Your Ultimate Guide to Sourcing Bantam Tools Desktop Cnc

Introduction: Navigating the Global Market for bantam tools desktop cnc milling machine

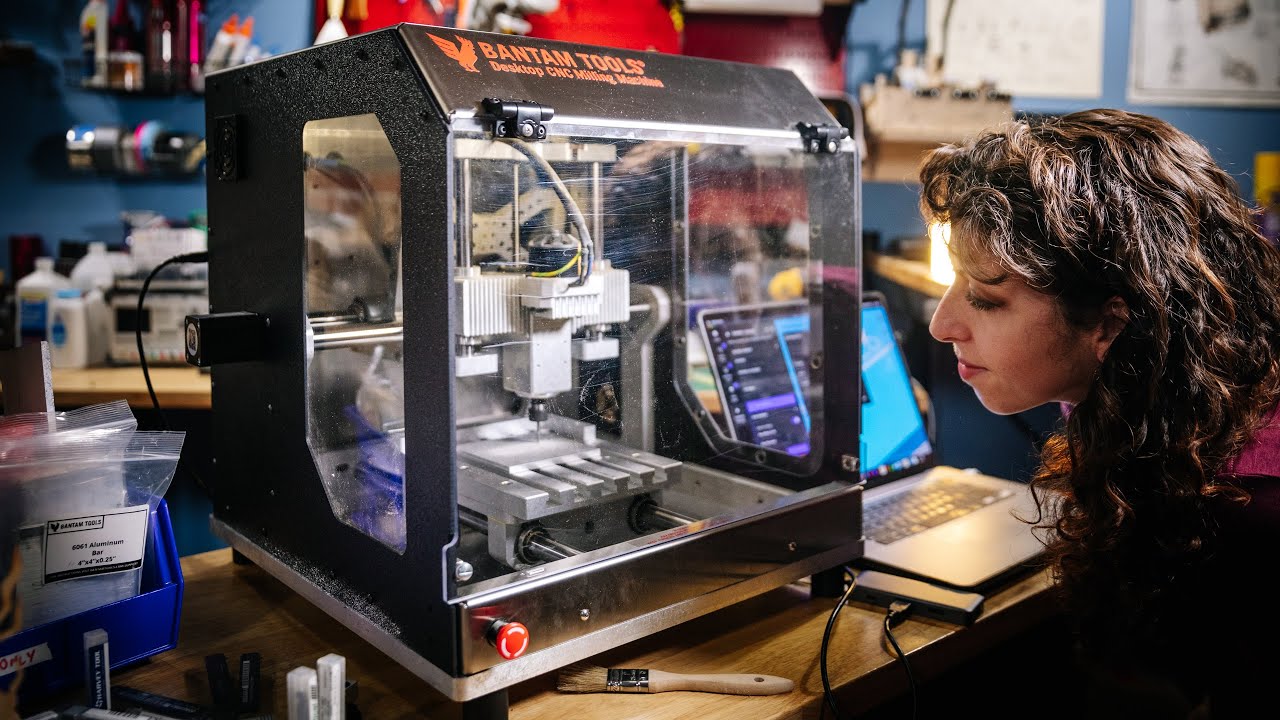

Navigating the complexities of the global market can be a daunting task for B2B buyers, especially when sourcing advanced manufacturing equipment like the Bantam Tools Desktop CNC Milling Machine. This innovative tool stands out in the realm of desktop manufacturing, offering precision and versatility that cater to diverse applications—from prototyping to small-scale production. Its ability to work with a variety of materials, including metals, plastics, and composites, makes it a valuable asset for businesses looking to enhance their manufacturing capabilities.

This guide serves as a comprehensive resource, equipping international buyers—particularly from Africa, South America, the Middle East, and Europe—with essential insights. We delve into the different types of Bantam Tools machines available, explore suitable materials for machining, and outline crucial manufacturing and quality control processes. Additionally, we provide a thorough analysis of suppliers, pricing structures, and market trends, ensuring that buyers are well-informed before making a purchase.

By leveraging the information within this guide, B2B buyers can make strategic sourcing decisions that align with their operational needs and budget constraints. Whether you are a startup in Nigeria seeking to innovate or an established firm in the UK looking to streamline production, understanding the nuances of the Bantam Tools Desktop CNC Milling Machine will empower you to navigate the global market with confidence and precision.

Understanding bantam tools desktop cnc milling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bantam Tools Desktop CNC Milling Machine | Compact design, user-friendly software | Prototyping, small batch production | Pros: Easy to use, versatile material options. Cons: Limited to smaller workpieces. |

| Bantam Tools Desktop PCB Milling Machine | Specialized for PCB fabrication, precise routing | Electronics prototyping, custom circuit boards | Pros: High precision, tailored for electronics. Cons: Requires specific tooling for PCBs. |

| Bantam Tools ArtFrame™ | Integrated drawing capabilities, artistic focus | Art installations, custom signage, educational tools | Pros: Unique artistic applications, supports creativity. Cons: Less suited for industrial-scale production. |

| Bantam Tools NextDraw™ | Enhanced drawing features, supports multiple media | Art projects, sketches, educational demonstrations | Pros: Versatile, supports creativity in design. Cons: May not have the same durability as standard milling machines. |

| Bantam Tools Studio™ | Comprehensive software suite for design and machining | Prototyping, educational environments | Pros: All-in-one solution, user-friendly interface. Cons: Software learning curve for new users. |

Bantam Tools Desktop CNC Milling Machine

The Bantam Tools Desktop CNC Milling Machine is designed for versatility and ease of use. Its compact form factor allows it to fit in smaller workshops or offices, making it ideal for startups and small businesses. It supports a wide range of materials, including plastics and metals, making it suitable for various applications such as prototyping and small batch production. Buyers should consider their workspace limitations and the types of materials they intend to use before purchasing.

Bantam Tools Desktop PCB Milling Machine

This specialized machine is tailored for the precise fabrication of printed circuit boards (PCBs). It features advanced routing capabilities and is equipped to handle intricate designs that are essential in electronics. Businesses involved in electronics prototyping or custom circuit board production will find this machine invaluable. Key purchasing considerations include the machine’s compatibility with different PCB materials and the availability of replacement parts and tools.

Bantam Tools ArtFrame™

The Bantam Tools ArtFrame™ integrates drawing capabilities with milling, allowing users to create artistic designs and installations. It is particularly useful in educational settings and for artists looking to explore new mediums. While it offers unique applications, buyers should evaluate whether its focus on artistry aligns with their production needs, as it may not be the best choice for industrial-scale manufacturing.

Bantam Tools NextDraw™

This tool enhances the creative process by allowing users to draw and design directly on various media. It’s particularly suited for art projects and educational demonstrations, providing a platform for creativity and innovation. Businesses should consider how the NextDraw™ fits into their workflow, especially if they prioritize artistic expression over traditional milling applications.

Bantam Tools Studio™

Bantam Tools Studio™ offers a comprehensive software suite that integrates design and machining processes, making it an attractive option for prototyping and educational environments. Its user-friendly interface is beneficial for those new to CNC milling, but buyers should be prepared for a learning curve as they familiarize themselves with the software’s capabilities. Considerations for purchase include the software’s compatibility with existing design tools and the support available for troubleshooting.

Related Video: Introducing The Bantam Tools Desktop CNC Milling Machine

Key Industrial Applications of bantam tools desktop cnc milling machine

| Industry/Sector | Specific Application of Bantam Tools Desktop CNC Milling Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | PCB Prototyping and Manufacturing | Faster turnaround for prototypes, reducing time to market | Material compatibility (e.g., FR-1 PCB blanks), precision requirements |

| Education | Educational Kits for Engineering and Design Courses | Hands-on learning experience, fostering innovation | Availability of training materials and support resources |

| Consumer Products | Custom Parts Production for Small Batch Runs | Cost-effective manufacturing for niche markets | Scalability of production, material options |

| Medical Devices | Creation of Surgical Instruments and Medical Prototypes | High precision and customization for critical applications | Compliance with health regulations, material safety certifications |

| Art and Design | Artistic Fabrication and Custom Art Projects | Unique design possibilities and rapid prototyping | Material diversity (e.g., acrylic, wood), finishing capabilities |

Electronics

In the electronics industry, the Bantam Tools Desktop CNC Milling Machine excels in PCB prototyping and manufacturing. This application allows businesses to quickly fabricate printed circuit boards (PCBs) for testing and development. With its capability to work with FR-1 PCB blanks, companies can significantly reduce the time to market for new electronic devices. International buyers should consider sourcing materials that meet their local standards and ensure the machine’s precision aligns with their design specifications.

Education

Educational institutions leverage the Bantam Tools CNC milling machine to provide students with hands-on experience in engineering and design. By incorporating this technology into their curriculum, schools foster innovation and creativity among students. For B2B buyers in Africa, South America, and the Middle East, sourcing educational kits that include the milling machine can enhance learning outcomes. It’s essential to ensure that training materials and support resources are readily available to maximize the machine’s educational impact.

Consumer Products

In the consumer products sector, businesses use the Bantam Tools machine for custom parts production, particularly for small batch runs. This capability allows companies to cater to niche markets without incurring the high costs typically associated with mass production. Buyers should evaluate the scalability of production and the range of materials available, ensuring they can meet diverse customer demands while maintaining quality and cost-effectiveness.

Medical Devices

The medical devices industry benefits from the precision and customization offered by the Bantam Tools CNC milling machine, particularly in creating surgical instruments and medical prototypes. This application is critical, as it requires adherence to strict regulatory standards and material safety certifications. Buyers in this sector should ensure that the machine’s capabilities align with the specific needs of their medical applications, including compliance with local health regulations.

Art and Design

Artists and designers utilize the Bantam Tools Desktop CNC Milling Machine for artistic fabrication and custom art projects. This application opens up unique design possibilities, allowing for rapid prototyping and the creation of intricate designs. For international buyers, sourcing diverse materials such as acrylic and wood is crucial to expand creative options. Additionally, understanding the machine’s finishing capabilities can enhance the overall quality of artistic outputs, making it a valuable tool for creative professionals.

Related Video: Bantam Tools Desktop CNC Milling Machine Review!

Strategic Material Selection Guide for bantam tools desktop cnc milling machine

When selecting materials for the Bantam Tools Desktop CNC Milling Machine, it is crucial to consider the unique properties of each material, their suitability for specific applications, and the implications for international B2B buyers. Below is an analysis of several common materials used with this machine, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

Machining Wax

Key Properties:

Machining wax is known for its low melting point, which allows for easy machining without excessive wear on the cutting tools. It has excellent dimensional stability and is non-toxic, making it suitable for various applications.

Pros & Cons:

The primary advantage of machining wax is its ease of use and low cost, making it ideal for prototyping and educational purposes. However, it lacks durability and is not suitable for high-stress applications. Its softness means that it can be easily damaged or deformed under pressure.

Impact on Application:

Machining wax is often used for creating molds and prototypes, especially in industries such as jewelry design and model making. Its compatibility with low-stress applications makes it a popular choice for initial design stages.

Considerations for International Buyers:

Buyers should ensure that the wax complies with local regulations regarding materials used in manufacturing. For instance, European buyers may refer to REACH regulations to ensure compliance with chemical safety standards.

Polycarbonate

Key Properties:

Polycarbonate is a robust thermoplastic with high impact resistance and excellent optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various applications.

Pros & Cons:

The key advantage of polycarbonate is its strength and versatility, making it suitable for applications requiring transparency and durability. However, it can be more expensive than other plastics, and its machining can be challenging due to its tendency to chip or crack.

Impact on Application:

Due to its durability and clarity, polycarbonate is often used in safety equipment, automotive parts, and electronic housings. Its compatibility with various environments makes it a preferred choice for industries requiring high-performance materials.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as ASTM or ISO for safety and performance. Additionally, understanding local market preferences for material properties can enhance product acceptance.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with excellent corrosion resistance and thermal conductivity. It is easy to machine and can be anodized for enhanced surface properties.

Pros & Cons:

Aluminum’s primary advantage is its balance of strength and weight, making it ideal for aerospace, automotive, and consumer products. However, it can be more expensive than other materials like plastics, and its machining requires specialized tools to avoid burrs and surface damage.

Impact on Application:

Aluminum is widely used in applications where weight savings are critical, such as in aerospace components and structural parts. Its thermal properties make it suitable for heat sinks and electronic enclosures.

Considerations for International Buyers:

Buyers should consider the specific aluminum alloy required for their application, as different alloys have varying properties. Compliance with international standards such as DIN or JIS is essential for ensuring product quality and performance.

Brass

Key Properties:

Brass is an alloy of copper and zinc, known for its excellent machinability, corrosion resistance, and aesthetic appeal. It has good thermal and electrical conductivity.

Pros & Cons:

The main advantage of brass is its workability and attractive finish, making it suitable for decorative applications and precision components. However, it can be more expensive than other metals, and its softness may limit its use in high-wear applications.

Impact on Application:

Brass is commonly used in plumbing fittings, musical instruments, and decorative items. Its compatibility with various environments makes it a versatile choice for many industries.

Considerations for International Buyers:

Buyers should be aware of the specific brass grades available in their region and ensure compliance with local standards for metalworking. Understanding the market demand for brass products can also guide purchasing decisions.

Summary Table

| Material | Typical Use Case for bantam tools desktop cnc milling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Machining Wax | Prototyping and mold making | Easy to machine | Low durability | Low |

| Polycarbonate | Safety equipment and automotive parts | High impact resistance | Expensive and challenging to machine | Medium |

| Aluminum | Aerospace components and structural parts | Lightweight and strong | Higher cost and specialized machining required | High |

| Brass | Plumbing fittings and decorative items | Excellent machinability | Higher cost and softness | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on the unique properties and applications of each material. Understanding these factors can enhance product development and market competitiveness across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for bantam tools desktop cnc milling machine

Manufacturing Processes for Bantam Tools Desktop CNC Milling Machine

The production of Bantam Tools’ desktop CNC milling machines involves a series of well-defined stages designed to ensure precision, reliability, and performance. This section delves into the key manufacturing processes and techniques employed, which are crucial for international B2B buyers looking to understand the intricacies behind the machines they may invest in.

1. Material Preparation

Material selection is fundamental to the manufacturing process. Bantam Tools primarily uses high-quality materials such as aluminum, brass, and various plastics (e.g., ABS, Delrin). The preparation phase includes:

- Sourcing: Reliable suppliers are chosen based on their ability to provide materials that meet strict specifications.

- Inspection: Incoming materials undergo Inspection Quality Control (IQC) to ensure they meet the required standards for dimensions and physical properties.

- Cutting and Machining: Materials are cut to specified sizes using advanced machinery, ensuring that they are ready for subsequent forming processes.

2. Forming

Forming processes are critical in shaping the components of the CNC milling machine. Bantam Tools utilizes techniques such as:

- CNC Machining: Computer Numerical Control (CNC) machining is employed to achieve high precision in component shaping. This includes milling, drilling, and turning operations.

- Injection Molding: For plastic components, injection molding is often used to create complex shapes with high repeatability.

- Casting: In some cases, metal parts may be produced through casting, allowing for intricate designs and robust structures.

These processes are executed with precision to ensure that components fit together seamlessly during assembly.

3. Assembly

The assembly stage is where individual components come together to form the complete CNC milling machine. Key aspects include:

- Workstations: Dedicated assembly lines with ergonomic workstations facilitate efficient assembly and minimize errors.

- Standard Operating Procedures (SOPs): Detailed SOPs guide technicians through the assembly process, ensuring consistency and quality.

- Quality Control Checkpoints: Throughout the assembly, Intermediary Process Quality Control (IPQC) checkpoints are established to monitor alignment, fit, and function.

This structured approach not only enhances efficiency but also minimizes defects.

4. Finishing

Finishing processes enhance both the aesthetic and functional qualities of the CNC milling machines. Techniques include:

- Surface Treatment: Processes such as anodizing for aluminum parts improve durability and corrosion resistance.

- Painting and Coating: Aesthetically pleasing finishes are achieved through painting and powder coating, which also provide additional protection.

- Final Assembly Inspection: Before packaging, a comprehensive inspection ensures that all components meet quality standards and function as intended.

Quality Assurance Standards

Quality assurance is paramount in the manufacturing of Bantam Tools’ CNC milling machines. To meet international standards and satisfy B2B buyers, the company adheres to several critical frameworks:

International Standards

- ISO 9001: This quality management standard ensures that the manufacturing processes are consistently monitored and improved, focusing on customer satisfaction and continual enhancement.

- CE Marking: Compliance with European safety, health, and environmental protection standards, indicated by the CE mark, is crucial for marketing the machines in Europe.

Industry-Specific Standards

- API: In certain applications, especially those involving oil and gas, adherence to American Petroleum Institute (API) standards may be necessary, ensuring equipment is suitable for demanding environments.

Quality Control Checkpoints

Bantam Tools employs a systematic approach to quality control throughout the manufacturing process, which includes:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before processing begins.

- In-Process Quality Control (IPQC): Regular checks during manufacturing allow for immediate corrective actions, reducing waste and defects.

- Final Quality Control (FQC): A thorough inspection at the end of the manufacturing process ensures that the final product meets all quality requirements.

Testing Methods

To validate the performance and safety of the CNC milling machines, Bantam Tools employs various testing methods, including:

- Functional Testing: Machines are run through operational tests to verify performance against specifications.

- Dimensional Testing: Precision measurements are taken to ensure that all components meet design tolerances.

- Material Testing: Samples from production batches may undergo stress testing or hardness testing to confirm material integrity.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, it is vital to verify the quality control practices of suppliers. Key strategies include:

- Supplier Audits: Conducting regular audits of suppliers can help assess compliance with quality standards and identify areas for improvement.

- Requesting Quality Reports: Buyers should request documentation of quality control processes and outcomes, including inspection reports and testing results.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased assessment of product quality and compliance with international standards.

Quality Control Nuances for International Buyers

International B2B buyers must navigate various nuances in quality control, such as:

- Cultural Differences: Understanding the local manufacturing culture and practices in regions like Africa and South America can help buyers set realistic expectations.

- Regulatory Compliance: Ensuring that products comply with local regulations in different markets (e.g., CE marking in Europe or ANSI standards in the USA) is crucial for legal and operational success.

- Communication: Establishing clear communication channels with suppliers facilitates transparency and ensures that quality concerns are addressed promptly.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when investing in Bantam Tools’ desktop CNC milling machines, ensuring they receive high-quality products tailored to their specific needs.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for bantam tools desktop cnc milling machine Sourcing

When sourcing the Bantam Tools Desktop CNC Milling Machine, understanding the comprehensive cost structure is essential for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. This analysis will cover the key cost components, price influencers, and actionable buyer tips to enhance negotiation and sourcing strategies.

Cost Components

-

Materials: The primary materials used in the manufacturing of the Bantam Tools Desktop CNC Milling Machine include high-grade aluminum, steel, and various plastics. The cost of these materials can fluctuate based on global market trends, making it crucial for buyers to stay informed about material prices.

-

Labor: Labor costs vary significantly depending on the manufacturing location. For example, countries in Europe may incur higher labor costs compared to those in Asia or South America. Understanding local labor rates can help buyers evaluate the overall production cost.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Buyers should inquire about how these costs are allocated in the pricing structure to ensure transparency.

-

Tooling: The Bantam Tools machine may require specific tooling for different applications. The initial investment in tooling can be substantial, but this cost is often amortized over the production volume, which is why understanding the expected usage is vital.

-

Quality Control (QC): Ensuring that the machines meet international standards may involve additional QC processes. Buyers should factor in these costs when comparing suppliers, as robust QC can prevent long-term issues and costs.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and size of the order. Understanding Incoterms is essential for clarifying responsibilities and potential costs associated with shipping.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s reputation, service level, and market demand.

Price Influencers

-

Volume/MOQ: Ordering in larger quantities can significantly reduce per-unit costs. Buyers should assess their needs and consider bulk purchasing to negotiate better prices.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should determine the necessity of customizations and seek standardized options where possible to control expenses.

-

Materials and Quality/Certifications: Premium materials and certifications (e.g., ISO) can enhance machine performance but may also lead to higher costs. Buyers must balance quality requirements with budget constraints.

-

Supplier Factors: The supplier’s location, production capacity, and market position can influence pricing. Building relationships with suppliers can lead to better pricing and service.

-

Incoterms: Different Incoterms can significantly impact the overall cost of sourcing. For instance, opting for DDP (Delivered Duty Paid) may seem convenient but could be more expensive than FOB (Free on Board) when considering logistics and duties.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of the cost components. Leverage knowledge about material costs and labor rates to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also operating costs, maintenance, and potential downtime. This perspective can lead to more informed purchasing decisions.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to local economic conditions and market demand.

-

Stay Updated: Continuously monitor market trends, material costs, and technological advancements. This vigilance can provide leverage in negotiations and help secure the best possible deal.

Disclaimer

Prices are indicative and can fluctuate based on market conditions, supplier negotiations, and other factors. Buyers should conduct thorough market research and engage with multiple suppliers to ensure competitive pricing.

Spotlight on Potential bantam tools desktop cnc milling machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bantam tools desktop cnc milling machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bantam tools desktop cnc milling machine

Key Technical Properties of Bantam Tools Desktop CNC Milling Machine

Understanding the essential technical properties of the Bantam Tools Desktop CNC Milling Machine is vital for international B2B buyers. Here are several critical specifications and their importance:

-

Material Compatibility

– The Bantam Tools CNC milling machine supports a variety of materials including aluminum, brass, copper, acrylic, and machining wax. This versatility allows businesses to cater to different projects, enhancing their production capabilities and market reach. Knowing which materials can be processed is crucial for buyers to ensure they can meet their customers’ needs. -

Machining Tolerance

– The machine is capable of achieving tolerances as tight as ±0.1 mm. High precision is essential in industries like electronics and aerospace, where even minor discrepancies can lead to significant failures. Buyers should assess their project requirements against the machine’s capabilities to ensure it meets their quality standards. -

Spindle Speed

– With a spindle speed range of 0 to 10,000 RPM, the machine allows for optimal cutting conditions depending on the material. Higher spindle speeds can improve machining efficiency and surface finish, which is particularly beneficial for intricate designs. Buyers must consider the spindle speed to align with their production timelines and quality expectations. -

Work Area Dimensions

– The work area dimensions of 100 mm x 200 mm x 100 mm provide ample space for a variety of projects. This specification is critical for businesses that may be working on larger components or multiple smaller parts simultaneously. Understanding the size constraints helps buyers plan their production processes accordingly. -

Software Integration

– The Bantam Tools CNC machine integrates with software like Fusion 360 and Bantam Tools Studio, enabling seamless design and machining workflows. Effective software integration is vital for enhancing productivity and reducing the learning curve for operators. Buyers should ensure that their team is proficient in these software applications to maximize the machine’s potential.

Common Trade Terminology

In addition to technical properties, understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the Bantam Tools Desktop CNC Milling Machine:

- OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing quality components and equipment.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory and budget effectively, especially when entering new markets or scaling production. -

RFQ (Request for Quotation)

– A formal document requesting price quotes from suppliers for specific products or services. Using RFQs can streamline the purchasing process and ensure competitive pricing, which is essential for maintaining profitability. -

Incoterms (International Commercial Terms)

– A set of predefined international trade terms that outline the responsibilities of buyers and sellers. Familiarity with Incoterms helps in understanding shipping, insurance, and liability, which are critical for international transactions. -

Lead Time

– This refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for project planning and ensuring that production schedules are met without delays. -

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

– These technologies are used for designing and manufacturing products. Familiarity with CAD/CAM systems is essential for optimizing the design process and ensuring compatibility with CNC machinery.

By grasping these technical properties and terminology, international B2B buyers can make informed decisions and enhance their operational efficiency when investing in Bantam Tools Desktop CNC Milling Machines.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bantam tools desktop cnc milling machine Sector

Market Overview & Key Trends

The global market for desktop CNC milling machines, including models like the Bantam Tools Desktop CNC Milling Machine, is experiencing robust growth, driven by the increasing demand for precision manufacturing across various sectors, including electronics, automotive, and aerospace. Key trends influencing this market include the rise of Industry 4.0, which emphasizes automation and data exchange in manufacturing technologies. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the shift towards integrated solutions that combine hardware with software capabilities, enhancing productivity and efficiency.

Emerging technologies such as additive manufacturing and advanced materials are also reshaping the landscape. Buyers are increasingly looking for suppliers that offer versatile machines capable of handling diverse materials like aluminum, brass, and plastics. The trend towards localization of supply chains is gaining momentum, especially in regions like Africa and South America, where manufacturers aim to reduce lead times and transportation costs. This shift is driven by the desire for rapid prototyping and small-batch production that desktop CNC machines facilitate.

Moreover, the growing focus on customization in product design is pushing B2B buyers to invest in machines that allow for quick iterations and modifications. As businesses adapt to these dynamics, understanding the specific needs of target markets and aligning sourcing strategies with technological advancements will be crucial for success.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the manufacturing sector, with increasing pressure on companies to minimize their environmental impact. For international B2B buyers of the Bantam Tools Desktop CNC Milling Machine, this means prioritizing suppliers who adopt sustainable practices throughout their operations. This includes the use of recyclable materials, energy-efficient manufacturing processes, and waste reduction initiatives.

Ethical sourcing is equally important. Buyers should ensure that their supply chains are transparent and responsible, avoiding materials that contribute to environmental degradation or human rights violations. Certifications like ISO 14001 for environmental management and FSC certification for sustainably sourced wood materials can provide assurance of a supplier’s commitment to sustainability.

Investing in machines that utilize eco-friendly cutting tools and lubricants can further enhance sustainability efforts. Additionally, as consumers increasingly favor brands with strong environmental credentials, B2B buyers can leverage sustainable practices as a competitive advantage, enhancing brand reputation and customer loyalty.

Brief Evolution/History

The Bantam Tools Desktop CNC Milling Machine represents a significant evolution in manufacturing technology, emerging from the need for more accessible and affordable CNC solutions. Initially, CNC machines were large, expensive, and primarily used in industrial settings. However, advancements in technology have led to the development of compact desktop models that deliver precision and versatility without the hefty price tag.

As the demand for rapid prototyping and small-scale production has increased, these machines have gained traction among startups, educational institutions, and hobbyists. The integration of user-friendly software and improved materials compatibility has made desktop CNC milling machines more approachable for a wider audience, ultimately democratizing access to advanced manufacturing capabilities. For B2B buyers, this evolution signifies an opportunity to enhance production capabilities while maintaining flexibility and cost-effectiveness.

Frequently Asked Questions (FAQs) for B2B Buyers of bantam tools desktop cnc milling machine

-

What should I consider when vetting suppliers for Bantam Tools Desktop CNC Milling Machines?

When vetting suppliers, focus on their reputation, experience in the industry, and customer reviews. Ensure they have a proven track record in providing Bantam Tools products specifically. Check for certifications related to quality management systems, such as ISO 9001, which indicates adherence to international quality standards. Additionally, consider their responsiveness to inquiries and willingness to provide references or case studies from previous clients, especially those in your region. -

Can I customize the Bantam Tools Desktop CNC Milling Machine to suit my specific needs?

Yes, many suppliers offer customization options for the Bantam Tools Desktop CNC Milling Machine. Discuss your specific requirements with the supplier, such as modifications in software, hardware configurations, or additional tooling. Be clear about your applications and the types of materials you will be machining, as this will help the supplier recommend the best custom solutions for your needs. -

What are the minimum order quantities (MOQ) and lead times for international orders?

Minimum order quantities can vary by supplier and your specific customization needs. Typically, for Bantam Tools machines, the MOQ might range from one unit to several, depending on the supplier’s policies. Lead times also differ based on the supplier’s inventory levels and your location. Expect lead times of 4-12 weeks for international orders, and always confirm specifics directly with your chosen supplier to avoid delays. -

What payment options are available for purchasing Bantam Tools machines internationally?

Payment options usually include wire transfers, letters of credit, and credit card payments. Some suppliers may offer payment plans or financing options, particularly for larger orders. It’s essential to discuss the payment terms upfront, including any deposits required and the conditions for payment upon delivery. Ensure that the payment method you choose offers security and protection against fraud. -

How can I ensure the quality and certification of the Bantam Tools machines I am purchasing?

To ensure quality, request certifications from your supplier that demonstrate compliance with international manufacturing standards, such as CE marking for European markets or FCC compliance for electronic components. Ask for detailed specifications and quality assurance processes that the supplier follows. Additionally, consider requesting samples or conducting inspections prior to shipment, especially if you are making a large investment. -

What logistics considerations should I keep in mind when importing Bantam Tools machines?

Logistics for importing machines include understanding shipping methods, customs duties, and local regulations in your country. Work with a freight forwarder experienced in handling machinery imports to navigate these complexities. Ensure that you have the correct documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, consider the cost of insurance for the shipment to protect against potential damages. -

What steps should I take in case of a dispute with the supplier?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through clear communication. Document all interactions and agreements in writing. If direct negotiations fail, refer to the terms outlined in your purchase agreement regarding dispute resolution, which may include mediation or arbitration processes. In some cases, it may be beneficial to involve a legal expert familiar with international trade laws to assist in resolving the issue. -

How do I handle after-sales support and maintenance for the Bantam Tools Desktop CNC Milling Machine?

After-sales support is crucial for the longevity and efficiency of your CNC milling machine. Confirm with your supplier about the availability of technical support, warranty terms, and maintenance services. Many suppliers offer training sessions for your team on machine operation and maintenance. Additionally, inquire about the availability of spare parts and how quickly they can be sourced, especially for urgent repairs. Having a reliable support plan in place will ensure minimal downtime for your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bantam tools desktop cnc milling machine

The Bantam Tools Desktop CNC Milling Machine presents an excellent opportunity for international B2B buyers seeking to enhance their manufacturing capabilities. With its versatility in machining various materials such as aluminum, brass, and PCB, businesses can achieve precision and efficiency in prototyping and production. The machine’s user-friendly software, including NextDraw™ and ArtFrame™, streamlines workflows, making it accessible even for those new to CNC machining.

Key Takeaways:

– Versatile Applications: Ideal for a range of industries, from electronics to custom manufacturing.

– Cost Efficiency: Reduces the need for outsourcing, allowing companies to save on costs while improving turnaround times.

– Support and Resources: Comprehensive guides and a robust support system enhance user experience and operational efficiency.

Strategic sourcing of the Bantam Tools Desktop CNC Milling Machine will empower businesses in Africa, South America, the Middle East, and Europe to innovate and compete on a global scale. As the demand for localized production continues to grow, investing in this technology is not just a purchase; it’s a commitment to future-proofing your operations.

Take Action: Explore the potential of the Bantam Tools Desktop CNC Milling Machine today, and position your business at the forefront of the manufacturing revolution.