Your Ultimate Guide to Sourcing Cnc Gantry Milling Machine

Introduction: Navigating the Global Market for cnc gantry milling machine

CNC gantry milling machines represent a pivotal technology in modern manufacturing, offering unparalleled precision and versatility for a diverse range of applications. As industries across Africa, South America, the Middle East, and Europe increasingly adopt advanced machining solutions, understanding the capabilities and advantages of CNC gantry milling becomes essential for international B2B buyers. These machines are not only critical for producing complex components with tight tolerances but also enhance production efficiency, ultimately driving down costs and improving product quality.

This comprehensive guide serves as a vital resource for B2B buyers looking to navigate the global market for CNC gantry milling machines. It covers a spectrum of topics, including types of machines suited for specific applications, the variety of materials they can process, and the manufacturing and quality control standards that ensure reliable performance. Furthermore, buyers will find strategic insights into supplier selection, cost structures, and prevailing market dynamics, equipping them to make informed procurement decisions.

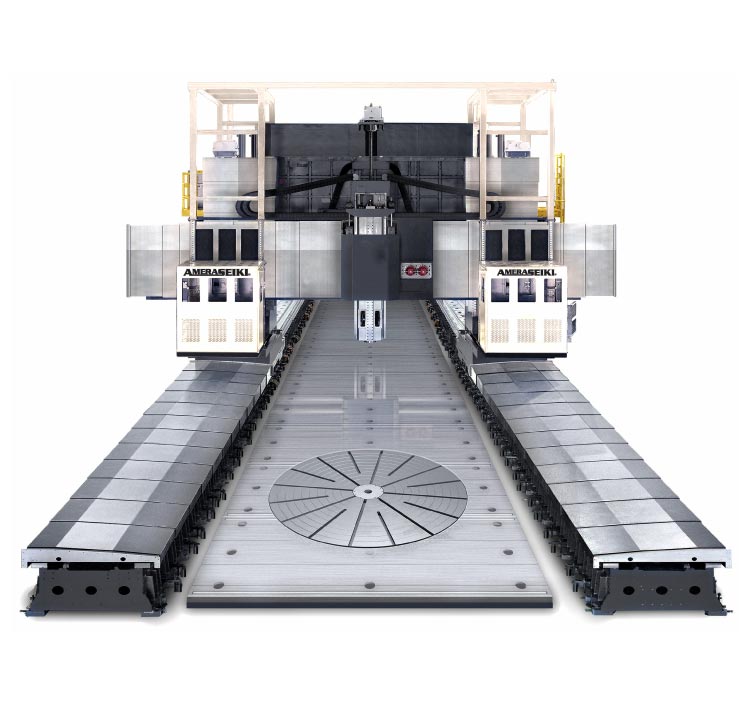

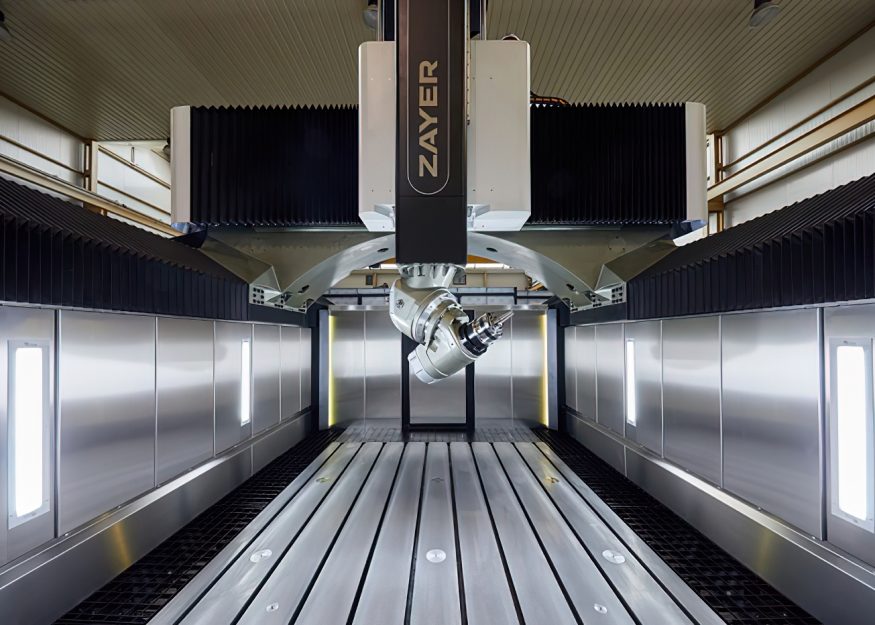

Illustrative Image (Source: Google Search)

By delving into this guide, buyers can effectively mitigate sourcing risks and establish robust supplier relationships, essential for thriving in today’s interconnected manufacturing landscape. Empowered with actionable insights, B2B buyers will be well-positioned to optimize their operations and achieve competitive advantages in their respective markets.

Understanding cnc gantry milling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Gantry Milling Machine | Fixed structure with a horizontal spindle for heavy-duty tasks | Aerospace, automotive, molds | Pros: High stability, suitable for large parts. Cons: Limited flexibility, higher initial cost. |

| Moving Gantry Milling Machine | Gantry moves along the X-axis while the workpiece remains stationary | Aerospace, automotive, energy | Pros: High precision, efficient for complex tasks. Cons: Requires space, potential setup complexity. |

| Double Column Gantry Milling Machine | Enhanced stability with two supporting columns | Steel structures, shipbuilding, wind energy | Pros: Excellent rigidity, ideal for heavy machining. Cons: Higher cost and footprint. |

| Bridge Type Gantry Milling Machine | Gantry supported by two columns, spindle moves along the X-axis | Mold making, automotive, general machining | Pros: Versatile, stable for large workpieces. Cons: Potentially slower than other types. |

| Five-Axis Gantry Milling Machine | Simultaneous movement in five axes for complex geometries | Aerospace, medical devices, advanced tooling | Pros: High precision, reduces setup time. Cons: Expensive, requires skilled operators. |

Fixed Gantry Milling Machine

The Fixed Gantry Milling Machine is characterized by its robust, immovable structure, which allows for heavy-duty machining of large components. This type is particularly suitable for industries such as aerospace and automotive, where precision and stability are paramount. B2B buyers should consider the initial investment and maintenance costs, as these machines can be expensive. However, their ability to handle large workpieces with high accuracy makes them a valuable asset for companies that require consistent quality in large-scale manufacturing.

Moving Gantry Milling Machine

In a Moving Gantry Milling Machine, the gantry moves along the X-axis while the workpiece remains stationary, providing high precision for intricate machining tasks. This design is commonly utilized in sectors like aerospace and energy, where detailed and accurate components are essential. For B2B buyers, the advantages include enhanced precision and efficiency, but they must also be aware of the spatial requirements and potential complexities involved in setup and operation.

Double Column Gantry Milling Machine

The Double Column Gantry Milling Machine boasts increased stability due to its two-column support system, making it ideal for heavy-duty machining applications such as shipbuilding and steel structures. This type ensures high rigidity, which is crucial for maintaining precision during extensive operations. While the upfront costs and required workshop space can be significant, the long-term benefits in terms of durability and performance can justify the investment for businesses focusing on large-scale production.

Bridge Type Gantry Milling Machine

The Bridge Type Gantry Milling Machine features a gantry supported by two columns, with the spindle moving along the X-axis. This setup is widely used in mold making and general machining applications. B2B buyers will appreciate its versatility and stability for handling large workpieces. However, they should be mindful of the machine’s potential slower operation speed compared to other types, which may impact production timelines in fast-paced environments.

Five-Axis Gantry Milling Machine

The Five-Axis Gantry Milling Machine is designed for advanced machining operations, allowing simultaneous movement along five axes for complex geometries. This type is particularly advantageous in industries such as aerospace and medical device manufacturing, where intricate designs are common. For B2B buyers, while the initial investment and need for skilled operators can be considerable, the machine’s ability to reduce setup time and enhance part accuracy offers a compelling return on investment, especially for high-demand markets.

Related Video: Transforming an Idea into a Finished Part on the MR-1 CNC Gantry Milling Machine

Key Industrial Applications of cnc gantry milling machine

| Industry/Sector | Specific Application of CNC Gantry Milling Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Machining of large, complex aircraft components | High precision and reduced lead times for critical parts | Supplier’s adherence to aviation standards and certifications |

| Automotive | Production of engine blocks and chassis components | Enhanced efficiency and consistency in mass production | Ability to handle large workpieces and provide quick turnaround |

| Energy | Fabrication of turbine components and frames | Improved durability and performance of energy systems | Expertise in working with heavy-duty materials and large dimensions |

| Shipbuilding | Machining of hull sections and structural components | Increased productivity and precision in ship construction | Capability to provide on-site services for large assemblies |

| Mold Making | Creation of molds for plastic and metal components | Superior surface finish and accuracy in mold production | Flexibility to adapt to various mold designs and materials |

Aerospace

In the aerospace sector, CNC gantry milling machines are essential for machining large and complex components such as wing structures and fuselage sections. These machines provide the precision required to meet stringent safety and performance standards. For international B2B buyers, particularly in regions like Europe and the Middle East, sourcing from suppliers with proven aerospace certifications is crucial. Understanding material specifications and the ability to deliver on tight schedules can significantly impact the success of aerospace projects.

Automotive

CNC gantry milling machines play a pivotal role in the automotive industry, particularly in the production of engine blocks and chassis components. These machines enable high-volume production with consistent quality, which is vital for maintaining competitive pricing and meeting market demand. B2B buyers from South America and Africa should prioritize suppliers who can manage large workpieces and provide rapid turnaround times to keep up with fast-paced automotive production cycles.

Energy

In the energy sector, CNC gantry milling is used for fabricating turbine components and structural frames for renewable energy systems like wind turbines. The precision and strength of machined parts directly affect the efficiency and reliability of energy systems. Buyers in this sector should focus on suppliers with expertise in heavy-duty machining and the ability to work with robust materials. Additionally, understanding the regulatory landscape for energy components is essential for compliance and quality assurance.

Shipbuilding

The shipbuilding industry relies on CNC gantry milling machines for machining hull sections and various structural components. These machines enhance productivity by allowing for the precise and efficient machining of large-scale parts. For international buyers, particularly in regions like Turkey and Egypt, it is vital to source from suppliers who can accommodate large dimensions and provide on-site machining capabilities to streamline the construction process.

Mold Making

CNC gantry milling machines are critical in mold making, where they create molds for both plastic and metal components. The ability to achieve superior surface finishes and tight tolerances is essential for producing high-quality molds that meet industry standards. B2B buyers should seek suppliers who demonstrate flexibility in adapting to various mold designs and materials, as well as those who can support quick prototyping and production runs to meet market demands.

Strategic Material Selection Guide for cnc gantry milling machine

When selecting materials for CNC gantry milling machines, international B2B buyers must consider the properties and performance of various materials to ensure they meet their specific application requirements. Below, we analyze four common materials used in CNC gantry milling applications, focusing on their properties, advantages, disadvantages, and considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight, has excellent corrosion resistance, and offers good thermal conductivity. Its strength-to-weight ratio makes it suitable for applications requiring reduced weight without sacrificing structural integrity.

Pros & Cons: The primary advantage of aluminum is its ease of machining and relatively low cost compared to other metals. However, it is less durable than steel and can deform under high pressure or temperature, limiting its use in heavy-duty applications.

Impact on Application: Aluminum is ideal for components that require good machinability and moderate strength, such as parts in the automotive and aerospace industries. It is compatible with various media, including water and air, but may not withstand harsh chemical environments.

Considerations for Buyers: Buyers should ensure compliance with international standards like ASTM and DIN when sourcing aluminum components. In regions with high humidity, additional coatings may be necessary to enhance corrosion resistance.

Steel

Key Properties: Steel is known for its high tensile strength, durability, and resistance to wear and deformation. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: The main advantage of steel is its robustness and long service life, which is critical for applications in industries such as construction and heavy machinery. However, steel is heavier than aluminum and can be more challenging to machine, increasing manufacturing complexity and costs.

Impact on Application: Steel is particularly effective for components requiring high strength and durability, such as frames and structural supports in CNC gantry milling machines. It is compatible with a wide range of media, including oils and solvents.

Considerations for Buyers: B2B buyers should be aware of the need for proper heat treatment to enhance the properties of steel. Compliance with standards like JIS and ASTM is crucial, especially for industries with stringent quality requirements.

Composite Materials

Key Properties: Composite materials, such as carbon fiber reinforced plastics, offer high strength-to-weight ratios and excellent resistance to corrosion and fatigue. They can be engineered to meet specific performance criteria.

Pros & Cons: The primary advantage of composites is their lightweight nature combined with high strength, making them ideal for applications where weight reduction is critical. However, they can be expensive to produce and may require specialized machining processes.

Impact on Application: Composites are suitable for high-performance components in industries like aerospace and automotive, where reducing weight can lead to significant efficiency gains. They are often resistant to various chemicals, enhancing their applicability in harsh environments.

Considerations for Buyers: Buyers must consider the availability of skilled labor for machining composites, as they often require different tools and techniques. Compliance with international standards for composite materials is essential to ensure quality and performance.

Titanium

Key Properties: Titanium is known for its exceptional strength, low density, and excellent corrosion resistance. It can perform well in extreme conditions, including high temperatures and corrosive environments.

Pros & Cons: The key advantage of titanium is its high strength-to-weight ratio, making it ideal for aerospace and medical applications. However, it is one of the more expensive materials and can be challenging to machine, leading to higher manufacturing costs.

Impact on Application: Titanium is particularly suited for components that must endure harsh conditions, such as aircraft parts and medical implants. It is compatible with various media, including seawater, making it valuable in marine applications.

Considerations for Buyers: International buyers should ensure that suppliers adhere to stringent quality standards, such as ASTM and ISO, when sourcing titanium components. Additionally, understanding the cost implications of titanium is essential for budget planning.

Summary Table

| Material | Typical Use Case for cnc gantry milling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace and automotive components | Lightweight and easy to machine | Less durable under high stress | Low |

| Steel | Structural supports and frames | High strength and durability | Heavier and more complex to machine | Medium |

| Composite | Aerospace and automotive high-performance parts | High strength-to-weight ratio | Expensive and requires special machining | High |

| Titanium | Aerospace and medical components | Excellent corrosion resistance | High cost and machining difficulty | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc gantry milling machine

Manufacturing Processes for CNC Gantry Milling Machines

The manufacturing of CNC gantry milling machines involves several critical stages that ensure precision, quality, and performance. Understanding these stages is essential for B2B buyers looking to make informed sourcing decisions.

1. Material Preparation

The first step in the manufacturing process is material preparation. High-quality raw materials, typically steel or aluminum, are selected based on the specific requirements of the gantry milling machine. The materials undergo cutting, shearing, or bending to create the initial components. This stage is crucial as the integrity of the raw material significantly affects the machine’s overall durability and performance.

2. Forming

In this phase, the prepared materials are formed into components using various machining techniques. These may include:

- CNC Machining: Precision cutting and shaping of components to meet exact specifications.

- Welding: Joining metal parts together to form the gantry structure. This step requires skilled welders to ensure strong, defect-free joints.

- Casting or Forging: For certain components, casting or forging methods may be employed, allowing for complex shapes and improved material properties.

Each technique requires careful consideration of the material properties and the intended application of the machine.

3. Assembly

Once the individual components are formed, they are assembled into the final machine. This stage includes:

- Sub-Assembly: Components such as the gantry, table, and spindle are assembled separately before being integrated into the main structure.

- Alignment and Calibration: Precision is key; thus, components must be aligned and calibrated to ensure optimal performance. This often involves the use of specialized tools and techniques to achieve tight tolerances.

- Integration of Electronics: The CNC control systems, motors, and sensors are integrated during this stage. Proper installation is essential for the machine’s functionality and automation capabilities.

4. Finishing

The finishing stage enhances the machine’s aesthetics and protects it from environmental factors. Common finishing processes include:

- Surface Treatment: Techniques such as anodizing or powder coating are employed to improve corrosion resistance and surface hardness.

- Quality Inspection: This is a critical step where the assembled machine undergoes rigorous testing to ensure it meets design specifications and quality standards.

Quality Assurance for CNC Gantry Milling Machines

Quality assurance (QA) in the manufacturing of CNC gantry milling machines is vital for ensuring reliability, precision, and compliance with international standards. Buyers should be aware of the key QA processes and standards.

Relevant International Standards

For B2B buyers, understanding the international quality standards that suppliers adhere to is crucial. Some of the most relevant standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is recognized globally. Suppliers certified to ISO 9001 demonstrate their commitment to quality and continuous improvement.

- CE Marking: Particularly important for machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For buyers in the oil and gas sectors, API standards ensure that the equipment meets specific quality and safety requirements.

Quality Control Checkpoints

Quality control (QC) should be integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted at various stages to identify defects early and mitigate risks.

- Final Quality Control (FQC): Before shipment, the finished CNC gantry milling machine undergoes a final inspection to verify it meets all specifications and quality standards.

Common Testing Methods

To ensure the quality and reliability of CNC gantry milling machines, several testing methods are commonly employed:

- Dimensional Inspection: Using precision measuring tools to verify that all components meet the required dimensions and tolerances.

- Functional Testing: Assessing the machine’s operational capabilities, including speed, accuracy, and response to commands.

- Load Testing: Evaluating the machine’s performance under various loads to ensure it can handle the intended applications.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control measures of potential suppliers is essential. Consider the following strategies:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality management systems, and adherence to standards.

- Quality Reports: Requesting documentation of quality control processes, including inspection and testing reports, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies can provide unbiased evaluations of the supplier’s quality management practices and the final product.

QC and Certification Nuances for International Buyers

When sourcing CNC gantry milling machines from suppliers in different regions, buyers should be aware of the nuances in quality control and certification processes:

- Regional Standards: Different regions may have varying quality standards and certifications, which can affect the acceptance of products in specific markets.

- Cultural Considerations: Understanding the local business culture and practices can help buyers navigate supplier relationships and quality expectations more effectively.

- Documentation Requirements: Ensure that all necessary documentation, including compliance certificates and quality reports, are provided and verified to avoid issues during customs clearance or regulatory inspections.

In conclusion, understanding the manufacturing processes and quality assurance practices for CNC gantry milling machines is vital for international B2B buyers. By focusing on these areas, buyers can ensure they are sourcing high-quality machines that meet their operational needs while maintaining compliance with relevant standards.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for cnc gantry milling machine Sourcing

When considering the sourcing of CNC gantry milling machines, international B2B buyers must navigate a complex cost structure that encompasses various components. Understanding these costs is crucial for making informed purchasing decisions that align with budgetary constraints and operational needs.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of CNC gantry milling machines. Common materials include high-grade steel, aluminum, and specialized alloys, which vary in price based on market demand and supplier availability. Buyers should factor in the cost of raw materials, which can fluctuate based on regional supply chains.

-

Labor: Labor costs encompass both direct and indirect expenses related to manufacturing. Skilled technicians are needed for assembly, programming, and maintenance of CNC machines, and wages can vary widely by region. For buyers in regions with high labor costs, it may be beneficial to consider suppliers in countries with lower labor expenses, provided that quality standards are met.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and administrative costs. Efficient manufacturing processes can help to minimize overhead, which is crucial for maintaining competitive pricing.

-

Tooling: Specialized tooling is necessary for CNC gantry milling machines to achieve precision in machining. The costs associated with tooling can vary significantly based on complexity and the types of operations intended. Buyers should inquire about tooling costs upfront to avoid unexpected expenses.

-

Quality Control (QC): Implementing robust quality control measures is essential for ensuring product reliability and performance. The costs associated with QC processes, including testing and certification, can add to the overall price. B2B buyers should prioritize suppliers with established quality standards to minimize risks.

-

Logistics: Shipping and transportation costs can vary based on the supplier’s location and chosen Incoterms. Buyers should be mindful of import duties, taxes, and shipping fees that may apply when sourcing from overseas suppliers. Efficient logistics management can help to optimize these costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s business model. Understanding the market dynamics can provide buyers with leverage during negotiations.

Price Influencers

Several factors influence pricing for CNC gantry milling machines, including:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQ) that align with their operational needs.

-

Specifications/Customization: Custom features or specifications can drive up costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials: As mentioned, the choice of materials affects pricing. Premium materials may enhance performance but also increase costs.

-

Quality/Certifications: Machines that meet international quality standards or certifications typically command higher prices. Buyers should assess the value of certifications in relation to their operational needs.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Established suppliers with a track record of reliability may charge more but can offer better support and quality assurance.

-

Incoterms: The agreed Incoterms can influence total landed costs. Understanding the responsibilities associated with shipping terms can help buyers make informed decisions.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing and terms. Leveraging multiple quotes can provide a stronger position during negotiations.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operational costs, and resale value. A lower initial price may not always yield the best value.

-

Pricing Nuances: Be aware of regional pricing variations, particularly for buyers in Africa, South America, the Middle East, and Europe. Currency fluctuations and local economic conditions can impact costs.

Disclaimer

The prices and cost structures discussed are indicative and may vary based on specific machine configurations, supplier negotiations, and market conditions. It is advisable for buyers to conduct thorough research and consult with industry experts to obtain accurate pricing information tailored to their needs.

Spotlight on Potential cnc gantry milling machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cnc gantry milling machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cnc gantry milling machine

Understanding the technical specifications and trade terminology associated with CNC gantry milling machines is crucial for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This knowledge not only aids in making informed purchasing decisions but also facilitates effective communication with suppliers and manufacturers.

Key Technical Properties

-

Material Grade

– The material grade of the machine frame and components affects durability and precision. Common materials include cast iron, steel, and aluminum. For heavy-duty applications, high-strength steel is preferred for its rigidity and ability to withstand thermal expansion.

– B2B Importance: Selecting the right material grade ensures longevity and performance, particularly in industries like aerospace and automotive, where precision is paramount. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. CNC gantry milling machines can achieve tolerances as tight as ±0.01 mm. This precision is vital for parts that require exact fitting and functionality.

– B2B Importance: Understanding tolerance levels helps buyers ensure that the components produced meet their quality standards and regulatory requirements, minimizing the risk of costly reworks. -

Axis Configuration

– Gantry milling machines can have different axis configurations, such as 3-axis, 5-axis, or even more advanced setups. The number of axes determines the complexity of the machining operations that can be performed.

– B2B Importance: Buyers need to match the axis configuration with their specific production needs. For example, 5-axis machines are essential for intricate aerospace components but may be unnecessary for simpler applications. -

Spindle Speed

– Spindle speed, measured in RPM (revolutions per minute), indicates how fast the cutting tool rotates. Higher spindle speeds can enhance machining efficiency and surface finish quality.

– B2B Importance: Understanding spindle speed is critical for buyers to optimize processing times and material removal rates, which can significantly impact production costs. -

Table Size and Load Capacity

– The table size dictates the maximum dimensions of workpieces that can be accommodated, while load capacity refers to the maximum weight the table can support. These specifications vary widely among gantry milling machines.

– B2B Importance: Buyers must consider their typical workpiece sizes and weights to ensure the machine can handle their specific requirements without compromising safety or performance.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the CNC milling context, this could involve sourcing machines or components from specialized manufacturers.

– B2B Importance: Engaging with reputable OEMs can guarantee quality and reliability, essential for maintaining production standards. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant in bulk purchasing scenarios.

– B2B Importance: Understanding MOQ helps buyers negotiate better terms and manage inventory costs effectively, especially in emerging markets with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a detailed quote for specific products or services. It typically includes specifications, quantities, and delivery requirements.

– B2B Importance: Utilizing RFQs can streamline the procurement process, ensuring that buyers receive competitive pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers regarding the transportation of goods. They specify who pays for shipping, insurance, and tariffs at various stages of the shipping process.

– B2B Importance: Familiarity with Incoterms helps buyers mitigate risks associated with international shipping, ensuring clarity in terms of costs and responsibilities. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. It encompasses manufacturing, shipping, and any potential delays.

– B2B Importance: Understanding lead times is crucial for planning production schedules and inventory management, particularly in just-in-time manufacturing environments.

By grasping these essential technical properties and trade terms, international B2B buyers can enhance their procurement strategies and ensure successful collaborations with suppliers in the CNC gantry milling machine market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc gantry milling machine Sector

Global drivers in the CNC gantry milling machine market are largely influenced by technological advancements, increasing demand for precision manufacturing, and the expansion of various industries, including aerospace, automotive, and energy. The rise of automation and Industry 4.0 initiatives is pushing manufacturers to adopt CNC technologies for improved efficiency and reduced lead times. Additionally, the demand for customized solutions is prompting suppliers to offer versatile milling machines capable of handling complex geometries and large workpieces.

Current trends indicate a growing emphasis on digitalization and data analytics in the sourcing process. Buyers are increasingly leveraging online platforms and marketplaces to access a wider range of suppliers and products, allowing for easier comparison and negotiation. Moreover, the focus on supply chain resilience has led buyers to consider local suppliers and diversify their sourcing strategies, minimizing risks associated with geopolitical tensions and global disruptions. In regions such as Africa and South America, where manufacturing capabilities are expanding, partnerships with local manufacturers can enhance competitiveness and responsiveness to market changes.

In Europe and the Middle East, there is a notable shift towards sustainable practices, with buyers prioritizing suppliers who adhere to environmental regulations and ethical sourcing standards. This trend is not just a regulatory requirement; it is also driven by consumer demand for sustainable products, making it a crucial consideration for B2B buyers looking to align with global sustainability goals.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes, including those involving CNC gantry milling machines, is a growing concern for international buyers. The industry is increasingly scrutinized for its carbon footprint, waste generation, and resource consumption. As a result, sustainability has become a critical factor in the sourcing decisions of B2B buyers.

Ethical supply chains are essential in mitigating environmental damage and promoting social responsibility. Buyers are encouraged to engage with suppliers who have transparent practices, focusing on the sourcing of raw materials, energy use, and waste management. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are indicative of a supplier’s commitment to sustainable operations.

Moreover, the adoption of green materials in the production of CNC gantry milling machines is becoming more prevalent. Materials that are recyclable or made from renewable resources can significantly reduce the environmental impact of manufacturing processes. By prioritizing suppliers that incorporate these sustainable practices, B2B buyers not only enhance their corporate social responsibility (CSR) profile but also align with global sustainability initiatives.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The evolution of CNC gantry milling machines can be traced back to the advancements in computer numerical control technology in the late 20th century. Initially designed for simple milling tasks, these machines have significantly advanced to handle complex geometries and large-scale components. The integration of digital technologies and automation has transformed them into high-precision tools capable of meeting the demands of various industries.

As industries continue to evolve, the role of CNC gantry milling machines has expanded, making them essential for modern manufacturing processes. This historical progression underscores the importance of staying updated with technological advancements and market trends for international B2B buyers seeking to maintain a competitive edge in their respective sectors.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of cnc gantry milling machine

-

What criteria should I use to vet suppliers of CNC gantry milling machines?

When vetting suppliers, focus on their industry experience, production capabilities, and certifications. Check for compliance with international quality standards such as ISO 9001 and any specific certifications relevant to your industry (e.g., aerospace or automotive). Request references from previous clients and assess their after-sales support, including availability of spare parts and technical assistance. Conducting a factory visit, if possible, can provide additional insights into their operational standards and reliability. -

Can CNC gantry milling machines be customized to meet specific production needs?

Yes, many manufacturers offer customization options for CNC gantry milling machines. This may include modifications in size, spindle power, and control systems to suit specific materials or production requirements. When discussing customization, clearly outline your specifications, production volume, and any unique operational needs. It’s advisable to work closely with the supplier during the design phase to ensure that the machine meets your precise requirements and performance expectations. -

What is the typical minimum order quantity (MOQ) and lead time for CNC gantry milling machines?

The MOQ for CNC gantry milling machines can vary significantly based on the supplier and the complexity of the machine. While some suppliers may accept single-unit orders, others might require a higher MOQ, particularly for custom machines. Lead times generally range from a few weeks to several months, depending on the machine’s specifications and the supplier’s production schedule. Always confirm these details upfront to plan your procurement and production schedules effectively. -

What payment terms are commonly offered by suppliers in international trade?

Payment terms can vary widely, but common practices include upfront deposits (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letter of credit (LC) options for large transactions, providing additional security for both parties. Be sure to clarify payment methods accepted, such as wire transfers or credit cards, and discuss potential currency exchange risks if dealing with international suppliers. Establishing clear payment terms can help avoid disputes later. -

How can I ensure quality assurance and compliance with industry standards?

Request detailed documentation regarding quality assurance processes from your supplier, including inspection reports and certifications. Many manufacturers conduct quality checks at various production stages, and you should ask for the results of these assessments. Additionally, consider third-party inspection services to verify compliance with your industry standards before shipment. Establishing these protocols will help mitigate risks associated with product quality and ensure that the machines meet your operational requirements. -

What logistics considerations should I keep in mind when importing CNC gantry milling machines?

Logistics play a crucial role in the procurement of CNC gantry milling machines. Consider shipping methods, which may include air freight for faster delivery or sea freight for cost savings. Ensure that you understand the import regulations and duties applicable in your country, as these can impact overall costs. Collaborating with a reliable logistics partner can help streamline the process, including customs clearance and transportation to your facility, ensuring timely arrival of your machinery. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, start by reviewing the contract to understand your rights and obligations. Open a line of communication with the supplier to discuss the issue and seek a resolution amicably. If informal negotiations fail, consider mediation or arbitration, which are often stipulated in international contracts as alternative dispute resolution methods. Document all communications and agreements related to the dispute, as this will be crucial if legal action becomes necessary. -

What are the common challenges faced during the sourcing of CNC gantry milling machines internationally?

Common challenges include navigating varying quality standards, dealing with language barriers, and understanding local regulations. Time zone differences can complicate communication and delay responses. Additionally, fluctuations in currency exchange rates can affect pricing. To mitigate these issues, conduct thorough market research, engage local experts or consultants, and establish clear communication channels with your supplier to ensure a smooth procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc gantry milling machine

CNC gantry milling machines represent a significant investment for international B2B buyers, offering unparalleled precision and versatility across various industries. Key takeaways from this guide emphasize the importance of understanding the different types of gantry machines, their applications, and the critical factors influencing supplier selection. Strategic sourcing is essential in this context, as it not only aids in identifying reliable suppliers who adhere to global quality standards but also helps in negotiating favorable terms that can enhance operational efficiency and reduce costs.

As markets evolve, particularly in Africa, South America, the Middle East, and Europe, the demand for sophisticated machining solutions will continue to grow. Buyers should remain proactive in exploring partnerships that leverage technological advancements and innovative materials to enhance production capabilities.

In conclusion, the future of CNC gantry milling is bright, with opportunities for businesses willing to adapt and invest strategically. Embrace these advancements by engaging with knowledgeable suppliers and exploring how CNC gantry milling can drive your business forward. The time to act is now—secure your competitive edge in the global marketplace.