaining product integrity, especially when supplying to regions with strict regulatory requirements.

-

Logistics: Transportation costs can vary widely based on distance from the production facility to the buyer, mode of transport, and local infrastructure. Import duties and tariffs also play a significant role in the overall logistics cost.

-

Margin: Suppliers typically apply a profit margin to cover their operational risks and ensure sustainability. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect Iron Sourcing Decisions?

Several factors influence pricing when sourcing iron:

-

Volume/MOQ: Minimum Order Quantities (MOQs) significantly impact pricing. Bulk purchases often lead to lower per-unit costs, making it advantageous for larger buyers.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers must clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO standards) usually come at a premium but are essential for certain applications. Buyers should weigh the importance of certifications against cost.

-

Supplier Factors: Supplier reliability, reputation, and production capacity can influence pricing. Established suppliers may charge higher prices due to their track record of quality and service.

-

Incoterms: The choice of Incoterms affects the total cost of ownership. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to accurately assess landed costs.

What Are the Best Buyer Tips for Cost Efficiency in Iron Sourcing?

To enhance cost efficiency when sourcing iron, B2B buyers should consider the following strategies:

-

Negotiation: Engage in proactive negotiations. Understanding market trends and being informed about competitors’ pricing can provide leverage during discussions with suppliers.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the purchase price. This includes logistics, maintenance, and potential wastage costs, providing a more comprehensive view of the investment.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, trade policies, and regional market conditions that may affect pricing.

-

Build Long-term Relationships: Establishing long-term relationships with suppliers can lead to better pricing, improved service, and preferential treatment during supply shortages.

-

Stay Informed on Market Trends: Regularly monitoring the iron market for price trends, geopolitical factors, and supply chain disruptions can help buyers make timely and informed purchasing decisions.

Disclaimer on Pricing

Prices for iron are subject to frequent changes due to market volatility. The insights provided here are indicative and should not be considered fixed prices. Always conduct market research and consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing iron periodic table With Other Solutions

Understanding Alternatives to Iron in Industrial Applications

In the landscape of industrial materials, iron remains a pivotal element due to its strength, versatility, and cost-effectiveness. However, various alternatives have emerged that offer unique benefits suited for specific applications. This section delves into a comparative analysis of the ‘iron periodic table’ and its alternatives, providing actionable insights for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

A stock image related to iron periodic table.

Comparison of Iron Against Alternative Materials

| Comparison Aspect | Iron Periodic Table | Aluminum Alloys | Composite Materials |

|---|---|---|---|

| Performance | High tensile strength; good ductility | Lightweight; corrosion-resistant; lower strength than iron | High strength-to-weight ratio; customizable properties |

| Cost | Generally low cost; abundant supply | Higher cost than iron; fluctuates with global demand | Varies widely based on materials; typically higher than iron |

| Ease of Implementation | Well-understood; widely available | Requires specialized processes for fabrication | Complex production; may require advanced technology |

| Maintenance | Prone to rust; requires protective coatings | Generally low maintenance; corrosion-resistant | Low maintenance; may require periodic inspections |

| Best Use Case | Structural applications; heavy machinery | Aerospace; automotive industries | High-performance applications; sports equipment; advanced construction |

Analyzing Aluminum Alloys as an Alternative to Iron

Aluminum alloys are increasingly utilized in industries that prioritize weight reduction without significantly sacrificing strength. They are particularly advantageous in sectors like aerospace and automotive manufacturing, where reducing weight can lead to improved fuel efficiency. However, while aluminum alloys are resistant to corrosion and have excellent thermal conductivity, they can be more expensive than iron and may not provide the same level of strength for heavy structural applications.

Exploring Composite Materials as a Modern Solution

Composite materials, which combine two or more constituent materials, present a unique alternative to iron. They offer high strength-to-weight ratios and can be tailored for specific applications, making them ideal for advanced engineering projects, such as in the aerospace and sports equipment industries. Despite their benefits, composites often require complex manufacturing processes and a higher initial investment compared to iron. Additionally, their long-term durability and recyclability can vary significantly based on the materials used, which may be a consideration for environmentally conscious buyers.

Conclusion: Choosing the Right Material for Your Needs

When selecting between iron and its alternatives, international B2B buyers must consider various factors, including performance requirements, budget constraints, and the specific application for which the material will be used. Iron remains a robust choice for structural applications due to its availability and cost-effectiveness. However, for industries that require lightweight materials or enhanced corrosion resistance, aluminum alloys or composites may be more suitable. By carefully evaluating these options against their unique needs, buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for iron periodic table

What Are the Key Technical Properties of Iron for B2B Buyers?

Understanding the technical properties of iron is crucial for international B2B buyers, particularly in sectors like construction, manufacturing, and automotive. Here are some essential specifications that should be considered:

1. Material Grades

Material grades indicate the quality and type of iron used in production. Common grades include carbon steel (low, medium, and high carbon), stainless steel, and cast iron. For instance, low carbon steel is ductile and malleable, making it suitable for welding, while high carbon steel is stronger and used in tools. Knowing the grade helps in selecting the right material for specific applications, influencing durability and performance.

2. Tolerance Specifications

Tolerance refers to the allowable deviation from a standard dimension. In iron products, tighter tolerances are often required for precision applications, such as machinery parts. Specifications such as ±0.01 mm can drastically affect the functionality and compatibility of components in machinery or construction projects. Buyers should ensure that suppliers can meet these tolerance requirements to avoid costly adjustments later.

3. Melting and Boiling Points

Iron has a melting point of approximately 1538°C and a boiling point of 2861°C. These properties are critical when considering the application environment. For example, components exposed to high temperatures in automotive engines need to withstand thermal stresses. Understanding these limits helps buyers choose appropriate materials for high-performance applications.

4. Density

Iron has a density of 7.87 g/cm³, which is a crucial factor in calculating weight and load-bearing capabilities in construction and manufacturing. In structural engineering, knowing the density allows for accurate weight distribution calculations, ensuring safety and compliance with building codes.

5. Corrosion Resistance

While iron rusts easily, certain alloys like stainless steel (which contains at least 10.5% chromium) offer enhanced corrosion resistance. For B2B buyers in coastal regions or industries like oil and gas, selecting materials that resist corrosion is vital to reduce maintenance costs and extend product lifespan.

6. Isotopes and Their Applications

Iron has several isotopes, with Iron-56 being the most stable and abundant. Understanding the isotopes can be important in specialized applications like nuclear reactors or medical technologies, where specific isotopes may be required for certain reactions or imaging techniques.

What Trade Terminology Should B2B Buyers Know When Dealing with Iron?

Navigating the iron market requires familiarity with specific trade terminology that can impact procurement processes. Here are key terms that international buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the iron industry, OEMs are vital suppliers for manufacturers needing specific iron components. Establishing relationships with reputable OEMs can streamline the supply chain and ensure quality.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For international buyers, understanding MOQ is crucial for budgeting and inventory management. Suppliers may set high MOQs for specialized iron products, which can affect smaller businesses’ ability to procure necessary materials.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. For B2B buyers, a well-structured RFQ can lead to competitive pricing and better terms, making it an essential tool for procurement.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help B2B buyers manage shipping costs and risks effectively, ensuring clarity in contracts and negotiations.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the iron industry, lead times can vary based on material availability and production schedules. Knowing the lead time helps buyers plan projects and manage cash flow effectively.

6. Certification Standards

Certification standards, such as ISO or ASTM, ensure that iron products meet specific quality and safety requirements. Familiarity with these standards is crucial for B2B buyers to ensure compliance and reliability in their supply chains.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the iron periodic table Sector

What Are the Current Market Dynamics and Key Trends in the Iron Sector?

The global iron market is experiencing significant shifts driven by various factors including economic recovery post-COVID-19, rising demand for steel, and technological advancements in mining and processing. Key markets in Africa, South America, the Middle East, and Europe are particularly influenced by infrastructural development and urbanization. For instance, countries like Turkey and Saudi Arabia are heavily investing in construction projects, which has led to an increased demand for high-quality iron and its alloys.

Emerging technologies such as automation in mining operations and the use of artificial intelligence for predictive maintenance are reshaping sourcing strategies. International B2B buyers are increasingly seeking suppliers who can provide not only raw materials but also innovative solutions that enhance operational efficiency. Additionally, the rise of e-commerce platforms for B2B transactions is making it easier for buyers in remote areas to access global suppliers and compare prices and quality.

Moreover, the shift towards renewable energy sources is creating a demand for specialized iron products, particularly those used in wind turbines and solar panels. This trend presents opportunities for buyers to diversify their sourcing strategies by considering suppliers who focus on these niche markets. As the demand for iron continues to grow, understanding these market dynamics and trends is crucial for international buyers to make informed procurement decisions.

How Is Sustainability and Ethical Sourcing Impacting the Iron Industry?

Sustainability is becoming a paramount concern for B2B buyers in the iron sector. The environmental impact of iron production, particularly through traditional blast furnace methods, is significant, contributing to carbon emissions and ecological degradation. As a result, there is a growing emphasis on ethical sourcing practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable mining practices and provide transparency in their supply chains.

Certifications such as ISO 14001 (Environmental Management) and initiatives like the ResponsibleSteel certification are gaining traction. These certifications ensure that the iron sourced meets specific environmental and social standards. Buyers in regions like Europe are particularly focused on sourcing materials that comply with stringent environmental regulations, making it imperative for suppliers to adapt to these standards.

Additionally, the market is witnessing a rise in demand for ‘green’ iron products. Technologies that utilize renewable energy in iron production and methods that reduce water usage are becoming more prevalent. Buyers should consider integrating sustainability criteria into their procurement processes, as this not only aligns with global trends but also enhances their brand reputation and compliance with regulatory requirements.

What Is the Brief Evolution and History of Iron in B2B Context?

A stock image related to iron periodic table.

Iron’s history dates back to ancient civilizations, with its discovery around 3500 BC marking the beginning of the Iron Age. The Hittites were among the first to smelt iron from its ores around 1500 BC, leading to advancements in tools and weaponry that significantly influenced trade and economy. Over the centuries, iron evolved from a rudimentary material into a cornerstone of modern industry, primarily through its transformation into various alloys such as steel, which is crucial for construction and manufacturing.

In the B2B context, iron’s evolution reflects the changing needs of industries worldwide. The development of technologies for efficient iron extraction and processing has allowed for increased production capacity, meeting the rising global demand. Understanding this historical context can provide valuable insights into current sourcing practices and the potential future trends in the iron market, enabling international buyers to make strategic decisions that leverage both historical knowledge and modern innovations.

Frequently Asked Questions (FAQs) for B2B Buyers of iron periodic table

-

How do I source high-quality iron for my manufacturing needs?

When sourcing iron, start by identifying reputable suppliers with a proven track record in your region. Utilize online marketplaces and industry trade shows to connect with potential vendors. Request samples to assess quality, and verify certifications such as ISO or ASTM compliance. Consider suppliers who can provide detailed material specifications, including alloy compositions and mechanical properties, to ensure the iron meets your production standards. -

What is the best type of iron for steel manufacturing?

The best type of iron for steel manufacturing is pig iron, which is produced from iron ore in a blast furnace. This form of iron contains a higher carbon content and impurities, making it suitable for further processing into various steel grades. For specialized applications, consider using wrought iron or cast iron, depending on the desired strength, ductility, and corrosion resistance. Collaborating with your supplier to understand the specific requirements of your projects can lead to more tailored solutions. -

How can I evaluate suppliers of iron in international markets?

To evaluate suppliers in international markets, conduct thorough background checks to assess their reputation and reliability. Look for reviews from previous clients and check their financial stability. Request references and visit their facilities, if possible. It’s also beneficial to verify their compliance with international trade regulations and certifications, such as ISO 9001, which indicates a commitment to quality management practices. -

What are common payment terms in international iron trade?

Common payment terms in international iron trade include letters of credit, advance payments, and net 30 or net 60 terms. Letters of credit provide security for both buyer and seller, ensuring that payment is made only upon fulfilling the contract terms. Discuss payment options with your supplier upfront to find mutually agreeable terms, and be aware of currency exchange rates and transaction fees that may affect the final cost. -

What are the minimum order quantities (MOQ) for iron products?

Minimum order quantities (MOQ) for iron products can vary widely depending on the supplier and the specific type of iron. Typically, bulk suppliers may have MOQs ranging from 1 ton to several tons for standard iron grades. For customized orders or specialty alloys, MOQs may be higher. Always clarify these details during negotiations to ensure your order aligns with your production needs and budget. -

How do I ensure quality assurance for iron products?

To ensure quality assurance for iron products, request detailed quality control documentation from your supplier. This includes material test reports, certification of compliance, and inspection records. Implement a quality assurance process that includes receiving inspections and periodic audits of the supplier’s facilities. Establishing a clear communication channel for reporting any quality issues can also help in maintaining consistent standards. -

What logistics considerations should I be aware of when importing iron?

Logistics considerations for importing iron include understanding shipping methods, lead times, and customs regulations. Choose reliable freight forwarders experienced in handling bulk materials, and assess the best shipping routes to minimize costs and delivery times. Be aware of import duties and tariffs that may apply, and ensure all necessary documentation, such as bills of lading and import permits, are in order to avoid delays at customs. -

How can I customize iron products to meet specific project requirements?

Customizing iron products involves collaborating closely with your supplier to define specifications such as alloy composition, dimensions, and treatment processes. Discuss your project requirements in detail, including mechanical properties and environmental conditions the product will face. Many suppliers offer tailored solutions, but early engagement is key to ensuring they can meet your customization needs within the desired timeframe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for iron periodic table

A stock image related to iron periodic table.

How Can Strategic Sourcing of Iron Enhance Your Business?

In conclusion, strategic sourcing of iron is essential for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the diverse applications of iron and its alloys—ranging from construction materials to catalytic processes—can significantly impact your supply chain efficiency and cost management. By leveraging local and global suppliers, businesses can optimize their procurement strategies, ensuring high-quality materials while minimizing risks associated with price volatility and supply disruptions.

Moreover, the emphasis on sustainable practices, such as recycling iron and utilizing advanced extraction methods, can enhance your company’s environmental footprint. As the demand for steel continues to grow, especially in emerging markets, aligning your sourcing strategies with the latest industry trends will position your business for long-term success.

What Steps Should B2B Buyers Take Next?

For buyers in regions like Saudi Arabia and Turkey, now is the time to evaluate your sourcing strategies. Engage with suppliers who prioritize quality, sustainability, and innovation. Attend industry conferences and participate in trade shows to build relationships and gain insights into the latest market trends. Embrace the opportunities that strategic sourcing of iron presents, and take proactive steps to secure a competitive edge in your sector.